404 error. Popular video dating for sex questionnaires

Sorry, the requested page was not found. Try starting from the main!

Free Dating Russia

Name: Yaroslava

City: Novorossiysk cheap prostitutes

Ad No: 79781872302

Women sponsors for sex

Gender: Married woman

Looking for: Couple

Age: 26 years old

Touch these papillae swollen with desire.

For: Intimate leisure

Phone: 79X6 513-88-68

Name: Raisa

City: Kurganinsk

Announcement #: 79556997015

Women for meetings

Gender: married woman

I am looking for love

Age: 27 years old

Cooney Man Unquestioning and trouble-free))!

For: Weekend Sex

Phone: 79X5 228-28-97

Name: Ulyana

City: Novorossiysk Primorsky District

Announcement #: 79328051749

Girls Naked Tits

Gender: Single woman

Looking for: Couple

Age: 24 years old

ALL ADDITIONALS. SERVICES ARE DISCUSSED AT PERSONAL MEETING. I am a welcome, appetizing, relaxed, sexy, experienced lady. Next to me you will forget about your problems and hardships. I will help you relax in a cozy environment

For: Sex free ad

Phone: 79X9 517-68-76

Name: Toma

City: Apsheronsk

Ad No .: 79694959645

Sex dating by SMS

Gender: married woman

I am looking for love

Age: 27 years old

Call me Lenusya. I’m already big, me. A charming and stunning beauty beckons a lonely guy. You will understand incredible pleasure from me. You have the opportunity to fuck a gorgeous minx for only rubles per hour. About me: a beautiful figure, elastic ass, great breasts. Call: I will teach you the skills of pleasure. Intends to bring to ecstasy right now. I prefer to be undressed. Ready to do: ending on the chest, group sex, point. Baby, it’ll be hot with me. Hurry up!

For: Prostitute

Phone: 79X2 773-29-54

Name: Sophia

City: Novorossiysk VIP prostitutes

Announcement #: 79525678405

Girl for Cash Sex

Gender: Girl

Looking for a boyfriend

Age: 24 years old

I love anal

For: Sex

Phone: 79X9 924-20-65

Name: Irina

City: Tuapse

Announcement No: 79650412393

Young, I want an adult

Gender: Woman

Looking for a boyfriend

Age: 21 years old

Photo%, I accept individually. Persons in a state of alcoholic and drug intoxication, please do not waste either your or my time! If I have not answered your call, please call back later, that.

For: Sex with a couple

Phone: 79X6 833-82-77

Name: Ksenia

City: Novorossiysk elite prostitutes

Listing #: 79752531744

I am looking for a girl for sex, communication without obligation

Gender: Girl

Looking for: Sex partner

Age: 22 years old

A girl with a nice figure and a great desire to please

For: Sex with a couple

Phone: 79X1 485-49-13

Online Novorossiysk elite prostitutes

Name: Isabella

City: Apsheronsk

Announcement #: 79178799206

Meet Swingers

Gender: Girl

Looking for a guy

Age: 29 years old

Do you want with me in our city? I am looking for a man who is ready to prove himself in bed only

For: Sex ad without registration

Phone: 79X8 686-68-32

Questionnaires: 423383

New: 4141

Online: 3270

- Prostitutes Kurganinsk

- Online dating

- Looking for a lover Kurganinsk

- Looking for a man for sex Kurganinsk

- The girl is looking for 2-3 guys Kurganinsk

- Dating with phone numbers without registration Kurganinsk

- Women who pay for sex Kurganinsk

- Online sex dating Kurganinsk

- I invite you to sex Kurganinsk

- Dating flirt for adults Kurganinsk

- Women sex ads Kurganinsk

- Sex quick dating Krasnodar

- I want sex from 35-40 years old Abinsk

- Number of a girl who wants to meet Armavir

- Free porn photos of Novorossiysk prostitutes with photos

- Prostitutes departure sauna Novorossiysk departure to the district

- Women offer sex Novorossiysk prostitutes verified

- Naked hairy girls in Tikhoretsk

- Girls want to meet Novorossiysk Yuzhny district

- Sex in city, Krymsk dating

Two girls looking for a man for the night Kurganinsk

Individual prostitutes Kurganinsk

Prostitutes online

Looking for a man for the night! Kurganinsk

- Choose another city in Russia

- Novorossiysk

- Novorossiysk Tsentralny district

- Novorossiysk Vostochny district

- Novorossiysk Novorossiysk district

- Novorossiysk Primorsky District

- Novorossiysk South District

- Novorossiysk exit to the district

- Novorossiysk prostitutes individuals

- Novorossiysk cheap prostitutes

- Novorossiysk elite prostitutes

- Novorossiysk VK

- Novorossiysk mature prostitutes

- Novorossiysk verified prostitutes

- Novorossiysk prostitutes with photos

- Novorossiysk VIP prostitutes

- Krasnodar

- Sochi

- Armavir

- Anapa

- Yeisk

- Kropotkin

- Gelendzhik

- Slavyansk-on-Kuban

- Tuapse

- Labinsk

- Krymsk

- Tikhoretsk

- Belorechensk

- Timashevsk

- Kurganinsk

- Korenovsk

- Temryuk

- Hot key

- Apsheronsk

- Ust-Labinsk

- Abinsk

- Novokubansk

- Gulkevichi

- Primorsko-Akhtarsk

- Khadyzhensk

Sitemap Copyright © 2020 akg-russia.ru

You are still not registered?

Go through a simple registration, it will not take very much of your time!

How to sharpen?

A circle with victorious solders or a regular wood disk for a circular saw can be sharpened with your own hands, restoring the sharpness of the teeth. True, when carrying out work, many factors will have to be taken into account. They can influence the choice of sharpening method – manually or using a machine. Higher accuracy is provided by mechanized processing, but for it you will need to purchase special equipment.

How to determine wear?

The decrease in the quality of the cutting element is largely associated with a decrease in the sharpness of its teeth. The sharpening of circular saw blades must be carried out in a timely manner, before deep damage appears, making restoration impossible. Determination of signs of wear is a task that requires special attention from the foreman.

Sharpening is necessary if the tool behaves in a special way..

- Heats up strongly, smokes. A dull saw blade increases the load on the engine. When overheated, it begins to generate heat intensively, smokes, and may even fail..

- Requires increased pressure. This feature applies mainly to models with a mechanical type of material supply. If you have to use more force than usual when sawing, it is worth checking the sharpness of the cutting blade..

- Leaves traces of carbon deposits, oils, a specific unpleasant odor on the workpiece.

Any of these signs, revealed during the operation of the circular saw, indicates that it is time to replace or sharpen the blade. Determine the degree of wear more accurately only by removing it from the tool.

Sharpening principles and angles

The cutting teeth in the design of the circular saw blade have 4 planes: 2 side, front and rear. According to their form, all these elements are divided into several groups..

- Straight. Such teeth are in demand when sawing materials in the longitudinal direction, at speed. The quality and precision of the cut are of no particular importance..

- Oblique. Teeth of this type always have an inclined plane offset to the left or right. Most often, such elements alternate on a disc, the edge is called variably beveled. For different types of materials – wood, plastic, chipboard – a certain angle of inclination is set. It will be maximum when cutting chipboard, and the option of tilting the front or rear part can be used.

- Trapezoidal. Such teeth on a circular saw blade have 1 big advantage – they slowly dull. Usually at the cutting edge, they are combined with straight ones, located above them. In this case, the trapezoidal elements will be used for rough work, and the straight ones will help to achieve a clean cut. Such discs are used in the processing of polymer sheets, MDF, particle boards..

- Conical. They are also auxiliary, used on discs for cutting laminate and other fragile materials. The special shape of the elements protects the surface from chipping and other damage. The leading edge of bevel teeth is usually straight or concave, good for fine sawing.

Depending on which type of teeth is used on the saw blade, a suitable sharpening angle and other parameters are selected. It is strictly forbidden to process all elements under a general slope, without taking into account the individual characteristics of each element..

Each saw blade in a circular tool has 4 main corners that require sharpening. They determine, along with the shape of the tooth, the features of the geometry of the cutting edge. For each individual element, it is customary to measure the cutting angles of the surface and directly front, back parts.

Depending on the type, purpose, mass of the saw, possible options are distinguished.

- For rip sawing. These discs use a 15-25 degree rake angle..

- For cross cutting. This uses a rake angle of 5-10 degrees..

- Universal. In this case, the tool teeth in the area of the rake corner are sharpened by 15 degrees..

The type of processed material also matters. The harder it is, the less should be the indicators of the selected angle. Softwoods can be cut at wider inclines.

When using carbide discs, wear can be seen literally with the naked eye. In this case, the front plane is erased more intensively than the back..

What is required?

Sharpening a disc mounted on a circular saw is possible only with the help of special tools. To increase the accuracy during work, specialized machines are used, which greatly simplify this process. And you can also use more primitive tools – a file and a vice for fixing, as well as a piece of wood.

Sharpening circular saw blades

- How to determine wear?

- Sharpening principles and angles

- What is required?

- How to sharpen?

The correct choice of the angle of sharpening of discs for a machine or for a circular saw is an important component of success when performing all operations yourself. Restoration of the sharpness of the teeth in this case is of particular importance, the master has to act very carefully. How to properly sharpen a saw blade with soldered wood with your own hands is worth talking in more detail.

Manual disc sharpening

When choosing this method of restoring the sharpness of the teeth on the saw blade, use the available tools. It is only important to prepare a special flat-shaped stand. It will avoid the need to hold the disc in your hands, protect you from injury.

The following requirements are imposed on the stand:

- coincidence at the level of the axis with the processed surface;

- the possibility of positioning the toothed circle in a perpendicular plane;

- swivel joint.

The stand serves not only as a fastener – it allows you to sharpen the teeth of the saw blade at different angles, guarantees injury safety when performing work. Preliminary marking of the surface with a colored marker will help to achieve higher accuracy. Additionally, a vice is used, with which the circle is pressed against the stand.

An angle grinder will help to facilitate the sharpening process itself, but experienced craftsmen eliminate minor bluntness with a simple file.

Multidirectional teeth require machining from 2 sides of the wheel. In this case, the disc is first fastened horizontally with the marked side, then turned. Actions are repeated. If necessary, you can change the angle if sharpening is carried out on a disc with a mixed type of teeth.

Using a grinder

If you have at hand special equipment with a manual or electric drive, the problem of restoring the sharpness of the teeth on the saw blade is solved quickly and easily. Special grinding machines have compact dimensions, are quite mobile and functional. They can be adapted for use in the home workshop.

It is necessary to choose a machine for sharpening circles for a circular saw, be sure to pay attention to the material of the abrasive used. The best options are made from:

- silicon carbide (green);

- elbora coated with diamond powder.

It is important to take into account that carbide discs do not lend themselves well to tool sharpening..

Variants with victorious spraying, other complex elements as a coating can also cause problems during operation. Even with a machine, it will be difficult to guarantee successful sharpening..

Working with grinding equipment is as simple as possible. The master only needs to fix the prepared disk on a special support with a lock, then perform several actions.

- 1 tooth is marked with a marker or chalk.

- The required angle is measured at which the processing is performed. If there are no special requirements, a universal slope of 15 degrees is chosen..

- Start sharpening by cutting from 0.05 to 0.15 mm. Sequentially process each tooth so that it acquires the necessary sharpness.

When sharpening carbide discs, it is recommended to grind the metal on the front and back surfaces of the teeth at the same time. With common steels and alloys, less effort can be dispensed with. Enough sharpening just the front.

How to Sharpen Circular Saw Blades – Trend Diamond Sharpening Tips

When working with a victorious disc, you must first be sure to free it from dust and dirt. It is important not to expose it to mechanical stress, only to remove foreign inclusions. In this case, the working planes of the teeth are processed sequentially. You cannot spend more than 20-25 times in one place. The machine usually removes a blunt edge in literally 1 pass. As the disc wears out, it is simply replaced with a new one..

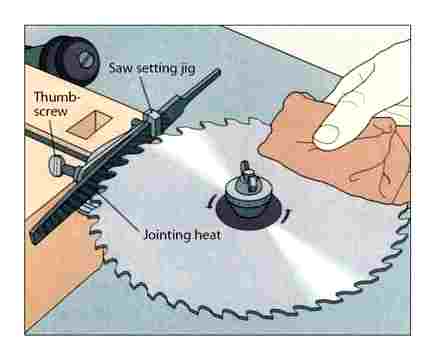

For a visual explanation of how to sharpen a saw, see below..

- What is needed?

- Stages of work

- On a note!

- Video

- Useful articles

Stages of work

Training

Correct sharpening of circular saw blades is largely ensured by a good fixture of the equipment. There are two options: the equipment can be removed from the tool and secured in a vice using wooden dies on the worktable, or sharpened directly on the tool – then, to fix it, you need to stick a bar between the teeth, resting it on some surface. It is important to remember that the saw must be de-energized before sharpening. Whichever method you choose, make sure the disk is firmly fixed – it should not rotate.

Markup

How to sharpen your circular saw blades, the easy way.

To make it easier to navigate from which tooth you started sharpening, you need to make a mark with a marker on the body of the disc. This will tell you that you have completed a full circle when machining the teeth, and will not grind them down a second time..

Sharpening

Manual sharpening of discs for circular saws is carried out with a file. A tool with a flat working end is suitable – it easily passes between the teeth. You should be aware that the main wear occurs on the upper cutting edge of the tooth. During sawing, it interacts most intensively with the material and gradually rounds off. The front edge of the tooth is also strongly grinded..

First, the posterior surface of the tooth is treated. A file is passed over it several times, applying a little effort. Each tooth is sharpened in turn with uniform movements.

Important to remember! When sharpening circular saw blades, apply the same force to each cutting segment and file the same number of times. This will help to sharpen the entire blade evenly – the teeth will be the same.

Having processed each tooth in turn, when the disc is fully rotated, you will return to the starting mark. After that, it is necessary to sharpen the front side of the teeth. Carry out the same actions – until the complete rotation of the tooling.

Important to remember! During sharpening, care must be taken to ensure that the point of the tooth remains perpendicular to the plane of the disc. Subsequently, when sawing workpieces, this will ensure an even and fast cut..

Visual inspection

To make sure that the teeth are sharpened properly, you need to carefully examine them. The presence of chips, scratches and cracks on the cutting part is unacceptable, and there should be no reflections on the edge. If the edges are shiny, file them carefully..

Checking the rig

After all teeth have been sharpened, the cutting properties must be checked. Attach the harness to the tool, turn on the power and cut a test piece of wood. Indicators of high-quality sharpening are easy cut, smooth running, quiet operation. If there is a lot of noise and uneven cutting of the material, it is necessary to check the height of the teeth – it may not be the same. To align all cutting segments, bring the marker up to the cutting edge and rotate the tooling a full turn in the opposite direction to the direction of rotation. Examine the surface: a mark should remain on each tooth to help compare the heights of all segments. Find the teeth with the greatest height and carefully reduce the length with a file.

- File

- Marker

- Wooden beams

- Gloves

- Vise

How to sharpen a circular saw blade by hand?

Notice that your circular saw is getting worse at work? It is getting more and more difficult to saw materials, black carbon deposits appear in the place of the cut, smoke forms and the smell of burning is felt? Clear signs that the disc needs to be sharpened! Otherwise, not only will the performance of the tool decrease, but there will also be a threat of overheating of the motor. We will tell you how to return the cutting properties to the equipment on your own..

On a note!

In order to keep the cutting equipment in good condition, it is necessary to monitor the degree of wear during operation. It is important to check the radius of rounding of the cutting edge – it should not exceed 0.1 – 0.2 mm. Also, the shape of the cut testifies to the bluntness of the teeth – the cut turns out to be uneven, the teeth seem to tear wood.

Important to remember! Manual sharpening is not applicable to carbide-tipped discs – they are processed on special machines. This tooling lasts 10 times longer than all-metal discs..

The main sharpening angles of circular saws

The front face, the one that first cuts into the workpiece in the direction of the saw movement, forms the main cutting edge with the rear face. The angle at which the leading edge meets the material is called the Y-angle (angle of attack). The angle between the back face and the front face is the taper angle. If you subtract the rake angle and the taper angle from 90 degrees, you get the clearance angle.

In practice, it is important to observe these angles when sharpening for each type of disc. It is according to the front angle that the saws are divided into types:

- Longitudinally cutting, where the rake angle must not go beyond 15-25 degrees.

- Transverse cutting, where it is permissible to sharpen the front face of the tooth at an angle of 5-10 degrees.

- Universal discs, which are easy enough to cope with both longitudinal and transverse cuts, their rake angle should be maintained in the region of 15 degrees.

The angle of the bevel of the rear and front planes is also important: the sharper it is, the easier it is for the saw to enter the material, but wear occurs faster.

Follow the rules! When cutting hard wood, the saws must be sharpened so that the taper and bevel angles are as small as possible (within acceptable limits). This extends the life of the blade until the next sharpening..

When to sharpen a circular saw

There are very definite signs by which one can judge the state of the instrument. Sharpening saws is necessary when the following is clearly manifested:

- During operation, smoke appears, a specific smell of burnt wood, the casing covering the saw teeth begins to heat up quickly.

- When moving the tool along the workpiece, significant efforts must be made to push the saw forward..

- After cutting the material and visual inspection of the sawn edge, black carbon deposits or a lot of chips, scuffing of the fiber, chipped areas are visible.

- A close examination of the saw teeth with a magnifying glass shows that the cutting parts are not sharp, but rounded edges..

All this requires an immediate cessation of work, otherwise there is a great risk of damage to the material and wear of the circular saw to such a state when sharpening will no longer help it..

Types of circular saw teeth setting

The complexity of the wiring process is due to the need to move the teeth to the side at the same distance. This can be achieved by using a factory set circulating saw setter. Each tooth should be started from the middle of its size. For wood materials of different density, the degree of setting the teeth should be different, but without going into details, we can say that they are bred wider for sawing soft species than for hard ones..

There are three main wiring methods:

- Stripping type wiring. This method boils down to the fact that the tooth after two remains in its place without change, the rest are rejected in different directions. This saw preparation is good for working with solid wood..

- A variant of the classic setting, when the saw teeth alternately move to the right and then to the left. This versatile method can be used for almost all types of saws..

- The so-called wavy layout, a distinctive feature of which is the retraction of the teeth not at a strictly defined distance from the center, but at different distances with a deviation of 0.3-0.7 millimeters.

General rules for sharpening a circular saw

- The main edges are processed first of all, of which the front wears out more.

- In extreme cases, with severe wear of the side faces, they are corrected.

- At a time, remove no more than 0.15 millimeters of the saw metal thickness.

- When finishing the edges with an electric tool, overheating of the metal is not allowed, in which case its properties deteriorate.

- To ensure the maximum service life of the saw, when it can be sharpened up to 30 times, both edges should be sharpened: both the front and the back, removing the same amount of metal.

- It is not allowed to sharpen circular saws with tools not intended for this, for example, an angle grinder and a disc for cutting metal.

After carrying out the basic sharpening operations, you can finalize the teeth with fine sandpaper. The quality control of the sharpening of the tool takes place in working conditions. If everything is in order, the cutting of the material will be clean, smooth, without visible defects and blackening..

How can you sharpen a circular saw

- Special wheels for sharpening saws, made on the basis of diamond abrasives.

- A regular file for sharpening a saw, but you also need to have a vise to secure the saw and a block of wood to use as a guide.

- Processing on professional equipment is the fastest and highest quality way of sharpening, but it requires large material costs for purchasing a tool.

How to sharpen a circular saw blade correctly

Saw blades must be sharpened regularly to avoid damage to the building material. We will tell you how to properly sharpen a saw blade with and without solders, what equipment and tools to use.

The disc tool for sawing wood is always useful in construction. The circular saw is convenient in that it allows you to quickly cut the material with minimal effort and time. As for the quality of the cut, we can say that it is perfect, but only when the saw is in good working order and well sharpened. Otherwise, it is even dangerous to work with such a tool, so you should sharpen the circular saw.

It is not difficult to determine the need for a sharpening operation: a blunt tool cuts the workpiece poorly, which immediately catches the eye. There are two options here: either send the disc to the workshop, which is not always beneficial in terms of time and money, or sharpen the circular saw with your own hands. This may seem daunting at first glance. But if you delve into the essence of the saw device in more detail, it will not be difficult to perform maintenance of the tool at home..

Do it yourself sharpening at home

Attention! To sharpen circular saws with your own hands, it is desirable to have certain skills in sharpening the tool. If there are none, at least practice on emery, sharpening an ordinary knife.

When working with a disc, the main thing is not to spoil the cutting surface, and this can easily happen if the hand trembles, the feed angle is violated. In order to avoid negative consequences, you should study the sharpening methods, and then everything will turn out right. Distinguish between a manual method of restoring cutting elements of a circular saw and a method using sharpening equipment.

Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut into the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and in each case use the appropriate type of saw, which differs from others in shape teeth.

and. cross cutting; b. longitudinal sawing; 1.wood; 2. saw cut; 3. line marking for sawing; Θ. the angle of inclination of the marking to the wood grain with mixed sawing.

When transverse sawing, transverse saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from transverse sawing in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the rip saws cut the wood like knives in a plane, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for cross and longitudinal saws are used to its fibers.

Saw sharpening

Let’s go over the material how to sharpen a saw for wood or sharpen a circular saw.

Sharpening saws on wood

A saw for wood is the most important tool in the hands of a specialist, which must work properly and reliably, especially if the saw is correctly sharpened. However, when buying this product, the consumer is not always happy with its pungency. Wood saws are often sold blunt. To a greater extent, this applies to large-toothed tools. Therefore, the issue of sharpening remains relevant for those who wish to achieve efficient saw operation..

It is known that there are different forms of sharpening for each type of work..

- The saw must be parted first if it is not sufficiently parted. It is best to do this using a specialized layout. But if such a part is not at your disposal, then you can use pliers..

- The saw is clamped with the teeth upwards, the operator must operate in such a way that he can see the whole process along the blade.

- Then you need to bend every second tooth in different directions, accompanying each movement by tilting the pliers at an equal angle.

- Often, wiring is already present to a small extent initially. The owner of the saw simply needs to increase it when it comes to raw wood or large saws. If the saw is small and is designed to perform work that requires great accuracy, then the factory wiring is sufficient..

In the process of sharpening a saw on wood, you will need a file that has three edges.

A triangular file is used to sharpen the teeth. This process is carried out from the inner surface in relation to the setting of the saw teeth. The file is positioned at an angle in the cutting edge. This angle should be sixty to forty-five degrees..

In practice, it is much more efficient to first sharpen one side of the teeth, and then, turning the saw over, sharpen them on the other side. Thus, a person makes the same type of movement, which allows you to sharpen the saw faster and more efficiently..

When sharpening saws, it is necessary to follow the most important rules that not only allow you to achieve a higher effect, but also ensure safety. To do this, when sharpening saws, you must:

- eliminate any background noise or communication with other people,

- you should turn off the radio, TV, thus achieving complete silence, creating a situation in which no one can distract you.

Otherwise, any careless movement or reaction of a person to a distracting sound can lead not only to damage to the instrument, but also irreparable consequences, causing damage to human health..

Experts advise you to pay attention when the saw goes to the side during cutting. This indicates an uneven setting of the teeth, which needs to be corrected by increasing their deflection from the side to which the saw is pulled..

How to sharpen a circular saw

- Sharpening circular saws

- How to set the disc teeth

- Mechanized disc sharpening

How to sharpen a circular saw? Circular saw # 8211; it is a necessary tool in the construction of a summer cottage. It surpasses other types of saws in terms of its accuracy and cutting quality. The duration of the structure’s operation depends on the quality of its sharpening..

The service life of the circular saw depends, among other things, on the quality of its sharpening..

An unsharpened disc increases the load on the mechanism. As a result, it can break..

Periodic sharpening of circular saws is required.

Signs that indicate that the saw needs to be sharpened:

- when cutting, a heavy load must be applied;

- the edges of the cut burn;

- the engine overheats;

- smoke appears during operation.

Saw blade sharpening

The circular saw is sharpened from the rear if you work in a position facing the material being cut.

- The front surface running into the material during sawing remains unchanged.

- You can sharpen the disc directly in the machine. Otherwise, you can remove it from the machine or circular saw.

- In the first option, you first need to unplug the plug from the socket to prevent the consequences of starting the machine, which can happen accidentally.

- The disc must be wedged, for which thin pieces of wood must be placed on both sides of it and pressed against the teeth.

- With a marker, you need to mark the side of the tooth from which you will begin to sharpen. This will allow you to avoid mistakes in such a responsible work..

- Attention and extreme caution must be exercised..

It is important to remember the number of movements you make when sharpening the first tooth, while you used a file or diamond file.

You will need the same efforts in order to sharpen all the other teeth..

If you removed the disc from the machine, it must be clamped in a vise in order to do the same activities that you read about above..

Then the disc returns to the machine, the unnecessary piece of wood is sawn. It is necessary to check the height of the teeth if your work was accompanied by a loud noise or an uneven feed was typical. This can be done by bringing a marker to the cutting edge and turning the disc with a hand in a slow rhythm one turn in the opposite direction to the direction of rotation. Each tooth will receive a mark; when examining the disc, it will be revealed which teeth are higher than the others. If there is a significant difference, it is necessary to carefully reduce their height..

How to properly dilute and sharpen a circular disc

Mechanized disc sharpening

Materials and tools:

- saw blade;

- disc sharpening machine;

- pendulum goniometer;

- marker.

How to sharpen a circular saw in a mechanized way? There are many different machines. Some mechanisms have software packages to provide a fully automated turning mode. In a home workshop, when disc turning is occasional, a simpler device can be used..

Saw blade teeth sharpening angles: rake angle (γ), rear (α) and bevel angles of the front and rear planes (ε1 and ε2).

How to sharpen a disc? In such a machine, after its installation and fixing in a position that provides the required sharpening angle, all other operations # 8211; rotation of the blade around its axis, control of the thickness of the metal removed from the tooth # 8211; performed manually.

Sharpening a straight tooth along the front plane is performed in the following sequence. Install the canvas on the frame of the machine. Clamped with a centering sleeve. Then, using a mechanism, it is installed in a strictly horizontal position. Thus, the bevel angle of the front plane is ensured equal to zero. If the machine does not have a built-in angular scale, the horizontalness of the disc is checked using a pendulum goniometer..

Then the screw of the mechanism is rotated, which provides horizontal movement of the frame with a circle. The required rake angle is set. The blade moves in a position in which the front plane of each element fits snugly against the working surface of the circle.

A marker is made to mark the first tooth from which sharpening begins. Then the engine is turned on and the front plane is sharpened. The machine brings the tooth into contact with the circle and performs several movements of the blade back and forth while simultaneously pressing the element against the circle.

After sharpening one element, the blade is removed from contact with the abrasive wheel, rotated by one element. Then the operation is repeated in the same way. This is how the machine works until the element marked with a marker has completed a full circle, showing that all elements are sharpened..

Sharpening a beveled tooth differs from straight turning in that the saw is positioned with an inclination equal to the bevel angle of the front plane. To sharpen an element along the back plane, it is necessary that the machine allows the blade to be installed so that the back plane of the element is in the same plane with the surface of the circle.

To sharpen a circular saw on a machine, you do not need to have special skills. Anyone can handle this work if they follow all the instructions and rules for working with disc sharpening machines..

Sharpening circular saws

Materials and tools:

Circular saw blades.

- saw blade;

- file;

- diamond file;

- marker;

- thin wooden blocks;

- vice;

- wiring;

- adjustable wrench.

How to sharpen a circular saw with a disc? The circular saw must be sharpened from the rear when working with the blade facing the tree. The front surface, which is on the material when cutting, remains in the same position.

You can turn the disc in the machine. You can pull the canvas out of it. If turning is carried out in the device, you must remove the plug from the electrical outlet to prevent accidental switching on of the device. It is necessary to glue the product by placing thin blocks under it on both sides and press them down to the teeth.

It is necessary to mark with a marker the element from which the turning is started. When turning, care must be taken and maximum care must be taken. Turning is performed with a file or diamond file.

It is necessary to remember the number of movements and applied forces when turning the first tooth. The same effort should be applied when turning the remaining parts. If the blade is removed from the machine, you need to clamp it in a vice, then sharpen each tooth in the same way. Then the web is installed back into the device..

Check the cut on the sample. If there is noise during operation or the material feed is uneven, check the tine height. To do this, bring the marker to the cutting edge. Then you need to slowly turn the canvas by hand 1 turn in the direction opposite to the direction of rotation. In this case, a mark will appear on each tooth. On examination, you can find out which elements are higher than the rest. If the difference turns out to be significant, you need to carefully reduce the height of the elements..