Saw blade sharpening process

The saw is installed on a mandrel, clamped using a tapered (centering) sleeve and nut, then set in a strictly horizontal position using the mechanism (3). This ensures that the bevel angle of the front plane (ε1) is equal to 0 °. In machines for sharpening discs, and not having a built-in angular scale in the tilt mechanism, this is done using a conventional pendulum goniometer. In this case, check the horizontal position of the machine.

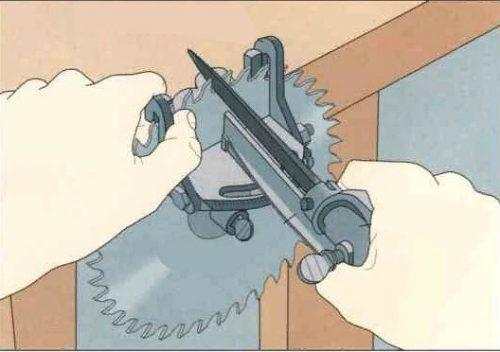

By turning the screw (4) of the mechanism providing horizontal movement of the mandrel with the circle, the required rake angle is set. In other words, the saw moves to a position in which the front plane of the tooth fits snugly against the working surface of the wheel.

A marker is made to mark the tooth from which sharpening begins.

The engine is turned on and the front plane is sharpened. Bringing the tooth into contact with the circle and Several movements of the saw back and forth while pressing the tooth against the circle. The thickness of the metal to be removed is regulated by the number of sharpening movements and the force of pressing the tooth against the abrasive wheel. After sharpening one tooth, the saw is removed from contact with the wheel, rotated by one tooth and the sharpening operation is repeated. And so on until the marker mark does NOT make a full circle, indicating that all the teeth are sharpened.

Tooth sharpening, skewing along the front plane. The difference between sharpening a skewed tooth and sharpening a straight one is that the dust must be installed not horizontally, but with an inclination. With an angle corresponding to the bevel angle of the front plane.

The tilt angle of the saw is set using the same pendulum protractor. First, a positive angle is set (in this case 8 °).

After that, every second tooth is sharpened.

After sharpening half the teeth, the blade angle changes from 8 ° to 8 °.

And every second tooth is sharpened again.

Rear sharpening. To sharpen a tooth along the back plane, it is necessary that the saw blade sharpening machine allows setting dust in such a way that the back plane of the tooth is in the same plane with the working surface of the abrasive wheel.

If there is no saw blade sharpener

Precisely maintain the required sharpening angles, keeping the dust in your hands by weight. The task is unbearable even for a person with a unique eye and enviable firmness of hands. The most reasonable thing in this case. Make the simplest sharpening device, which makes it possible to fix dust in a certain position in relation to the circle.

The simplest of such devices for sharpening circular saws is a stand, the surface of which is flush with the axis of the grinding wheel. Put a saw blade on it, you can ensure the perpendicularity of the front and rear planes of the tooth in relation to the saw blade. And if the upper surface of the stand is movable. By hinging one side and the other. Leaning on a couple of bolts, which can turn in and out. Then it can be installed at any inclination, getting the opportunity to sharpen an oblique tooth along the front and back planes.

True, in this case, one of the main problems remains unresolved. Exposure of the same front and rear sharpening angles. You can solve this problem by fixing the center of the saw with the abrasive wheel in the desired position. One way to implement this. Make a groove on the surface of the stand for the mandrel on which the saw is installed. Move the mandrel with the circle along the groove, it will be possible to maintain the required rake angle of the tooth sharpening. But for sharpening circular saws with different diameters or sharpening angles, it must be possible to either move the motor or the stand and the groove with it. Another way to ensure the required sharpening angle is simpler, and is to install the locking disc in the desired position on the table. At the end of the article there is a demonstration of such a device.

Sharpening angles of teeth

The sharpening angles are determined by the purpose of the saw. THOSE. The one for which material cutting and in which direction it is intended. Rip saws have a very large rake angle (15 °. 25 °). In cross-cutting dust, the γ angle usually ranges from 5-10 °. Versatile saws designed for cross and rip sawing have an average rake angle. Typically 15 °.

The values of the sharpening angles are determined not only by the direction of the cut, but also by the hardness of the material being cut. The higher the hardness, the smaller the front and back angles should be (less sharpening of the tooth).

The rake angle can be not only positive, but also negative. Saws with this angle are used for cutting non-ferrous metals and plastics.

Equipment and materials for sharpening saw blades

When using abrasive wheels (especially diamond), it is desirable to cool them with coolant.

As the temperature rises, the microhardness of abrasive materials decreases. An increase in temperature to 1000 ° C reduces the microhardness by almost 2-2.5 times in comparison with the microhardness at room temperature. An increase in temperature to 1300 ° C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on the parts and assemblies of the machine. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.) are added to the water, which form protective films. For normal sanding, soap and soda solutions are most often used, and for fine sanding. Low-concentration emulsions.

However, when sharpening saw blades at home with a low intensity of sharpening work, they do not resort to cooling the wheel so often. Not wanting to waste time on it.

To increase the productivity of sharpening with abrasive wheels and reduce specific wear, the largest grain size should be chosen, which ensures the required surface cleanliness of the sharpened tooth.

To select the grit size of the abrasive, in accordance with the sharpening stage, you can use the table in the article on sharpening bars. For example, in the case of using diamond wheels for rough grinding, wheels with a grain size of 160/125 or 125/100 can be used for finishing. 63/50 or 50/40. Wheels with grit sizes 40/28 to 14/10 are used for chipping.

The peripheral speed of the wheel when sharpening carbide teeth should be about 10-18 m / s. This means that when using a circle with a diameter of 125 mm, the rotation speed of the engine should be around 1500-2700 rpm. Sharpening of more brittle alloys is carried out at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation of increased stresses and cracks, and sometimes to chipping of the cutting edges, while the wear of the wheel increases.

When using machines for sharpening circular saws, the change in relation to the position of the saw and the grinding wheel can be realized in different ways. Moving one saw (the wheel motor is stationary), the saw and the motor move at the same time, only the wheel motor is moving (the saw blade is stationary).

A large number of sharpening machines of various functionality are produced. The most complex and expensive programmable complexes are capable of providing a fully automatic sharpening mode, in which all operations are performed without the participation of a worker.

In the simplest and cheapest models, after installing and securing the saw in a position that provides the required sharpening angle, all further operations. Turning the saw around its axis (turning per tooth), feeding for grinding (putting it in contact with the wheel) and controlling the thickness of the metal removed from the tooth. Produced by the worker by hand. It is advisable to use such simple models at home, when the sharpening of circular saws is occasional.

An example of a simple machine for sharpening circular saws is the system, the photo of which is shown in the photo below. It consists of two main units. A motor with a disc (1) and a support (2) on which the saw to be sharpened is mounted. The turning mechanism (3) is used to change the angle of inclination of the blade (when sharpening teeth with a beveled front plane). The screw (4) moves the saw along the axis of the abrasive wheel. This ensures the setting of the required rake angle. The screw (5) is used to set in the desired position of the limiter, which prevents the disc from excessively entering the interdental cavity.

Material and properties of carbide teeth

In domestic saws, sintered tungsten-cobalt alloys of VK (VK6, VK15, etc.) are used as the material for cutting plates. The number means the percentage of cobalt). In BK6 the hardness is 88.5 HRA, in BK15. 86 HRA. Foreign manufacturers use their own alloys. VK hard alloys consist mainly of cobalt cemented tungsten carbide. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Fasten the carbide plates to the disc by high-temperature brazing. As a material for soldering, at best, silver solders are used (PSR-40, PSr-45), at worst. Copper-zinc solders (L-63, MNMTS-68-4-2).

Carbide tooth geometry

The following types of teeth are distinguished by shape.

Straight tooth. Typically used in rip saws where quality is not critical.

Oblique (beveled) tooth with left and right angles of inclination of the posterior plane. Teeth with different inclination angles alternate with each other, which is why they are called alternately cut. This is the most common tooth shape. Depending on the size of the sharpening angles, saws with alternating teeth are used for sawing a wide variety of materials (wood, chipboard, plastics). Both in the longitudinal and transverse directions. Saws with a large flank angle are used as scoring saws when cutting boards with double-sided lamination. Their use allows you to avoid coating chips at the edges of the cut. Increased bevel angle Reduces cutting force and reduces the risk of chipping, but at the same time reduces tooth life and strength.

Teeth can be inclined Not only back, but also front plane.

Trapezoidal tooth. A feature of THESE teeth is the slow speed of blunting of the cutting edges in comparison with alternating cut teeth. They are usually used in combination with a straight tooth.

Alternating with the latter and slightly rising above it, the trapezoidal tooth performs rough sawing, and the straight one following it. Fine. Saws with alternating straight and trapezoidal teeth are used for cutting boards with double-sided lamination (chipboard, MDF, etc.), as well as for sawing plastics.

Conical tooth. Tapered saws are auxiliary and are used to cut the lower layer of the laminate, preventing it from chipping when passing the main saw.

In the vast majority of cases, the front face of the teeth is flat, but there are saws with a concave front face. They are used for fine cross-cutting.

The main sharpening angles of circular saws

The front edge, and that the first one cuts into the workpiece along the movement of the saw, forms the main cutting edge with the back edge. The angle at which the front face meets the material is called the Y-angle (attack angle). The angle between the back face and the front. Sharpening angle. If you subtract the rake angle and the taper angle from 90 degrees, you get the clearance angle.

In practice, it is important to observe these angles when sharpening for each type of disc. It is according to the front angle that the saws are divided into types:

- Longitudinally cutting where the rake angle should be within 15-25 degrees.

- Transverse cutting, where it is permissible to sharpen the front face of the tooth at an angle of 5-10 degrees.

- Universal discs, which are easy enough to cope with both longitudinal and transverse cuts, their rake angle should be maintained in the region of 15 degrees.

The angle of the bevel of the rear and front planes is also important: the sharper it is, the easier it is for dust to enter the material, but wear is faster.

Sharpening dust with your own hands at home

When working with a disc, the main thing. Do not spoil the cutting surface, and this can easily happen if the hand trembles, the feed angle is violated. In order to avoid negative consequences, you should study the sharpening methods, and then everything will turn out right. Distinguish between a manual method of restoring cutting elements of a circular saw and a method using sharpening equipment.

Types of setting circular saws

The complexity of the wiring process is due to the need to move the teeth to the side at the same distance. This can be achieved by using a factory circulating dust distribution device. Each tooth should be started from the middle of its size. For wood materials of different density, the degree of setting the teeth should be different, or, without going into details, we can say that they are bred wider for sawing soft species than for hard ones.

There are three main wiring methods:

- Stripping type wiring. This method boils down to the fact that the tooth after two remains in its place without change, the rest are rejected in different directions. This saw preparation is good for working with solid wood.

- A variant of the classic setting, when the saw teeth alternately move to the right and then to the left. This versatile method can be applied to almost all types of dust.

- The so-called Wavy layout, a distinctive feature of which is the retraction of the teeth not at a strictly defined distance from the center, but at different distances with a deviation of 0.3-0.7 millimeters.

Manual way

It is possible to independently sharpen the teeth by hand using a file, so that it is of high quality, if they do not have a slant, that is, the surface of the front face is perpendicular to the surface of the blade. The process looks like this:

- A block is prepared from dense wood with a section of somewhere 50×50 mm and a length of 100 mm. The sides of the bar Must be located strictly perpendicular to each other.

- Mark any tooth with a marker, which will be reportable and the first to be processed.

- The saw blade is clamped in a vice together with a bar in such a way that the front edge of the workpiece is flush and in the same plane with the surface of the bar (in this case, the bar acts as a guide for the file).

- A thin file (its thickness should allow it to fit freely into the cavity between adjacent teeth) is applied to the surface of the tooth to be treated and at the same time to the bar and methodically back and forth, sharpening is carried out.

- This is how each tooth is gradually sharpened, Monitor the condition of the bar and, when working out its surface, slightly shift the plane.

General rules for sharpening circular saws

- First of all, the main edges are processed, of which the front wears out more.

- In extreme cases, with severe wear of the side faces, correct them.

- At a time, they remove no pains 0.15 millimeters of the saw metal thickness.

- When finishing the edges with an electric tool, overheating of the metal is not allowed, in which case its properties deteriorate.

- To ensure the maximum service life of the saw, when it can be sharpened up to 30 times, both edges should be sharpened: both the front and rear. Removing the same amount of metal.

- Sharpening the dust of the circular is not allowed with tools NOT intended for this, for example an angle grinder and a disc for cutting metal.

After carrying out the basic sharpening operations, you can refine the teeth with fine sandpaper. The quality control of the sharpening of the tool takes place in working conditions If everything is in order, the material will be cut clean, smooth, without visible defects and blackening.

How can you sharpen a circular saw

- Special wheels for sharpening saws, made on the basis of diamond abrasives.

- A normal file for sharpening a saw, but it also needs pressure to hold the saw and a block of wood used as a guide.

- Processing on professional equipment. The fastest and highest quality way of sharpening, but requiring large material costs for purchasing a tool.

Saw blade sharpening

The saw of the circular version is sharpened from the rear if you work in a position facing the material, which is being processed.

- The front surface that runs into the material during sawing remains in a constant position.

- You can sharpen the disc directly in the machine. Otherwise, you can remove it from the machine or circular saw.

- In the first option, you first need to unplug the plug from the socket in order to prevent the consequences of starting the machine, which can happen accidentally.

- The disc must be wedged, for which thin pieces of wood must be put on both sides of it and pressed against the teeth.

- With a marker it is necessary to mark the side of the tooth from which you will begin to sharpen. This will allow you not to make mistakes in such a responsible work.

- Attention and extreme caution must be exercised.

It is important to remember the number of movements you make when sharpening the first tooth, while you used a file or diamond file.

You will need the same efforts in order to sharpen all the other teeth.

If you removed the disc from the machine, it must be clamped in a vise in order to do the same activities in which you read above.

Then the disc returns to the machine, the unnecessary piece of wood is sawn. It is necessary to check the height of the teeth if your work was accompanied by a Loud noise or an uneven feed was typical. This can be done by bringing a marker to the incisal edge and returning the disc with a hand in a slow rhythm one revolution in the direction opposite to the direction of rotation. Each tooth will receive a mark; when examining the disc, it will be revealed which teeth are higher than the second. If the difference is significant, it is necessary to carefully reduce their height.

Sharpening and setting the saw

The main cutting element of any hand saw. A series of teeth that are cut into the blade and are wedge cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers, in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished and in each case use the corresponding type of saw, different from other tooth shapes.

A. Cross cut; b. Longitudinal sawing; 1. Wood; 2. Drank; 3. Marking line for sawing; Θ. The angle of inclination of the marking to the wood grain with mixed sawing.

When crosscutting, cross saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from transverse sawing in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the teeth of the longitudinal dust planes the wood like knives in a plane, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for transverse and longitudinal dust are used to its fibers.

Wood saw sharpening

Saw on wood. The most important tool in the hands of a specialist, which must work properly and reliably, especially if the saw is correctly sharpened. However, when buying this product, the consumer is not always happy with its sharpness. Wood saws are often sold blunt. To a greater extent, this applies to large-toothed tools. Therefore, the issue of sharpening remains relevant for those who wish to achieve efficient saw operation.

It is known that there are different forms of sharpening for each type of work.

- Dust must be diluted first if it is not diluted enough. It is best to do this by applying a specialized layout. But if you have such a part, then you can use pliers.

- The saw is clamped with the teeth up, the operator must perform actions so that he can see the whole process along the blade.

- Then you need to bend every second tooth in different directions, accompanying each movement by tilting the pliers at an equal angle.

- Often wiring is already present to a small extent initially. The owner of the saw simply needs to increase it when it comes to raw wood or large saws. If the saw is small and is designed to perform work that requires great accuracy, then factory wiring is sufficient.

In the process of sharpening a saw on wood, you will need a file that has three edges.

A triangular file is used to sharpen the teeth. This process is carried out from the inner surface in relation to the setting of the saw teeth. The file is positioned at an angle in the cutting edge. This angle must be sixty. Forty five degrees.

In practice, it is much more effective to first sharpen one side of the teeth, and then, turning the dust over, sharpen them on the other side. Thus, a person makes the same type of movement, which allows you to sharpen dust faster and more efficiently.

We sharpen the dust, it is necessary to follow the most important rules, which not only allow to achieve a higher effect, but also ensure safety. To do this, when sharpening saws, you must:

- Eliminate any background noise or communication with other people,

- You should turn off the radio, TV, thus achieving complete silence, creating a situation in which no one can distract you.

Otherwise, any careless movement or reaction of a person to a distracting sound can lead not only to damage to the instrument, but also irreparable consequences, causing damage to human health.

Experts advise Pay attention when the saw goes to the side during cutting. This indicates an uneven setting of the teeth, which needs to be corrected, to increase their deviation from the side into which dust pulls.

How to sharpen a circular saw

- Sharpening circular saws

- How to set the disc teeth

- Mechanized disc sharpening

How to sharpen a circular saw? Circular Saw # 8211; it is a necessary tool when building a summer house. It surpasses other types of dust in its accuracy and cutting quality. The duration of the structure’s operation depends on the quality of its sharpening.

The service life of a circular saw also depends on the quality of its sharpening.

An unsharpened disc increases the load on the mechanism. As a result, it can break.

Periodic sharpening of circular saws is required.

Signs that indicate that the dust needs to be sharpened:

- When sawing, a heavy load must be applied;

- The edges of the cut burn;

- The engine is overheating;

- Smoke appears during operation.

Mechanized disc sharpening

Materials and tools:

- Saw blade;

- Disc sharpening machine;

- Pendulum Protractor;

- Marker.

How to sharpen a circular saw in a mechanized way? There are many different machines. Some mechanisms have software packages to provide a fully automated turning mode. In a home workshop, when disc turning is intermittent, you can use a simpler device.

Saw blade teeth sharpening angles: rake angle (γ), rear (α) and bevel angles of the front and rear planes (ε1 and ε2).

How to sharpen a disc? In such a machine, after installing and fixing it in a position that provides the required sharpening angle, all other operations # 8211; rotation of the canvas around its axis, control of the thickness of the metal removed from the tooth # 8211; performed manually.

Sharpening a straight tooth along the front plane is performed in the following sequence. Install the blade of the insert machine. Clamped with a centering sleeve. Then, using a mechanism, it is installed in a strictly horizontal position. Thus, the bevel angle of the front plane is provided equal to zero. If the machine has a built-in angular scale, the horizontalness of the disc is checked using a pendulum goniometer.

Then the screw of the mechanism is rotated, which provides horizontal movement of the frame with a circle. The required rake angle is set. The blade moves in a position in which the front plane of each element fits snugly against the working surface of the circle.

A marker is made to mark the first tooth from which sharpening begins. Then the engine is turned on and the front plane is sharpened. The machine brings the tooth into contact with the circle and performs several movements of the blade back and forth while pressing the element against the circle.

After sharpening one element, the blade is removed from contact with the abrasive wheel, rotated by one element. Then the operation is repeated in a similar way. This is how the machine works until the element marked with a marker does NOT complete a full circle, showed that all elements are sharpened.

Sharpening a skewed tooth differs from direct turning in that the dust is placed with an inclination equal to the bevel angle of the front plane. To sharpen an element along the back plane, it is necessary that the machine allows you to install the canvas so that the back plane of the element is in the same plane with the surface of the circle.

You don’t need any special skills to sharpen a circular saw on a machine. Anyone can cope with this work if he follows all the instructions and rules for working with disc sharpening machines.

Saw Tooth Set

The teeth are set when it is required to provide more free movement of the saw blade. The teeth in turn are bent in different directions at the same distance, using a set. With its help, the tooth is folded back approximately in the middle of its height. The setting is a tool for setting the saw teeth, it has the shape of a plate in which there is a slot. You can also use an adjustable wrench, which also successfully sets the teeth.

To work with soft woods, the teeth must be set more, in the case of hard ones. Smaller. But this advice is hardly useful to those who work directly in the forest. In THESE conditions, the degree of hardness, density and moisture of trees is hardly possible. In order to choose the right wiring, you will have to test this device in different conditions, the best option would be three tenths. Five tenths of a millimeter one way. The general requirement is that the tooth set is NOT greater than the blade thickness on two sides. It is necessary to do the wiring before sharpening.