How to tension the belt on the power tiller?

Replacing the belt on the OKA motoblock is carried out without the use of technical devices by releasing the clamping mechanism, so you can perform this action yourself, without attracting technical specialists. The main thing is to be attentive and careful when working. It is important to use identical parts of the drive train.

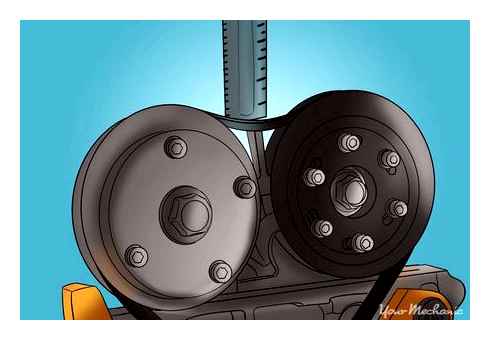

- First you must remove the reverse belt. Loosen the drive pulley bolt and pull the replacement part away from the lever.

- Unscrew the two bolts from the bracket, remove the limiting pins and remove the front drive belt.

- Put the new belts in place of the old ones, according to the direction of the front pulley and reverse pulley, then screw the drive pulley and bracket bolt.

- To assess whether the belts are correctly positioned on the power tiller, you must release the clutch lever. If they sag in this position, it means that all the above actions have been performed successfully. Otherwise, it is necessary to adjust the position of the belt drive until it is in the correct position.

Choosing models of belts for a power tiller

In order to correctly select this mechanism for your Neva brand motorblock, you need to comply with a number of recommendations, which are given by the manufacturer, as well as by experienced owners of special equipment for agriculture. Let’s look at the main points to pay attention to when selecting:

- first of all, the length of the belt used is taken into account (depending on the model of equipment, this parameter may vary);

- when choosing, it is important to pay attention to the manufacturer (buying products of unknown brands is not recommended);

- also when selecting pay attention to the cost (here we are talking about original parts, not analogues);

- It is not recommended to choose too cheap models, because there is a possibility of running into low-quality goods;

- before buying, it is necessary to carefully study the number of the device, which was previously installed on the single axle tractor;

- buy the same belt as installed (the length of the belt to be replaced and the belt to be purchased are the same);

- You should not try to compare the tension of the two copies, because the old model in use stretches;

- experienced owners recommend to use the second belt on a single axle tractor from the Neva manufacturer of wedge shape and cross-section.

It is recommended that after purchasing a new consumable item to rewrite the number from its surface, so that later you do not have to look for values all over again. The cost of this element is quite high, which is why it is necessary to have accurate information.

Vittorazi Motors V-Tutor. Replacement and belt tensioning

it is important! Only after selecting the appropriate model for the drive mechanism, you can begin to replace the device (when using a device of a different size, there is a risk of damaging not only the structural integrity of the consumable element, but you can also disrupt the operation of the drive mechanisms).

Belt size on a single axle tractor

When planning to replace a damaged element, you should first find out what belt stands on the Neva motoblock in a particular modification. To do this, you will need to perform the simplest algorithm of actions, which allows you to know the dimensions of the installed element and replace it with a similar one:

Dismantle the product from the power tiller. Check the item for the presence of numbers reflecting its size

As a rule, they are located on the outer side of the product. Particular attention should be paid to the color of the number, which can be white, blue or orange. If the marking is worn out, you should measure it yourself.

To this end, measure the distance between the rotating nodes, for the connection of which the product is used, and then determine its size, using a special table placed on the website of the manufacturer of the equipment. Reliable information about the size can be obtained from the seller of components, if you show him the dismantled old element.

Belt tension of the Neva motoblock: an algorithm of actions

The Neva MB-2 and MB-1 are characterized by a different location of the belts. That’s why the parts installation scheme will be different. Belt tensioning on the model MB-1 is performed in a certain way:

- Initially, the cover is removed from the V-belt mechanism;

- From the pulley carefully remove the back bar;

- Use a wrench to loosen the spring-loaded roller;

- The old element is removed and the new element can be installed;

- The pre-dismantled spare parts of the unit are installed.

It is worth considering how to perform belt replacement for units of the MB-1 model range:

- Removed the shield and cover of the V-belt system;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts holding the bracket are loosened;

- The front drive belt is removed;

- The new elements are installed and tensioned, everything is secured and the previously removed parts are put back into place.

Adjustment of the belt on the motor-block Neva MB-2 is made as follows:

- Removing the cover;

- The screw loosens the tension of the standard belt;

- Removed all the screws that hold the bracket on the body of the unit;

- The old part is pulled out and the pulleys are adjusted;

- Before putting the belt, the places between the elements are thoroughly wiped, the hoses are blown;

- The new belt is installed. One end is connected to the gearbox shaft, the other. to the pulley, which is in the motor;

- The design can be fully restored.

details about how to tension the belt on the Neva motoblock, you should learn from the proposed video.

Mostly a new element is stretched when the power tiller breaks down. Much rarer replacement in advance to prevent malfunctions during machine operation. In any case it is necessary to perform the work of replacing the belt carefully, because if it is stretched too much, belt breakage is inevitable.

Features and varieties of drive belts of “Neva” power tillers

Features of drive belts for Neva motor blocks:

- functionally replace the transmission and clutch;

- ensure easy start-up of the device by disconnecting the motor part and the gearbox at the moment of changing over to another speed mode;

- Change the power smoothly and without jerks.

- localization:

- in the drive part. between the “motor-reducer” pulleys;

- reverse gear;

- forward gear.

- cross-sectional shape at:

- V-belts;

- rounded;

- flat

- toothed;

- type of mutual positioning of shaft and belt:

- open transmission;

- semi- and cross-over;

- angles;

- material. usually a reinforced line for trimmer (cord) covered with vulcanized rubber and a special protective coating;

- size. the calculated, internal and external diameter length is taken into account

MB-1 and MB-2 versions are usually equipped with trapezoidal (wedge-shaped) belts, which have high efficiency and better transmission capacity.

Belt installation and replacement

| Dimensions of belts for motor-block “Oka” and modifications | |

| The drive belt to make the forward motion: | A-1180 vn I GOST 1284.1-89;A-1213 I GOST 1284.2-89. |

| Power transmission belt for reverse driving: | Z(0) 1400 I or Z(0) 1400 in I GOST 1284.1-89. |

Belts are removed manually by loosening the adjusting screw. The belts are replaced by analogous ones of the same width and length. It is desirable to purchase spare parts, in t.ч. and belts, in stores of branded spare parts for power tillers. These stores work directly with manufacturing plants.

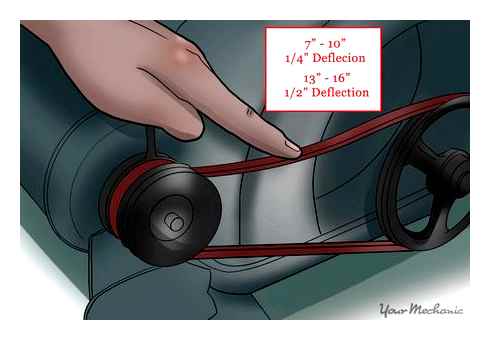

If the belt is pressed by hand, it should only deflect slightly when pressed. If they sag, the engine will hum, and you may even hear a grayish smoke from overheating. Worn belts recessed in the belt cells need to be replaced. First remove the nuts fastening the belt frame. Tighten the belts further by means of the adjusting bolt, checking periodically the degree of tension by hand.

The same manipulation is carried out after the installation of new belts in order to regulate them.

Running in

After installing a new machine you must run it in without putting any loads on it to avoid damaging its components. When using the machine, it is necessary to re-tighten the gears after every 25 hours of operation. This prevents rapid wear of friction wheels and ensures the smooth movement of the power tiller.

See the following video on how to change the belt on your power tiller.

The Neva series power tillers are an indispensable helper in the garden. Fulfilling many functions, with frequent use they experience considerable overload, contributing to the appearance of faults. Among the possible problems that can occur with the cultivator type “Neva”, users often encounter a breakage of transmission belts.

The remoteness from service centers, the need to quickly resume the machine operation and the desire to save money on consultations of specialists encourage self-repair of the cultivator at home. It does not take much, as you will see after reading this material.

Belt tension trick

Belt dimensions for the Neva power units

When selecting drive belts, special attention should be paid to their dimensions. To determine the right part, you can use the table provided. It is worth measuring the distance from the pulleys to the pulleys beforehand, the new element will be mounted to them. This will allow you to choose more accurate dimensions of the belt.

The Neva MB-2 and MB-1 power tillers are characterized by different location of belts. Therefore, the scheme of installation of parts will be different.

Belt tensioning on the MB-1 model is carried out in a certain way:

- Initially, the cover is removed from the V-belt mechanism;

- From the pulley carefully remove the back bar;

- A key is used to loosen the spring-loaded roller;

- Dismantle the old element and you can put a new one;

- The previously disassembled spare parts of the unit are installed.

It is worth considering how to perform a belt replacement for units of the MB-1 range:

- The shield and cover of the V-belt system are removed;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts that secure the bracket are loosened;

- The forward drive belt is removed;

- The new elements are installed and tensioned, everything is secured, and the previously removed parts are put back in place.

Belt adjustment on the Neva MB-2 motor-block is performed as follows:

- The shroud is removed;

- The screw loosens the tension of the regular belt;

- All screws holding the bracket to the machine housing are removed;

- The old part is pulled out and the pulleys are adjusted;

- Before installing the belt, the places between the elements are thoroughly wiped and the hoses are blown;

- A new belt is installed. One end is connected to the gearbox shaft and the other end to the pulley in the motor;

- The design can be fully restored.

details about how to tension the belt on the power tiller Neva, it is worth to learn from the proposed video.

Basically, a new element is stretched when the motoblock breaks down. It is much less common to change in advance to prevent malfunctions while the unit is running. In any case it is necessary to perform work on the replacement of the belt carefully, because if it is stretched too much, its breakage is inevitable.

Belt adjustment

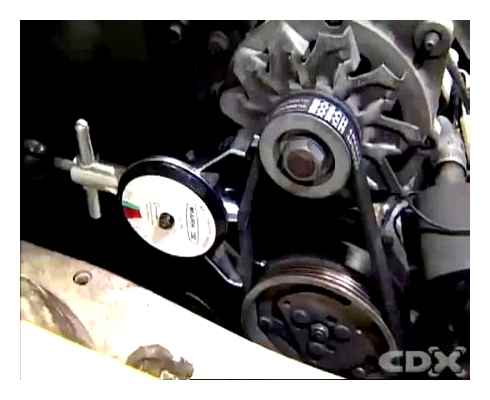

Adjustment of the belt tension on OKA motoblocks just like the installation of belts on a single-axle tractor does not require excessive physical costs and technical equipment.

Important! If when you press the belt drive by hand, it only lowers slightly, then there is nothing wrong with it.

Excessive slack in them can lead to negative consequences such as:

This is interesting: the drive belt of the motor-block Neva.

Adjustment of the belt drive parts of the Oka motorblock is carried out as follows:

- Release the motorblock frame with the motor part from the nuts with a universal wrench;

- We tighten the adjusting bolt and at the same time control the degree of tension of the belts. It is necessary to achieve the effect that they will spring back easily to their original position. You don’t want to overtighten it, as this can damage the bearing;

- It is important to pay attention to the engine’s position. If any shifts or misalignments are observed, unscrew the adjusting screw and fix the nut on the back of the machine body.

A similar check would be appropriate for new belt drive parts for more accurate adjustment and tensioning.

If you properly monitor the condition of your rotary cultivator and timely replace the parts that become unusable, the machine will serve for many seasons.