External ceiling

External ceiling corner view

We already cut the ceiling corners on the inside of the device..

Having inserted the left plinth into the miter box, we cut off the left outer corner. Substitute Right – Right Outer Edge Mode.

Features of cutting various angles

We have disassembled the general technology of how to cut off ceiling plinths.

Diligence Produces Results

If you still have any questions, then the visual in this article will help to resolve them..

By carefully following the recommendations and taking into account the peculiarities of the material with which you work, you can give your ceiling beauty and originality. Choose the method that you like and go ahead! You will succeed (read also about the advantages of PVC skirting boards).

Such an angle in geometric problems occurs quite often, so it is important to understand what it is and how to build it..

The easiest way is to build an angle of 45 degrees without special tools (like a protractor) on a sheet of a notebook in a box.

Cutting without miter box

If you do not have such a device, and you are not going to purchase it for one-time use, then you can use the following methods, how to cut the plinth at 45 degrees.

- The first way is to make this simple carpentry tool yourself. To do this, knocks down the most ordinary wooden tray. Then we measure the cut line with a protractor or school square. We cut the grooves and we have a primitive device ready.

- Second way. how to cut a skirting board at an angle is even easier. It is especially painless to use it in cases where the corners of the room are not even..

We don’t need a tray. Two boards knocked down at 90 degrees and a stencil made of cardboard with a line drawn for orientation is enough.

- Third way. In this case, we do not knock anything down at all, but simply use a table set against the wall or any other similar structure..

We mark the future joints directly on the product itself, on the wall and on the ceiling. We apply the plinth the way we are going to mount, and cut according to the marked marks.

The simplest way without the use of special tools

Remember: hold the tool vertically while cutting to obtain a right angle.

Cutting methods

The product is installed around the perimeter of a rectangular room. Trimmed to trim right angles. Therefore, we will consider how to cut the skirting board at 45 degrees..

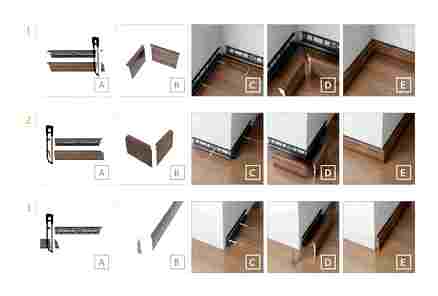

Indoor ceiling

Interior ceiling corner view

By analogy with the outer corner, we cut off the inner one. We only cut the inner left and right edges respectively.

It is important to remember: the product is always mounted upside down on the ceiling. Therefore, insert it upside down into the miter box. This will help you cut the skirting board correctly..

Indoor floor

Inside corner view

First, let’s set the left and right skirting boards at right angles. We insert the left product into the miter box, applying it to the outside, cut off the left inner corner. Then we do a similar operation with the right one. Done.

Cutting with a miter box

What is a miter box? This is a special tray made of wood, aluminum or plastic with provided grooves to guide the saw at the desired angle.

Here is a quick guide to using such a carpentry tool:

- Training. We take the product and put it in the tray. Align in the position in which it will be installed on the ceiling.

- Cutting. With the other hand, insert the cutting tool into the groove. It can be a knife or a hacksaw. And we cut it boldly. The device will not let you miss the intended place.

You should know: a blade for metal is also suitable for cutting foam.

- Treatment. Wood skirting boards may need to be filed to level the cut edges. Plastic or foam can be tweaked with a knife, the main thing is that it is sharp enough.

Tip: When cutting, do not put pressure on the product. Styrofoam can crumble, and the tree can split altogether..

It’s so easy and simple to use the miter box

How to cut at a 45 degree angle

Often, during repairs, you can face a situation when it is necessary to saw off a piece from a part, at an angle of strictly 45 degrees. Usually, this is needed to connect two parts at right angles, 90 degrees, such as: door trim, plinth, pieces of furniture and much more. An experienced craftsman, professionally engaged in repair work, can often do without special devices, and practically by eye is able to cut the necessary part evenly and clearly. But if you are a novice repairman, and you have a desire to do the work as efficiently as possible, without damaging expensive parts, then you just need to purchase a miter box – a special device that allows you to saw off material at a given angle without any special tricks.

To work, you need to have: a miter box, a hacksaw, a protractor with a pencil, a workpiece made of wood, a screwdriver with screws or a clamp.

Using a ready-made miter box

Self-made miter box

- 1. First, you need to assemble the box of the future tool. To do this, it is necessary to drill holes in its side walls, for future fastening with screws and, having smeared the ends of the parts with glue, connect them in such a way that both walls are strictly perpendicular to the bottom and parallel to each other, after which we fix them with screws.

- 2. Using a protractor, mark an angle of 45 degrees with a pencil, if necessary, add additional mowing lines for the grooves. The most critical part is the cuts, it is best to make them with the same hacksaw blade as you will be cutting products. It is necessary to cut by holding the blade, avoiding strong pressure on the tool, first we cut one side, then the other.

- 3. We start processing the material. With a clamp or screws, we fix the miter box on the working surface. At the place of the future cut on the plinth or board, we make a mark. How to cut at an angle of 45 degrees becomes clear if you press it tightly against the side wall and align the mark with the slot on the template. We insert the hacksaw into the groove and cut the workpiece, while the work of the blade is limited to cuts, which allows you to make the cut as smoothly and accurately as possible.

- 4. Before sawing the skirting board, make sure that the corner of the room is really straight and, if it is not, you need to adjust the cutting angle of the workpiece. To do this, measure the inner corner of the junction of the walls, and divide the result by two. If you do not have a professional rotary miter box that can change the cutting angle by the required amount, then to achieve the result, you need to saw additional grooves at the desired angle in a homemade miter box. This way you can cut the skirting board for the most accurate alignment..

Now you know how you can cut a workpiece at a 45 degree angle. Perhaps the time has come to move from theory to practical action. The team of the mebeldok.com portal is sure that everything will definitely work out for you. stay with us!

Cut 45 degree corner skirtingboard, how I cut an external mitre, outside corner on skirting boards.

How to use the miter box

A miter box will help you cut the plinth at a 45 degree angle. By the way, do you know how to use the miter box? The specialists of our portal have prepared for you a step-by-step.

How to cut the corners of a ceiling plinth

This is an instruction manual on how to cut the corners of a ceiling plinth. Considered options for solutions, such as.

Types of corners in rooms

When installing skirting boards, you need to arrange the corners in some way. By their appearance, corners are external (which protrude forward) and internal (for example, corners in a room). In rooms with normal geometry, the corners are straight, i.e. 90 °. When joining two pieces of the plinth strip in the corner, they are cut so that each has an angle of 45 °.

To arrange the outer and inner corner, the skirting board must be cut

But how to make an angle on the plinth so that it is exactly forty-five degrees? To do this, use a special carpentry tool – miter box.

Important nuances

If you tried as best you could, but a small gap at the junction still “got out” do not be discouraged. In wooden fillets, such a gap is easily covered with furniture wax. To cover the gap on the baseboards made of polyurethane, foam, plastic or gypsum, a putty is perfect. Naturally, the color of the composition should match the color of the skirting board.

All cracks in the area of the ceiling fillets are sealed with putty.

Wide ceiling fillets are certainly beautiful, but they can only be mounted on perfectly flat walls. If the plane of the wall in relation to the ceiling is a wave, then it is better to buy narrow polyurethane fillets, they are elastic and will smooth out this drawback.

Most of the questions arise about how to cut the wallpaper for the ceiling plinth. There is nothing complicated here: the wallpaper is glued with a slight overlap on the baseboards and when the wall is completely glued, take a large spatula, apply it to the corner and cut off the excess along the blade with a knife.

How to cut wallpaper for a ceiling plinth with your own hands.

But keep in mind – neither the knife nor the spatula can be torn off the wall until you have passed the entire plane. That is, they put a spatula from the corner, cut off the wallpaper along the length of the blade, and then, without lifting the blade from the wall, move and cut until you reach the next corner.

How to cut skirting board or baseboard corners. No power tools required!

How to make a skirting angle more or less than 90 °

Not all angles are exactly 90 degrees. If the deviation is small, the cracks can be removed with sandpaper. In other cases, you will have to mark and cut taking into account the real degree. The main task in this case is to find a point on the floor where two plinths will join.

Let’s start by explaining how to properly slice the outside corner if it’s not 90 degrees. We take the bar, put it to the corner on one side, press it tightly against the wall – as it should stand. Draw a line on the floor with a pencil along the bottom edge of the plinth. We apply the bar to the other side of the corner, do the same. The intersection of the two lines will be the joining point of the two skirting boards.

How to join a skirting board if the angle is less than or more than 90 degrees

Now we attach the plinth strip again, set it in the way it will be attached. We make two marks: at the top at the turn itself, at the bottom in the place where the lines we draw intersect. Now an important task: it is necessary to make a cut according to these marks. If you have a miter saw or a miter box with an adjustable saw tilt, set it up and cut it. If not, carefully cut it with a hacksaw. In order not to get lost, you can use a pencil to apply the fishing line along which you need to cut. Similarly, mark and cut off the second part. Modifying the connection of the skirting boards with sandpaper.

Few of the professionals process the joints with sandpaper – this is time and additional work. But if you join skirting boards in the corners in your own house, with your own hands, you definitely want everything to be beautiful. This is what this manual debugging is for..

With a custom-sized inner corner, everything is exactly the same. We put a plinth in the corner, draw a straight line on the floor. We do it on the other side. Transfer the point of intersection to the planks.

All three methods described by me work, the choice depends on which tool you have in stock and what your professional skills are. If after watching the video you still have questions, welcome to the comments, than I can, I will help.

If you are not confident in your abilities, then for both floor and ceiling skirting boards there are connecting elements that allow you to do without trimming.

Today it is impossible to imagine the interior of a residential building or apartment without ceiling plinths. The skirting board covers the irregularities of the suspended ceiling or wallpaper, cracks and imperfections in the walls, and gives the interior completeness. But how to make the skirting board perfectly fit in the most important place – in the corner? There are several ways.

How and what to cut a plastic skirting board

All of the above applies to MDF and wood skirting boards. Cutting them with an ordinary hacksaw is not a problem. It is advisable to take a blade for metal, since it has a smaller tooth and the saw cut is smoother, you will have to work less with sandpaper. With plastic, the situation is different – when you try to cut a piece, some thin-walled skirting boards crumble and break.

Cutting plastic is not very convenient because of the thin walls

To cut normal quality plastic skirting boards you can use:

- Hacksaw for metal.

- angle grinder (angle grinder) with diamond disc.

- A revolving miter saw. Before cutting, speed up the disc and only then start cutting.

- A jigsaw and a file with a fine tooth. Here you have to try – select the speed and file.

- Sharp knife.

- Metal scissors. In any case, it is not difficult to make straight cuts with them..

Only personal experience will help you decide what is more convenient for you to cut a plastic floor plinth. If you have a miter saw, try using it. It is not a problem to try your angle grinder with a diamond disc a couple of times. If all this does not work well, try a hacksaw, jigsaw, or knife. There are, of course, special scissors for plastic, but they are too expensive to buy for a single use..

Accessories for the design of corners and joints of PVC skirting boards

In plastic skirting boards, you can design corners and joints using special fittings. There are external and internal corners, plugs and connectors. Basically, they allow you to assemble the desired configuration. Each manufacturer makes its own fittings – for its own profile, colors. But the principle of their use is the same.

How to shape the corners of a plastic skirting board

The first rule is that all cuts are made straight. Strictly perpendicular. Marks in the corners are set at a distance of 1-1.5 mm from the corner. The fact is that the rigidity fittings have their own jumpers. For them, it is necessary to retreat a couple of millimeters, but no more. Otherwise, a gap will appear or the skirting boards will pop out of these corners.

This is the result of the assembly

I must say that not everyone likes the look of plastic corners. You can make a corner on a PVC skirting board in the same way as described for wood or MDF. The only difficulty is that you have to be careful with plastic – it breaks down from excessive efforts. There is one trick – before cutting the plastic skirting board, add a little polyurethane foam on the back side and wait for the polymerization to begin. It will be tougher, easier to cut, less deformation. If the foam subsequently interferes, it is not a problem to remove it, but to cut it is, indeed, easier..

How to cut a skirting board at 45 degrees

When installing skirting boards, it is important to arrange the corners correctly. It is they who often spoil the overall picture. How to make a corner on the plinth – external and internal, how and with what to cut. We will discuss all this further.

A few words about tools and materials

Floor skirting boards are now made of wood or polyvinyl chloride (PVC), in other words, plastic. Ceiling fillets have a slightly larger list:

The range of ceiling plinths is much wider than that of the floor direction.

- Polyurethane – these skirting boards have good elasticity and can bend around radial and other curved surfaces, but in any case they need to be cut at clear angles;

- Foam plinths are the simplest budget option, the price of foam plinths is low and they are cut very easily;

- PVC – the principle is the same as for floor skirting boards, but the range is much wider;

- Wooden – similar to the floor ones, only here there are still wide models;

- Gypsum – with the advent of polyurethane and polystyrene, gypsum ceiling fillets receded into the background, firstly, they are heavy, and secondly, fragile. But in fairness, it’s worth mentioning them.

Since it is impossible to properly cut the ceiling plinth and its floor counterpart without a good tool, we will dwell on this issue in a little more detail..

The best, almost perfect tool for trimming all kinds of skirting boards and more is the swing miter saw. The high-speed disc makes smooth and precise cuts, and the bed in these units can be rotated at any angle. The only problem is the serious cost of this tool..

It is believed that one of the best hand tools for accurately cutting small pieces of wood is the backsaw. In principle, this is true, but to be honest, a really high-quality saw, even with the current assortment, is not easy to find. If you still decide to buy a similar tool, then take a saw with a fine tooth.

The bow saw is convenient when working with a miter box.

In theory, foam and polyurethane can be cut with any sharp and sturdy knife. But at the same time, you need to have a firm hand and at least a little experience in cutting foam. Plus, it is very problematic to cut wide fillets with a knife..

Without experience, making a clear cut with a knife is very problematic..

Personally, in the absence of trimming, I only use a hacksaw for metal. It is suitable for cutting absolutely any material, from foam to wood. By the way, they often ask the question of how to cut a plastic baseboard for the floor, and so – take a hacksaw for metal and you definitely won’t be mistaken.

For trimming skirting boards, a hacksaw for metal is considered one of the best tools.

Types of corners in rooms

When installing skirting boards, you need to arrange the corners in some way. By their own form, corners are external (which protrude forward) and internal (for example, corners in a room). In rooms with normal geometry, the corners are straight, i.e. 90 °. When joining 2 pieces of the plinth strip in the corner, they are cut so that any one has an angle of 45 °.

But how to make an angle on the plinth so that it is exactly 40 5 degrees? To do this, use a special carpentry tool – miter box.

Method number 3. Applied universal

Undercutting at 45º is a common option, but what if you need a different angle and only have a hacksaw and a pencil? It turns out that there is an extremely common way out of this situation. Plus, this method is universally applicable, it suits both external and internal corners..

Moreover, I can assure you that those angles that visually appear to be straight, in fact, differ by a couple of degrees. As a result, you buy a good tool, cut it off correctly 45º, and when joining, the gap between the skirting boards “comes out”. Here this discrepancy disappears. And then, using an example, we will see how to cut the ceiling plinth in the inner corner..

Take the fillet, apply it on one side of the corner and use it to draw 2 strips, along the wall and along the ceiling.

Advice: so that the stripes are inconspicuous, they can be drawn not with a pencil, but, for example, with a nail or the edge of a knife.

A few words about tools and materials

Floor skirting boards are currently made of wood or polyvinyl chloride (PVC), in other words, plastic. For ceiling fillets, the list is slightly larger:

The range of ceiling plinths is significantly wider than that of the floor direction.

- Polyurethane – these skirting boards have good elasticity and can bend around radial and other curved surfaces, but in any case, they must be cut at exact angles;

- Foam plinths are the most common economical option, the cost of foam plinths is low and they are extremely easy to cut;

- PVC – the principle is the same as for floor skirting boards, but the range is much wider;

- Wooden – similar to the floor ones, only here there are still wide models;

- Gypsum – with the emergence of polyurethane and polystyrene, gypsum ceiling fillets receded into the second plan, firstly, they are languid, and secondly, fragile. But in fairness, it’s worth mentioning them.

Since it is unrealistic to correctly cut the ceiling plinth and its floor counterpart without a good tool, we will dwell on this issue in little more detail.

The best, virtually flawless, tool for trimming all skirting boards and more is the Swivel Miter Saw. The high-speed disc makes smooth and precise cuts, and the bed in these units rotates at any angle. The only problem is in the harsh cost of this tool.

The miter saw is virtually the perfect tool for trimming skirting boards and more.

It is believed that one of the best hand tools for cutting small pieces of wood accurately is the backsaw. In principle, this is true, but to be honest for you, a really benign saw, even with today’s assortment, is not easy to find. If you still dare to take a similar tool, then take a saw with a small tooth.

The bow saw is comfortable when working with a miter box.

In theory, foam and polyurethane can be cut with any sharp and sturdy knife. But at the same time, you must have a firm hand and at least a little experience in cutting foam. Plus, it is very problematic to cut wide fillets with a knife..

Without experience, making an accurate cut with a knife is very problematic..

Personally, in the absence of trimming, I only use an alloy hacksaw. It is suitable for cutting completely any material, from polystyrene to wood. By the way, they often ask the question of how to cut a plastic plinth for the floor, and so – take a hacksaw on the alloy and you definitely won’t be mistaken.

For trimming skirting boards, an alloy hacksaw is considered one of the best tools.

How to cut the skirting board in the inner corners: an action plan step by step

Begin installing the skirting boards in one of the corners. If this is the 1st experience for you, choose that part of the room in which something will stand. Not all the time, it’s over, the first pancake is lumpy, but it’s still better to be on the safe side. To make the corner on the plinth neatly, work without haste. One was sawed off, checked, adjusted. We run over to the next one. It is better to fasten after two adjacent corners are assembled. But you shouldn’t postpone the assembly too much..

How to use a miter box to cut skirting boards? Place the device in front of you, preferably on a table, but also on the floor. Whichever side to turn it is unimportant, it is symmetrical. Insert the bar into the profile, turn it so that it will stand against the wall. When washing down the floor plinth in the miter box, the “wall” is the wall that is farther away from you. Once again: press the plinth strip firmly against the back wall in the position in which it will be installed. Insert a hacksaw into the desired slots. You can start sawing.

You will also be curious to read

How to cut a skirting board at any angle and without gaps – 3 working methods from a practitioner

Tips on how to cut a plinth at 45 degrees on the network are currently more than enough, the only bad thing is that most of them are given by people who have never done this. Further, from the point of view of practice, I will tell you how to cut skirting boards at the corners with your own hands in 3 options, while you will learn both about conventional methods and about popular all-purpose recipes.

The science of how to properly trim ceiling skirting boards in corners is not as difficult as it might seem..

Important nuances

If you tried as best you could, but a small gap at the junction still “got out” do not be discouraged. In wood fillets, such a gap is simply covered with furniture wax. To cover the gap on the baseboards made of polyurethane, polystyrene, plastic or gypsum, putty is unrivaled. Naturally, the color of the composition should match the color of the skirting board.

All cracks in the area of the ceiling fillets are sealed with putty.

Wide ceiling fillets are certainly wonderful, but they can only be mounted on completely flat walls. If the plane of the wall in relation to the ceiling is in a wave, then it is better to buy narrow polyurethane fillets, they are elastic and will smooth out this drawback.

For a wide fillet, completely flat walls are needed.

Most of the questions arise about how to cut the wallpaper for the ceiling plinth. There is nothing complicated here: the wallpaper is glued with a small overlap on the baseboards and when the wall is one hundred percent glued, take a large spatula, put it in the corner and cut off the excess with a knife along the blade.

How to cut wallpaper for a ceiling plinth with your own hands.

But keep in mind – neither the knife nor the spatula can be torn off the wall until you have passed the entire plane. That is, they put a spatula from the corner, cut off the wallpaper along the length of the blade, and then, without lifting the blade from the wall, move and cut until you reach the next corner.

Three working methods for trimming skirting boards

For floor and ceiling skirting boards, the trimming annotation is virtually the same. But if on the floor the curved corner can be covered with something, then on the ceiling this is already a discrepancy, therefore we will pay more attention to how to cut the ceiling plinths.