Can the wrench be used as an electric screwdriver

In the near future is to tighten a lot of screws and I decided to think about choosing a drill-electric screwdriver, but here I came across such a hitherto unknown to me a class of tools as “impact wrench.

Please tell me what are the fundamental differences between an ordinary electric screwdriver (or a drill-electric screwdriver) and an impact wrench? What are their main applications? What is the best to use for what tasks??

Because I do not really understand how they work.

Bosch GSR 10,8 V-LI-2 Max. Torque (hard screwdriving). 30 Nm RPM: 0. 400 / 1.100 min-1

Bosch GDR 10,8 V-LI Max. torque (hard screwdriving). 100 Nm RPM: 0. 1.800 min-1

Where does this torque come from, if the rpm is higher?? And apparently the engine is the same, and it was logical that if RPM is lower, torque is higher (which requires reducing gear), but here it’s vice versa.

And if I only need to torque self-tapping screws into wood and other materials, what class of tool would I prefer??

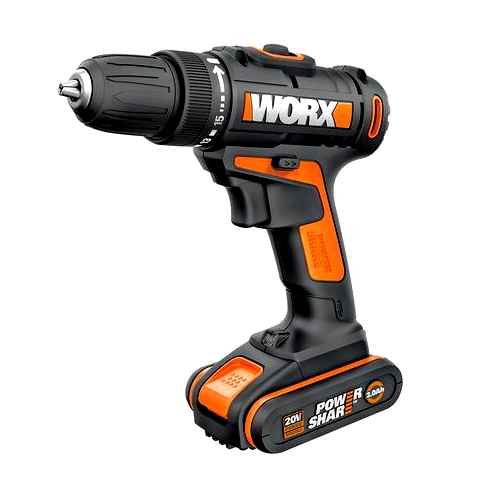

P.S. I’ve never seen an impact wrench in person but I see in the photo that it has a socket for bits, which are used to tighten the self-tapping screws.

Tangential impact is used in impact wrenches. Т.е. not a constant torque but a series of pulses (as if you put a ring spanner on the head of the bolt and tighten it not in one movement, but by quickly and rapidly tapping with a hammer on the handle end of the wrench). The gigantic torque indicated is the sum of the force of those very blows per unit of time.

What size self-tapping screws do you need to torque?

In fact, I know of at least one thread with basically the same title, and it can be found by searching

Different nature of screwing. Before determining. Effort spins at its high RPM, then begins to pound (the principle is well described by Mr. Dobson). Eddy21 )/. Hence the disadvantages to a conventional electric screwdriver:

- Very limited drilling capability. Т.е. it is possible to drill only up to the transition to impact (in impact mode the speed drops sharply). And before the transition to impact, it is usually with drills of sufficiently small diameters

- Actually, that’s why (and to ensure shorter tool lengths) they don’t put cam chucks on them. Т.е. even if they do drill, it is only with drill bits with hexagonal tails

- The nature of screwing makes it very difficult to create a torque limiting clutch. Accordingly, they do not make such sockets (or rather, there are 3 tools with a cosmic price of 20 t.p), i.e.е. The moment when you need to stop, you need to keep track of yourself, which, for example, in the first phase at high speeds is difficult (as with a high-speed drill, for example).

- If a heavy task, t.е. all the time twists with a bang. then works slower than a normal screwdriver. By the way, in shock mode is also quite loud

Advantages. well, obviously, high torque. It’s perfect for nuts. quickly torque on the bolt, then tap to tighten. Or on the contrary, turn it away. everything in the reverse order.

Nutrunners FUBAG: eredu ezagunen ikuspegi orokorra

FUBAG GmbH Alemaniako fabrikatzailearen intxaur-torteen gaman, erreminta pneumatikoen talde bat nabarmentzen da. Kategoria honetako modeloek hainbat abantaila dituzte aukera elektriko, bateria eta hidraulikoekiko, errendimendu eta momentu handiko ezaugarriak dira. Hori egiaztatzea erraza da Fubag giltza pneumatikoen adibide onenen berrikusketan.

Inpaktu-giltza Fubag IW680(100110)

Teknikoki, gailua pistola gisa egiten da, hau da, konpresorearen aire konprimituak bultzatuta. Gasa 6×8 mm-ko diametro gomendatua duen mahuka baten bidez hornitzen da, egokitzearen tamaina. 1/4F. “Fubag IW680 (100110) azkoin-giltzak konpresore estazio batekin bakarrik funtziona dezake. Egoera hori desabantaila izango litzateke, ekipamendu osagarriak erosteko kostua baitakar, baina sare elektrikoekiko erabateko independentzia horrek eragozpen hori estaltzen du.

FUBAG azkoin-gidariak aplikazio sorta zabalean aurkitu du. Hauek dira bulkanizazio zentroak, eraikuntza, nekazaritza-makinen mantentze-lanak, zerbitzuguneak, hegazkingintza eta trenbideen konponketa tailerrak. Arlo horietan, lan-baliabide handi hori eta etenik gabeko lan luzea behar dituzu, Alemaniako tresna batek eskaintzen dituena.

Gailuaren gorputza metalezkoa da, eta horrek barneko elementuak suntsipenetik babesten ditu. Tresnaren neurriak (LxWxH). 225x205x80 mm, pisua. 2,42 kg.

| Eragin funtzioa | Ez dago |

| Konpresorearen presioa | 6.3 atm |

| Buruaren bira minutuko | 7500 |

| Gas konprimituaren kontsumoa | 380 l / min |

| Botere momentua | 680 Nm |

| Finkagailuaren tamaina | M16 mm-ra arte |

| Eranskin plaza | 1/2 hazbeteko |

| Energia iturria | konpresorea |

Ekipo indartsu handia. Giltza hau ona da lokailu astunak askatzeko.

Inpaktu-giltza Fubag IW720(100192)

Motor faltagatik arina, modeloak abantaila handi bat du: ardatzaren mugimenduaren norabidea aldatzeko funtzioa (alderantzizkoa). Honek hardware hertsiak eta itsatsitako elementuak zerbitzatzeko aukera ematen du.

Gai honi buruz gehiago: Ezaugarriak, Force autoko erreminta-tresnen ezaugarriak maleta batean, onenen balorazioa erosleen arabera

Konpresorearen gasaren kontsumo ekonomikoak (226 l / min) 6,3 bar-eko presio operatiboan ez du 720 Nm-ko momentu gailurra oztopatzen. Eremu profesional eta erdi-profesionalerako ekipamendu sendoa da. Fubag IW720(100192) giltzak M27 mm-ko torloju handiak maneiatzen ditu.

- hezetasun handiko geletan lan egiten du;

- sute arrisku txikia;

- I’ve got a lot of trouble to deal with;

- potentzia-momentua doitzeko gaitasuna;

- dimentsio trinkoak. 240x228x71 mm;

- pisu arina. 2.8 kg.

| Eragin funtzioa | Ez dago |

| Aire konprimituaren kontsumoa | 226 l / min |

| Ardatzaren biraketa minutuko | 8000 bira/min |

| Abiadura kopurua | 4 bi aldetara |

| Sartzea | 1/2 hazbeteko |

| Aire egokitzea | 1/4F |

| momentua | 720 Nm |

“Fubag” kolpe pneumatikoko giltza eros dezakezu 6 errubloko prezioan.

Ezagutzen ez duenarentzat, alemaniar aire-pistolak tximista-abiaduraz askatzen ditu azkoinak Twin Hammer perkusio-mekanismoari esker. Ekipamendu fidagarriak auto-konponketa-taileretarako. Ez dut etxeko erabilerarik ikusten.

Inpaktu-giltza Fubag IWS680(100111)

Eredua kolpeen aurkako plastikozko kaxa batean dator. Konfigurazioan, jabeari ekipamendu-multzo bat eskaintzen zaio: 8 buru 3/4 hazbeteko tamaina, 6 alboetako giltzak 4 eta 5 mm-rako. Neurriak. 316x294x98 mm, pisua. 3.09 kg.

IWS680 (100111) indizearen azpian bateria-kitaren ezaugarriak:

- lan baliabide ikusgarria;

- eragiketa luzea prozesua gelditu gabe;

- helduleku erosoa ergonomikoa;

- biraketa-abiadura aldagarria.

| alderantzizko biraketa | Bai |

| Eragin funtzioa | Bai |

| Gas konprimituaren kontsumoa minutuko | 234 l |

| Konpresorearen airearen presioa | 6.3 atm |

| Potentzia gailurreko unea | 680 Nm |

| Intxaurren gehienezko tamaina | M19 mm |

| Toberaren barruko diametroa | 1/4F |

| Chuck biraketa minutuko | 4800 bira/min |

Alde onak: hainbat ekipamendu, indar momentu handia, gorputz sendoa.

Inpaktu-giltza Fubag IW900(100195)

Erreminta pneumatiko hau konfigurazio aldetik aberatsenetakoa da. Multzoan:

- buruak. 10 pcs. 9 eta 27 mm bitarteko neurriak;

- luzapena;

- olio ihinztagailua;

- plastikozko kaxa;

- gurina plater;

- egokitzea 1/4F.

electric bike, boat motor, homemade with his own hands from an old engine

The presence of an electric screwdriver inspires many craftsmen to create additional devices and tools on its basis. The fantasy of these guys is limitless. Equipment for the carpentry workshop. lathe, drill, milling machine, drill and angle grinder, mechanical saw and wrench.

Even children’s vehicles. electric cars and snowmobiles. are not left aside. What to say about household appliances. grass trimmers and lawn mowers, and even a boat engine. The most amazing thing is that all listed “homemade” devices, made by our own hands, operate on the basis of an old electric screwdriver and the talented design solutions of home craftsmen.

Generator

The design of an electric screwdriver is such that a small improvement is enough to get power in camping conditions. If you remove the circuit board with electronic regulator from the inside of the electric screwdriver and put a diode bridge on the output, it allows you to spin the alternator in either direction. It remains to clamp the self-made handle in the chuck. the generator is ready!

Wind turbine generator

Using the electric screwdriver motor can construct a small wind turbine generator for summer cottage or homestead, and be independent of electricity supply. And it will also help in case of power failure in the network.

It takes a little time to create a wind turbine. The rotor part is removed from the electric screwdriver. The motor shaft is attached to the plastic plate with a staple. We bolt the flywheel to the pinion and fix four blades on it, made of PVC-tube. For the housing you can use a tin from the tea can, carefully sealing the cracks sealant. The wind generator is ready to provide electricity, which does not cost you anything.

Equipment for the woodworking shop

Every craftsman carpenter equips his workshop with the necessary equipment for his tasks. Not always a person for domestic use can afford expensive machines of industrial manufacture. And this situation is the impetus for the realization of homemade products on the basis of available parts and tools.

Wood lathe

Wood lathe will be an indispensable tool for home craftsmen. Circular blanks, handles for doors, spherical and cone-shaped fragments for wooden railings, chair legs and much more. all this can be made with a homemade lathe based on an electric screwdriver.

There is no need to spend money on factory equipment, if such a lathe without much effort can be made with your own hands from an old electric screwdriver, using a minimum of means and materials.

We can briefly describe one of such variants of “homemade” machine. A rectangular box (frame) made of plywood with three sides is made. In the short side is cut a landing slot. This simple wooden base is where you install the electric screwdriver, with the button up.

The frame, in this case a rectangular wooden box, is screwed to the table and clamped. This is done in order to fasten the base plate with the tool securely to the work table.

A wooden bar is used as a support bar for the cutter, which is also screwed to the table with a clamp.

A piece of rod with a thread suitable for hooking is clamped into the chuck of the electric screwdriver. A wooden blank (ingot) is set on the rod. An electric screwdriver is turned on and twists the wooden workpiece. With the help of a cutter, resting on the support bar, the master cuts out the desired volume-shaped piece.

The tool is extremely necessary for craftsmen who use wooden parts and fragments in their work.

Bench-mounted drilling machine

A table drill is indispensable for many craftsmen in garages and workshops for precise drilling holes in wood, metal, plastic, etc.д.

Talented craftsmen do not spend money to buy production equipment. It takes a little bit of effort and engineering ability, ingenuity, and desire. The result can be a good construction of a table drilling machine from improvised materials.

The gearbox from an electric screwdriver can serve as the base of the tool. The piston rod (stand) of the frame can be made of various materials. Everything goes: metal rods, typewriter carriages, wooden constructions, etc.

The mechanism of raising and lowering the gearbox vertically is also made in many different ways. Even springs from an expansion joint are not superfluous.

For fixing the gearbox to the base plate shaft selfmade clamps made of textolite are made, or suitable parts from other devices or even automobiles are used.

Each construction is individual and interesting in its own way. The main thing is that the task that is set for the drilling machine. to be performed with the utmost accuracy and at the proper quality level.

Do not use for the machine broken and old screwdrivers, as backlash in the chuck does not allow to achieve the desired diameter of the hole.

Manual router: step-by-step instructions

If when working with wood you have the task of cutting a groove or circle, you should not go and buy an expensive router. Showing ingenuity, you can easily solve this problem and turn an electric screwdriver into a manual milling machine, creating with your own hands the bottom frame. a structure that would hold vertically the tool. Manufacturing attachments for milling on screwdrivers (drills) are on sale, but buying them is not always financially justified.

The most readily available handy material for the home craftsman. plywood and wooden bars. These are the ones we will make a bed attachment for milling, following the step-by-step instructions:

- Let’s make the bottom part of the frame. Let’s take 8 mm thick plywood and cut a ring with an external diameter of 10 cm and an internal diameter of 5 cm. For this work we use an electric screwdriver with a “drill bit” for wood.

- On the sides of the ring, we screw two wooden bars 4x2x10 cm with self-drilling screws. Let’s put the made construction with bars upwards. It will resemble a stool, put upside down.

- Let’s make the upper part of the bed. Let’s cut out one more ring from plywood with the outer diameter of 9 cm and the inner diameter of about 4.5 cm (about the size of the electric screwdriver’s body).

- We screw the upper part of the frame to the bars with the lower part.

- Let’s put the stand on the housing of the electric screwdriver. It sits tightly in the round hole of the upper part of the bed.

- We put the cutter needed in the chuck and adjust the cutter cutout. Tightening the chuck.

How to make an ice drill from an electric screwdriver with your own hands, video example

The ice drill is an indispensable tool of any winter fishing enthusiast. Whether a real fisherman or an angler with experience, and winter fishing without this helper is not very interesting. Of course, you can also break through with an ice axe if the ice is thin, but if the ice is thick, you can’t do without an ice drill. And it feels more comfortable to drill a hole in one-two. Consider the technology of making an ice drill from an electric screwdriver with your own hands.

Ice axe making by yourself

Many fishermen are engaged in self-made fishing accessories and the ice drill, is no exception.

Still, not everyone can buy a ready-made tool, let alone a mechanized one. To make it, you will need the following parts:

- Metal pipe of an appropriate diameter.

- Metal plates for auger production.

- Prepare blades of quality steel.

- Connect all the elements into one construction by welding and grind with a grinder.

- Paint the finished tool.

In the process you may need a lathe or turner.

The quality of drilling is influenced by:

- Blade hardening. Modern models of ice axes are characterized by the hardness of the blades in the range from 30 to 70 units.

- Precision craftsmanship of the knives. Blades should have two cutting edges. Proper sharpening allows very fast drilling of the ice.

Material for making blades

- P18 steel is mainly used, although analogues are also available. Pay attention to the hardness of the material, shape, and sharpness.

- Titanium nitride coating. Such blades serve for a very long time. A value of 75 indicates high wear resistance.

Fishermen use two options for making such a tool. Using an electric screwdriver improves its performance by speeding up drilling.

Ice axe from an electric screwdriver with their own hands

Fishermen have been able to improve the ice drill by attaching an electric screwdriver. They just realized what it costs to waste precious time, especially in the winter.

To make it necessary to have:

As a rule, the optimal size of the hole is about 10 cm.

Characteristics of an electric screwdriver for the ice drill

An ice drill is a tool that can facilitate winter fishing conditions and make it more comfortable. To drill holes without problems, it is necessary to choose an appropriate electric screwdriver and, accordingly, a cordless.

Tool characteristics

For an elementary upgrade drill suitable models such as Mora Nova System or Ise Arctic (Micro, VIKING), Rapala. Domestic designs, such as Tornado, Barnaul, Tonar are also suitable.

How to choose an electric screwdriver

As a rule, anglers punch a few holes, and sometimes a few dozen, as winter fishing. is a constant search for places of stay fish. Therefore, fishing turns into hard, exhausting work, and it can not be compared with the pleasure of fishing.

How to Find a Battery

Basically, two types of power source are used:

Nickel. cadmium, which tolerates sub-zero temperatures well, but makes the tool heavier.

- Lithium-Ion. The power supply can be operated at temperatures.10°C and thin ice thickness. Despite this, this source allows to drill up to 60 holes, 10-16cm in diameter. At lower temperatures, the battery can be removed from the unit and placed in an inside jacket

- Nickel metal hydride battery. hardly ever used in a screwdriver.

It is always advisable to carry a spare battery with you and keep it warm.

How to Make an Adapter with Your Own Hands

An adapter or adapter serves to connect the electric screwdriver to the rest of the structure. It can be purchased in a store, or you can make one yourself.

Adapter has a hexagonal shape and one side is clamped in the chuck of an electric screwdriver. At the same time, it should be taken into account that the connection is reliable. Clamping the hexagonal part with a special wrench. The other side of the adapter is connected to the auger. To do this, it is necessary to drill a hole in the cylindrical part, and then take a bolt of the appropriate size and fasten the auger with an adapter.

It doesn’t hurt to have a handle to hold the drill with, which will prevent it from falling into the water. It is not necessary to make the auger of large diameter, because it increases the load on the electric screwdriver, which will lead to a rapid discharge of the battery. optimal diameter of the hole is 10-13cm, which allows to catch fish of medium size. The adapter has the following dimensions: the diameter of the cylindrical part of 18 mm, the shank has a hexagonal shape, the presence of a stop is mandatory.

Advantages of an ice drill with an electric screwdriver

Since winter fishing fans know what it means to drill a dozen holes by hand, and even more, they prefer this design.

- Easy modernization that does not require special skills and professionalism.

- No need for large financial outlay.

- The genuine interest that this simple design arouses.

electric screwdriver or wrench?

Some anglers use wrench to mechanize the process of drilling holes, noting the following advantages:

There are 0 users on the page now

No users viewing this page.

quote: Originally posted by alexei2011june:

How to work with a wrench not to over tighten the screw? You can control the tightening torque? Is it possible to assemble furniture with it??

mozayu set screwdriver and impact “wrench” Milvoki 18 volt lithium, happy as hell, Makita sucks in a screw next to both in performance and price (screwdriver Makita cost as a set of Milvoki in a suitcase, and still twice in the repair visited, dust). The striker with a “chuck” for the bit, t.е. there is a 6 facet hole in the end. Pulls just any screw, twisted without drilling and 1506 with a cross under the posydrive N 3. Smooth push button gives low speed, no adjustments, as torque increases, completes by itself with torque, when screwed all the way in, locks itself without overtightening. Screwed hundreds of screws, head breakage was a couple of times.Runs at full power for 30 minutes, there is a charge indicator in the battery. Sucks the battery dry, no power loss.

Forget about assembling furniture with this impactor. For furniture, I took Makita electric screwdriver, folds from straight to G-shaped, took the blue “proff”, still alive, but the batteries at 7 volts saturate quickly, for half an hour of work and replaceable also charged a half-hour maximum.

| hunter1957 | posted 4-9-2011 22:30 Only need to consider that the lithium ion batteries are not adapted to work and store at subzero temperatures. |

| ehpebitor | posted 4-9-2011 22:45 |

quote: Originally posted by Mower_man:

7 volt battery drains quickly, in half an hour, but the battery is charged in half an hour at most.

A little announcement: Skil will be releasing a new 6222 Energy 2-speed cordless drill/driver model, which will be available in September 2009. If it were not for the 6-meter power cord (220 V), it would be very difficult to distinguish it from its battery-powered counterpart. The model is planned for delivery to several dozen European countries, including Russia.

0.45 Amp. Speed (idle): stepless adjustable in two ranges. 0-300 and 0-850 rpm./min. Diameter of screws to be driven (max.): 6 mm. Quick-action chuck, 1.0-10 mm diameter. Drill diameter (max.): in steel up to 8 mm, in wood 10 mm. 19 steps torque adjustment drill mode. Reverse. weight: 1.2 kg.http://www.holodilnik.ru/domestic/drills_and_screwdrivers/skil/6222ab/

quote: Originally posted by ehpebitor:

If it wasn’t for the 6 m power cord (220 V), t

All the corded “handheld” stuff is screwed, real cords get fucked up, I carry a lot in my waist bag or by the hook on my work belt. With the larger units, of course, is a different story.

quote: Originally posted by Mower_man:

cords are really getting in the way

quote: Originally posted by ehpebitor:

The bit is indispensable at home once a year to unscrew, screw, drill and other screws.

It depends on what kind of house and at what stage of finishing/construction, I’ve wrapped more than a dozen thousand screws. I have under 30 doors, tomorrow I will put the permanent doors, 6 and 7 in a row.

| alexei2011june | posted on 4-9-2011 23:19 Not a serious point. Li-ion has no disadvantages, no worse in temperature than nimh. Don’t know what they put in the tool, best cans Panasonic NCR-18650 LiNiCoO2. working range.20 to 60 deg. I have one in a 18650 assembly, protected, record capacity 11Wh. In extreme cold.40 we’re switching to lithium batteries. Too bad, tool manufacturers do not use standard RC123 batteries (as in cameras) and their li-ion 18650 analogues. about self-powered. There is a useful thing 12/220 inverters. For the tool preferably pure sine. no overheating, soft start. Experience inverter 600w 2.5kg. Regular Soviet drill 420W. no problem. Small angle grinder 800W. works, but does not saw with full power. The cable problem is solvable. Where I can’t get a cable, I take an autobattery and a converter box.I like the Bosch wrench in the household better. Something in an old car you can’t turn neatly without this. Too bad he might have a problem with screws. |

| Mower_man | posted 4-9-2011 23:27 |

quote: Originally posted by alexei2011june:

I was more attracted to the Bosch wrench in the household.

Bosch, the blue pro (so called, but in fact disposable) and Makita blue of cordless hand tools for myself crossed out.

The Bosch GDR is moderately priced, its size is appropriate for various applications, and I do not anticipate much work.What is the difference between an impact wrench and an impact screwdriver?

quote: Originally posted by alexei2011june:

impact screwdriver

That does not yuzalit that does and how to torque (my version does not twist nuts (there is a 1/2-inch version for heads, then I’ll buy), so in American would be “torque”). I wrote.

By the way, it breaks shitty bits at once, but does not break crosses in the screws, while the electronics and the brake are well designed. The screws will go in the wood, the screwdriver has to “push” hard. Milwaukee has a 5 year warranty in the U.S., I am happy about that. I took the advice of the local frame-builders. They make money on the loaf and know a thing or two about these things.

RPM 0-2600 rpm 1/4 inner hex socketMax. 125 NmReverse is Battery voltage 12VBattery capacity 2 (NiCd) AhCase included with the kit has aComplete set: 2 batteries 2 Ah (NiCd), battery charger, a suitcase.

quote: Originally posted by alexei2011june:

I have already given up assembling furniture (I do it only rarely).

There are 0 users on the page right now

There are no users viewing this page.

quote: Originally posted by alexei2011june:

How to use the impact wrench without over tightening the screws? You can control the tightening torque by turns? Can I assemble furniture with it??

Yuzayu set screwdriver and impact “wrench” Milvoki 18 volt lithium, happy as hell, Makita sucks in a row in a pinch as for performance and price (Makita screwdriver cost as a set of Milvoki in a suitcase and still twice in the repair visited, dust). The striker with a “chuck” for the bit, t.е. 6 facet hole in the end. Pulls just about any screw, twisted without drilling and 1506 with an N 3 cross under the posydrive. Smooth clicking on the button gives low speed, no adjustments, with increasing torque, completes by itself with torque, when tightening to the stop, stops itself without overtightening. Screwed hundreds of screws, head breakage was a couple of times.Runs at full power for 30 minutes, battery has a charge indicator. Sucks the battery dry, no drop in power.

Forget about assembling furniture with this drum, will scroll through. For furniture, I took Makita electric screwdriver, folds from straight to L-shaped, took the blue “proff”, still alive, but the batteries at 7 volts saturate quickly, for half an hour of work, but the replaceable is also charged a half-hour maximum.

| hunter1957 | Posted 4-9-2011 22:30 pm The only thing you should consider is that lithium ion batteries are not suited for use and storage at subzero temperatures. |

| ehpebitor | posted 4-9-2011 22:45 |

How to Make a Screwdriver using DC 12V 300RPM Motor and Pipe PVC

quote: Originally posted by Mower_man:

7 volt batteries go down quickly, in half an hour of work, but the changeable is also charged in half an hour at most.

A little announcement:Skil will be releasing a new 2-speed corded drill/driver model. 6222 Energy, which will be available in September 2009. If it were not for the 6-meter power cord (220V), it would be very difficult to distinguish it from its battery counterpart. The model is planned for delivery to several dozen European countries, including Russia.

0,45 Amp. Speed (idle): stepless adjustable in two ranges, 0-300 and 0-850 rpm./min. Diameter of screws to be driven (max.): 6 mm. Quick-action chuck, 1.0-10mm diameter. Drilling diameter (max.): up to 8 mm in steel, 10 mm in wood. 19 steps torque adjustment drill mode. Reverse:. Weight: 1.2 kg.http://www.holodilnik.screwdrivers/skil/6222ab/

quote: Originally posted by ehpebitor:

If it were not for the 6 m long power cord (220 V), t

All corded “manual” into the furnace, the cords are really getting bogged down, I carry a lot of it in a waist bag or by the hook on the work belt. With larger units, of course, it’s a different story.

quote: Originally posted by Mower_man:

the cords are really getting in the way

quote: Originally posted by ehpebitor:

If the production, then to some extent I agree, but for the home once a year to unscrew, screw, drill an indispensable thing.

It depends on what kind of house and at what stage of finishing/construction, screws wrapped more than a dozen thousand. I’ve only got about 30 door panels, tomorrow I’ll put the permanent doors, 6 and 7 in a row.

| alexei2011june | Posted 4-9-2011 23:19 No big deal. No disadvantages of li-ion, no worse in temperature than nimh. I do not know what they put in the tool, the best banks Panasonic NCR-18650 LiNiCoO2. operating range.20 to 60 deg. I have one of these in a 18650 assembly, protected, with a record capacity of 11Wh. In severe frost.40 switch to lithium batteries. It is a pity the tool manufacturers do not use standard RC123 batteries (as in cameras) and their analogues li-ion 18650. about self-powered. There is a useful thing. 12/220 inverters. Clean sine is better for the tool. no overheating, soft start. Experience inverter 600W 2.5kg. No problem with a regular Soviet 420W drill. Small angle grinder 800W. works, but not enough power to cut. The cable problem is solvable. Where you can’t get a cable, I take a car battery and a converter box.I was more attracted to the Bosch wrench. Something in an old car can’t be turned off neatly without it. Too bad it can have problems with screws. |

| Mower_man | posted 4-9-2011 23:27 |

quote: Originally posted by alexei2011june:

I was more attracted to the Bosch wrench in the farm.

Bosch, blue pro (so called, and in fact disposable) and Makita blue of cordless hand tools for myself crossed out.

Bosch GDR is moderately priced, its size is suitable for different applications, no high volume of work is expected.What is the difference between an impact wrench and an impact screwdriver?

quote: Originally posted by alexei2011june:

impact screwdriver

Not zuzalit that does and how to torque (my version of the nut does not twist (there is a 1/2 inch version for sockets, then I’ll buy), so in American would be “torque”). I wrote.

How To Make Rechargeable Electric Screwdriver From DC Motor at Home

By the way, it crappy bits break at once, and the screws do not break crosses at the same time, it seems the electronics and the brake is well designed. Screws go in the wood by themselves, screwdriver has to “squeeze” noticeably. Milwaukee has a 5 year warranty in the US. I got it on the advice of the frame builders over there. They use them for the loaf and know a lot about these things.

Speed 0-2600 rpmChuckle 1/4 inner hexMax. 125 NmReverse is Battery voltage 12 V battery capacity 2 (NiCd) AhCase included in the kit is aComplete set: 2 batteries 2 Ah (NiCd), battery charger, a suitcase.

quote: Originally posted by alexei2011june:

Delicate assembly of furniture for the time being, I will sacrifice (I rarely do).

Is it possible to make a nutrunner from an electric screwdriver by yourself?

Of course you can, but with one important proviso: it is unlikely to get the same power as an industrially produced tool. But, very often too much power is not required. For example, if you have to To change the rubber on the car. Many people know how long the process of tightening the nuts on wheels is. Of course, it is possible to go to the experts, but it will cost money. If you have an electric screwdriver at hand, it can be quickly converted to a wrench: all you need is an adapter with a head of a certain size, which must fully coincide with the size of the cylinder wrench. It remains to fit this adapter into the chuck and to install the drive head. The nut drill from an electric screwdriver is completely ready.

Of course, it will not be a complete tool, because you still need to loosen the nut by hand, but the time required for all wheels is only one minute.

Higher tightening torque and at the same time less pressure on the tool by the operator.

Many people often ask what are the advantages and differences of an electric impact wrench (nutrunner) from a conventional one, and who needs this tool and why? And then it is important not to confuse the impact drill with an impact electric screwdriver, which is sometimes correct to call a nutrunner. An electric impact wrench or impact wrench has a tangential impact (in a plane perpendicular to the axis of rotation), t.е. the effort to tighten the screws or nuts is not applied continuously, but in a high-frequency series of small blows, as if you put a socket wrench on the nut and start tapping it with a hammer. The total applied force is calculated as the sum of the forces of these strokes per unit of time.

On this basis, we can immediately emphasize the advantages and disadvantages of this class of tools.

Disadvantages of impact wrenches

- Low drilling speed when switching to the impact mode.

- Applicability of cam chucks (only hexahedrons) with rare exceptions.

- Inapplicability of torque limiting clutch, so that the process of tightening has to be controlled by yourself all the time, which is not always convenient at high speed of the tool shaft.

- Increased noise in impact mode.

And in order to visualize the difference between an electric impact screwdriver (nutrunner) and a conventional one, we will summarize their main technical characteristics in one table:

How to make a wrench from an electric screwdriver

For various reasons in everyday life, it may be necessary to unscrew a couple dozen nuts. Buy for the sake of such a fleeting need wrench, pretty pricey, but also by hand do not want to twist, when in the possession of an old-fashioned electric screwdriver. It performs the main rotating function, now it needs to be reconstructed for nuts unscrewing. Here it is very simple.

To make a nutrunner from an electric screwdriver, you will need a special adapter for bits and nozzles themselves, the size for your nuts. The adapters cost about 300 and are sold in most construction stores. When all components are at hand, we clamp the adapter’s shank in the chuck, put on the needed accessory and use the home-made nutrunner from an electric screwdriver.

In the near future I have a lot of screws to turn, and I thought about choosing a drill driver, but then I stumbled upon such a hitherto unknown to me class of tools as “impact wrench.

Please tell me what the fundamental differences are between a normal electric screwdriver (or a drill/driver) and an impact screwdriver? What are their main uses?? For what tasks what is the best to use?

Because I do not really understand the principle of their work.

Bosch GSR 10.8 V-LI-2 Max. torque (tightening screws). 30 Nm RPM: 0. 400 / 1.100 min-1

Bosch GDR 10.8 V-LI Max. max. torque (tightening screws). 100 Nm RPM: 0. 1.800 min-1

Where does the torque come from when the rpm is higher?? But obviously the engine is the same, and it is logical to say, if RPM is lower, torque is higher (which requires reducing gear), but here it is vice versa.

And if I will need only to twist screws in wood and other materials, then what class of tool to prefer?

P.S. I’ve never seen an impact wrench in person but I see in the photo that it has a socket for bits, which are used to tighten self-tapping screws.

Impact wrenches (screwdrivers) use a tangential impact. Т.е. the head of a screw does not experience a constant torque, but a series of pulses (as if you put a socket wrench on the head of the screw and tighten it not in one movement, but by quickly and rapidly tapping with a hammer on the end of the wrench handle). The specified gigantic torque is the sum of forces of these very blows per unit time.

What size self-tapping screws do you have to torque?

In fact, I know at least one topic with almost the same name, and you can find it by searching

The screwing pattern is different. Before opred. effort twists at its high rpm, then begins to pound (the principle was well described by Wu. Eddy21 )/. Hence the disadvantages to a conventional electric screwdriver:

- Very limited drilling capabilities. Т.е. Drilling can only be done up to impact mode (in impact mode, the speed drops drastically). And before switching to impact. it’s usually with drill bits of fairly small diameters

- Actually, that’s why (and to keep the tool length shorter) they don’t use cam chucks. Т.е. even if drilling, only with drill bits with hexagonal tails

- The nature of screwing makes it very difficult to create a torque limiting clutch. Accordingly, such clutches are not made (or rather, there are 3 tools with a cosmic price of 20 tons).p), t.е. When to stop, you have to find out by yourself, which is hard to do in the first phase at high RPM (as with a high-speed drill, for example).

- If the task is difficult, t.е. All the time it is spinning with impact, it is slower than a normal screwdriver. By the way, the impact mode is also very loud

The advantages. well, obviously, the high torque. Ideal for nuts. quickly torque the bolt, then impact tighten. Or on the contrary, to unscrew. everything in the opposite order.

Is it possible to make a nutrunner from an electric screwdriver

Of course you can, but with one important proviso: you are unlikely to get the same power as an industrially produced tool. But, very often, too much power is not needed. For example, if you have to change the rubber on the car. Many people know how long the process of tightening the nuts from the wheels is. Of course there is an opportunity to call in specialists, but it will cost money. If you have at hand an electric screwdriver, it can be quickly converted into a nutrunner: it only requires an adapter with a head of a certain size, which must fully coincide with the size of the cylinder wrench. It remains to fix this adapter in the chuck and install the head. The impact wrench from an electric screwdriver is fully assembled.

Of course, it will not be a complete tool, since you still need to loosen the nuts by hand, but the time spent on all the wheels is only one minute.