Why a screwdriver can’t be unscrewed. let’s diagnose

Often, if you correctly identify the problem, the solution logically follows from the question posed. That is, it should provide just what is missing.

Let’s look at practical cases of extracting metalware with a torn-off head. Keep in mind that a torn off screw head can have sharp torn edges that are easy to hurt yourself: be careful!

Varieties of screws

To begin with, a screw is a cylindrical rod with a special head that has a screw groove. Screws are produced according to a number of normative documents, including GOST 1144-80, GOST 1145-80, etc. д.

At the same time, there are two main types of hardware:

Carving screws for metal and wood To indicate in this case, use the diameter and length of the screw (for example, a product with a diameter of 5 mm and a length of 3.5 cm will be referred to as 5×35 mm). In addition, hardware can be classified according to the shape of the slot and the features of the head itself:

Types of screw heads All of these varieties are made with a cross-shaped slot, with a straight (flat) and with a Torx slot (the latter is also known as “star”), as well as with an internal hexagon and other, less popular variants. There are also screws with heads of six- and octagonal shape (roofing), which are also made with different slits.

For your information! According to the type of thread screws are also divided into several varieties, which is determined primarily by the materials to be connected and the specific purpose (metal, wood, drywall or small appliances).

How you can prevent such a situation?

To avoid “slipping” edges, you must, first of all, treat the threaded joint with a penetrating liquid such as “WD-40”.

If the nut is old and you doubt whether it will “go” or not. treat it with “WD-40”, not too hammer on the nut to destroy existing corrosion inside the threaded joint.

If design and safety precautions allow, you can use the heat on the threaded joint. As the rust heats and cools, it cracks and makes it easier to undo the bolt or nut. And only after that you can try to unscrew.

Prevention is always better than cure! To avoid buying tools and heads for ripped edges, and not to puzzle over how to unscrew the nut on the wheel do this! Use a special lubricant (copper, graphite, or alternative) with each repair to avoid corrosion and oxidation of threaded joints.

Also always apply WD-40 liquid penetrating agent to all connections before attempting any work, or kerosene as a last resort. Allow time for the fluid to dissolve oxides and corrosion before disassembly.

That’s all, thank you for your attention! I am waiting for your Комментарии и мнения владельцев, please write which method is the most effective in your opinion. I would also appreciate it if you could share your secrets of dealing with “plucked” edges. If this article was helpful to you, share a link to it with your friends on social networks.

Screw types

To begin with, a screw is a cylindrical rod with a special head, to which the screw groove is applied. Screws are produced according to a number of normative documents, including GOST 1144-80, GOST 1145-80, etc. д.

At the same time, there are two main types of metalware. these are:

For designation in this case are used diameter and length of the screw (for example, a product with a diameter of 5 mm and a length of 3.5 cm will be designated as 5×35 mm). In addition, hardware can be classified according to the shape of the slot and the features of the head itself:

All of these varieties are made with a cross shaped slot, with a straight (flat) and a Torx slot (the latter is also known as a star), as well as with an internal hexagon and other, less popular variants. There are also screws with the head of the six-and octahedral shape (roofing), which are also made with different slots.

For your information! According to the type of thread screws are also divided into several varieties, which are conditioned, first of all, by the connected materials and the specific purpose (metal, wood, drywall or small household appliances).

How to undo a small screw

As a rule, before screwing in small screws some paint is put on their threads to increase their fastening strength. Therefore, if the head is not completely off, try heating it with a soldering iron with a thin tip. It is important not to overdo it, t.к. If there are plastic body parts near the screw, they can be melted to the screw.

After heating immediately try to unscrew the screw, it should give in easier. The main thing is not to overdo it so that the threads are not completely stripped.

If the thread is completely stripped, superglue will help you. Put a drop of glue in the torn hole in the head and push the screwdriver in. Press down on the screwdriver to make a better connection between the screw and the screwdriver. Do not wiggle the screwdriver while the glue is drying!After waiting a while (depending on how quickly the glue dries) carefully, without making any sudden movements, begin to undo the screw by slowly increasing the force.

You can also try a drop of solder instead of glue, but this is less effective.

If all of the above measures do not help, take a drill with a diameter equal to the screw head. Carefully drill out just the head (!) of the screw, being careful to touch the plastic of the part where the screw is screwed into as little as possible. After you disassemble the laptop (phone), part of the screw will remain sticking out of the bottom of the connection. It can be gently unscrewed with pliers.

For reassembly use a new screw and washer instead of the drilled screw (t.к. Diameter of a hole in plastic increased after drilling).

It often happens that the edges of fasteners get torn off during construction work. This usually happens at the most inopportune moment when you need to finish the job on time. How to unscrew a screw with a torn edge? Why do such troubles occur? What solutions can eliminate the problem? About all this we will talk further in the article.

Ways to remove a screw without a screwdriver

Let’s look at the most effective ways depending on the type of slot. Let’s start with the cross.

Option #1. Phillips head slot

To begin with, let’s notice that in some screws one groove on the head may be longer than the other. If so, you should work only with the longest recess, because it makes things easier. Let’s also add that the edges of these cavities can be abraded, and therefore you should work carefully, otherwise you can ruin the product.

One of the easiest methods is to use a coin. The method often works only with small screws. Insert the coin into the groove and then turn it counterclockwise.

You can try to remove a loose screw with your fingernail. The procedure is the same as in the previous method.

You can try to unscrew it with your fingernail

Take a knife, place it in the groove (long one if they are different lengths) and twist. Be careful, because if the screw is tightened too much and the knife you use is of poor quality, it (the knife) can be bent, not achieving the desired result.

Using a knife to remove the Phillips head screw

Use an old CD. Place its edge in the groove and turn it. The CD itself can be damaged by such manipulation, so make sure that it is no longer needed. This method is definitely not helpful if the screw is tightened too much.

You can saw a long groove on the head with a hacksaw, but this method is effective only when the hardware is not completely screwed on. е. if the head protrudes slightly above the surface. Hold the saw at right angles to the head, saw slowly and carefully. Then, when the groove is finished, the screw can be unscrewed with a flathead screwdriver or with improvised means (for example, a credit card).

A long groove is cut into the screw head

Take a flat screwdriver of appropriate size in the absence of a Phillips head screwdriver. Note that this will only work with large/mediumdiameter screws. Be careful not to tear off the slotted faces!

How to Unscrew a Screw Without a Screwdriver

You can try to undo a Phillips head screw with a flathead screwdriver

Another option is to use a toothbrush. Melt one end with a lighter, then immediately insert it into the recess on the head of the screw. After waiting a little to allow the melted plastic to solidify, turn the brush counterclockwise. Of course it doesn’t help if the screw is tightened too much.

Using a toothbrush to remove a screw

Option 2. Flat spline

As mentioned before there is only one cavity in the head of this screw. If you do not have a flat screwdriver, the product can be unscrewed by improvised means. Let’s see how it can be done.

Use a credit card. put it in the groove and try to turn it. Use only unnecessary card, because it may well get damaged during unscrewing.

Screw out the screw with a credit card

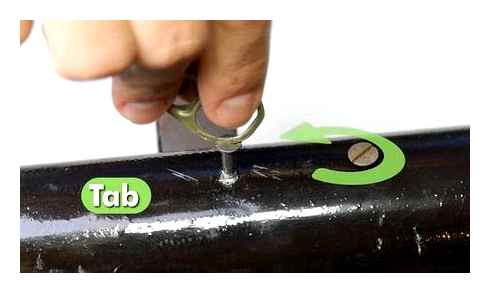

You can also use the eye of a tin can (soda pop, beer). Insert break off eyelet in groove on head of hardware, twist.

Use an ordinary coin. put it in the groove and try to unscrew it in the same way.

Screw out a flat head screw with a coin

If it is not too tight, you can try turning it with your fingernail. The method is not always effective due to obvious reasons.

Try to unscrew the screw with a knife by inserting the blade of the latter into the groove. In doing so there is a risk that you will bend the knife.

Insert the blade of the knife into the recess and twist counterclockwise

The last method is to use pliers. Suitable if the screw is not completely screwed in. It is advisable to use a pair of needle-nose pliers rather than a pair of ordinary pliers.

The flat head screw can be opened with the pliers

Option No3. Unscrewing the Torx screw

It is a screw with a notch in the form of a six-rayed star on the head. Such screws, by the way, can be guarded, with a pin in the center of the star. In any case, act carefully, because the facets of such a slot can easily be damaged.

Try to cope with a flathead screwdriver. Insert its sting into a pair of opposite rays, gently scroll counterclockwise. And if the screw is secure, the screwdriver is inserted between the rod and any of the rays, and twist in the opposite direction.

Use a small flat screwdriver

To unscrew secure Torx screws try to use a screwdriver for unprotected ones, but in this case you have to remove the head pin (this can be done e.g. with a punch and hammer).

Removing the center pin on the head of a protected Torx screw

Another possibility is to drill a hole in the tip of an ordinary screwdriver for the star head.

Drilling a hole in the screwdriver for a regular Torx screw

Finally, you can use the same toothbrush, melting one end with a lighter (proceed in the same way as described in one of the previous methods).

Option #4. Remove the small screw

Note right away that small screws are especially difficult to remove without the proper tools at hand. Typically, these screws are found in a variety of electronic devices. Ideally, for unscrewing should be used tools designed for repairing glasses (with their search there will be no difficulties, and they do not cost very much). If you do not have such equipment, resort to one of the following methods.

Table no 1. How to unscrew a small screw.

| Step 1 | Use a knife. put the sharp end into the groove and try to twist it. It is advisable to insert the tip at a slight angle to increase the contact area. |

| Step 2 | Use a nail file. Proceed in the same way as the previous method. |

| Step 3 | If you have a pair of scissors, pointed at the ends, you can use them. But note right away that such scissors are not the best option for unscrewing screws. |

| Step 4 | Use tweezers. Insert the sharp end into the groove and try to twist it. |

As a side note! Another good option is to use a common nail, the square point of which is ideal for the Phillips spline. For example for screws of a cell phone an 80 mm nail will do.

How to unscrew a small screw

- – small screwdriver;

- – superglue;

- – Use a soldering iron with a narrow tip;

- – a drill and a small drill bit.

As a rule, the threads of the smallest screws before screwing them in are painted to increase the strength of the fastener. So if the head is not completely off, try heating it with a soldering iron with a thin tip. It is important not to overdo it, t.к. If there are plastic body parts near the screw. you can melt them into the screw.

After heating immediately try to undo the screw that should give way easier. The main thing here is not to overdo it not to tear off the threads finally.

If the threads are completely stripped, superglue can help. Put a little glue in the torn hole in the head and put a screwdriver in it. Press down on the screwdriver for a better connection between the screw and the screwdriver. Do not wiggle the screwdriver while the glue is drying! Having waited for some time (depending on how quickly the glue dries), gently, without sudden movements, begin to unscrew the screw, gradually increasing the force.

You can also try a drop of solder instead of glue, but it is less effective.

HOW TO REMOVE A DRILLED Screw (Secret Information)

If all of the above measures did not help, take a drill with a diameter equal to the diameter of the screw head. Carefully drill out only the head (!) of the screw, trying as little as possible to touch the plastic of the part in which the screw is screwed. After you disassemble the notebook (phone), a part of the screw will remain sticking out of the lower part of the connection. It can be gently unscrewed with the pliers.

To reassemble, use a new screw and washer instead of the drilled out screw (i.e.к. The diameter of the hole in the plastic increased after drilling).

It is quite common for fasteners to have their faces torn off during construction work. This usually happens at the most inopportune moment when you need to finish the job in time. How to unscrew a screw with a torn edge? Why do these troubles occur? What solutions can fix the problem? We will talk about all of this later in this article.

Method #2. Sawing

You can try to unscrew any type of screw with a flathead screwdriver. Using an angle grinder or metal saw make a straight slot in the screw head. But remember the slot must be at least ½ the height of the head, otherwise you risk breaking it. This method can be used in combination with others.

Variant No1. The Phillips head slot

For starters, note that some screws may have one recess on the head longer than the other. If so, you should only work with a deeper hole of a longer length to make it easier for you. Let’s also add that the edges of these cavities can be abraded, so you should work carefully, otherwise you can ruin the workpiece.

One of the easiest ways is to use a coin. The method often works only with small screws. Insert the coin into the groove and then turn it counterclockwise.

You can try to use your fingernail to remove a screw that is too loose. The procedure is the same as in the previous procedure.

You can try to remove the screw with your fingernail

Take the knife, place it in the recess (long if they are different lengths) and scroll. Be careful because if the screw is tightened too much and the knife you use is of poor quality, it (the knife) can be bent without achieving the desired result.

READ How to cut a skirting board for PVC panels

Using the knife to drive out a Phillips head screw

Use an old CD. Place its edge in the groove and twist it. The CD itself might be damaged by such manipulation, so make sure in advance that it is no longer needed. This is definitely not a good method if the screw is screwed too tight.

You can saw a long groove in the head with a metal saw, but this method is only effective with partially twisted hardware, t. е. if the head protrudes slightly over the surface. Hold the saw at a right angle to the head, saw slowly and carefully. Then, when the groove is ready, the screw can be unscrewed with a flat-blade screwdriver or with improvised means (e.g. credit card).

Make a long groove in the screw head

Take a flathead screwdriver of appropriate size as opposed to a Phillips head screwdriver. Typically, this will only work on large/medium-diameter screws. Be careful not to tear the slot edges!

You can try to undo a Phillips head screw with a flathead screwdriver

Another option is to use a toothbrush. Melt one end with a lighter and then immediately insert it into the cavity on the screw head. After waiting a bit for the melted plastic to solidify, turn the brush counterclockwise. Of course, it will not help if the screw is screwed too hard.

Unscrewing a screw with a toothbrush

Option 2. Flat spline

As mentioned above, there is only one recess on the head of such a screw. If you do not have a flat-blade screwdriver, you can use improvised means to unscrew the product. Let’s see how to do this.

Use a credit card. put it in the groove and try to turn it. Use only the card you don’t need, because it may well get damaged during the unscrewing process.

Screw out the screw with a credit card

You can also take the “ear” from a tin can (soda can, beer can). Insert break-off “ear” in groove on head of hardware, twist.

Use an ordinary coin. put it in the groove and try to twist it the same way.

A flat head screw can be unscrewed with a coin

If the screw is not tightened too much, you can try to unscrew it with your fingernail. This method is not always effective for obvious reasons.

Try to unscrew the screw with a knife by inserting the blade of the latter into the groove. There is a risk of bending the blade.

Insert the blade of a knife into the cavity and turn it counterclockwise

The last method is to use pliers. It is okay if the screw is not completely screwed in. It is preferable to use a needle-nose pliers for this, instead of the usual ones.

A screw with a flat grill can be opened with a pair of pliers

Ways to unscrew the screw without a screwdriver

Let’s consider the most effective ways depending on the specific type of slot. Let’s start with the cross head.

Option #1. The Phillips head slot

To begin with, let’s see that for some screws one underbore on the head can be longer than the other. If so, only work with a longer recess to make it easier. Let’s also add that the edges of these pits can be chipped, and therefore you should work carefully, otherwise you can ruin the product.

One of the easiest way is to use a coin. The method often works only with small screws. Insert the coin in the groove and then turn it counterclockwise.

If the screw is loose, you can try to unscrew it with your fingernail. Same steps as the previous method.

You can try to undo the screw with your fingernail

Take the knife and put it in the recess (long one if they are different lengths) and twist it. Be careful because if it is tightened too much and the knife you use is of poor quality, it (the knife) can be bent and you will not obtain the desired result.

Using a knife to drive out a Phillips head screw

Use an old CD-ROM. Put its edge in the groove and turn it. The CD itself can be damaged by such manipulations and you should make sure beforehand that you do not need it anymore. This will not help if the screw is too screwed in.

You can saw a long groove on the head with a metal saw, but this method is effective only when the screw is not completely tightened. е. If the head protrudes slightly from the surface. Hold the saw at right angles to the head, saw slowly and carefully. Then, when the groove is ready, the screw can be unscrewed with a flathead screwdriver or with improvised means (e.g. credit card).

A long groove is cut into the screw head

Take a flathead screwdriver of appropriate size in the absence of a Phillips head. Characteristically, this can only work with large/medium-diameter screws. Be careful not to tear the facets of the slot!

You can try a Phillips head screwdriver to open it with a flathead screwdriver

Another option is to use a toothbrush. Melt one end with a lighter and immediately insert it into the cavity in the screw head. After waiting a little to let the melted plastic harden, turn the brush counterclockwise. Of course it does not help if the screw is tightened too much.

Remove the screw with a toothbrush

Variant No2. Flat spline

As mentioned before there is only one cavity in the head of this screw. If you don’t have a flat screwdriver, you can use improvised means to unscrew the product. Let’s see how it can be done.

Use a credit card. put it in the groove and try to twist it. Use only unnecessary card as it can get damaged while unscrewing.

Screw out the screw with a credit card

You can also use the ear of a tin can (soda pop, beer). Insert the broken off ear into the groove on the head of the item and twist.

Use a regular coin. put it in the groove and try to twist it the same way.

Screw out a flat head screw with a coin

If the screw is not too tight, you can try turning it out with your fingernail. The method is not always effective for obvious reasons.

Try to unscrew the screw with the knife, inserting the blade of the latter in the groove. There will be a risk that you will bend the knife.

Insert the blade of the knife into the cavity and twist counterclockwise

The last method is using pliers. Suitable if the screw is not screwed in completely. It is desirable to use needle-nose pliers for this, but not usual ones.

The flat head screw can be opened with a pair of pliers

Variant No3. Remove the Torx screw

We are talking about screws with a notch in the form of a six-pointed star on the head. Such screws, by the way, can be guarded. with a pin in the center of the star. In any case, proceed with caution, because the facets of such a slot can easily be damaged.

Try to cope with a flat screwdriver. Insert its stinger in a pair of opposite rays, and twist it carefully counterclockwise. And if the screw is protected, insert the screwdriver between the rod and any of the beams and twist in the opposite direction.

A small flathead screwdriver is used

To unscrew the Torx-protected screw, try using a screwdriver for the unprotected one, but then the stem on the head has to be removed (this can be done e.g. with a punch and hammer).

Removing the central pin on the head of a protected Torx screw

Another possible option is to drill a hole in the tip of an ordinary screwdriver for the star shank.

Drilling a hole in the screwdriver for a regular Torx screw

Finally you can use the same toothbrush and melt one end with a lighter (follow the same procedure as described in the previous method).

Option #4. Remove the small screw

It should be said straight away that small screws are especially difficult to remove if you do not have the right tools at hand. As a rule, such screws are found in various electronic devices. Ideally, tools designed for spectacle repair should be used for unscrewing (they are not difficult to find and do not cost very much). If you don’t have one, try one of the following methods.

Table No1. How to unscrew a small screw.

| Step 1 | Use a knife. place the sharp end into the slot and try to scroll. Insert the tip at a slight angle to increase the contact area. |

| Step 2 | Use a nail file. Proceed in the same way as the previous method. |

| Step 3 | If you have a pair of scissors, pointed at the ends, you can use them. But note right away that such scissors are not the best option for unscrewing screws. |

| Step 4 | Use tweezers. Insert its sharp end into the groove and try to turn it. |

For your notes! Another good suggestion is to use a common nail, the square point of which is ideal for the Phillips head slot. For example, an 80-mm nail is ideal for cell phone screws.

How to unscrew the screw in the laptop that can not be unscrewed You can drill out the screw with a drill or electric screwdriver. I have an electric screwdriver, but I decided to try a third option. The third option is to make a notch along the head of the screw and unscrew the screw with a flathead screwdriver. I did so.

Another option is to use a toothbrush. Melt one end with a lighter, and then immediately insert it into the cavity on the head of the screw. After waiting a bit for the melted plastic to solidify, turn the brush counterclockwise.