Preventive measures

A cardboard washer will allow you to unscrew the nut after any emergency situations

This method is simple and convenient, but still it is more convenient not to break anything, but simply unscrew it. In addition, there are times when the discs are simply clamped hard. It takes a long time to break a stripping abrasive with a thickness of 5 mm, and then grind it under the nut, because there is a method that allows you to avoid the situation when it will be impossible to unscrew the nut with a wrench.

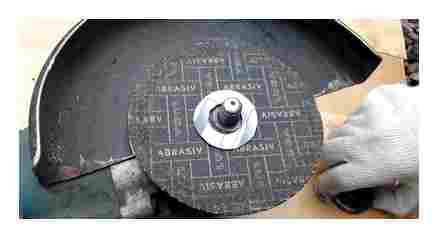

To do this, you only need to make a spacer washer from cardboard.

Cheap and angry

The tool is ready to work.

Step

Break not build

We break the remains of the cutting disc with pliers. Removing as much as possible.

We remove the cutting disc in a non-standard way

angle grinder is the most dangerous power tool

Discs on an angle grinder are fixed with a nut, which is screwed in the same direction in which the spindle of the power tool rotates. And when the rotation stops abruptly, self-tightening of the fixing nut occurs.

In order to unscrew it later, you need an effort that significantly exceeds that that arose with a wedge, and it is simply impossible to do this with a “native” or gas wrench.

There is not enough strength to unscrew the nut, and the key will jump off

You need to do otherwise, namely, remove the cutting disc from under the nut, and then nothing will interfere with the unscrewing of the last.

Step

Unscrew and remove unnecessary remains of the consumable

The obstacle has been removed, you can now unscrew the nut and remove what is left of the cut-off wheel. The nut is easily unscrewed, in most cases this can be done by hand, without the use of tools.

Step

Remove all abrasive

For the next step, you will need a metal plate that is less thick than the disc. We turn on the angle grinder, and with this plate we grind off the remnants of the abrasive, which is located under the fixing nut. Do not forget about safety precautions.

How to unscrew the nut on an angle grinder without a key: a simple life hack

An angle grinder or angle grinder is one of the most traumatic power tools. If used improperly, the cutting disc can jam, and even if everything is okay, after this incident it is unlikely that it will be possible to unscrew the fixing nut after this incident by standard methods – neither a “native” key, nor a gas key, nor even a chisel with a hammer will help. How to unscrew the nut on the angle grinder?

Clamped DISK Angle Grinder UNLOCK the tightened nut EASILY. Cut Angle Grinder, Angle Grinder. Work with Angle Grinder

How to unscrew the nut on an angle grinder without a key: a simple life hack

Feedback from our readers is very important for us. Leave your rating in the comments with the reasoning for your choice. Your opinion will be useful to other users.

Tapping the nut

This method is similar to the previous one, only you can use a suitable metal rod or chisel. After fixing the spindle head, tap on the edges of the clamping holes in the direction of the wheel movement. Slightly moving the lock from a dead center, you can unscrew it by hand. However, the method is not the most harmless for the tool – the mounting holes for a standard key are damaged.

The first way

Then you need to take a metal plate, the thickness of which is less than that of the disc. With the help of this plate, its remnants will be grinded. To do this, turn on the angle grinder, and clamp the metal piece securely with pliers. After completing these steps, the nut can be unscrewed even by hand..

Measures to prevent jamming

Taking care in advance about the safe operation of the angle grinder, you will save yourself the need to take measures to eliminate an abnormal situation. Such events include:

how to loosen angle grinder disc nut

- Placement of cardboard or plastic washers between disc, flange and spindle head. They do not allow the tool to jam, but even in the case of a corkscrew, they can be removed / melted and the element can be easily unscrewed..

- The abrasive wheel must be installed correctly. To do this, place the front side of the circle on the support flange (picture to the gearbox). It must not come into contact with the clamping nut. In this case, the standard metal ring in the center will act as a washer that protects against jamming..

- Weld a regular nut on the clamping flange, which allows you to press the installed disc using a conventional wrench.

- Check the tightening torque. No excessive force is required to install the cutting element. Otherwise, it will jam under intense loads..

What causes the problem?

It is difficult to face this problem when spinning at idle speed. Especially when working with light wheels and tools with soft start function. However, after an increase in revolutions and contact with the cut surface, the following occurs:

That’s it, the process of tightening the fixing flange is completed – an abnormal situation is obvious. Its occurrence is influenced by the following factors:

- Large circle size.

- High tool power.

- Rotor massiveness.

- A sharp increase in the depth of cut, i.e. increase in resistance.

In this case, it can be very difficult to remove the disc from the angle grinder. Additional measures need to be taken.

Step

The obstacle has been removed, you can now unscrew the nut and remove what is left of the cut-off wheel. The nut is easily unscrewed, in most cases it can be done by hand, without the use of tools.

Safety regulations

When working with an angle grinder, it is important to remember that this tool has an increased risk of injury. Accordingly, it is impossible to lose vigilance in any case, even when disconnected from the mains. When using auxiliary tools and materials to replace the disc, be careful with them as well. Locksmith tools can also cause perceptible injury..

Replacing a disk in normal mode

Regularly working with an angle grinder, you need to constantly change the wheels, which are a consumable. If the tool is already inconvenient to work, then the worn out abrasive wheel should be replaced..

Important! Be sure to check the disconnection from the mains to avoid personal injury..

With a gas wrench

The use of this tool is justified by an increase in the applied torque due to the increased shoulder. It will be much easier with a gas wrench to unscrew a jammed connection. However, when eliminating biting, it is important to remember that if you apply excessive force, there is a risk of damage to the spindle lock or jam nut..

How to unscrew a hexagon without a key?

This problem is often faced by motorists who decide to repair their car on their own. An internal hexagon almost always has a drain plug on the gearbox and often a plug in the engine sump.

The home craftsman may encounter hexagons when repairing a bathtub faucet or ball valve – ordinary fasteners simply do not fit there..

Moreover, in all these cases, the size of the hex is pretty decent. What to do? A bolt with a regular hex head will help.

The bolt head is inserted into the hex slot and unscrewed by the rod with a gas wrench. You can also screw 3-4 nuts onto the thread of the bolt, wedge them well for each other and unscrew with an ordinary spanner wrench.

When unscrewing, it is necessary to twist the nut closest to the head, and when tightening, on the contrary, behind the far one. If the hexagon has a non-standard size, then the head of the key bolt can be sharpened with a file or on a sharpening machine.

Remove a grinder disc without the wrench very dangerous

Internal Hexagon Advantages

Allen screws and bolts have a number of advantages over conventional fasteners. Firstly, there is no need to leave space for the fastening tool around the head with such a slot. In this case, you can completely “sink” the screw into the part, which is very convenient for all kinds of drain plugs.

Second, the torque transmitted to the workpiece can be up to ten times that of a Phillips head fastener. Therefore, the Inbus spline is often used in components that work under heavy loads (metalworking machines, road equipment). It also allows the use of small screw heads with large shank diameters, allowing the same size tool to be used to service different assemblies. Cyclists know this well – one Allen key is enough to service the bike on the road..

Thirdly, when using a suitable high-quality wrench, it is quite difficult to tear off the notches of the internal hexagon. The notches hardly wear out, the fasteners can be reused, which is important for fastening various types of inspection hatches that require frequent opening and closing.

Fourth, the socket wrench is simple and cheap compared to the open-end, box and socket wrenches of the external hex..

And finally, screws with an internal hexagon head are much safer, since they do not have sharp outer edges, and they look more aesthetically pleasing..

How to unscrew an angle grinder without a key

Andrew Taylor (taylor.a), flickr.com CC BY

Fasteners in modern technology are very diverse. These include common hex bolts and nuts, flat and Phillips screws, Torx sprockets and many others. Parts with an internal hexagon stand out here. It is rather difficult to unscrew them without a suitable tool..

For the first time, the internal hexagonal slot was patented in 1936 by the German company Bauer Schaurte. In foreign technical literature, such screws are usually referred to under the Inbus trademark. This is an abbreviation of the German phrase Innensechskantschraube Bauer und Schaurte. socket head screw from Bauer Schaurte.

What to do if the hexagon is ripped off?

It happens that attempts to unscrew a screw with an internal hexagon by means of improvised means or a wrench of a slightly inappropriate size lead to a breakdown of the edges. In this case, there is also a way out..

If the hexagon is small, then you can drive a TORX sprocket of a suitable size into it and unscrew it using it. If the head is available, then it is worth trying to unscrew the screw with pliers, a gas wrench or manual vise.

If space is available, a hammer and chisel almost always help. The chisel should not be very sharp, and blows should be applied tangentially in the direction of unscrewing. By the way, check, maybe the thread on the screw is left?

For steel bolts and screws with an internal hexagon, a nut, a piece of reinforcement or something similar can be welded to the head, for which the bolt can be unscrewed.

And remember that one person screwed it down – the other can always unscrew it.

And here’s another way to unscrew problem screws using an engraver with a cut-off wheel. This can be done on a large scale using a hacksaw or an angle grinder..