How to sharpen with a mechanical sharpener?

Holding the knife firmly, place it in the special groove (first zone) and swipe it toward you over the entire length of the blade. The procedure should be repeated several times. the specific number of repetitions depends on the degree of sharpening.

The body of the sharpener has an internal cavity in the form of a cone, in which the tip of the pencil is placed for sharpening. It can be made of plastic or metal, most often aluminum The tip of the blade cuts the thin shavings of the wooden frame, sharpening it to a taper. As the wood is removed, the pencil lead is torn off.

The best chainsaw sharpeners for everyday workshop use Review 2021

For everyday or occasional cutting, chainsaw sharpeners are an essential tool to keep chainsaw blades ready and sharp. knife.

In addition to the traditional use of files for sharpening chain teeth, there are other types of machines that perform this process. They can be in the form of electric sharpeners with different mounting options (e.g., on a bench, wall or vise). Some types of sharpeners may also have rod-mounted guides, like the Granberg G-106B rod-mounted sharpener. In addition to these heavy-duty sharpeners, there are also handy, lightweight, portable chainsaw sharpeners. The EYBS portable chainsaw sharpener excels in this category.

Because of their differences, it is important to remember their basic characteristics, with the maximum speed being the main aspect to consider. Keep in mind that higher speeds mean faster sharpness and can obviously affect your hours of operation.

In addition, for any other types, great emphasis is placed on pitch compatibility. Although most modern sharpeners offer five-step compatibility (0.250 in.325 inch, full profile 0.375 inch, low profile 0.375″ and 0.404 in.), there are also others, such as the Katzco chainsaw sharpening file set, which offer a limited number of compatible sections. Keep in mind that brand, features, ease of use and ergonomics also require consideration before deciding to buy.

That being said, the wide variety of chainsaw sharpeners on the market has actually made it difficult for interested buyers to determine the best among the rest. So we, along with our team of experts and professionals, have tested and compared chainsaw sharpeners from leading manufacturers such as Oregon, Buffalo Tools, Granberg, Katzco and EYBS. With the important information we have gathered, we aim to highlight their best qualities so that you can easily determine what to get. Also, take the time to weigh their value based on our facts.

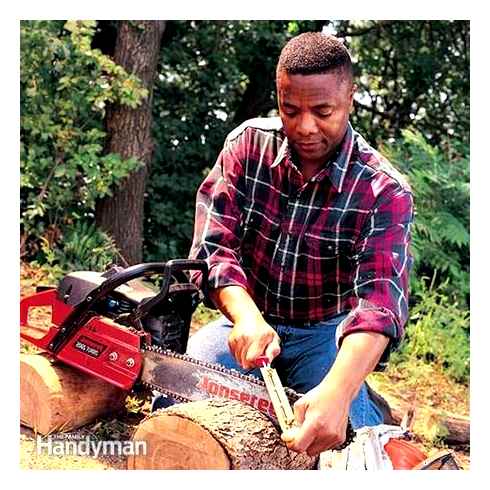

Technology for sharpening the chain with a file

It is necessary to sharpen the chain without removing it from the saw, which, in its turn, is installed on an even surface. The tension should be as high as possible. The saw must be put on the brake. To do this turn the locking lever. The chain is inspected beforehand for defects, which can be expressed in breaks, cracks, chips. When sharpening the chain of a chainsaw, take into account the main technological peculiarities:

- the teeth are sharpened from inside to outside;

- The degree of sharpening is determined by special marks made by the manufacturer;

- the tooth to be sharpened is centered.

Attention! Be sure to wear protective gloves on your hands to avoid cutting yourself on the sharp chain teeth.

To simplify the process use special devices for sharpening chainsaw chains in the form of holders, with the help of which determine the depth of the limiter and the sharpening angle. clamps the right machine to the rail and angles the guide rails so that the degree of sharpening is specified. The tooth to be sharpened should also be secured with a stop, over which a file is placed.

Regardless of what additional tooling you use, sharpen the edges first, then level the depth stop. Care must be taken to form the height difference between the limiter plane and the edge.

Step by step instruction for sharpening saw chain with a file

- securing the saw;

- Mounting the handpiece with the scale readings in mind;

- Sharpening angle of chainsaw chain is specified by raising it by 1/5 over the holder point;

- minimum sharpening size is determined by the bluntest tooth;

- Start with a circular file, working backward smoothly. 2 to 3 times for each tooth.

Warning! The file should be turned over from time to time to avoid uneven grinding.

The teeth must be sharpened on both sides, turning the chain over as the operation is completed. It is recommended that a template be set for the limiter, placing the index part between the teeth. The protrusion over the template is ground with a flat file.

Negative consequences of working with a faulty headset

The need to sharpen the cutting edges of the saw chain becomes evident if the main signs of ineffective operation of the tool are present. This:

- Increased vibration and difficulty in penetrating the blade with each new cut;

- Significant reduction in sawing performance;

- the smell of overheated wood;

- fine sawdust structure.

Even with an effective emergency brake and chain breaker, there is still a risk of injury if the chain saw is blunt. Strenuous use of the chainsaw’s engine and kinematics has a negative effect on the service life of the tool as a whole.

Preparing your tool

Considering how to use a chainsaw correctly. Start by reading the manufacturer’s instructions in detail. Here are all the details for operating the machine.

Before you start, you should check the tool. Start with the chain tension. For this purpose it is pulled by the upper link. Ideally, the shank should protrude a few millimeters out of the slot. In doing so, the lower section of the chain should not sag. Otherwise the chain must be tensioned. It should then pull easily. It cannot be pulled too tightly.

The handgrip of the parking brake must not make contact with the main handle. Otherwise the clutch will shift when the saw is in operation. A basic first check can greatly reduce the chance of a machine breakdown.

Assembling a chain saw chain sharpening machine with your own hands. instructions and drawings

Can you sharpen a chainsaw chain yourself?? Despite the complex configuration of the cutting part, this process is feasible at home. Sharpening can be accomplished with a set of files, which will be long and not always produce the desired result. In the constant use of a chainsaw, it is best to make a machine that provides the best quality and the required speed to perform this procedure.

Sharpening technology

The main cutting element of the chain is a specially shaped tooth. It removes wood chips in the same way as a planer. But unlike it, the tooth has two sharpened edges that are angled in relation to each other. One of the teeth cuts horizontally and the second one vertically. In doing so, the teeth are alternately attached to the right and left sides of the chain.

Before proceeding to the selection of the optimal scheme of a chain saw chain sharpening machine, it is necessary to get acquainted with the recommendations and rules. The main one is to observe the angles of contact between the sharpening tool and the cutting part of the link.

- The front angle formed by the end blade and the sliding surface of the link should be 60 to 85°.

- Rear angle of top blade. 50 to 60°.

- Angle of sharpening of upper cutting part. from 25 to 35°.

The last parameter is decisive for the choice of the machine tool making scheme. These dimensions impose strict requirements on the design

Also pay attention to the intensity of the sharpening tool’s impact on the cutting edge. It is unacceptable to change the configuration of the blades. increasing the angle of cut, reducing its plane

The exception is the reduced height of the kerf limiter. This is done only when working with “clean” wood, in which there is no metal debris.

Manual way

If you have a light chain saw you can sharpen it manually. You will need a set of files and a special template. It is best to buy a set that includes these items.

To form a quality cutting edge it is necessary to fix the chain. That’s why it’s recommended to clamp the guide bar in a vice. In this way it is possible to ensure the precise position of each link. After installing the template, the tooth blade and the end blade are sharpened with the files.

However, this technique has a number of special features that must be taken into account.

- Sets are designed for chains with a specific configuration. pitch 3/8″ and a link thickness of 1.3 mm.

- Low sharpening speed.

- If the cutting attachment is significantly damaged, it’s almost impossible to repair it manually.

- Low cost of the kit. starting at 600

That is why semi-automatic machines are preferred for intensive work. They have a great performance, and if the sharpening technology is followed, the quality result will always be superior to the manual method.

The electric lathe

Is it reasonable to make a machine for sharpening chains by yourself?? Already at the stage of designing and selecting accessories you may encounter a problem. making a working table. It is intended for fixing the chain and adjusting the link in relation to the cutting edge of the sharpening disc.

Structurally, it consists of a platform, on which the working table and the electric motor with the abrasive element is located. With the help of a screw system the position of the link is adjusted. A graduated scale is mounted on top of the table for greater accuracy.

Т.е. To manufacture such a device with your own hands you need to make the base, which is a time-consuming and complicated process. To do this you need to use a lathe to manufacture all the components, calculating their exact dimensions beforehand. An alternative is to buy a prefabricated base. However, its cost is not much different from the price of a factory chain saw chain sharpening machine.

| Model Name | Cost, |

| Avangard MZC-100/450 | 1700 |

| Einhell BG-CS 85 E | 1990 |

| Brigadier Professional GM4P | 2270 |

| TAIGA MZ-600 | 4320 |

How to use the best and easiest Stihl 2 in 1 chainsaw sharpener

If the frame is available, you will need to choose the correct accessories for it:

- The electric motor must be designed for 220 V (50 Hz).

- Optimal power 250 to 600 W.

- Speed of rotation. 3000-6000 rpm.

- Abrasive wheel thickness is up to 3,2 mm.

After installing the electric motor, corresponding to these parameters, you can start sharpening directly. It is best to adjust the position of the abrasive for each link, as often the degree of deformation of the cutting part is different. In addition, accurate adjustment will increase the service life of the chain.

How to sharpen using the machine tool method?

In case of heavy wear of the saw band the only reasonable solution would be resharpening of the teeth located on it. The easiest way to do this is to use an electric machine, which provides a uniform supply of force while processing the metal. Do not use a simple tool, but one with a sharpening disk that can reciprocate. In this case, the chain is removed from the saw, mounted in a special rotating holder on the machine.

Machine tool method is considered the safest and most effective. Such sharpening is fast, not time-consuming. In addition, a fine adjustment of parameters ensures that the expected results are achieved. Depth and plunging angle of disc can be adjusted.

The main recommendation when sharpening chain teeth for gasoline and electric saws is to control the heating of the metal. If it is overhardened, the material will become brittle. In this case, during operation, the cutting edge will crumble and break quickly. Standard contact time between the rotating disc and the chain tooth during sharpening should be no longer than 2 seconds. If you don’t get the result in one pass, repeat the sharpening after a break in which the metal has had time to cool down.

An alternative to an automatic sharpening machine can be its manual counterpart. In this case, the rotation of the circular file is done mechanically. All angles can be carefully measured, and the teeth can be straightened. Sharpening is done in 2-3 movements, avoiding overheating of the metal. This is best for first-time users who would like to get a good result.

tool retention

In order to start the chainsaw correctly, it is important to hold it the right way when starting. Here the position of the saw is very important. The hold-down during start-up can be done in two ways.

In the first case set the saw on a flat surface, keep the left hand straight and hold the tool by the upper handle, put the right foot on the protection of the second hand, and the tool itself pressed to the ground. In this position, it will be convenient to start the tool, because your right hand is free and the tool is fixed quite securely.

Regardless of the position in which you plan to start the saw, be sure to engage the saw price brake.

In the second option, you need to take a standing position and hold the upper handle of the tool with your left hand, while the back handle is squeezed between your legs. This position makes it easy to start your power tool and secures it safely, and thus protects you against accidents.

How to Sharpen Chainsaw Chain. Ozito Tool Tips [PXCCSSS-018]

How to work with a chainsaw

wikiHow is based on the wiki principle, which means that many of our articles are written by more than one author. There were 23 people(s) who worked on this article, including anonymously, to edit and improve it.

Number of views of this article: 5200.

Working with a chainsaw can be dangerous and stressful. Never start without familiarizing yourself with specific safety requirements and operating procedures.

- For the beginner, the type of saw with a set of teeth will be more practical than a cutting blade, so this article will discuss the chain saw. The length of the saw must be at least one-third the diameter of the tree.

- Usually, the horsepower and displacement of the motor matches the length of the chain and is set at the factory. A well-tuned motor and sharp blade will allow you to cut quickly, easily and accurately, resulting in a safer.

Look at the area you plan to work in before filling up the saw. It is better to do this indoors for greater safety. This means looking out for overhead power lines and rough terrain, nearby cars and buildings, and a safe place to protect the saw operator from falling trees and branches.

- Cutting is the process of felling trees.

- Limbing is the removal of the ends from a tree before or after it is cut down.

- Pruning (when using a chain saw). Refers to trimming knots and branches (if you do not use a saw, it may be similar to shaping a bush, will not be discussed here).

- Bucking. cutting a log into pieces of the right length, such as logs for a fireplace.

Look at your chainsaw. If you are preparing to start a saw that you have already selected, it must be suitable for your project.

Fill the tank with the right fuel/blend, which is usually made from one gallon of gasoline and 4-6 ounces (110-170 grams.) Two-stroke motor oil. Because chainsaws have a two-stroke engine, they do not support other lubricants and fuel will burn quickly if the correct mixture is not used.

Check safety. Make sure the chain is in place, has proper tension, and does not move when the chain brake is applied. Make sure the air filter is properly installed and that the pressure nuts on the face plate are tight.

It should be noted that there are two filter caps on your saw, next to the gas handle. The caps may be labeled, usually the larger cap will be for fuel and the smaller one for oil. Fill the grease reservoir, check that both caps are tight and place the saw on a flat surface. This is especially important for cranking a very large saw, because the blade will begin to rotate as soon as the saw starts and gains traction.

Many new models have an ignition button on the carburetor, if yours has one, press it 3 or 4 times. If your saw is equipped with a throttle, put it in the closed position. Engage the chain brake. Turn the saw on, this may be a toggle switch, roller, or switch depending on the model. Pull the starter rope sharply to start the engine. If the engine has made an attempt but does not start, release the throttle and pull again. This usually takes 4 or 5 tries with a tuned saw.

When the saw is running at idle speed, the blade should not move or spin. Let’s think you’ve selected a suitable piece of wood or branch with a suitable place to cut. Put the cutter in the position of the cut you want to make, turn off the chain brake, squeeze the throttle all the way open, and lean the cutter against the wood. Do not speed up the cutter, it should only cut under its own weight or moderate pressure. Keep the saw on full throttle while you cut, loosen the throttle only when you are about to complete the cut on the opposite side of the log.