How to use a manual tile cutter

How to work correctly during construction and finishing work with ceramic tiles?

Need to:

- Be neat;

- Think carefully about every step;

- Use special cutting attachments.

You need to cut the tiles with a special tile cutter, a feature of which is the presence of a sharp cutter. As a rule, it is set with a diamond, as it is a more durable and wear-resistant material. In order to carry out the cut, it is necessary to lay the blade on the base of the device, so that when cutting the blade it does not stagger, and the cut is not made according to a previously drawn mower line.

over, the device is perfect for home use. It is worth noting that handheld equipment has a number of advantages for electric tools. It is small and much easier to handle. In addition, it is considered the safest.

Safety rules when working with the tool

Each tool has its own safety, which must be observed in order to exclude unpleasant consequences, such as deformation of the phalanges of the fingers and the like.

Safety regulations:

- Before direct work, it is imperative to conduct a thorough inspection of the tool for malfunctions, since this can be a prerequisite for both breakdown and accident.

- Before cutting the tiles, you need to make a couple of idle movements to make sure they are smooth and there is no jolting.

- Pay attention to the tubular guides, which should be as clean as possible. It is especially important that they are free of dirt. If there are contaminants, then it is necessary to eliminate them, as well as traces of the solution, which is being processed. To make the operation of the device as efficient as possible, it is worth doing the processing of parts with machine oil.

- It is necessary to inspect the cutting disc itself, since it should be in perfect condition, and not bent, and rotation without fluctuations and along one axis. There should be no difficulties and obstacles in rotation, as well as additional whistle.

- To avoid injury, you should wear special glasses and gloves.

- Experts recommend checking the water supply to the disc before work, which will ensure quick work.

Cutting starts only after the blade reaches maximum speed.

Recommendations: how to properly cut tiles with a tile cutter

The instruction for the tile cutter does not contain special instructions on which professional training should be, and the work is carried out quickly and easily. However, it is worth following the recommendations from the manufacturer so that even such a simple moment as a tile cut is as correct as possible and without oversight.

Instructions:

- The tool must be placed on a flat, stable surface. She must be solid.

- It is imperative to check how sharp the cutter is, as well as the fastening strength of each element.

- When cutting tiles, the order of work must be followed. Namely, on the front side of the tile, a fishing line is initially drawn along which the cut will be made. It is enough to use a pencil or marker and a ruler.

- The tile is installed on the base of the tile cutter.

- The tool must be set perpendicular to the working surface. To do this, you need to make a Strong emphasis on the far corner of the device, and then correct the position of the web, be sure to Consider the mark made earlier.

- It is important to remember that the reference point is taken on the central line located on the working surface of the unit.

- Next, using the handle, the cutter is brought to the tile.

- It should be installed on the edge of the product, the one that is closer to the master.

- Then the handle is pressed firmly so that the cutter touches the tile surface. Thus, it will be sandwiched between the metal part and the rollers in the equipment.

- To make a cut, it is enough to make a sharp and clear movement. Through it, a small groove is made from oneself and to the opposite edge of the canvas.

- After that, in order to break off the cut off part of the tile, you need to press its handle and the canvas will be broken along the previously drawn mowing line.

Thus, you can cut a tile and get two even parts of the product. The cutting line will be clear and without chipping, which will allow you to carry out repair work efficiently and without defects.

Rules: how to work with a tile cutter and why you need one

Some people think that using a roller tile cutter is possible without preliminary preparation and even trivial reading of the instructions.

What are the consequences:

- Illiterately cut part of the tile.

- Security breach.

- Damage to health, in particular to the upper limbs.

If we consider in more detail the moment for which a tile cutter is needed, then at first glance. This is the simplest device, which is not difficult to use and does NOT require professional special education. Hand tools are considered more convenient for use at home, since electric ones are too difficult to work with.

Electric and manual tile cutters have the same names, but different purpose and method of operation. The only exception is the final result. An electric tool has a sharper cutter and it is impossible for them to make a simple groove, since it cuts quickly and sharply. Electric tile cutters are either mains or battery powered, and some may resemble circular saws in appearance. In addition, when working with a power tool, there is a possibility of significant injury, since the rotation speed is too high in the diamond disc.

How to use a manual tile cutter

A manual tile cutter is used much more often than an electric one, and we are talking not only in domestic conditions, but also in industrial ones. At first, the process of cutting tiles may seem complicated and almost impossible, but in fact it only requires researching the instructions and safety recommendations. There are many nuances in functioning, but all of them are not difficult to remember and you should NOT forget about them while working. Safety rules are considered especially important, and even more than compliance with the phased work.

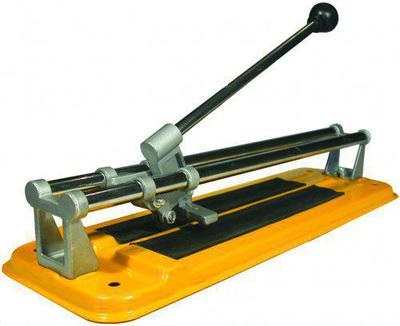

Manual tile cutter device

The device of manual tile cutters is the same, there are only a few differences regarding functionality. The following working parts are distinguished:

- The base, which serves as a platform for the location of all work items;

- Tubular guides along which the carriage with a cutting wheel moves;

- Carriage. In addition to the cutting roller, it is equipped with a special concave foot for breaking off the cut part of the tile;

- Cutting element. Carbide roller, rotating on the axis;

- The handle with which the carriage moves.

We cut the tiles with a tile cutter

To properly cut tile elements, follow the technology recommendations described below:

- With a special construction pencil over the tile, draw a line of the marking. Important! Experts in the field of construction recommend soaking the tiles in water before handling them in order to make the cut easier. Also apply a couple of drops of machine oil along the mowing line of the cut to make the cut easier.

Place the tile in the machine frame so that the cutting line coincides with the line of the carriage movement path, on which the cutting element is attached. Important! Make sure that the distance from the edge of the tile to the cut is at least 1 cm, otherwise the edges will be NOT neat.

Move the carriage along the intended line with light pressure. Important! At this stage, it is extremely important to control the pressure so that the tiles are not sold, but at the same time make a cut deep into the glaze.

Pass the cutter roller over the tile element once. Important! DO NOT make an additional cut on the surface otherwise, if you repeat it, the cut will be uneven.

Turn the tool handle to working condition and lower it with a sharp motion. Important! When performing such a manipulation, the tile will neatly break off along the cut.

How a tile cutter works?

The principle of operation of the tile cutter resembles that of a conventional glass cutter, which consists in cutting the tile glaze with a roller. During the cutting process, the tiles are tightly clamped in the body of the unit. After applying the floor glaze cut, the tile breaks off along its mowing line. To get more accurate and clear cut mowing lines, guides are set in the tile clamping field. The manual cutter is also used for making round holes.

Important! Before cutting a tile with a tile cutter, please note that a manual tile cutter is most convenient for cutting a small amount of material. In general, it is quite simple to use such a mechanism if you have even minimal skills in performing this work.

How to properly cut tiles with a tile cutter

Experienced craftsmen, before cutting the tiles with a manual tile cutter, recommend holding the tiles in warm water for a while. It will become slightly softer, which will reduce the likelihood of cracks and chips. To reduce friction and improve cut quality, it is advised to drip machine oil directly onto the line or the cutter wheel.

How to use the tile cutter.

View the instructions for use of the manual tile cutter with a clear example of the work performed by a qualified specialist. After viewing, you will have no doubts about the ease of use of this tool.

View.A review of the device of the electric tile cutter and the technology of its use, in order to exclude the appearance of any unclear issues when operating the tool on your own.