Trimmer carb setting

The operator needs to adjust the work node in certain cases:

- The new engine was run in using 4-5 liters of fuel;

- Changed the composition of the fuel. the brand of motor oil and gasoline;

- Weather conditions have changed (in winter, summer);

- The level of rarefaction of air has changed;

- The load on the power plant increased;

- After prolonged storage of the unit;

- The formation of persistent soot on the spark plug;

- After starting, the motor stalls immediately or does not develop the required speed;

- When vibrating, the tuning screws loosened;

- The amount of fuel consumed has increased;

- Gasoline is not pumped into the cylinder;

- It turns out a lot of exhausts.

The initial step in restoring the correct operation of the fuel system is to clean the air filter.

Experts recommend rinsing it every 10-15 hours in a solution of water with detergents. Direct adjustment of the trimmer carburetor is carried out by three adjusting screws:

- fuel feed adjustment screw (“L”);

- high speed adjustment screw (“H”);

- the screw responsible for the engine idling (“T” or “AT”).

Before starting the carburetor adjustment of the gas trimmer, it is necessary to warm the engine to operating temperature.

To do this, start the engine and at idle let him work 10-15 minutes. At the first stage, with the trimmer working, slowly tighten the screw “L” until the beginning of intermittent operation or until it dies. Next, unscrew the screw by ¼ turn and check the speed of maximum speed.

If the lawn mower easily and quickly reaches high speeds, this will be the most economical mode. In most models on the market, the fuel screw “L” is screwed in clockwise, however, there are trim tabs where the decrease and increase in the mixture flow occurs in the reverse order.

The screw "T" ("AT") serves as a limiter of the reciprocating movement of the fuel damper and when it is twisted, an increase in engine speed occurs, and unscrewing leads to a decrease in the speed of the crankshaft. Professionals advise adjusting the idle screw of the lawn mowers so that the ICE works a little faster at minimum speed, but the head with the fishing line or knife remains motionless.

After restoring the fuel supply at minimum speed and adjusting the idle speed, it is necessary to check the stability of the mechanism at an increased speed.

Adjustment of the motor at high speeds is carried out in order to protect against overheating and reduce hand fatigue when pressing the accelerator key. If the internal combustion engine is unstable at maximum speed, then screw “H” must be slowly turned in to ensure smooth and clear operation.

During operation of the lawn mowers, it may be necessary to adjust the fuel feed screw (“L”) for an optimal set of revolutions.

The main problems and malfunctions of the carburetor.

If you make a list of breakdowns that owners of gasoline trimmers most often encounter, it turns out like this:

- Engine;

- Carburetor

- Broken rod;

- Stihl;

- Starter;

- Fuel supply;

- Air filter;

- Muffler;

- Gearbox.

Below we will try to help those who want to fix the gas trimmer with their own hands using improvised tools.

Check the gas trimmer spark plug. is it dry or in fuel?

In order to find out the cause of the breakdown, the fuel filter cover is unscrewed to remove the strainer. If dirt has simply accumulated on it, washing with gasoline or blowing will help.

With visible damage to the strainer, it is imperative to install a new one. There may also be damage on the fuel supply pipe (during repair, check this element).

The carburetor starter in most cases does not function due to blockages. Use rinse with acetone or the same gasoline.

Blowing off carburetor parts with a blockage of compressed air is an acceptable and convenient repair practice.

The throttle body, the bundles of carburetor parts, the intake or exhaust pipe. all of these parts are subject to depressurization. You can probably check it in a primitive way. smear the problem area with soap suds.

In order to find out the cause of the breakdown, the fuel filter cover is unscrewed to remove the strainer. How to set the ignition on the push-pull on the patriot lawn mower. If it just accumulated dirt, then washing with gasoline or blowing will help.

With visible damage to the strainer, it is imperative to install a new one. There may also be damage on the fuel supply pipe (during repair, check this element).

The carburetor starting device almost always does not work due to blockages. Use acetone or the same gasoline for flushing.

Blowing off carburetor parts with a blockage of compressed air is an acceptable and comfortable repair practice.

The throttle body, the bundles of carburetor parts, the intake or exhaust pipe. all of these parts are subject to depressurization. Probably you can check with a simple method. smear the problem area with soap suds.

Damage to the trimmer carburetor occurs due to the use of poor quality gasoline, a damaged air filter and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair a carburetor with your own hands. The following are typical malfunctions of the carburetor lawn mowers.

A common malfunction that “chases” the fuel pump is deformation of the pump diaphragm. For this reason, it does not fit properly and the pump channels are not sealed.

The causes of membrane deformation can be as follows:

- long operation of the trimmer;

- use of unsuitable fuel;

- gas entering the pulse channel.

As a result, damage to the membrane reduces the performance of the pump, and as a result:

- there is a depletion of the combustible mixture;

- difficulty starting the engine;

- there are interruptions in the motor;

- the piston is damaged.

Also, the aforementioned consequences for the engine can cause clogging of the pump cavity on the impulse side. In this case, dirt enters the membrane through the pulse channel.

To eliminate clogging, you will have to disassemble the carburetor and clean the membrane.

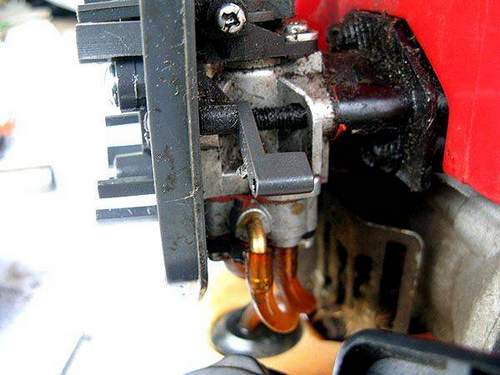

The strainer may become contaminated when contaminated fuel enters through a fuel hose or defective suction head. In the photo below you can see what a clean filter looks like and dirty (the parts are separated by a dash).

A thorough cleaning and rinsing of the strainer will be required to resolve the malfunction. It is also recommended that all openings in the trimmer carburetor body be blown with compressed air.

This failure occurs when the contact surface of the lever wears out.

The contact surface is erased due to the presence of abrasive particles in gasoline or due to strong vibration of the motor during operation. This defect of the adjusting lever causes problems with the inlet, as well as improper engine idling.

Inlet needle wear

The intake needle fails, usually due to the presence of abrasive particles in the fuel fluid.

- the tightness of the seat of the inlet needle is violated;

- leakage of the combustible mixture appears;

- there are malfunctions in the engine, associated with the re-enrichment of the fuel mixture.

Also, the inlet needle can simply jam.

Jamming the inlet needle can cause dirt in the fuel, or a long idle time without working.

If dirt accumulates in the adjustment cavity, the inlet needle cannot close the hole tightly and a lot of fuel is poured into the chamber.

This causes re-enrichment of the fuel, and the engine starts to work incorrectly. It is necessary to disassemble the carburetor and clean the cavity of the adjusting membrane.

The membrane can undergo deformation during prolonged operation of the unit and when using aggressive fuel.

The impossibility of normal adjustment due to a defect leads to:

- piston damage;

- difficulty starting;

- depletion of fuel;

- engine malfunction.

This problem may occur if the adjusting lever is not installed correctly, or bend it before installation. As a result, the contact surface takes the wrong position, which disrupts the additional fuel supply.

Damper wear

Throttle and air dampers mostly wear out due to the presence of abrasive particles in the air. Defective flaps look like they were sandblasted.

As a result of wear of the dampers, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder cover wear out.

The air and throttle shaft may wear out for the following reasons:

- insufficient and improper maintenance of the air filter;

- the air filter is damaged;

- The air filter is not suitable for this unit.

Due to the ingress of poorly cleaned air, the shaft wears out and can break. Broken parts of the shaft can enter the combustion chamber or crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace the defective filter or rinse the existing one (serviceable). The filter must be washed in soapy water and dried.

Strainer There are only two tasks with this element:

In order to find out the cause of the breakdown, the fuel filter cover is unscrewed to remove the strainer. If it just accumulated dirt, then washing with gasoline or blowing will help.

With visible damage to the strainer, it is imperative to install a new one. Custom carburetor petrol trimmer favorite. There may also be damage on the fuel supply pipe (during repair, check this element).

New gas trimmers

Before setting up the carburetor assembly, a certain algorithm of actions is performed:

- The motor is washed;

- The spark plug is replaced or cleaned;

- The air filter is replaced or cleaned. It can be dipped in warm soapy water, after the filter is completely dried;

- A cord or knives are installed in the trimmer coil to increase the load on the power plant during tuning. The gas engine should run idle for at least ten minutes.

If the cutting headset continues to rotate at idle, it is worth reducing the speed of the power plant. The operation of the T screw is adjusted, on some models it is marked LA. The idle speed control is twisted counterclockwise until the cutting element stops moving.

The trimmer carburetor adjustment is dependent on three screws:

- L is responsible for the level of pumping the fuel mixture at reduced speeds. It is set up first. It is necessary to achieve maximum speed by unscrewing the screw to the desired point. After the regulator turns a quarter of a turn to the left;

- T (LA). sets idle operation. When you turn the screw to the left, the engine speed decreases, to the right. increase;

- H allows you to enrich the fuel at maximum speed. The screw adjusts high revs, fuel economy and power plant power level.

The motor cannot run at full speed for more than 10 seconds, as it may break.

Eliminates engine damage proper tuning:

- With the engine running, give full throttle;

- The screw N is unscrewed clockwise until the unit starts to slow down;

- Knob H rotates to the left until the motor is stable.

If you follow all the instructions, the carburetor for lawn mowing is considered tuned: the engine runs at the required speed, slightly quadruples at high speeds, the cutting elements do not rotate without load.

The trimmer does not belong to complex household appliances, because most of its failures are mechanical in nature and can be successfully removed with their own hands. Even if the engine fails for severe reasons. damage to the piston ring, for example, repair is reduced to replacing the part.

And with a relatively conventional design, such a part of the device as a carburetor needs to be adjusted.

The presence of a gas trimmer significantly simplifies the life of those who often have to mow grass around the house or in the garden, as well as harvest hay for animals. However, the simplicity of operation does not exclude the occurrence of malfunctions, moreover, the complexity of the mechanism entails the complexity of the repair. And after-sales service imposes additional costs on the tool.

In order to extend the life of the tool, preventive measures are necessary. So, for example, do not overload the device, every time after 15 minutes, take a 10-minute rest. Do not neglect the rules of operation and do not mow the grass, the height of which exceeds the permissible. If a breakdown occurs, do not rush to contact the after-sales service, inspect the device to determine the cause, maybe it is possible to actually repair the gas trimmer with your own hands, especially if you have some skill in working with the equipment.

First, find out how to independently find the cause of a device malfunction, then talk about why these breakdowns occur and how to fix it.

If, for example, the tool stalls immediately after the factory or does not start at all, then pay attention to the ignition system:

Now a few recommendations that will help you fix the breakdown and repair the tool yourself.

To ask yourself as little as possible how to repair an engine, carburetor, or gearbox of a gas trimmer with your own hands, do not purchase rare models, as it will be extremely difficult to find details for them, and at official dealers the prices do not always correspond to the capabilities of buyers.

If you are new to working with complex technical products, it is better to contact a service representative for help. self-adjusting the carburetor, for example, can subsequently lead to the combustion of the entire piston system. In addition, some parts cannot be repaired at all, and an entire unit is subject to replacement; repairing one yourself in this case will not make sense. Also, do not rush to open the tool body, if it is under warranty.

To help, we can offer you to turn to the services of a master for repairing trimmers, which can be found on one of the sites, for example, pro.ru. LINK (do not forget to choose your city). At least, if the repair is carried out by the master, you can be sure of the result.

Carburetors for lawn mowers can be purchased here: How to adjust the carburetor, if configured.

The correctness of the carburetor option is determined by the operation of the engine and the color of the candle. Adjusted.

All varieties of carburetors produced by manufacturers of gas trimmers are almost impossible to cover. But, since the design of this module, as well as its operating principle, is largely similar between different models, a generalized description of the processes occurring in the carburetor can be made. This information will allow the user to understand the principles of operation of the device, eliminate the problems that have arisen and operate it correctly.

The basis of the trimmer carburetor is a one-piece aluminum housing. Below is a diagram of this unit.

At the bottom of it, there is a diffuser, which is also called a Venturi nozzle (18). Air is sucked in by the motor through this nozzle.

In the upper part of the diffuser there are fuel channels (11,12). Through these channels, the flow of air draws in gasoline. The fuel pump itself, the jets and the system used to control the flow of the fuel-air mixture can be built-in or installed externally.

The throttle (9) controls the amount of air drawn into the carburetor. Its amount affects the power that the engine develops. The damper (7) is used for cold start. It must be closed if you intend to start the unit. After the engine has started, it needs to be opened, otherwise, the motor will immediately stall.

The pulse channel (1) connects the pulse chamber of the pump to the crankcase, namely, with its internal volume. The piston located in the cylinder, making a reciprocating motion, successively changes the pressure in the crankcase (vacuum or pressure increase). Pressure drops make the membrane move (4). Therefore, the operation of the pump is synchronized with the operation of the engine.

Leaking gasoline from the tank occurs precisely with the participation of the membrane (4). Gasoline enters the carburetor through the fitting (2). Further, its path lies through the inlet valve (3), the exhaust valve (5), through the strainer (6), the fuel channel (10), passes by the needle (14) and fills the chamber (16) having a control membrane (18).

Video: Husqvarna 128 R Trimmer Piston Replacement

The valve (14) by means of a lever (17) is connected to the membrane (18). The cavity, which is located below the membrane, is connected to the atmospheric air through the hole (19).

The device operates as follows.

- A vacuum is created in the diffuser during the suction stroke. This fact causes air leaks. The position of the throttle (9) determines the amount of air entering the carburetor chamber, as well as engine power and the number of revolutions.

- At this time, fuel from the chamber (16) is sucked through the jets (11,12), after which it is mixed with the flowing air. Gasoline, mixed with air, begins to spray. Thus, an air-fuel mixture is created.

- The finished mixture enters the cylinder, where it is compressed by a rising piston and ignites at its correct point from the spark generated by the spark plugs.

- Since the volume under the control membrane (18) is connected with atmospheric air through the channel (19), the membrane goes up, opening the valve (14) by means of the lever (17). After opening the valve (14), a new portion of fuel enters the chamber (16).

- After the chamber (16) is full, the membrane (18) returns to its original position, and the valve (14) closes.

- Regardless of the manufacturer, there is a factory defect of the carburetor parts of the lawn mowers.

Adjusting screw spring

For example, the adjustment method described above may not give positive results with an excessively large number of turns at the spring of the mixture feed screw and, as a result, the impossibility of optimally reducing the level of gasoline supplied. To eliminate this, you can independently shorten the spring yourself or purchase a new one in accordance with the instruction manual.

Many owners of lawn mowers when buying oil follow the recommendations indicated there for the preparation of the fuel mixture.

Oil for gas trimmer

So, often the information on mixing gasoline and oil indicated on the bank differs from the indications in the trimmer’s passport. As a result, black soot can quickly form on the spark plug, which leads to a drop in power and an increase in fuel consumption. Therefore, when preparing the working mixture, the recommendations specified in the instruction manual should be followed. In most cases, the proportion for a run-in ICE is 1:25. It is worth noting that many owners of the tool prefer to cook fuel “by eye”, which will inevitably lead to rapid wear of the piston spit in case of a reduced portion of oil and the formation of soot on the spark plug with an increased amount of lubricant.

The device of the carburetor lawn mowers

The basis of the carburetor of the lawn mowers is an aluminum case. It contains a diffuser (a hole with internal contours). Air is blown through this hole. The oxygen (air) flow rate depends on the cross-section (passage opening) of the diffuser.

The diffuser is equipped with fuel channels. Of these, fuel is drawn in using an air stream.

Outside the carburetor is installed:

- fuel pump;

- jet system;

- fuel / air mixture control system;

The base of the carburetor of the lawn mowers is a duralumin case. It contains a diffuser (a hole with internal contours). Air is blown through this hole. The oxygen (air) flow rate depends on the cross-section (passage opening) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn from them by an air stream.

- fuel pump;

- jet system;

- system for adjusting the consistency of fuel with air;

The principle of the carburetor lawn mowers

A carburetor is a module of the power system in which liquid fuel and air are mixed before being fed into the engine cylinders. Depending on the tool and its operating mode, mixing and feeding are adjusted appropriately.

The carburetor device of the lawn mowing is uniform for virtually all cases. It belongs to the category of float devices. The latter provide constant characteristics of the finished consistency.

The mechanism of the module is as follows.

- Air enters the body of the tube with an air damper. The latter increases or decreases the air flow depending on its own position.

- In the area where the hole for supplying gasoline is formed, the tube has a constriction. a diffuser. Here the flow rate increases.

- Fuel from the float chamber through the nozzle is fed into the tube. The float level determines the amount of fuel supplied. Because the pressure in the chamber is normal, and the pressure in the tube is low due to the greater dilution of air, gasoline is sucked through the nozzle.

- Accelerated airflow picks up fuel and atomizes it, forming an air-fuel mixture of suitable density.

- The mixture is sucked into the cylinder through a pipe.

The stronger the air damper in the tube is open, the higher the density of the air flow, which means that more fuel enters the cylinder. Setting the carburetor of the lawn mowers is reduced to setting such a ratio of the dampers at which the density of the fuel consistency becomes good.

Carburetor Repair Lawn Mowers and Chainsaws

Petrol tool carburetors have a little-known but serious problem that can be easily treated.

Chinese lawn mowing carburetor repair

Spare parts for Chinese lawn mow Chinese lawn mowing repair.

The throttle valve determines the amount of air for supply, and engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. Further, the fluid moves through the inlet and outlet valves of the pump. Filtered by mesh. The needle valve moves into the membrane chamber.

Phased operation of the device:

- Air supply to the tube with an air baffle (damper). The partition controls the intensity of the air flow.

- The fuel supply system must be narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and nozzle tube with narrowing. A camera with a float adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already low. Due to the pressure drop, fuel enters through the nozzle.

- The acceleration of the air flow contributes to the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the necessary proportion or density is formed.

- The air-fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the flap is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on the lawn mower is creating the optimal fuel mixture due to the correct air supply.

The throttle valve determines the amount of air to be supplied, and the motor power directly depends on this.

Carburetor adjustment of lawn mowers in practice

Carburetors for lawn mowers can be purchased here: How to adjust the carburetor, if configured.

Carburetor adjustment of Chinese lawn mowers. Practice.

The correctness of the carburetor option is determined by the operation of the engine and the color of the candle. Adjusted.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. Further, the fluid moves through the inlet and outlet valves of the pump. Filtered by mesh. How to adjust the carburetor on a wound mowing lawn: lawn mowing how to assemble a handle. The needle valve moves into the membrane chamber.

- Air supply to the tube with an air baffle (damper). The partition controls the intensity of the air flow.

- The fuel supply system is certainly narrowed with a mixer to speed up the flow.

- Gasoline through the float chamber and nozzle tube with narrowing. A camera with a float adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already small. Due to the pressure drop, fuel leaks through the nozzle.

- The acceleration of the air flow contributes to the transfer of fuel (gasoline) and its atomization. Save as pdf. Video is nothing at all about how to adjust a carburetor while looking at a carburetor on a wound lawn mower. Why is it necessary to adjust the 128 Husqvarna carburetor on ours. Ultimately, an air-fuel mixture of the desired proportion or density appears.

- The air-fuel mixture seeps into the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the flap is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on the lawn mower is creating a good fuel consistency due to the correct air supply.

A carburetor is a power system module in which liquid fuel and air are mixed before being fed into the engine cylinders. Depending on the tool and its operating mode, mixing and feeding are adjusted accordingly.

The carburetor device for lawn mowers is the same for almost all cases. It belongs to the category of float devices. The latter provide stable parameters of the finished mixtures.

The principle of operation of the module is as follows.

- Air enters the body of the tube with an air damper. The latter enhances or reduces air flow depending on its position.

- In the area where the hole for supplying gasoline is formed, the tube has a constriction. a diffuser. Here the flow rate increases.

- Fuel from the float chamber through the nozzle is fed into the tube. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal and low in the tube due to the greater dilution of air, gasoline is sucked through the nozzle.

- Accelerated airflow picks up fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through a pipe.

The more open the air damper in the tube, the higher the density of the air flow, which means that more fuel enters the cylinder. Setting the carburetor of the lawn mowers is reduced to setting such a ratio of dampers at which the density of the fuel mixture becomes optimal.

Thus, using 3 adjusting screws, it is possible to achieve maximum engine performance, as well as to configure its smooth operation at any ambient temperature, and even in mountainous areas.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. Further, the fluid moves through the inlet and outlet valves of the pump. Carburetor adjustment of the gutbrod lawnmower. Filtered by mesh. The needle valve moves into the membrane chamber.

- Air supply to the tube with an air baffle (damper). The partition controls the intensity of the air flow.

- The fuel supply system is certainly narrowed with a mixer to speed up the flow.

- Gasoline through the float chamber and nozzle tube with narrowing. Cleaning carburetor lawnmower gardenlux video. A camera with a float adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with narrowing is already small. Due to the pressure drop, fuel leaks through the nozzle.

- The acceleration of the air flow contributes to the transfer of fuel (gasoline) and its atomization. Ultimately, an air-fuel mixture of the desired proportion or density appears.

- The air-fuel mixture seeps into the engine cylinder through the fuel pipe.

Faulty carburetor 2t-engine lawn mowers.

How often do we manage to start the lawn mowing engine, which in all external parameters can be considered serviceable? This happens often, even at the most inopportune moment.

We do not find defects in the engine design. The fuel mixture is composed correctly and based on fresh ingredients. Sparking is present. The carburetor mode settings were not changed, but the engine of our lawn mowers still does not start. Why?

Each product of the technical industry has units or parts that have either fine-tuning or high dimensional accuracy when manufacturing and when placing them in the finished product.

Most modern 2t low-power engines are equipped with carburetors with the ability to control modes, depending on the fuel used and the condition of the engine. The design of carburetors may differ among themselves, but the principle of operation of the carburetor, the formation of a fuel-air mixture, remains the same.

In order for you to understand the meaning of the following description, I will say that in case of any malfunction, some owners give the product for repair and do not load their heads with an unnecessary problem.

Others buy a new one or carry out repairs with a partial replacement of components, and most of the owners of faulty chainsaws or lawn mowers independently carry out diagnostics and repairs, determining step by step the cause of the malfunction. Someone is interested and informative, but someone does not have enough time and money for after-sales service.

In the beginning, I want to pay attention to some signs that indicate a faulty unit or element of a similar carburetor.

- A working, compacted lawn-mowing engine is started only when several grams of the fuel mixture are poured into the working chamber through the spark plug hole or through the open carburetor diffuser. (!) I’ll clarify that the discussed engine is working and it will start, but for a few seconds.

- The engine, which has a reduced compression ratio in the cylinder, has a significant output of piston rings or one of the crankshaft oil seals is not tight enough, it will not start in the usual way (!). A test run of such an engine with the addition of fuel directly to the piston chamber makes sense, since with a working carburetor such an engine can start and can continue to work, but it can be restarted in the usual way no later than a couple of minutes after it stops, while the volume of the crankcase and cylinder contains the unsettled fuel-air mixture.

To make sure that there is no mixture formation, it is possible to spray a little fuel mixture in front of the window of the carburetor diffuser just started by the engine described above, using a medical syringe. The engine will run until you provide fuel to it.

Each part of the carburetor must be carefully disconnected from the adjacent element and carefully inspected.

- Check the tightness of the carburetor parts through the gaskets. Tightness may be impaired due to gasket defects, loosening of assembly and mounting bolts.

- If there is no fuel in the carburetor’s fuel chamber, check the passage and tightness of the channel through which the pressure of the fuel pump membrane is controlled from the crankcase. Check the primer’s membrane and mushroom valve, if any.

- If there is fuel in the carburetor’s fuel chamber, then this is exactly the case when owners desperately change the carburetor for a new one without knowing the reason, because they can’t start the engine.

In this case, the reason lies in the last segment, in front of the hole of the fuel atomizer, where its valve is installed, which is made of rubberized fabric and the channel controlled by it can be closed, which rarely happens, or is still open.

The opening of the spray channel, as a rule, is always open when the spray valve is faulty, and no matter how hard you try to start the engine, you will not succeed. A serviceable valve opens only when there is a clear discharge and closes when it is absent. If the valve is faulty, fuel will not flow under the nozzle opening at the moment when the fuel-air mixture should form. And here is why it can be faulty, read on.

The entire valve consists of a bronze glass, at the bottom of which there is a seat for the valve itself. A locking ring with restrictive protrusions is installed on top of the glass. The active element inside the valve is a round petal made of rubberized fabric.

In the locking state, the petal rests on the saddle and closes the fuel channel. In the open state, the petal is raised and is located at the locking ring itself, but the fuel channel in front of the atomizer is not blocked, since the restrictive protrusions on the ring do not allow the petal to press against the hole and block the entire surface. Fuel at this moment enters the atomizer.

As a rule, the engine of your scythe works at high speeds, otherwise the centrifugal clutch will not work and the cutting knife of the scythe will not have enough power. It is so?

And this is so, which means that the valve petal will move synchronously with the engine piston and will hit the saddle and the restrictive protrusions with the greater force, by how many greater differences between pressure and discharge in the carburetor diffuser will occur at high engine speeds.

Gradually, with each hour, the valve petal wears out and there comes a moment when the engine of the lawn mowers stops and no longer starts up at any attempts, except for the verification methods I have indicated earlier. The integrity of the petal is violated and it seems that someone intentionally pierced the petal.

The most interesting thing is that not everyone can take into account this cause of a faulty carburetor and mislead itself about other possible causes of a malfunction of the engine itself.

I assure you that it is possible to restore the carburetor atomizer valve, and this can be done quickly and easily. Watch the video.

We take a membrane from the automobile fuel pump (gasoline) and a drift. You can carefully cut the petal with scissors, but few will get it. The punch in our version is one of the knees of a suitable diameter of the telescopic antenna of the radio receiver.

On a wooden or rubber surface with a punch, we cut out the petal from the membrane of the automobile pump, remove the valve locking ring, change the petals, carefully lock the valve with the ring and assemble the carburetor.

A working engine starts up as if nothing had happened.

The type of carburetors used on lawn mowers with 2t engines is vacuum and needle. Vacuum is understandable, but needle-shaped because the amount of fuel supplied by the atomizer to form the mixture is controlled by a metal rod called a needle.

In the design of some carburetors, the shape of the rod is conical, while other carburetors are equipped with a metering needle in the form of a conventional metal rod. The fixed position of the metering needle for all carburetors is set differently.

Who remembers or knows for sure that the amount of fuel supplied by carburetors on our motorcycles could be changed by fixed needle positions? Below the octane number of gasoline. the needle is higher, the high octane in gasoline. lower the needle. We enrich or impoverish the fuel-air mixture.

Over time, with prolonged operation of the engine, the needle breaks the spray channel a little, and whether you want it or not, you have to lower the needle a little, thereby impoverishing the fuel-air mixture. You can install a needle with a larger diameter and longer length.

We have cases when handling problematic braids, on the carburetors of which adjusting bolts of a fixed position of the spray needle were turned out. For the sake of curiosity, they rely on a certain jet. You will return everything to its place and the engine can be freely started.

How to adjust a carburetor on a lawn mower

Before adjustment, carefully clean the filters according to the maintenance in the instructions.

Right (L). fuel mixture adjustment for low revs.

Need to find the maximum idle speed. To do this, slowly turn the screw (L) to the right and left.

To adjust, turn the screw a quarter of a turn necessarily counterclockwise.

Lower (T). is responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

For proper adjustment of idling, it is typical:

- steady work of the cold engine;

- not overestimated speed of the hot engine;

- a large headroom for the trimmer head;

- stable operation of the engine when changing position (sharp rise or descent of the knife).

Left (N). adjusts the mixture at high speeds. (The screw is configured last).

The left-hand screw (N) determines the general adjustment of the maximum speed, engine power, temperature and gas mileage.

Setting the carburetor lawn mowers with the last screw is performed as follows:

- Open the throttle to full, while giving out full throttle. Turn the screw clockwise until the speed drops (in this case, they are oriented by ear).

- Turn the screw as slowly as possible counterclockwise until the engine runs unevenly.

- Then turn back quite a bit, barely hearing a stable, smooth operation.

- For a more visual application of skills, it is more convenient to consider the work of an experienced user:

It is interesting that from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not just by the speed and stability of the engine.

The correct setting of the carburetor with your own hands in this case is the combustion of the fuel mixture without residue, the color of the candle should be light brown.

Before adjusting, you must carefully clean the filters according to the maintenance in the annotation.

Right (L). Adjusts the fuel consistency for low revs.

It is necessary to find the highest idle speed. To do this, slowly unscrew the screw (L) to the right and to the left.

To adjust, turn the screw a quarter turn without fail counterclockwise.

Lower (T). is responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

For the correct adjustment of idling, it is typical:

- steady work of the cool motor;

- not overestimated speed of a hot engine;

- for the trimmer head a large reserve of revolutions;

- stable operation of the motor when changing position (sharp rise or lowering of the knife).

Left (N). adjustment of consistency at high speeds. (The screw is configured last).

The general adjustment of the highest revolutions, engine power, temperature and gas mileage depends on the left screw (H).

Setting the carburetor lawn mowers with the last screw is as follows:

- Open the throttle to full, while giving out full throttle. Turn the screw clockwise until the rpm falls (in this case, they are oriented by ear).

- Turn the screw as slowly as possible counterclockwise until the motor runs unevenly.

- Then turn back completely completely, just hearing a measured, steady work.

- For a more pleasant implementation of abilities, it is more convenient to discern the work of an experienced user:

It is curious that, based on the beliefs of the creator of the video, the setting (its correctness) is determined by the color of the candle, and not just by the speed and stability of the motor.

The correct setting of the carburetor with your own hands in this case is the combustion of the fuel consistency without a trace, the color of the candle should be light brown.

Signs of imbalance

Carburetor debugging is certainly done in the manufacture of the apparatus. Usually, the owners will find out about the need to adjust the fuel supply with their own hands only after quite severe breakdowns, during the correction of which the module was removed and, for example, cleaned.

Signs of a failure in the settings are as follows:

- it starts up, but the motor stalls here. since the engine can only work when a certain amount of gas is supplied, with very “poor” fuel, in other words, blocking the supply channel, the motor will stop;

- very high fuel consumption, a lot of exhaust gases. the result of incomplete combustion of consistency. In this case, there is a lot of fuel, and the mixture comes out extremely dense.

Carburetor debugging is necessarily carried out in the manufacture of the apparatus. As a rule, the owners will only learn about the need to adjust the fuel supply with their own hands after sufficiently serious breakdowns, during the correction of which the module was removed and, for example, cleaned.

Signs of a failure in the settings are as follows:

- it starts, but the engine stalls right away. since the engine can only work when a certain amount of gasoline is supplied, if the fuel is too “poor”, that is, when the feed channel is blocked, the motor will stop;

- too much fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the mixture. In this case, on the contrary, there is too much fuel and the mixture turns out to be excessively dense.