What you should pay attention to?

Once the adjustment of the Husqvarna carburetor is complete, you need to make sure that the engine is stable and the saw easily picks up and drops the required speed. It is considered abnormal to rotate the chain at idle speed, therefore it is necessary to re-adjust its connection with the clutch using the screw H.

Do not forget that the unit is not configured immediately: you need to wait a while, since the Husqvarna chainsaw does not immediately respond to changes in the position of the screws. This time can range from 5 to 15 seconds. This time does not prescribe the table, so you can only find out experimentally.

If, after adjustment, a huge amount of smoke appears during operation, then the supply of the fuel and oil mixture must be adjusted. For these purposes, rotate the screw L.

What is responsible for the air supply

Two dampers are responsible for the air supply, installed on the diffuser chamber. The first can regulate the amount of air at the moment the accelerator is pressed and is called the throttle, and the second ensures the restriction of the air supply at the moment when the chainsaw is cold started. To facilitate starting, the flap is closed, which means that the mixture becomes rich, as it is saturated with a large amount of fuel. It is easier to work in this mode, but since it increases fuel consumption, this mode is not applied throughout the entire operation. The saw is worn out.

A non-return valve is used to spray fuel into the cylinders.

Husqvarna chain saw carb adjustment

The principle of operation is simple: it restricts the return of the mixture back to the chamber. All the main malfunctions of chainsaws, most often, manifest themselves when this mechanism does not work properly.

- The most common mistake is storing the instrument for too long. The fact is that with prolonged inactivity, the valve sticks and either fills the cylinder with fuel, or simply does not open.

- The second problem is an increase in the amount of air in the mixture, caused by its suction from the outside when the valve does not work properly. It is no longer possible to regulate here, since in this case only valve repair or its replacement helps, since the saw will not react to the adjusting screws.

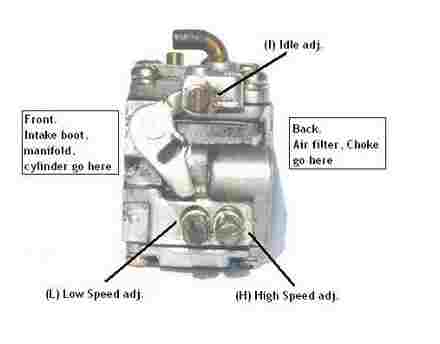

Unlike the car, the tuning of the chainsaw carburetor provides for three adjusting screws that are responsible for the quality of the mixture, the amount and nominal speed of the crankshaft of the Husqvarna engine:

- screw L. designed to adjust the number of revolutions when operating in medium modes and regulates low revolutions;

- Screw H. adjusts the number of high revolutions and thrust of the installation;

- T. designed to adjust the total amount of fuel and adjust the operation of the throttle assembly.

It is not recommended to touch the first two screws without special skills. The problem is that if you configure them incorrectly, then the carburetor will not be able to start the engine, or even start it in the wrong operating modes. Such adjustment of the screw can lead to its early wear and failure. This principle is embedded in many devices.

No table lists the settings parameters. Therefore, you should not look for these data in special literature, but only strictly follow the instructions. The table in the passport has only informational value regarding the characteristics of the engine.

How does the carburetor work on a Husqvarna 137 chainsaw?

On chainsaws of these models, the Walbro carburetor is most often installed from the factory. Before adjusting the Walbro carburetor on a Husqvarna chainsaw, you must have a minimal understanding of its structure and know how it works.

How to adjust the carburetor on a Husqvarna 365 chainsaw

Adjusting the carburetor Husqvarna 372 XP, 365

Adjusting the carburetor of a Husqvarna 372 XP chainsaw involves adjusting the engine to local criteria such as climate, altitude, gasoline quality and type of oil for 2-stroke engines.

The carburetor is equipped with 3 regulation options:

L = Low speed jet.

H = High speed jet.

T = Screw for adjusting idle speed.

The L and H jets regulate the amount of fuel to match the clot of air supplied by the throttle valve.

If the jets are screwed in clockwise, the mixture will be lean (less fuel in relation to the amount of air), and when unscrewing the jets counterclockwise, the mixture will be richer.

A lean mixture gives higher revs and a richer mixture. lower revs. How does the Husqvarna 142 carburetor adjust? The T screw adjusts the position of the throttle at idle.

If the screw T is turned clockwise, then the number of idle turns will increase, and if you turn the screw counterclockwise, then the number of turns will decrease.

Presetting and running in a Husqvarna 365 XP chainsaw

When checking the work at the factory, a preparatory adjustment of the carburetor was made. Preparatory adjustment: H = 1 turn, respectively L = 1 turn.

So that the parts of the Husqvarna saw motor receive sufficient lubrication (running in), the carburetor is set to a slightly overestimated enrichment of the fuel consistency for the first 3-4 hours of operation.

For such an installation, the maximum number of revolutions is set at 6-700 rpm below the recommended.

If there is no ability to check the maximum number of revolutions with a tachometer, then the H jet should not be installed on the fuel mixture below the preparatory installation.

It is prohibited to exceed the maximum number of revolutions. Adjusting the carburetor on a Husqvarna chainsaw is the basic setting for a chainsaw. If the chainsaw chain rotates at idle speed, turn the screw T counterclockwise to achieve its full stop.

Precise adjustment of the carburetor of the Husqvarna 365, 372 XP chainsaw

Fuel mixture preparation

When operating the chainsaw, a fuel mixture of gasoline and oil in a ratio of 15: 1 by volume should be used, that is, 1 liter of oil should be added to 15 liters of gasoline and the mixture should be thoroughly mixed. The amount of gasoline and oil in the fuel mixture is shown in this table:

| Gasoline l | one | 2 | 3 | four | five | 6 | 7 | 8 | 9 | ten |

| Oil, l | 0.06 | 0.13 | 0.20 | 0.26 | 0.33 | 0.40 | 0.46 | 0.53 | 0.60 | 0.66 |

| Fuel mixture, l | 1.06 | 2.13 | 3.20 | 4.26 | 5.33 | 6.40 | 7.46 |

ATTENTION! Application of oils: Lukony-2T; TNK-2T OIL: AZMOL Sport 2T GD ”and others, and used oil in the fuel mixture will lead to failure of the needle bearing of the connecting rod.

Page 29: Fine adjustment, Conditions, Low speed adjusting screw l, Fine idle setting t, Low speed needle screw n, Maintenance, Low speed adjusting screw

Attention! The text in this document was automatically recognized. To view the original page, you can use the “Original” mode.

Operation, pre-adjustment,

ATTENTION! Do not start the saw without the

saw blade, chain, and clutch cover

(chain brakes). Otherwise, it may

the clutch will fly off, which

cause serious injury.

The carburetor controls the engine speed with

throttle valve. Air is formed in the carburetor

fuel mixture, the composition of which can be adjusted. For

maximizing saw performance

the carburetor must be correctly adjusted.

Carburetor adjustment means tune the engine to

work in certain conditions, such as climate, height above

sea level, gasoline and oil used in the fuel mixture

for two-stroke engines

The carburetor has three

possible areas

adjustments:

L = low speed jet.

H = high speed jet.

T = idle adjustment screw

throttle stroke.

The required air quality

heating mixture, depending on the air flow, regulated

throttle valve, adjustable by turning the adjusting screws

Fuel supply ports L and H. Turning them clockwise

(tighten), then the quality of the working mixture (air /

fuel) becomes leaner (less fuel), and if you turn them

counterclockwise (unscrew), then the quality of the working mixture

enriched (more fuel). Depletion of the working mixture gives

* Husqvarna 440 chainsaw carburetor adjustment

increase in engine speed, and enrichment. decrease.

How To Adjust / Tune a Chainsaw Carburetor | Husqvarna Stihl BEST Way

The T screw adjusts the idle speed. By adjusting the position

throttle valve, it increases or decreases the flow

air, depleting or enriching the working mixture. Turning the screw T in

clockwise increases idle speed, turn counter-clockwise

clockwise decreases idle.

Setting basic parameters and running in

Basic carburettor adjustments are made at the factory

the manufacturer during the test of the chainsaw.

In this case, the following basic

setting: H = 1 turn, respectively L = 1 turn.

To ensure proper lubrication of the engine mechanisms (during

break-in time) carburetor during the first 3.4 hours of operation

must be adjusted to a richer working mixture. For

to ensure this mode, you need to adjust the screw H

maximum revolutions 6. 700 rpm lower than recommended

at maximum mode (full throttle without load).

If you cannot check the rpm using a tachometer, then the screw

adjustment H should be turned towards the enrichment of the working

mixture with respect to the established preliminary position.

The recommended maximum speed must not be exceeded. it

leads to overheating and damage to the saw motor.

After “running in” the chainsaw, you need to carry out an accurate

Fine adjustment should

performed by a specialist. First you need to configure

jet L, then idle screw T and then jet H.

Engine operating speed:

Maximum RPM Idling RPM

Before adjusting the carburetor, clean the air

filter and install the cylinder cover. Carburetor adjustment with

a dirty air filter will cause

cleaning the working mixture will be lean. This can lead to

to serious engine damage.

Gently turn the L and H jets clockwise until

refusal. Now turn them one turn counterclockwise

arrows. The carburetor is now set to H = 1 and L = 1.

Now start the saw according to the starting instructions

and let it warm up for 10 minutes.

the chain rotates at idle, then by turning the screw

T counterclockwise you need to achieve its full

stopping.

Place the chainsaw on a flat surface with a saw

away from you so that the saw blade and chain are not

touched the surface or any objects.

Low speed adjusting screw

idling by turning

L clockwise or

respectively counterclockwise

arrows. When will

idle speed,

counterclockwise

arrows. NOTE! If a

the chain rotates at idle, turn the idle screw

counterclockwise until the saw stops.

Precise setting of idle speed T

Adjust idle speed with screw T. Then

turn it counterclockwise until the chain stops. When

If a readjustment is necessary, first turn the screw T clockwise

arrow until the saw chain starts rotating. When correct

the adjusted idle speed, the engine starts to work

smoothly from any position. In addition, there should be a clear

threshold value of revolutions at the moment of chain rotation.

if the idle speed is not

adjustable until the chain stops completely,

please contact your dealer. Not

use the chainsaw while it is not

properly configured or repaired.

Low speed needle screw H

High adjustment screw

revolutions H affects

saw power. Customization

high speed screw H on

too lean mixture (screw H

closed too tight)

causes increased revs

and damages the engine.

Give the saw some work

thief at full speed about

10 seconds and pay attention

attention to the sound of work. Then

release the gas and turn the screw

H 1/4 turn counterclockwise.

Let the saw run again at full speed for about 10

seconds and notice the change in sound

engine. Turning screw H an additional 1/4 turn counterclockwise

arrows, repeat the procedure. So, the saw is tested in

the following positions: H = ± 0, H = 1/4, H = 1/2 with respect to

initial position. In each position (on full

rpm H is set correctly if the saw is slightly “quartering”. If a

the saw whistles, the mixture is too lean. If you saw hard

The chainsaw is a great helper for any man living in his home. The chainsaw device is a complex system that requires careful maintenance and requires increased attention. Today you will learn how to adjust the carburetor of a Husqvarna 137 chainsaw with your own hands in the garage?

How to repair a Husqvarna carburetor with your own hands?

During operation and diagnostics, defects in the carburetor may be found. Most of them can be eliminated on their own with a minimum of knowledge and without contacting a specialized repair center.

Among the methods of elimination are:

- Replacement of various gaskets at the joints of sealed parts;

- Cleaning or replacing the filter elements of the carburetor;

- Replacement of pump elements or valves;

Almost all of the above parts can be positioned as a repair kit, which is used for minor repairs of carburetors. After installing them, the carburetor of the Husqvarna 137 chainsaw can forget about malfunctions for a long time, and the regulation will become easier.

What you need to adjust the Husqvarna carburetor with your own hands?

In order to correctly adjust the carburetor of the chainsaw, you need to stock up on the appropriate tool in advance.

You will need the following list:

- The most common screwdriver, with which you can unscrew or tighten the adjusting screws;

- A tachometer designed to count the revolutions of the crankshaft. It is necessary when adjusting the idle speed, since it is quite problematic to determine the number of revolutions per minute by ear;

- Phillips screwdriver. It is needed to be able to unscrew the screw (T);

- Compressor with a special gun connected to them. The blowing device will help get rid of excess debris and dirt, since the carburetor must always be clean.

Many Husqvarna chainsaws use special section adjusting bolts. See in advance which ones you have installed and purchase the appropriate kit. This will help to avoid many difficulties at the initial stage.

Purpose and capabilities of the saw

The Husqvarna 440 chainsaw is designed for cutting materials such as:

- wood;

- foam concrete;

- gas silicate blocks;

- plastic.

Huskvarna 440. General view

The need to perform such work arises during construction, ennobling green spaces, harvesting firewood. This is especially true for private households. But the possibilities of a chainsaw are much wider. Detailed information about the appearance of the saw can be seen in the video

It can be easily transformed into other useful tools. With the installation of additional equipment on the main unit, the Huskvarna 440 turns into:

- plane;

- milling cutter;

- “Grinder”;

- bilge pump;

- ice screw for fishing.

Abrasive cutting attachment

It is not difficult to make them yourself. The work of the milling head is shown in the video.

Despite the simplicity of the design of the nozzles, it is best to give preference to those that are manufactured at the factory.

Specifications

Husqvarna chainsaws are represented by a wide range of models. Let’s get acquainted with the most demanded of them. Huskvarna 440 and Huskvarna 440e.

Table 1. Main technical characteristics

As you can see from the table, the main technical characteristics of these models are almost the same. The fact is that all models of the fourth series are intended for private owners, although according to gradation they are included in the manufacturer’s semi-professional line.

The Husqvarna 440e chainsaw, unlike others, is equipped with a slightly modified starter. An additional spring is mounted in it, which made it easier to start the engine and led to a change in the overall dimensions of the saw downward. In addition, it is equipped with a simplified chain tensioner.

Review of practical chainsaw Husqvarna 440 (Husqvarna 440e)

Another masterpiece in timber processing was the invention of the Husqvarna chainsaw by Swedish engineers. Simple in the device, easy to operate, it has gained popularity all over the world. It is widely used in construction, in summer cottages and in the preparation of firewood in the private sector. What is this famous brand. the Husqvarna 440 chainsaw?

- Purpose and capabilities of the saw

- Specifications

- Design features

- Consumer reviews

Design features

The fourth series saw creates a comfortable working environment. Convenient handles, easy engine start, low vibration level make it a pleasant unit in operation. The ease of maintenance is striking. the chain is tensioned without the use of tools, the air filter can be easily removed thanks to its modernized fastening. The time between the next filter service is increased.

Chain tensioner cover

Great attention is paid to the safety of the saw operator. The chain brake is applied forcibly (by hand), or automatically when a threatening situation arises. In addition, the chainsaw is equipped with a chain catcher if during operation it breaks or slides off the guides.

The engine deserves special attention. Its performance compares very favorably with other two-stroke engines. The increase in torque and combustion efficiency have reduced fuel consumption. The engine has become more economical and less smoky. Thanks to the forged crankshaft, the service life of the engine as a whole is significantly increased.

A properly adjusted and tuned engine does not require professional maintenance. It is enough to fill only with recommended gasoline and oil, and also keep it clean. All engine mechanisms, including cleaning the carburetor, are carried out without disassembling them. The exception is the air filter and spark plug. Their maintenance is described in detail in the “Chainsaw Operating Instructions”.

Replacing the recommended brands of fuels and lubricants with unauthorized ones is strictly prohibited.

Consumer reviews

All chainsaws of the fourth series of Husqvarna are distinguished by high reliability and durability, along with the convenience of their operation. A striking representative is the Husqvarna 440e, which has incorporated all the advantages of this model range. Working with the Husqvarna 440 saw is comfortable and easy. This can be clearly seen in the video about the device and starting the saw, the rules for handling it.

How to adjust correctly

For this, the device has 3 adjusting nozzles. The idle speed screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on the Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter of a turn.

- Hold the gas button with one hand for 15 seconds. At this time, we turn the H jet to the right until it stops and reaching the maximum speed. Then we turn it back one and a half turns, or until the “squeal” of the engine disappears.

- With the throttle released, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture.

If this happens, it is necessary to tighten the jets of the minimum and maximum speed until they stop. Then turn them back one and a half turns and try to start the saw.

The device and principle of operation of the carburetor

The carburetor is used to prepare a combustible mixture in a ratio determined by the operator from gasoline and air.

An excessively rich, as well as an excessively lean mixture will lead to unstable engine operation, can cause overheating and accelerate wear of the piston system.

The correct functioning of the device depends on the correct setting and adjustment.

And for this you need to know the principles of operation of the Husqvarna chainsaw carburetor.

Its design consists of the following elements:

- body with clamping bolts and a set of gaskets;

- fuel pump. a device that pumps a gasoline-oil mixture into the carburetor;

- diaphragm. designed to limit the supply of a combustible mixture to the engine;

- float chamber. fuel is collected in it, the level is regulated by the float, as necessary, the mixture is fed into the main chamber for mixing with air;

- the main chamber. air passes through it, and fuel is injected there, the amount of mixture supplied to the engine is regulated by the throttle valve located here;

- diffuser. section of narrowing of the air supply tube at the place of fuel injection;

- needle valve. a device that regulates the fuel supply;

- jet. screws that regulate the supply of the mixture at high and low speeds, as well as an idle screw.

Also in the carburetor device, in addition to the throttle, there is a damper located at the inlet from the air filter. It artificially reduces the air supply, making the mixture richer for easier cold starting.

The injector valve is responsible for fuel injection into the main chamber, it also prevents air from entering. When adjusting the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct effect on the operation of the engine. Long-term storage may cause the nozzle to stick. This will restrict fuel flow and prevent the engine from starting.

Also, from prolonged use or due to a factory defect, the valve can let air into the main chamber. In this case, only replacing it will help fix the problem.

The carburetor works as follows: the air flow entering the diffuser is mixed with the injected fuel, the resulting mixture is fed into the engine. The amount of the mixture is regulated by the throttle valve. The more mixture, the higher the engine speed.

Husgvarna 240 chainsaw carburetor repair

This video shows a common cause of a malfunction on chainsaws with an accelerator pump. Be ATTENTION

How to understand that everything is done correctly

After setting up, you need to start the chainsaw. Check the stability of idling. In this case, the chain must not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At the minimum and maximum rpm levels, the Husqvarna 350 should work stably, without extraneous noise. At the time of operation, there should be no sharp loss of power or shutdown.

Chainsaw “Husqvarna 240”, the technical properties of which you can see below, is the equipment that follows the line “Husqvarna 236”. If we compare these 2 variations, then it should be emphasized that the latter has a higher power, a slightly longer tire and has an engine that allows you to save fuel up to 25%.

Chainsaw “Husqvarna 240”, the repair of which is not required so often, is a non-hazardous tool for the environment, which is very important for some consumers. The volume of harmful emissions into the atmosphere has been reduced, and the number of cuts per fuel filling has been increased. Quite often, the products of the above-mentioned Swedish company are associated with chainsaws from the Stihl manufacturer. As an advantage of the former, the presence of a primer should be emphasized to simplify the start-up. But, as practice indicates, this does not greatly affect the process of starting up the equipment.

What is important for the consumer to remember

Chainsaw “Husqvarna 240”, the technical properties of which should help you to make the right choice, after purchase asks for refinement with ratfil. In this case, we are talking about adjusting the carburetor. It is also important to remember that this equipment does not have a system for adjusting the oil supply for chain lubrication, but it quite often happens that the oil tank is emptied faster than the tank designed for the fuel mixture.

Algorithm and description of setting the Husqvarna carburetor

Husqvarna carburetor, adjustable in the same way as setting up carburetors on chainsaws from other manufacturers.

Immediately before adjusting, it is necessary to carry out a complete diagnosis of the saw and make sure that there is no obstruction of the fuel supply and air leakage into the crankcase of the chainsaw. It is also necessary to make sure that the air filter is clean and, if necessary, replace it with a new one.

The order of work is as follows:

- On the muffled saw, the factory settings of the Husqvarna carburetor are set.

- The engine starts and the saw warms up for a few minutes.

- By turning the screw (L) clockwise, the position is found at which the engine develops maximum speed, after which the screw must be unscrewed 1⁄4 back. If at the same time the chain of the chainsaw rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting the power of Husqvarna at maximum speed and adjusting their number. To do this, the tachometer is connected to a running chainsaw, the throttle stick is squeezed out to full, after which the tachometer readings are checked. If the value of the maximum revolutions differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

- brake lever;

- economical fuel consumption;

- anti-vibration system.

But this list is not considered complete by consumers. They like the presence of a brake lever in the model, as well as the ergonomic design, low exhaust volume, as well as the presence of a chain tensioner.

When adjustment is needed

The need to adjust the carburetor of a chainsaw is rare. often there are problems with the flow of fuel, air or wear of parts. But sometimes adjustment is still required:

- a running engine stalls after a few seconds, or it does not start. the reason for this is a too rich mixture;

- excessive exhaust, high revs, increased consumption. in this case, on the contrary, the mixture is too lean, that is, there is not enough air;

- RPM is kept at the same level after its decrease or increase by the operator. the cause may be a stuck needle valve.

The factors leading to such changes can be the following:

- Severe vibration damages the protective cover and the adjusting jets are unscrewed, changing the setting. In this case, it is possible to adjust the carburetor on the chainsaw.

- Wear of elements of the piston system. Adjusting the carburetor in such a situation can be of temporary help. Replacement of worn-out components is recommended.

- Poor quality fuel, faulty filter, or long storage can cause blockages. In this situation, the carburetor must be removed, washed with a special liquid or clean gasoline, assembled and re-adjusted.

It is best to start tuning the saw by checking the jets, fuel and air supply. After that, proceed to dismantle the carburetor, and then. to check the piston system.