The setting of the saw carburetor can be studied in the video below. In this video, the wizard shows how the step-by-step adjustment of a Champion chainsaw, made in China, is performed without using a tachometer. Carries out after adjustment check in various modes.

How the carburetor is adjusted?

The algorithm for setting up the chainsaw is quite simple and consists of the following steps:

- Warming up the engine to operating temperature (the adjustment must be carried out only on a warm engine, this will allow you to get a more accurate adjustment).

- Adjusting the engine for smooth operation at low rpm.

- Setting the carburetor for the correct supply of the fuel mixture at maximum speed.

- Fine adjustment of the carburetor for idling.

- Chainsaw check in all modes.

Almost all carburetor models have three adjusting screws.

- The screw (T) is responsible for fine tuning in idle mode.

- Screw (H) setting for maximum speed.

- Screw (L) regulates the formation of a mixture at low rpm.

By tightening the screws (L) and (H), the fuel supply and the mixture becomes leaner, respectively, the speed increases.

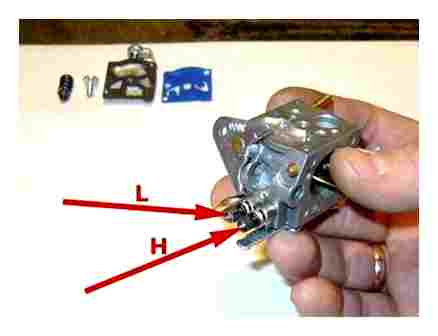

Carburetor adjusting screws L – minimum rpm and H – maximum engine rpm.

Now let’s look at how the correct adjustment of the chainsaw carburetor goes in more detail..

Adjusting the carburetor of a Chinese chainsaw

Carburettors installed on Chinese-made saws are made similarly to European ones and have the same adjustment screws.

The carburetor of a Chinese chainsaw is adjusted according to the algorithm presented above, and differs in that when initially adjusting the screws (L) and (H), they must be turned out two turns. Further, the carburetors of the Chinese saw are adjusted in the same way as the European ones..

How to adjust the carburetor of a Chinese chainsaw in just 3 steps, read here (a very useful article). As an example, we recommend looking at the article about adjusting the carburetor on the Carver chainsaw..

How to properly adjust the chainsaw carburetor

During the operation of the tool, situations arise when it is necessary to adjust the carburetor of the chainsaw. Within the framework of the article, we will figure out when to configure, how to do it correctly and whether it is worth adjusting it yourself, or is it better to give it to a specialized service. The carburetor is an important unit, the service life of the saw depends on how correctly it works.

- Situations in which adjustment is necessary

- Tools

- How the carburetor is adjusted?

- Process description

- Adjusting the carburetor of a Chinese chainsaw

- Video

- Summing up

Process description

- If the carburetor of the chainsaw is not adjusted and it is not possible to start the chainsaw, then the adjustment starts by setting the screws (L) and (H) to the standard setting. This is 1/5 of a turn of the screws until completely tightened..

- After that, you need to start the engine, let it run a little and warm up.

- The next step is to set up the low speed mode. Optimum low engine performance can be achieved by adjusting the screw (L) and idle speed (T). To do this, first the screw (L) is tightened until the maximum engine speed is obtained, then it is released by 1/4, and the idle speed is normalized with the screw (T)..

- After adjusting the work on the “bottom”, the thrust and maximum engine speed are adjusted. To do this, slowly tighten the screw (H) and check the speed according to the readings of the electronic tachometer. It is unacceptable to allow exceeding the maximum engine speed declared by the manufacturer!

The location of the carburetor adjusting screws on the Husqvarna chainsaw.

An important step is to check the saw in all operating modes after adjustment, for this you need to let the chainsaw cool down, and then start it according to the cold tool start algorithm. If the saw starts up normally and idles smoothly, you need to check how it is sawing. If in the process of checking deficiencies in the power of the chainsaw are found, then it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the thrust in operation.

Loss of thrust at maximum RPM recommended by the manufacturer is an indicator of CPG wear or poor fuel quality. Speaking of fuel, 90% of faults are due to fuel. Which one to use? 92 or 95? How much is stored? We answered all these questions in the article on which gasoline to pour into the chainsaw..

We recommend watching a video on how to clean and adjust the carburetor of a chainsaw, the author of which also talks about the detrimental effect of fuel on the components of the carburetor. This example shows how to rebuild your carburetor using an inexpensive repair kit..

Situations in which adjustment is necessary

New chainsaws are supplied by the manufacturer with adjusted carburetors. This is called standard adjustment. But for the normal passage of the running process, it is required to lower the maximum engine speed, adjust the carburetor. After running in, the chainsaw needs fine tuning to achieve maximum engine efficiency..

Also, a signal for cleaning and adjustment is an increased fuel consumption, which negatively affects the operation of the exhaust system. Simply put, the chainsaw begins to smoke heavily and the muffler becomes clogged with carbon deposits, which in turn will lead to a decrease in power..

With an excess of fuel in the mixture, engine parts are poorly lubricated and premature wear occurs. Also, a poor-quality mixture can cause the engine to jam due to overheating (this is one of the reasons why the chainsaw will not start).

It looks like a jammed, overheated piston, from a disassembled chainsaw with an incorrectly tuned carburetor.

Adjustment is necessary when the engine does not idle, stalls, or does not develop full power. Carburetor tuning should be done with clean air and fuel filters. We also recommend reading an interesting article that tells in detail about the main reasons why the chainsaw starts up and immediately stalls..

Tools

To adjust, you will need the following tool: a tachometer, screwdrivers, in rare cases, special keys. We will analyze their purpose, the need for availability and cost.

| Tool | Appointment | Recommended | |

| Screwdriver set (slotted screwdriver) | Most chainsaws require a simple flat-blade screwdriver to turn the adjusting bolts.. | 300 – 700 rubles | Required |

| Special adjusting key | For example, to adjust the carburetor on Husqvarna chainsaws, a special key is required, it is available only in certified service centers authorized for repair by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who are engaged in repairs without official permission to do so.. | Out of stock | Chainsaw dependent |

Setting up the chainsaw, if possible, should be carried out in official service centers that have a manufacturer’s certificate and an appropriate permit for repair work..

Summing up

Chainsaw carburetor adjustment, although it looks simple, requires an attentive and responsible approach. The article describes the entire setup process in detail, but if there is no experience in adjusting the chainsaw, then you should contact a specialized service for the repair of construction tools, this will help save time, nerves and money.

How to adjust correctly

For this, the device has 3 adjusting nozzles. The idle speed screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter of a turn..

- Hold the gas button with one hand for 15 seconds. At this time, we turn the H jet to the right until it stops and reaching the maximum speed. Then we turn it back one and a half turns, or until the “squeal” of the engine disappears.

- With the throttle released, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving..

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture..

If this happens, it is necessary to tighten the jets of the minimum and maximum speed until they stop. Then turn them back one and a half turns and try to start the saw.

How to understand that everything is done correctly

After setting up, you need to start the chainsaw. Check the stability of idling. In this case, the chain must not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At minimum and maximum rpm, the Husqvarna 350 should run stably, free of extraneous noise. At the time of operation, there should be no sharp loss of power or shutdown..

Tools required for work

Before proceeding with the tuning of the Husqvarna carburetor, you need to take care of having all the tools that may come in handy. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, as the adjusting screws on Husqvarna chainsaws may have different cross-sections. You will have to purchase a special, this is a feature of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

How the carburetor is adjusted

The algorithm for setting up the chainsaw is quite simple and consists of the following steps:

- Adjusting the engine for smooth operation at low rpm.

- Setting the carburetor for the correct supply of the fuel mixture at maximum speed.

- Fine adjustment of the carburetor for idling.

- Chainsaw check in all modes.

Carburetor adjustment must be done after the engine has run a little and heats up..

Now let’s look at how the correct adjustment of the chainsaw carburetor goes in more detail. Almost all carburetor models have three adjusting screws. The screw (T) is responsible for fine tuning in idle mode. Screw (H) setting for maximum speed. The screw (L) controls the mixture formation at low rpm. By tightening the screws (L) and (H), the fuel supply and the mixture becomes leaner, respectively, the speed increases.

Adjusting the carburetor of a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw..

Husgvarna 240 chainsaw carburetor repair

The H screw adjusts the power and speed. Adjusting the carburetor to a lean mixture leads to excess rpm, engine overheating and wear of the piston chainsaw.

We warm up the engine of the chainsaw at idle for two or more 10 seconds and turn the screw H 1/4 turn counterclockwise. Let the engine run for about 10 seconds. then we check the highest engine speed with a tachometer. If the passage does not match the highest speed with the passport, the operation should be repeated. When feeding a very rich consistency, the muffler starts to smoke, with a very poor saw squeals and overheats.

We finish the adjustment by adjusting the idle speed, as already described above. The idle speed is set correctly if the engine runs smoothly at low speeds and the chain does not rotate during all this.

The carburetor is adjusted if the engine accelerates rapidly and sounds like a four-stroke at full throttle..

Factory settings

The factory default setting for the Husqvarna carburettor is the position of the screws (H) and (L), in which a working chain saw is guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L). In the process of adjustment, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed..

DIY carburetor repair

If in the process of carrying out a full diagnosis of the Husqvarna chainsaw, carburetor defects were found, then some of them can be repaired without contacting a Husqvarna AB service center. For example, you can independently:

- change the gaskets under the covers of the main chamber and the fuel pump;

- clean or replace the strainer;

- replace the diaphragm or needle valve of the main chamber;

- troubleshoot the fuel pump diaphragm.

Gaskets, diaphragms and a rocker needle valve can be found in the repair kit provided for each Husqvarna chainsaw carburetor model..

Also, if you have some experience, you can try to restore the faulty injector valve, but you cannot guarantee a positive result when you try to restore the injector, if it is faulty, the manufacturers recommend changing the carburetor completely. To do this, you need to perform the following series of actions:

Husqvarna chain saw carb adjustment

- Before removing the carburetor, clean the saw with a compressor, as dirt can interfere with a quality repair.

- Next, open the top cover of the chainsaw, remove the air filter, disconnect the rods from the air and throttle control levers.

- After that, unscrew the screws securing the carburetor.

- Disassemble the carburetor body for repair. This is quite simple to do. The main chamber cover is held in place by four screws, which can be removed with a regular screw, the fuel pump cover is secured with one wide screw.

Below is a video that will make it clear how exactly you can repair the carburetor without contacting a Husqvarna service center.

Algorithm and description of setting the carburetor Husqvarna

Husqvarna carburetor, adjustable in the same way as carburetor settings on other brands of chainsaws.

Immediately before adjusting, it is necessary to carry out a complete diagnosis of the saw and make sure that there is no obstruction of the fuel supply and air leakage into the crankcase of the chainsaw. It is also necessary to make sure that the air filter is clean and, if necessary, replace it with a new one..

The order of work:

- Saw muffled with Husqvarna carburetor factory setting.

- The engine starts and the saw warms up for a few minutes.

- By turning the screw (L) clockwise, the position is found at which the engine develops maximum speed, after which the screw must be unscrewed 1⁄4 back. If at the same time the chain of the chainsaw rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting the power of Husqvarna at maximum speed and adjusting their number. To do this, the tachometer is connected to a running chainsaw, the throttle stick is squeezed out to full, after which the tachometer readings are checked. If the value of the maximum revolutions differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

Tools required for work

Before proceeding with the tuning of the Husqvarna carburetor, you need to take care of having all the tools that may come in handy. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, as the adjusting screws on Husqvarna chainsaws may have different cross-sections. You will have to purchase a special, this is a feature of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

Nuances of adjustment

After making the adjustment, the chainsaw should easily pick up and drop speed, work stably at low and high speeds. If the saw chain rotates at idle speed after adjusting the carburetor control screws, this is a sign that the adjustment has been made incorrectly and it is necessary to correct the position of the screw (T).

Also, when adjusting the Husqvarna carburetor, it is worth considering the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five, ten seconds.

One of the indicators of an incorrect adjustment is a strong smoke during the operation of the saw, which indicates a large amount of fuel entering the combustion chamber. If such a situation arises, you need to correct the position of the screw (L).

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know how it works and how it works. In fact, everything is not as difficult as it seems at first glance..

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers..

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for restricting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw.

At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode..

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems during the operation of the saw can be caused by defects of this particular element..

For example, a valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation, it will be necessary to repair or replace the unit..

Three adjusting screws installed in the carburetor body are responsible for setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode:

- screw (L) – adjusts the amount of fuel at low and medium speed;

- (H) – is responsible for traction at high speeds and their number;

- (T) – changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Attention! Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Improper adjustment of the quality and amount of the fuel mixture can cause the engine to stop working or malfunction, leading to rapid wear or even seizure..

When does the carburetor of a Husqvarna chainsaw need adjustment?

There are a lot of problems that can be solved by adjusting the carburetor. Adjusting the carburetor of your Husqvarna chainsaw is necessary when such malfunctions appear:

How To Adjust / Tune a Chainsaw Carburetor | Husqvarna Stihl BEST Way

- increased idle speed;

- strong smoke during tool operation;

- Difficulty starting a cold or hot engine;

- lack of traction and reduced maximum revs.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In some cases, adjusting the quality and quantity of the fuel mixture is carried out after an engine overhaul or in the process of scheduled maintenance of the chainsaw.

Husqvarna AB recommends adjusting the carburetor before and after running in the saw..

Factory settings

The factory default setting for the Husqvarna carburettor is the position of the screws (H) and (L), in which a working chain saw is guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L).

In the process of adjustment, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed..

Adjusting the carburetor of a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw..

- When does the carburetor of a Husqvarna chainsaw need adjustment?

- The structure and principle of operation of the Husqvarna carburetor

- Tools required for work

- Algorithm and description of setting the carburetor Husqvarna

- Nuances of adjustment

- Factory settings

- DIY carburetor repair

- Output