Fine tuning.

Precise adjustment of the carburetor can only be carried out in warmed up condition by specialists with special equipment (revolution counter).

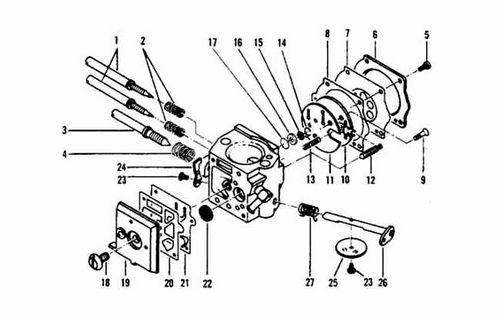

Adjusting and adjusting the carburetor Husqvarna 137

Husqvarna137 carburetor adjustment

In the picture above, you see three adjustment screws. Each of them has its own purpose:

Screw T is required to adjust the idle speed.

Screw L serves to adjust low rpm.

Screw H regulates high rpm.

Adjustment procedure:

First, with the L screw (rotating it), we look for the highest idle speed. After we have found them, it is necessary to return this screw a quarter of a turn against the clock hand. If in this position the chain continues to rotate, then by rotating the screw T we achieve its stop.

Then we warm up the engine at full speed in the region of 10-15 seconds and turn the screw H a quarter counterclockwise. We wait 10 seconds and listen. the engine should work as a 4-stroke in sound. If a squeal is heard, then the mixture is poor (unscrew the screw), if the enriched mixture smokes (tighten the screw).

After adjusting the low and high speeds, we set the idle speed with screw T. This is done as follows:

1.The engine must be running

2.Turn the screw T clockwise until the chain starts to rotate.

3.Rotate the screw in the other direction until the chain stops.

Product overview from Husqvarna

Exactly 50 years ago, Husqvarna released its first series-produced chainsaw, which became the prototype of all modern dust. Since the appearance of the first Husqvarna chainsaw, the company’s engineers have made a number of outstanding discoveries, thanks to which the modern chainsaw has become not only a convenient, but also a safe tool for the user.

Today, Husqvarna chainsaws are renowned the world over and the company continues to work to improve a wide variety of tool performance. One of the latest inventions of Husqvarna, which became the prerequisite for another great success, is the E-TECH® and X-TORQ® technology. This know-how made it possible to reduce fuel consumption by 20%, and the amount of exhaust of harmful impurities arising during its combustion process by 60%. At the same time, the engine power was preserved.

Husqvarna’s passion for excellence is reflected in both professional and amateur tools. The 4th series of Husqvarna chainsaws, released in 2008, is today the pinnacle of the model range, bringing together all the most significant technical achievements. With its appearance, new standards arose in the production of chainsaws, this time, focused on the private user.

Husqvarna XP series professional chainsaws

Quality and performance without compromise XP® chainsaws are exclusive to the Husqvarna range of chainsaws. Powerful engines, which are equipped with chainsaws, provide fast acceleration and optimum performance. Every Husqvarna XP® series chainsaw is built to tough demands for professional performance, comfort and ergonomics. All chainsaws are equipped with features such as Air Injection, Smart Start®, LowVib vibration reduction and are lightweight. Fuel consumption and emissions are significantly reduced thanks to unique X-TORQ® engine technology.

The Husqvarna 3120 XP Chainsaw is the largest saw, one of the most powerful tools in the world, designed for professional felling in difficult conditions. The advanced Husqvarna 395 XP chainsaw is designed to tackle the toughest jobs in the forest. It is the ideal solution for hardwood harvesting using long bar saws. Model 395 XP® G has heated handles. Chainsaw The Husqvarna 390 XP is a very powerful chainsaw from the latest generation of large chainsaws. High power and vibration suppression make it easy to work with the introduction of an elongated cutter. The chainsaw is equipped with a special connector for long tires (0.404 “).

What keys do we use ?: Adjusting the carburetor of a husqvarna chainsaw adjusting the carburetor of a Husqvarna chainsaw adjusting the carburetor of a chainsaw friendship

The device and principle of operation of the carburetor

The carburetor is used to prepare the fuel mixture in the proportion of gasoline and air determined by the operator.

The correct operation of the device depends on the correct setting and adjustment.

And for this you need to know the principles of operation of the carburetor of the Husqvarna chainsaw.

Its design consists of the following elements:

- Body with clamping bolts and a set of gaskets;

- Fuel pump. a device that pumps a gasoline-oil mixture into the carburetor;

- Diaphragm. designed to limit the supply of the combustible mixture to the engine;

- Float chamber. fuel is collected in it, the level is regulated by the float, as required, the mixture is fed into the main chamber for mixing with air;

- The main chamber. air passes through it, and fuel is injected there, the amount supplied to the engine of the mixture is regulated by the throttle valve located here;

- Diffuser. section of narrowing of the air supply tube at the place of fuel injection;

- Needle valve. a device that regulates the fuel supply;

- Jet. screws that regulate the mixture supply at high and low speeds, as well as an idle screw.

Also in the carburetor device, in addition to the throttle, there is a damper located at the inlet from the air filter. It artificially reduces air flow, making the mixture richer for easier cold start.

The injector valve is responsible for fuel injection into the main chamber, it also prevents air from entering. When adjusting the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct effect on engine performance. Long-term storage may cause the nozzle to stick. This will restrict fuel flow and prevent the engine from starting.

Also, from prolonged use or due to a factory defect, the valve can let air into the main chamber. In this case, only replacing it will help fix the problem.

The carburetor works as follows: the air flow, entering the diffuser, is mixed with the injected fuel, the resulting mixture is fed into the engine. The amount of the mixture is regulated by the throttle valve. The more mixture, the higher the engine speed.

Adjusting the carburetor of your Husqvarna chainsaw.

First you need to find the Highest idle speed by slowly turning screw L clockwise (or counterclockwise). After finding the position Highest turns, screw L must be turned back 1/4 turn counterclockwise. If the chain rotates at idle speed, return the screw T forgiven clockwise until the chain stops.

How to properly adjust the carburetor on a Husqvarna chainsaw

How to tune the carburetor on a chainsaw Husqvarna Chainsaw carburetor adjustment with 3 THL screws.

Chainsaw carburetor adjustment

Most chainsaw carburetors have three adjustment screws:

- L. jet screw for adjusting low speed

- H. jet screw for high speed adjustment

- Screw. T in partner and Husqvarna (in Stihl LA). adjusting the idle speed of the chainsaw

Screws H and L adjust the ratio of the mixture of gasoline and air, determined by opening the throttle valve of the carburetor. When the screws are unscrewed, the mixture is enriched, and the revolutions increase accordingly, when the screws are tightened, the mixture becomes leaner. the revolutions fall.

The screw T (LA) is designed to adjust the idle speed. The basic setting of the chainsaw is made at the factory during the final test. The carburetor is usually adjusted for a richer (than optimal) fuel mixture. The factory setting must be maintained during the first hours of saw operation. Then (optional) a more precise carburetor adjustment is made.

We begin the adjustment by setting the idle speed, for this we turn the screw T (LA) counterclockwise, achieving a complete stop of the chain at stable engine speeds.

Humidity fine adjustment will need a tachometer and it is better to entrust it to specialists. Especially since in most cases it may NOT be needed.

We start setting up the tool with the L screw, then use the H screw and finally the T screw (LA).

We look for the highest idle speed, for this we slowly turn the screw L in different directions. After finding the position of the highest engine speed, it is necessary to return the screw L by 1/4 turn counterclockwise. If the chain rotates at idle speed, the screw T should be turned clockwise until it stops.

The screw H adjusts the power and speed. Adjusting the carburetor to a lean mixture leads to excessive speed, overheating of the engine and failure of the piston chainsaw.

We warm up the engine of the chainsaw at idle speed for at least 10 seconds and turn the screw H 1/4 turn counterclockwise. Let the engine run for about 10 seconds. Then we check the maximum engine speed with a tachometer. If the maximum speed does not match the passport, the operation should be repeated. When the mixture is too rich, the muffler starts to smoke, when the saw is too lean, it squeals and overheats.

We begin the adjustment by adjusting the idle speed, as already described above. The idle speed is set correctly if the engine runs smoothly at minimum speed and the chain does NOT rotate.

The carburetor can be considered adjusted if the engine accelerates quickly and sounds like a four-stroke at full throttle.

How to understand that everything is done correctly?

The carburetor is properly adjusted if the engine accelerates immediately and is noisily running like a four-stroke at full throttle. Adjusting screw L to a too lean mixture leads to difficult starting and poor acceleration of the engine.

When the throttle trigger is smoothly pressed, the engine should confidently and quickly pick up revs from idle to maximum (from 2800 rev. To 11500-15000 rev. Depending on the unit). If revolutions are gained slowly, with a delay, screw L must be slowly Unscrewed counterclockwise, but no more than 1/8 of a turn.

After adjusting the acceleration and maximum speed, the saw should be checked again at idle speed. the engine should be stable, the chain should not move. Chainsaw tuning should be repeated if this condition is not met but with the exception of the basic adjustment step.

# Spoiler # end_spoiler