How the gas trimmer carburetor works and works

It is almost impossible to cover all types of carburetors produced by manufacturers of gas trimmers. But, since the design of this module, as well as its principle of operation, is largely similar between different models, a generalized description of the processes occurring in the carburetor can be made. This information will allow the user to understand the principles of operation of the device, eliminate the malfunctions that have arisen and operate it correctly..

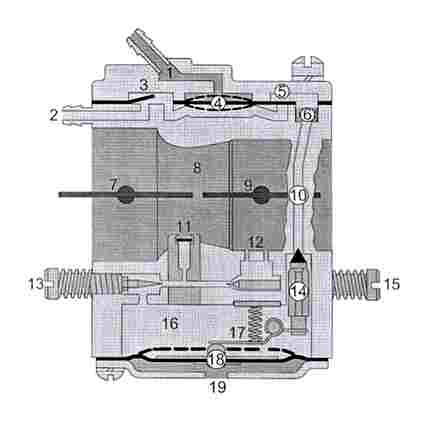

The carburetor trimmer is based on a one-piece aluminum body. Below is a diagram of this block.

At the bottom of it, there is a diffuser, which is also called a Venturi nozzle (18). Air is drawn in by the motor through this nozzle..

The smaller this hole, the faster the air flows, and the higher the level of its rarefaction in the zone with the smallest diameter.

The top of the diffuser contains the fuel channels (11,12). Through these channels, the flow of air draws in gasoline. The fuel pump itself, jets and the system used to regulate the supply of a mixture of fuel with air can be built-in or installed externally.

The throttle valve (9) controls the amount of air sucked into the carburetor. Its amount affects the power that the engine develops. The damper (7) is used for cold starting. It must be closed if you are going to start the unit. After the engine has started, it must be opened, otherwise, the engine will immediately stall.

The impulse channel (1) connects the impulse chamber of the pump to the crankcase of the engine, namely, to its internal volume. The piston located in the cylinder, producing reciprocating movements, successively changes the pressure in the crankcase (vacuum or pressure increase). The pressure drops force the diaphragm (4) to move. Therefore, the operation of the pump is synchronized with the operation of the engine..

The suction of gasoline from the tank occurs precisely with the participation of the membrane (4). Gasoline enters the carburetor through the union (2). Further, its path lies through the inlet valve (3), the exhaust valve (5), through the mesh filter (6), the fuel channel (10), passes the needle (14) and fills the chamber (16), which has a control diaphragm (18).

The valve (14) is connected to the diaphragm (18) by means of a lever (17). The cavity, which is located below the membrane, is connected to atmospheric air through the hole (19).

The device functions as follows.

- A vacuum is generated in the diffuser during the suction stroke. This fact causes air leakage. The position of the throttle valve (9) determines the amount of air entering the carburetor chamber, as well as the engine power and the number of its revolutions..

- At this time, fuel is sucked in from the chamber (16) through the jets (11,12), after which it is mixed with the flowing air. Gasoline, mixing with air, begins to spray. Thus, an air-fuel mixture is created..

- The finished mixture enters the cylinder, where it is compressed by the rising piston and ignites at its highest point from the spark generated by the spark plugs.

- Since the volume under the control diaphragm (18) is connected to atmospheric air through the channel (19), the diaphragm goes up, opening the valve (14) by means of the lever (17). After opening the valve (14), a new portion of fuel enters the chamber (16).

- After the chamber (16) is full, the diaphragm (18) returns to its original position, and the valve (14) closes.

Further, when the motor is running, all the above processes are repeated. A screw (13) is used to adjust the amount of fuel entering the diffuser through the nozzles. The screw (15) is also used to adjust the idle speed. When the regulators are twisted, the fuel mixture is enriched, and when the regulators are twisted, the mixture becomes lean. Also, in some models of carburetors, you can adjust the idle speed of the engine with a quantity regulator. It is usually located outside and, when twisted, abuts against a lever attached to the throttle shaft..

Thus, using 3 adjusting screws, you can achieve maximum engine performance, as well as adjust its smooth operation at any ambient temperature, and even in mountainous areas..

Intake Adjustment Lever Problem

This problem can occur if the adjusting arm is not properly installed or if it is bent before installing. As a result, the contact surface takes the wrong position, which disrupts the additional fuel supply..

Damper wear

The throttle and choke valves are mainly subject to wear due to the presence of abrasive particles in the air. Defective dampers look like they have been sandblasted.

As a result of valve wear, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder coating wear out.

Clogged control cavity

If dirt accumulates in the control cavity, then the inlet needle cannot tightly close the hole and a lot of fuel pours into the chamber..

This causes over-enrichment of the fuel and the engine starts to malfunction. It is necessary to disassemble the carburetor and clean the cavity of the control membrane.

Intake needle wear

The inlet needle fails, as a rule, due to the presence of abrasive particles in the fuel fluid.

- the tightness of the inlet needle seat is disrupted;

- there is a leakage of a combustible mixture;

- there are malfunctions in the engine operation associated with re-enrichment of the fuel mixture.

Also, the inlet needle may just jam.

A jammed inlet needle can cause dirt in the fuel or a long idle time..

Fuel pump problems

A common malfunction that “pursues” the fuel pump is the deformation of the pump membrane. For this reason, it does not fit properly and the pump passages are not sealed..

The reasons for membrane deformation can be the following:

- long work of the trimmer;

- use of unsuitable fuel;

- ingress of gases into the impulse channel.

As a result, diaphragm damage reduces pump performance and, as a result:

- depletion of the combustible mixture occurs;

- it is difficult to start the engine;

- there are interruptions in the operation of the motor;

- the piston is damaged.

Also, the above-described consequences for the engine can cause clogging of the pump cavity on the impulse side. In this case, dirt enters the membrane through the impulse channel..

To remove the blockage, you will have to disassemble the carburetor and clean the membrane..

When to adjust

Carburetor adjustment is necessary in the following cases:

- the new engine was run-in (4-5 liters of fuel mixture were used);

- the composition of the fuel has changed (brand of oil and gasoline);

- the weather has changed (it became hot, cold);

- the rarefaction of air has changed (applies to mountainous regions);

- after long-term storage;

- increased load on the engine (after tool change, etc.);

- due to vibration, the adjustment screws spontaneously unscrewed;

- fuel consumption has increased, the carburetor overflows fuel;

- carbon deposits quickly appear on the spark plug electrodes (while the fuel mixture is prepared correctly);

- the engine starts and immediately stalls or gains momentum poorly;

- no gasoline enters the cylinder;

- large amount of exhaust gases.

Chainsaw carburetor device

Not a single repair event is complete without knowledge of the basics of the mechanism. By understanding the constituent elements and the principle of operation, it is easier to determine the cause of the breakdown.

Any malfunction in the carburetor threatens to stop the engine

The carburetor is one of the main functional parts of the engine, which serves to prepare and supply a fuel mixture consisting of certain proportions of fuel and air. As soon as the proportions are violated, the engine starts to “junk”, or even stops working altogether.

You can achieve the correct operation of the carburetor by examining its “stuffing”:

- Cross-flap tube for air flow regulation.

- Diffuser – Constriction to increase the air flow rate, located near the fuel inlet.

- Sprayer from which fuel comes (fuel needle in the diagram).

- Float chamber that regulates the fuel level at the entrance to the channel.

This is how it looks in the diagram:

The diagram shows the interaction of fuel and air flow

How it works: A jet of air in the diffuser atomizes the fuel, creating a mixture that enters the cylinder. The greater the amount of fuel supplied, the higher the engine speed. Different carburettors work in the same way..

When is adjustment necessary at all?

Specifically, adjusting the carburetor of a chainsaw is required in rare cases, more often problems arise related to the flow of fuel or wear of parts. But sometimes the “symptoms” indicate that it is necessary to precisely adjust the mechanism. Here are some signs:

- After the engine starts, it immediately stalls. Alternatively, it will not start at all. The reason lies in the excess of air and lack of fuel..

- Increased fuel consumption and, as a result, a large amount of exhaust gases. This is due to the reverse process – oversaturation of the mixture with fuel.

The reasons for the adjustment failure can be mechanical:

- Due to strong vibration, the protective cap is damaged, as a result, all three bolts lose their established fixation.

- Due to wear on the piston part of the engine. In this case, adjusting the carburetor of the chainsaw will only help out for a while, it is better to replace the worn part.

- Due to clogging caused by low-quality fuel, scale or damage to the filter. The carburetor requires complete disassembly, flushing and adjustment.

If the chainsaw suddenly stops working, you need to disassemble it to find out the reasons

Step-by-step instructions for disassembly

The carburetor device of models of different brands is almost the same, so take the Partner chainsaw as an example. We carefully remove each element and put it in order, so that later it would be easier to assemble.

Chainsaw carburetors from different manufacturers, if they differ, it does not matter

The top cover is removed by loosening three screws. Followed by foam rubber, an integral part of the air filter.

The arrows indicate the bolts that must be unscrewed to remove the cover

Then we remove the fuel hose, followed by the drive rod.

The upper arrow points to the fuel hose, the lower arrow points to the drive rod

Next, remove the tip of the cable.

The arrow shows the end of the cable to be removed.

On the left from the fitting, we pull together the gasoline hose.

We also carefully remove the gasoline hose indicated by the arrow

We finally disconnect the carburetor, it is ready for adjustment. Its mechanism is rather complicated, therefore, if further disassembly of the carburetor is required, the elements should be removed very carefully – they are small, so they can be lost.

The carburetor consists of many small parts, which should be laid out in order during disassembly.

Chainsaw carburetor adjustment: we analyze all the technical nuances of the work

Summer cottage construction and repairs are not complete without the use of a chainsaw, as well as garden maintenance. Due to a malfunction of the tool, all work can get up, so it is so important to be able to disassemble it yourself, find problems and fix them. With enough experience and dexterity, it is even possible to adjust the carburetor of a chainsaw – a complicated procedure, or rather, jewelry. How to carry out the adjustment procedures, we suggest you disassemble today.

Features of setting and adjustment

To find out how to adjust the carburetor on a chainsaw, you should learn to distinguish between three screws (some models have only one).

The L and H screws are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- “L” is for setting low rpm;

- “H” is needed to adjust the upper speed;

- “T” is needed to adjust the idle speed (for models with one screw, only it is present).

The factory setting is optimal, and with the help of the screws they adjust the operation of the engine in special situations (work associated with different climatic conditions).

The diagram shows the outputs of the carburetor adjustment screws with the lid closed

A special tool is used to set up the chainsaw.

Adjustment is carried out only with screws L and H. To increase the speed, turn them clockwise. To decrease – counterclockwise. The sequence of using screws: L – H – T.

If you have doubts about the adjustment, it is better to contact a specialist, since an incorrect setting can damage the engine..

Do-it-yourself chainsaw carburetor adjustment

Chainsaw carburetor adjustment ensures efficient operation of the tool at full power while saving fuel. Adjustments must be made with a clean fuel and air filter. For a larger number of carburetors, the adjustment is carried out with three screws: for maximum and minimum revolutions and idle speed adjustment.

The H and L screws adjust the ratio of the mixture of gasoline and air, which is determined by opening the throttle valve of the carburetor. When the screws are unscrewed, the mixture is enriched, and the revolutions accordingly fall, when the screws are tightened, the mixture becomes leaner – the revolutions grow.

The designation H refers to the maximum speed screw that controls the main jet, L. to the minimum speed screw that controls the idle jet. The S screw is used to fine-tune the idle speed. Sometimes, to simplify tuning, the number of available carburetor adjusting screws is reduced..

Chainsaw carburetor tuning is divided into two stages – basic (factory settings), carried out with the engine off. and the final, produced on a running warm engine. The exact value of the angles of rotation should be taken from the operating instructions for the particular chainsaw. Failure to follow the manufacturer’s instructions may result in engine damage.

Basic carburetor adjustment.

The adjusting screws for maximum H and minimum L turns are slowly turned clockwise until they stop, then turned back 2 turns, other settings are also possible

Checking and adjusting idle speed.

We find the highest idle speed, for this we slowly turn the screw L in different directions. After finding the position of the highest engine speed, turn the screw L 1/4 turn counterclockwise. If the chain rotates at idle speed, screw T or (S) should be turned clockwise until it stops..

Checking and adjusting the maximum speed.

The maximum number of revolutions is changed by screw H. When screwing it in (clockwise rotation), the revolutions increase when it is turned out. decrease. Chainsaw engines have the highest rotation speed of 11500 rpm. up to 15,000 rpm. A higher speed does not provide ignition, moreover, it becomes dangerous for the engine. The rpm limit can be determined by misfiring. If they come, turn the screw H slightly counterclockwise..

If the engine is not checked for acceleration and maximum speed, then the adjustment of the chainsaw cannot be considered complete..

Easily fix a trimmer that won’t idle

When the throttle trigger is smoothly pressed, the engine should confidently and quickly gain speed from idle to maximum (from 2800 rev. To 11500-15000 rev. Depending on the unit). If revolutions are gained slowly, with a lag, screw L must be slowly unscrewed counterclockwise, but no more than 1/8 of a turn..

After adjusting the acceleration and maximum speed, the saw should be checked again at idle speed. the engine must run steadily and the chain must not move. Chainsaw tuning should be repeated if this condition is not met but with the exception of the basic adjustment step.

Causes of carburetor breakdowns

When using lawn mowers (for example, “Patriot” or “Soyuz”), the carburetor may be damaged, and the user will need to repair it on his own or with the assistance of specialists. This can happen for a number of reasons. One of the most common is non-compliance with the rules for using the device. If, during prolonged operation of the trimmer, maintenance and adjustment of the carburetor have not been carried out, the device breaks down.

Another reason for the breakdown is an improperly prepared fuel mixture. Often, equipment owners buy oil and prepare fuel according to the recommendations written on the packaging of fuels and lubricants, which is incorrect. When preparing the fuel, you must take into account the operating instructions for the lawn mower itself. In addition, you should not make the mixture “by eye”, as incorrect proportions also lead to equipment breakdown..

Most of the breakdowns of carburetors are equally common for lawn mowers of different brands, be it Echo, “Cedar”, Homelite or a device from another manufacturer..

Principle of operation

A carburetor is a power system module in which liquid fuel and air are mixed before being fed into the engine cylinders. Mixing and flow are adjusted accordingly depending on the tool and its mode of operation..

The carburetor device for lawn mowers is the same for almost all cases. It belongs to the category of float devices. The latter provide stable parameters of ready-made mixtures.

The principle of the module is as follows.

- Air enters the body of the air damper tube. The latter increases or decreases the air flow depending on its position..

- In the area where the hole for the gasoline supply is formed, the tube has a narrowing – a diffuser. Here the flow rate increases.

- Fuel from the float chamber is fed through the nozzle into the tube. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal, and in the tube it is low due to the greater rarefaction of the air, gasoline is sucked in through the nozzle.

- The accelerated air flow picks up the fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through the pipeline.

The more open the air damper in the tube, the higher the density of the air flow, and, therefore, more fuel enters the cylinder. Adjusting the carburetor of lawn mowers is reduced to setting such a ratio of flaps, at which the density of the fuel mixture becomes optimal.

Instrument adjustment

After all the premature work has been done, you should already resort to adjusting the engine carburetor.

First of all, you need to do what the good work of the machine depends on – idle speed. Here it is necessary to take into account continuous operation at a speed of 50 km / h. You need to make sure that the car moves quickly and slowly.

Using the screws, adjust the idle speed of the car. After that, you should turn on the motor. You need to understand that if, after these manipulations, the revolutions of the machine become much lower, then they need to be returned to their normal state..

The next step is to place the propeller in such a position that the car will move at the same pace and without stopping..

Next, you need to find the point of the screw at which the engine stops working in such conditions. Such an operation is necessary to find the most correct screw position, at which the amount of CO will be the least.

In order to make sure that the adjustment has been made with high quality, you need to unscrew the screw during the engine operation, which is responsible for the number of revolutions.

If after these manipulations your car stalled, then we can congratulate you! This means that the vehicle has been adjusted correctly..

How the carburetor works

The functioning of the node is as follows:

- First, as a result of the stroke of air intake by the motor, a certain vacuum is created in the diffuser, which leads to the suction of air masses;

- At the same time, fuel seeps through the jets from the combustion chamber, which is subsequently mixed with air. After being enriched with air, gasoline begins to gradually spray, resulting in an air-fuel mixture;

- Further, the finished mixture enters the cylinder of the internal combustion engine, where the piston acts on it. At the top of the piston lift, the fuel is ignited by a spark generated by the lawn mowers’ spark plug;

- Due to the fact that the inner cavity under the membrane is connected with air from the environment through a channel, when the membrane rises, the valve opens. This leads to the supply of air into the cavity under the membrane;

- As soon as the chamber is filled with the fuel mixture, the membrane quickly returns to its original position. This also closes the valve..

The scheme of the unit operation is repeated constantly, throughout the entire cycle of operation of the garden trimmer.

Why do you need to clean and adjust the carburetor

The factory settings of Solex / Ozone carburetors are designed for a certain fuel quality and the average driving style of the driver, and are made on a specific engine. And if the car is operated in accordance with the manufacturer’s instructions and on high-quality fuel, then carburetor adjustments can be avoided for a sufficiently long time..

At the same time, the parameters of the content of harmful substances in the exhaust gases must be checked at a technical inspection at intervals from two years (if the car is not older than 7 years) to one year (which is more likely for cars with a carburetor engine).

The process of adjusting the carburetor is carried out with two screws and may well be done independently (at least on a properly working carburetor). We recommend watching the video at the end of the article..

The operations here are simple: by consistently tightening the screws of quality and quantity, stable and smooth operation of the engine in the range of 800-900 rpm is achieved (for winter time, the range of 900-1000 rpm is recommended).

When self-adjusting the carburetor, it must be remembered that it is performed on a warm engine..

It is a different matter when malfunctions appear that may be associated with the operation of the carburetor. Most often this is the overflow of gasoline in the float chamber and unstable idle speed. In the first case, it is necessary to adjust the position of the float (respectively, the needle valve) or replace the chamber parts, and in the second case, it is not the carburetor that is most often to blame, but the “jamming” of the “gas” cable, which must be eliminated.

Sometimes carburetor malfunctions can manifest themselves in dips and jerks when driving or sluggish gaining power. However, similar symptoms can occur due to malfunctions of the ignition or fuel supply system, therefore, before disassembling the carburetor, you must make sure that these systems are in good working order..

The quality of the fuel can also significantly affect the performance of the carburetor, so it is necessary to periodically (at least once every 50 thousand km, and more often if the fuel is obviously bad) to clean it from dirt and deposits. There are a lot of cleaning agents now, you just need to remember that the most aggressive of them can harm non-metallic parts (for example, the material of the diaphragms).

In order to avoid the ingress of tissue residues into the carburetor, old fuel is usually removed with a rubber bulb..

To clean the nozzles, it will usually be sufficient to blow them with compressed air, and only in advanced cases may it be necessary to clean them with a soft copper wire..

Do-it-yourself lawn mowers carburetor adjustment

I started it several times in the same way

Tvvi9: any elastic part is called a spacer?

Sasha Sh: Good time everyone. The third day they try to trim. The problem is what. About 20 minutes, half an hour working like a beast. Then he gradually begins to choke, and eventually kirdyk. They disassemble the carb, blow it out, put it on, and everything for a maximum of half an hour. I thought it was warming up, and left it until morning. Until I get into the carburetor, no changes. I tried to put another carburetor. Same. The leader changed the filter. The adapter on the cylinder too. Also hoses, candle.

Question. Can oil seals suck in but not eject oil? Because it’s dry. It’s dry under the cylinder too.

Ivan Ivanov: You are more useful than the government …

Tatiana Yu: For a forest dweller, try to clean the exhaust from carbon deposits and tighten all the bolts.

Artyom Lesnoy: You do not know what the reason is, the trimer is idling, you let the gas stall, the fuel filter is clean and air filter.??

Artyom Dobritsa: Good day. Need some advice. When you press the gas trigger several times, the trimmer starts to gain momentum sharply, holds for 2-3 seconds at high speeds, then recession and stalls. This is because of the carburetor?

djandrej1991: Tell me what the problem may be – after work, the mixture flows out of the carburetor (from the air damper), there is no leakage during operation, but the trimmer is unstable, often stalls. I increased the flow of the mixture, began to work better, but it heats up very much, after turning off the gasoline hisses in the carburetor. Trimmer Elitech T 1150

Taras Ivanov: greet everyone. Benzotrimer storm, it starts up on a cold one, after warming up horseradish you will start. A small amount of gasoline into the plug hole helps, and so on all the time. At idle, it is not stable, it works more or less under load. I went through all the gaskets, plus sealant. I sin on the crankshaft oil seal (air leak) What can you say about this?

Diy lawn mowers carburetor adjustment

Setting up the module does not apply to repair and replacement of spare parts is not required. In this case, the lawn mowers carburetor repair kit will not be needed..

Three screws are provided for debugging:

- L – is regulated first, since it is responsible for supplying fuel at low speeds;

- H – he is responsible for the supply of gasoline at high speeds, as well as for fuel consumption and temperature;

- T – it is used to debug idle.

There are options, as a rule, this is the carburetor of a Chinese lawn mower, when only one screw remains on the body for debugging – for adjusting the idle speed. This does not mean that the module is configured automatically – it means that it will be difficult to carry out even such a type of repair as debugging. In the photo – adjusting the carburetor of a Chinese lawn mower.

- The module is configured only when the engine is warm: for this, the device is pre-switched on for 10 minutes. If the mowing head rotates at idle speed, then the debugging is started immediately: turn the screw T counterclockwise until the rotation stops.

- Adjustment begins with screw L. The screw is turned to the right and left until it is found such a position at which idle speed does not become maximum.

- Then the screw is turned ¼ turn counterclockwise. This will be his working position..

- Idle speed must be adjusted by turning counterclockwise to increase the number of revolutions and clockwise to decrease it. Its debugging consists in achieving such a mode in which a sufficient number of revolutions are made before the start of rotation of the mowing head. In this case, the engine must work stably at different positions.

- The position of screw L is determined last – at maximum speed, the trimmer should not work for more than 10 seconds. The throttle opens, the screw turns clockwise, very slowly, until a decrease in the number of revolutions is audible.

- Then, also slowly, the screw rotates counterclockwise until the motor starts to malfunction. Then the screw is turned back clockwise until the engine starts working normally again..

If there is a tanometer, and if the recommended rpm values are indicated in the product passport, the correction can be made more accurate, focusing not on hearing, but on the readings of the device.

The adjustment of the carburetor of the lawn mowers in the video was carried out by ear.

7 comments on the post “Adjustment and repair of the carburetor lawn mowers”

- Dmitry Pavlovich 07/04/2016

Please clarify. In the adjustment section p. 5, screw L – error? Should you read screw A? Thank you.

prompt the initial position of the screws H L LA

SHOW START POSITION

prompt the initial position of the screws H L LA

Thank you very much for the video about the accelerator and did not know, but the defect is very important and creates a huge problem that almost everyone is silent about. BRAVO….

Maybe all the same tachometer is a rpm meter, and not a tonometer blood pressure meter

and I have L, H, LA, it’s LA instead of T?

The heart of any chainsaw is a two-stroke internal combustion engine..

The trimmer is not a complex household appliance, so most of its floor.

There was a need to purchase a reliable and reliable mechanical tool.

Gone are the days of Soviet agro-industrial gigantomania. Gig gone.

Tiller is an economical tractor option for small-volume jobs.

Tiller Neva is produced today in different modifications, this one is specialized.

Gas trimmer carburetor repair tips

Regardless of the manufacturer, there is a factory defect in the carburetor parts of the lawn mowers.

Spring for adjusting screw

For example, the tuning technique described above may not give positive results if the number of turns at the spring of the screw for supplying the mixture is too large and, as a consequence, the impossibility of optimally reducing the level of supplied gasoline. To eliminate this, you can independently shorten the spring a little or, in accordance with the operating manual, purchase a new one.

Many lawnmower owners follow the fuel mixture recommendations listed there when buying oil..

Petrol trimmer oil

So, often the information on mixing gasoline with oil indicated on the bank differs from the instructions in the trimmer passport. As a result, black carbon deposits can quickly form on the spark plug, leading to a drop in power and increased fuel consumption. Therefore, when preparing the working mixture, you should follow the recommendations specified in the operating manual. In most cases, the proportion for a run-in ICE is 1:25. It should be noted that many tool owners prefer to prepare fuel “by eye”, which will certainly lead to rapid wear of the piston streamer in the event of a decrease in the portion of oil and the formation of carbon deposits on the spark plug with an increased amount of lubricant.

Tips for adjusting the trimmer carburetor correctly performed above will help to avoid not only engine overheating, increased fuel consumption, but also significantly increase the service life of other parts and assemblies of the tool

Pay attention to the operation of the lawn mowers in all modes and carry out the regulated maintenance and repair of the tool in time.

Engine idle speed adjustment.

Before you start adjusting the engine on gas, you should make sure that the engine runs stably on gasoline. To do this, it is necessary to adjust the carburetor as accurately as possible. Warmed up to operating temperature (80 ° C) the engine, first set the minimum stable crankshaft speed with the number screw and slightly increase it. Then use the quality screw to find the position at which the engine speed will be highest. If the revolutions become higher, then the screw of their number must be reduced and then returned to the increased ones. Again, but this time with a quality screw, you should achieve maximum speed (sometimes these steps have to be repeated).

Next, slowly tighten the quality screw until the engine runs with noticeable interruptions, and then turn the quality screw back one third.

So, the carburetor of a gasoline engine is adjusted to a normal mixture at a low crankshaft speed (750 … 800 min 1 ) idling.

Next, the engine should be turned off and proceed directly to adjusting it on gas, having previously produced gasoline from the carburetor.

In some designs of gas cylinder equipment there are metering tees with one or two screws for the amount of gas (see. fig. 2.15, item. 16), and in others one screw on the gearbox (see. fig. 2.13, item. eleven).

Before starting the adjustment, the screws of the dosing tee should be unscrewed by two or three turns..

The screw for the quantitative adjustment of the carburetor throttle valves in gearboxes with an idle speed system must set the minimum speed for this engine model.

Removing the idle screw (cm. fig. 2.9, pos. 4 and fig. 2.10, pos. 2), make sure that the engine operates at an increased crankshaft speed (1100 … 1300 min 1 ). If the speed does not correspond to the specified values, it must be achieved by adjusting the number of throttle valves with the screw. Tightening the idle speed screw of the gearbox, set the increased crankshaft speed (900 … 1000 min 1 ).

Some gearboxes have both an idle speed adjustment screw and a pressure adjustment screw for the second stage of the reducer (see. fig. 2.9, pos. 3), which takes effect last.

In gearboxes in which there is no idling system, adjustment should be made with the pressure screw of the second stage of the reducer (fig.2.12, pos. 10; fig.2.9, pos. 3; fig. 2.13, item. 12a).

This method of adjustment, in which the crankshaft speed is set to 15 % more than the idle speed, it is very uncomplicated. By unscrewing the pressure adjustment screw of the second stage of the reducer, set the maximum frequency. The number screw is achieved to return to the initial increased frequency and again the initial crankshaft speed is set with the pressure adjustment screw of the second stage of the reducer. The mixture quality screw on the carburetor should not be used with gas fuel.

It should be borne in mind that when the screws of the metering tee are turned out as much as possible (one or two screws for the amount of gas), the engine performance is improved, but at the same time, the fuel consumption increases. If the engine runs stably, you can slightly reduce the amount of gas supplied in order to save it. The optimal position of the throttle screw is usually set when the car is moving at a speed of 20 to 50 km / h in 2nd, 3rd and 4th gears.

To adjust the gearbox at any test speed, stop periodically, 2 … 3 times, and turn the gas amount screw until the car jerks..

In case of poor acceleration dynamics or dips in engine operation, it is necessary to unscrew the screw 1/4 of a turn, achieving good throttle response with a sharp opening of the throttles.

In case of unstable operation of the engine in any modes or with an increased content of carbon monoxide in the exhaust gases, it is necessary to check the serviceability of the gearbox.

When adjusting the engine on gas, it is recommended to set an earlier ignition timing (by 3 … 5 0 for CIS and 8 … 10 0 for CNG) so that when driving on gasoline and a sharp opening of the throttle valves, a characteristic metallic sound is heard.

Dosing devices (fig. 2.35, a and b) have two adjusting elements; screw 5 and plunger 4. Screw 5 regulates the amount of combustible mixture supplied when the engine is running at partial loads, and by plunger 4 – when the engine is running at full load. This plunger has already been adjusted as shown in the Gas Dispenser section..

Unscrew screw 5 to the limit, while the engine will run unstable. Set the engine crankshaft speed to an increased speed and screw in the screw 5, determining the moment of the termination of the engine interruptions. This completes the adjustment of the dispenser shown in fig. 2.35, ends, and the dispenser shown in fig. 2.35, still to be adjusted along the way of the vehicle. If you find poor acceleration dynamics or dips in engine operation, adjust the dispenser by turning the adjusting screw clockwise by half a turn each time until the engine starts to work clearly in all modes.

It is much easier to adjust the SAGA-6 gas equipment. There is only one adjusting screw in its gearbox..

If a sudden drop in engine thrust is felt while the vehicle is moving, release the accelerator pedal immediately and press it again after a while. This is explained by the temporary depletion of the mixture, a slowdown in the rate of its combustion in the cylinders. The reason for this phenomenon is the same as the cause of pops in the carburetor when running on gasoline: the cooling system does not work well, one of the spark plugs is faulty, the head gasket is broken, the valve is burnt out, the ignition is incorrectly installed.

How To Adjust the Idle Speed Screw on a Trimmer/Blower

When the ignition is turned on, gas can enter the mixer, which is felt by the smell. Reason: the tightness of the valve of the second stage of the reducer is broken. Remove the second stage cover and repair or replace the valve seal.

Starting a cold engine on gas fuel is possible at an air temperature above 5 0 C. At temperatures below 5 0 C the engine must be started on gasoline. To do this, when entering the garage upon returning from a trip or when the car is parked for a long time, switch the fuel type switch to petrol, and in order to avoid glow ignition of the working mixture, let the engine run 1 min at the minimum speed of the crankshaft at idle speed. Then turn off the ignition.

When starting the engine on gas, if the mixer is installed between the carburetor and the air filter, do not press the accelerator pedal in order not to reduce the vacuum in the throttle space. The air damper must be open.

For an engine running on liquefied gas, the same type of spark plugs is practically suitable as for a gasoline engine. In exceptional cases, with weakened sparking, the spark gap between the electrodes can be reduced by 0.1 mm.

If the car is operated only on gas, during long journeys at a constant high speed, then it is possible for 2 … 3 0 increase the ignition timing or use colder plugs.