RPM

RPM or idle speed is another important characteristic that determines the efficiency of the machine. This ranges from 3,200 to 6,000 rpm for the various models. The higher the idle speed, the better the cut is on the mitre saw.

Professional models have variable speed capability. It makes sense to pay attention to it first of all for cabinetmakers and everyone who uses a face mill for carpentry needs. RPM adjustment of the saw blade makes it possible to adapt cutting process to the material in question: different types of wood, chipboard, etc.д. For “flow” sawing work at high RPM to achieve greater speed and productivity. Reducing the RPM gives you more control over sawing, which is important when cutting critical parts.

There are two types of saws available on the sales network. Some fit the billboard’s intended use, while others come with extra features.

different saws are available in terms of price and manufacturer. Makita, Interskol, Bosch, Metabo and others.

A crosscut saw includes a motor, a saw blade with which the cuts are made, a footrest where the engine start button is installed, a handle which holds and guides the saw.

Every kind of this tool has a disc. The discs can be made of different solid metals. For this reason the saw is indispensable for any work in the household.

The crosscut saw motor can be fitted with a collector or an asynchronous motor. Collector motors do not require constant monitoring and lubrication.

Asynchronous motors will last longer, they make less noise when working. The motor is often located on the right side of the cutting element.

There are some models of the saw where it is mounted on the rear side. In this case, the visibility when working with your hands is improved.

The motor drives the disc through a gearbox. It can be driven by gears or belts.

When using belt transmission, the machine makes less noise, while working, vibration of the cutting part of the saw is eliminated.

The toothed gear does not allow the tool to slip when cutting material at high loads.

There is a type of trimming saws, which have a special surface on which the work is done. All operations will go quickly, accurately.

Such a tool is not a machine tool, but it is preferred to be used in workshops, to work with their own hands at home.

Some types of end saws are equipped with a broaching function.

In them, the disk is mounted on parallel slats and carries out free movement. Such a device has an increased width of the cut.

Is it possible to cut metal with a crosscut saw

There are quite a few tools for cutting metal, but only the pendulum (or socket saw) provides the ability to make an angular cut.

With its help, window stops, door frames and many other products that are used everywhere.

However, in this article will be specifically considered only facing (pendulum) saw for metal.

General Information

Along with circular and circular saws as well as jigsaws, trimmer can cut metal profiles, sheets, different types of pipes.

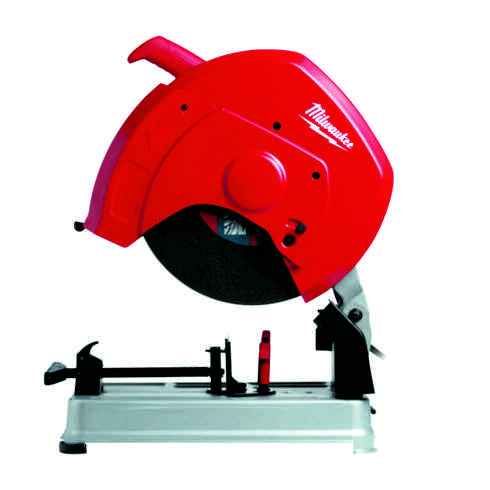

The structure of the device is very simple. key elements are: gearbox, saw blade, frame (base), handle with the “start” button, motor. The latter is divided into two varieties:

The advantage of the collector type of saw is ease of maintenance, the asynchronous type. long life and less noise during operation.

The motor with the saw blade is connected by means of a toothed or belt transmission. They have their disadvantages and advantages. For example, the belt saw is practically silent. It eliminates the vibration of the disk, but is capable of slipping off the base during prolonged work, forcing the owner to stop the work process. The toothed saw is free of this disadvantage, but instead it makes noise during work and gives a slight vibration. The working tool in a sabre saw is the blade. It is made of strong types of metal, because it carries all the main and quite serious load.

On the planes of some removable components of this type of saw there are cuts or wavy mowing line. This is conceived to reduce the noise level during operation, as well as to compensate for deformation that occurs at high temperatures.

According to the purpose we can distinguish household equipment, professional and machine tools. The first are characterized by low power (no more than 1500 watts), compactness and For example, Bosch GKM 18 (cordless, cost. 15 thousand. р.).

Pendulum saws: a variety of types

A crosscutting tool lends itself to classification much more easily than, for example, an electric jigsaw, which can be either electric or mechanical. The mechanisms under consideration can be divided by criteria:

Examples may include such products as:

- Bosch GKM 18 saw (cordless modification, cost about 15000 r.);

- Kolner KMS 210 saw (;)

- Domestic cutter “Kalibr PTE-900” of 900 W power at a cost from 4500.

Trimming machine is not a piece of equipment for household purposes, used only at the plants that produce rolled metal products, and every day involved in their cutting or processing. Sold such units for tens, and sometimes hundreds of thousands, their capacity exceeds 1000 watts, and weighs several hundredweight.

- Machines of domestic manufacturer;

- DT 10-4 (3 kW, weight 360 kg, price 105 ths. );

- CKB-40K (power. 5,5 kW, weight ca. 700 kg, price 340 ths. ).

Professional metal end saws for profiles, sheets and pipes according to the marked parameters occupy an intermediate state. For example:

Makita LF 1000 (power 1650 W, cost from 60 ths. ), DeWALT d27111 (power 1500 W, price from 50 ths. ).

The presence of a broaching function gives the user a certain advantage when working with long plates or pipes.

The models have two parallel slats on which there is a freely moving disc.

Converting a 18v Miter saw into a Metal Cutter Easy as a blade? | Tenryu Steel-Pro Stabilizer

The broaching tool is distinguished by a solid cutting width of the workpiece and the addition of very fine teeth on the disc. In addition, the tool in some cases has a laser pointer for process control and easy marking.

Trimmer for metal, equipped with a broach, has a weight higher than usual, and the presence of an option increases the cost by 25-30%.

Cutting blade size is the central criterion for classification

The sizes of teeth determine the width and depth of cut, and the material is determined by the possibility of using the unit on a particular metal.

Trusted manufacturers

Below are recommendations for a preferred brand of mitre saws. Based on customer reports and forum information.

Optimal face saw in terms of comfort, manufacturability and safety at work is considered a product of one of the following firms: “Corvette”; DeWALT; Metabo; Makita; “Interskol”. Hitachi; Bosch.

Most of these manufacturers provide an extension of the special table under the workpiece, however, for the cutting of large parts in some cases requires additional support. You can find these, for example, in the LF 1000 trimmer from Makita. This addition greatly simplifies the work of the user. In addition, the moving part of the metal saw is included in the stable frame, which has a place to assemble the angle of cut.

The best crosscut saw, in terms of stability and reliability, is the one, whose frame is made of magnesium or aluminum alloy. They are stable, durable and also have an acceptable weight. An example is the Bosch GCM 10, which is the most popular modification among professional models. With all other advantages, it weighs only 15 kg.

The leading manufacturer of hacksaws with the permitted cutting edge inclination to the workpiece is Hitachi. Whereas Bosh, Metabo or Makita mostly allow measuring cutting angle of only 0, 90 or 45 degrees, this Japanese company gives the operator an opportunity to make cuts of 30, 15, 22 and even 5 degrees. The option provided makes it necessary for the operator to add a pivoting device to the design of the device. Nevertheless the weight of the system for cutting sheet metal, pipes or profiles would not exceed 30 kg. However, the cost will also increase by 15 to 25 percent.

The manufacturer of saws DeWALT distinguishes advantageously the presence of the XPS system, which allows you to project a clear line. A shadow projection from the saw blade occurs before the start of work, making the metal sawing more accurate. Models of the domestic manufacturer “Interskol” are, in terms of design, very simple, because they have:

Additional pluses of the device. are very affordable (you can pick up models from 5000), easy to hold on the weight.

To cut a metal sheet, profile or pipe, it is necessary to turn either the disc or the table. The disc can rotate on its axis and against, which is very convenient for the work of the master.

Before making a purchase, we recommend that you pay your attention to the models of the above manufacturers, weigh all the advantages and disadvantages.

Tips for choosing a crosscut saw

Now let’s touch on recommendations for optimal investment of money in equipment. Posted below tips before buying a tool is a must-read for every potential user.

For infrequent and short-lived activities, select household equipment according to the following parameters:

For permanent jobs, the purchase of professional equipment is recommended. Optimal parameters for it:

The more powerful the motor, the less heated it will be in the process of work, the greater will be the efficiency of the tool, respectively, the larger can be the disk, which can be put on its own. This may be necessary in case it needs to be replaced.

Some circular saw blades have a manufacturer’s recommendation for the material or types of material to be cut (pipes, sheets or profiles). This is also worth paying attention to.

Saw models equipped with a spacious blade for larger and more comfortable work are more expensive, but cutting metal on such units is incomparably more convenient. Their design also welcomes the presence of a depth stop, so you can find the optimal slot for the processing of the workpiece width.

Is it possible to cut metal with a crosscut saw? Trimming saw: how to choose a wood mitre saw? How to put a cutting disc on a crosscut saw

Processing metal sheets in small volumes can pose the problem of choosing between different types of tools. Two or three logs can be handled with a regular hand saw, without having to worry about power lines and other logistical problems. Full-size machines will help to serve even a dozen products in a few minutes, but it is not rational to buy such equipment for domestic use. The best choice is a metal facing saw that is mobile, productive and has a wide range of functions.

Tips for selecting a crosscut saw

The following tips are required reading before buying a tool.

- For rare and short-term work choose household equipment (low power, compact size, ), for permanent. professional (price from 15 thousand and above, the power. more than 1 kW).

- The more powerful the motor, the less heated it will be during operation, the higher the tool performance and the larger the disk can be supplied by your own hands when you need to replace it.

- Many discs show the manufacturer’s recommendations for the material to be cut or the type of material (for sheets/tubes/profiles); pay attention to this.

- Models with a spacious blade for work are more expensive, but cutting metal on them much more convenient.

- The design welcomes the presence of a depth of cut limiter. so you can choose the groove to work the width of the workpiece.

- Consider whether or not you need laser light, tractor broach and other similar options. If not, don’t overpay.

- If the blade guard does not cover the blade during cutting, this is a bad tool that is dangerous to use.

- The wider the workpieces you cut with the mitre saw, the larger the blade diameter should be.

- The heavy weight of the device will cause fatigue when cutting, even though the cost is higher than for its compact counterparts.

This material briefly examines the types of crosscut saws for metal and advice on choice. You can describe your experience of using the devices or give advice on choosing a tool to the visitors of our site.

Why it is important not to make a wrong choice

Before you start working on any material, it is important to know what kind of electric saws there are and choose the right disc intelligently.

The following aspects should be taken into consideration:

Do not grab the first wood circular saw blade that comes to hand and carry it home to install it in the saw, you should first carefully study the information on the packaging. Always pay attention to the marking: speed and dimensions must be indicated. The pictograms below show the material for which the disc is meant to be used. The information about the cutting direction should also be included.

Popular disc manufacturers and high price of discs

Bosch

German company and leader in the manufacture of power tools and related materials. Large variety of cutting heads for bucking machines: diamond and abrasive cutting discs for stone, metal and wood. ISO certified products.

Characteristics of Bosch wheels on the front of the disc

Canadian manufacturer of professional and household tools. The range is represented by a wide choice of cutting discs for metal and stone.

Dremel

American company. Produces high quality power tools. There is also a wide range of bolt cutter bits:

Husqvarna

Swiss company known for its high performance and level of durability of its products. Wide range of diamond and abrasive cutting discs. The negative point is the high price.

MESSER

Korean manufacturer. Rich assortment of nozzles for bolt cutters:

- carbide wheels on high-carbon steel;

- Segmented diamond for concrete and asphalt;

- Discs for cutting ceramic, porcelain and marble.

Russian company. Produces power tools and cutting equipment. Wide selection of universal angle grinder attachments.

Hitachi Power Tools, Luga Abrasiv Extra

Luzhsky abrasive factory”, JSC manufacturer. Excellent price. quality ratio. You can find budget options in the range, which does not affect the quality of products.

Metal mitre saw: types, reliable manufacturers

ImhoDom Forums hands out of the shoulders Cutting profile pipe with an end saw with a metal disk. it is possible? There are 9 replies in this thread, 7 participants, last updated by kaifsheg 5 years/years, 11 months. back.

Greetings. No pendulum saw and/or band saw on hand, t. ч. the question arose, but need to make a cut on a profile tube (ferrous metal, 50x50x2).

Accordingly, the question. is it realistic to use a crosscut saw with a disk on metal (cut-off) and, if so, what should be the speed/power?

Is it realistic to use a jigsaw with metal saws and, accordingly, what should be the power?

1.Buying a band saw/pendulum saw doesn’t fit into this design budget, cutting to order, again, ruled out. too much hassle with shipping, etc.

The problem with an angle grinder is getting more or less close to 90gr. cut, that’s why you want to use an end trimmer (which has a 90g. exposed) or a jigsaw on a guide rail.

Budget, here’s a pendulum for a simple angle grinder.

On a facing tool, you can put a disc for metal, but on the angle grinder. disk on wood can not, the speed is different, it can all end badly.

Maybe someone will be useful, I have long since I do not use abrasive discs, such as meadows All discs we use are “turbo” diamond discs for stone, one disc lasts for a year or two. At a price of 300-500r it pays for itself in 10-20 times.

There are cutting machines for metal. Price Interskolovsky and other Chinese about 2.5k (probably). They are just for abrasive discs. I would not spoil a slicer. There is a lot of plastic on it, and as you know it burns from sparks. And yet for facing discs there are discs for metal with hard-alloy tips (disk with teeth, but another form compared to the wood). It costs about 6 thousand.

Something you, my dear, you bent 6 thousand for the drive. At these prices, it is easier to buy an angle grinder assembly with a pendulum.

Jigsaw. definitely not considered, nonsense, sawing pipes with a jigsaw.

Trimmer with a cutting disc. the saw will not last long, the disc will not fit, it is necessary to koryat adapter, and the speed of power is not the same also not an option

Stand for the angle grinder. flimsy, uncomfortable, the angles float, it is desirable to mount it permanently, otherwise the angle grinder can behave unpredictably. If you don’t have much to cut, you can do with it. the lesser of two evils. But if in the future it will be necessary to saw, I strongly advise to buy a cutting machine. 6-8 thousand, but it’s worth it.

It might come in handy for someone, I haven’t used abrasive discs like meadows for a long time We cut everything with a diamond turbo for stone

And what kind? I have tried several. they get very hot. I tried solid, for waterless cutting

I had a matrix went a year, everyday use, until the car was not opened, and the angle grinder did not do legs saws slower than the abrasive, but the roof beats off for 2-3 days and tiles, and sawed pipes and rebar.

And really bent. Apparently, I was deceived by the store manager.

I saw how such a disc sawed the corner with the shelf in 5 mm. thickness. Saws!

Sidewinder in the usual sense can cut wood, plastic and soft metals (aluminum). profile). Such saws typically have a capacity of 1.3-1.8 kW, drive up to 200-300 mm, speed 4000-5000 rpm.

Pipes and other metal is sawed with cut-off machines. they look similar to mitre saws but have different characteristics. power of 2.2 kW, drive from 350 mm, speed up to 4000 rpm.

at seemingly small differences in performance, linear speed of a circular saw blade will be about 1.5 times less than that of a cut-off saw, with more power of the latter. So, the facing disc just can’t take the load when sawing metal.

we mustn’t forget about problems connected with compatibility of tools and disks (thicknesses, diameters, seating dimensions).

We choose the machine. to be able to do everything!

Choosing a tool, at an external review and feeling you should pay attention to the absence of gaps between the parts, the accuracy of fixation in different positions, the ability to rotate the working part in all planes, as well as the presence of all kinds of scales of settings, through which and gets to do cuts at completely different angles. Compare the RPMs of the machines: the higher the number, the cleaner the cut. 4000-5000 rpm is a good indicator for such a tool!

It is desirable that the tool has a function of quick braking, which provides a quick and smooth stop saw after it is turned off, and the soft start system will not overload the electrical system at the start-up. It is mandatory to have protection against accidental switch-on, as well as general protection against overheating, power surges. Some models of trimmers are equipped with depth of cut limiters, thanks to which it is possible to select grooves in materials or to process parts with a strictly fixed thickness.

Based on the tasks you intend to assign to the machine, think about which option you should choose: the unit can be both stationary and portable. In the first case it is better to prepare a suitable platform for the tool. to make a long and narrow work table, divided into two planes by a saw. The left side of such a machine should be three times longer than the right side for right-handed people, and vice versa, left-handed people should swap sides. The width of the table is enough to make within a quarter of a meter. the finished result will really make cutting easier, and most importantly more accurate!

When you buy a saw, for example, for a construction crew that travels from site to site, it is best to buy a small mobile unit. By the way recognized manufacturers produce quite tiny models (10-11 kg) with very high power parameters. one can work with such models the whole day without stopping! Therefore, small does not mean weak, especially if it has a 1500 W motor under the housing.

Buying a high quality saw you can be sure in the quality of the circular saw blade that is initially installed on it. With such a saw you can even perform finishing trimming of wooden and plastic parts. However, for rougher works, it is better to buy an inexpensive blade. if you will use the tools as intended, the cutting element itself can last up to 10 years! The main thing is to sharpen the teeth in time. do it with a regular file, clamping the blade in a vice.

Metal saw due to the high speed performs cutting even with a blade not designed for this purpose, but this does not mean that it should be so! For sawing aluminum profiles buy a special saw. having a large set of saws, you will prolong the life of each blade at times, and to repair trimmer saws will not have to apply often! For particularly critical work, in which it is very important to make the cleanest cuts, it is better to buy and a new blade. such costs will pay for themselves.