Silicone LED strips: features, types, installation

Lighting the ceiling or kitchen unit requires the use of not only the strip itself with a power supply. We will also need other parts:

In principle, you can do without connectors, but then you will have to solder the wires to the strip, protecting the point of contact with insulation or heat shrink tubing. It turns out more reliable, but it takes longer.

In addition to the elements listed in the table, we will need:

- glue for ceiling skirting boards;

- solvent to degrease subfloor;

- primer for walls;

- double-sided adhesive tape or self-tapping screws for fixing the furniture plinth;

- connecting wires (two-core and four-core copper);

- heat shrink tubing for insulation.

For insulation, it is convenient to use heat shrink tubing, as in this photo

Tools for work

In order to perform the installation of LED lighting yourself, you need tools:

Tools and equipment for installation of the furniture profile

- A saw or a carpet knife to cut the plastic baseboard;

- A wire cutter (a device for trimming baseboards in corners);

- Trowels and glue brushes;

- rollers for primer;

- Pliers and pliers to work with wires;

- soldering iron with a thin sting.

- screwdriver for terminal blocks.

It is convenient to cut the ceiling tape with a wire cutter

What to do if the LED strip comes off?

The first thing to do is to assess the extent of the tragedy. If the LED strip is hidden inside the profile, you need to remove the diffuser and inspect its entire length. If the local sag is insignificant, you can get by with a few drops of superglue, without breaking the entire structure. If the situation has become critical, it is better to re-glue the tape. To do this, it will have to carefully dismantle it, and the base to which it was attached, clean off the remains of the old glue.

Then take a thin double-sided adhesive tape and stick it on the prepared surface, where previously was the tape. After that, remove the film from the tape and mount the LED strip on a fresh adhesive base. If you do it right and use good quality duct tape, high strength is guaranteed.

To re-attach the LED strip is recommended to use scotch tape well-known brand “3M”, which is a leader in manufacturing durable adhesives and products based on them. By the way, on the reverse side of some types of LED tapes you can also find the symbol “3M”, indicating the high quality of the adhesive applied.

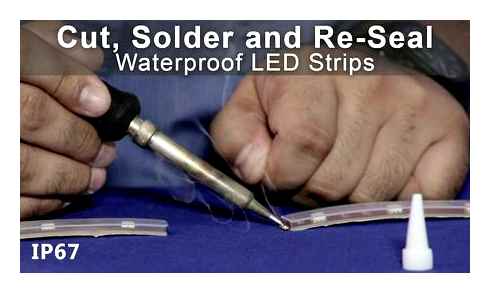

Can you cut the Waterproof LED strip?

Waterproof LED strip can be cut into segments of three LEDs or six (depending on the operating voltage of the tape DC12V or DC24V), but do not forget to seal the place of the cut.

Cut the LED strip on 220 volts can only be in special places. is a gap in a flexible carrier board length of 1.5-2 cm, containing only conductive tires under the silicone jacket. The cut should be made in the middle of this tear.

Why LED strip lights up different colors?

Different colors of LEDs can be obtained by simply painting the shell in one color or another. These LEDs are quite common, and at their core are the usual white LED. In this simple way you can get a variety of colors of glow.

To connect one-color LED strip with a length of 5 to 10 meters will need only the power supply for the strip and 2 LED strip spools. If you want to connect more than 5 meters of tape to a single power supply, each strip is connected to the output block directly or with additional wires.

Why do LED strips light up in different colors?

Different colors of LEDs can be obtained by simply painting the skin in a particular color. These LEDs are quite common, but at their core is a conventional white LED. That simple way you can get a variety of colors of light.

To connect the one-color LED strip length of 5 to 10 meters will only need a power supply for the strip and 2 LED strip spools. If you want to connect more than 5 meters of strip to one power supply, then each strip is connected to the output of the unit directly or with additional wires.

Is it necessary to observe the polarity when connecting the LED strip?

LED strips run on direct current, so they need to be connected with regard to polarity. In other words, such lights have a plus and minus, and the connection is carried out plus to plus, minus to minus.

When you connect with your own hands must be sure to respect the polarity. And if you connect more than one fixture, you need to connect the “pluses” to the “minuses” in series. It is important to keep in mind that the total power of the lights must not be greater than the power supply.

How to connect the LED strip. scheme

Modern light sources, which will be discussed in this article, created from the light elements marked Surface Mounted Device (SMD), which translates as “devices for surface mounting. LEDs and resistors are soldered onto a long, non-broad band to control the current. The LED strip is powered by a rectifier and voltage transformer combined into a power supply. It provides 12 V voltage to run the strip and has a rectifier diode bridge with an RC-filter on the output, which is designed to smooth out voltage spikes from the household network. Connect the product directly to a network with 220 V is not recommended, since it will put the tape out of operation, the diodes will burn due to overload. Before we talk about the wiring diagram, recall the characteristics of the tape, important for installation.

It can be as follows: SMD 3028, SMD 5050 and SMD 5050 RGB. The numbers indicate the size of the crystals. For example, one crystal on a 30×28 μm chip, and three crystals on a 50×50 μm chip. That is, the more crystals, the brighter the LED. But the brighter the glow of the diode, the more it heats up in the process, and the less its lifetime. Each type of diode has a specific angle of light. from 120 to 160 °.

1.2. Number of LEDs

Affects the saturation of luminous flux. To date, 60 LEDs per meter. the most popular option, although the sale can meet tape with 120 LEDs per meter and 240. In the latter case, they are arranged in pairs, one under another. Thus, the LED strip will give the more light, the more diodes on it.

1.3. Power consumption and operating voltage

Calculated based on the power consumption of diodes on a section of 1 m. Strip with 60 LEDs per 1 meter has a capacity of 4.8 W, with 120 LEDs. 9.6 W, with 240 LEDs. 16.8 W. By multiplying this value by, for example, 16 m, we obtain the power consumed by the entire strip. This value is important to know before buying a power supply, because not enough powerful block will not provide the necessary luminescence diodes. In addition, the power supply must have a power reserve of at least 30%. Modern strips have a working voltage of 12, 24, rarely 36 V (appeared on the market relatively recently).

1.4.Glow color and shades of white

Ribbons are divided into monochrome and multicolor. RGB. The first give the same shade of glow, such as warm or cool white, red, yellow, green, etc.д. Today there is no LED that gives a pure white glow, so you can get it in two ways: turn on all the diodes simultaneously on RGB-tape and set the same brightness, and on a monochrome strip to use blue LEDs coated with phosphor. It looks like a light yellow stain covering a blue LED crystal. But over time, the properties of this substance are lost, so that the glow from pure white gradually begins to turn bluish. The brightness of this phosphor LED strip can be reduced after months by 20. 30%. If we talk about multi-color, rgb tape has chips with three LEDs: red, blue, green. It emits hundreds of different colors and shades thanks to a separate power system for each LED. That is, you can light up the crystals of one color at 50% brightness, the second. 100%, and the third does not light up at all. Thus you can adjust the hue of the glow and its saturation. Connection rgb strip provides a controller associated with a remote control: pressing its buttons can adjust any shade of color LEDs, as well as the possibility of changing colors.

Important for choosing where to install the tape. The lowest level of protection IP20 makes it possible to install it in places where moisture is excluded, for example, get a successful LED ceiling light in bedrooms or furniture. IP65 tape has protection against splashing and water vapor. You can buy these LED strips for bathroom lighting, and in some cases for street lighting. For the bathroom or sauna, you should connect a moisture-proof tape with a standard not lower than IP65, for example, LS35287-120LED-IP68-W-eco-5m. IP68 rated 100 percent waterproof, the strip can be installed submerged underwater, no deeper than 1m, or even frozen in ice. Good for illuminating any outdoor facility and areas with high levels of humidity. aquariums, swimming pools, etc.д.

Wiring diagram in 4 steps and 2 important details

Checking ribbon performance. Before you power and connect the LED strip, t.е. Before you start to cut it, turn it on and let it run for 2 to 4 hours. If there are any defects, the tape can be returned under warranty to the seller, otherwise he will not accept it, citing a violation of the integrity of the goods.

Selecting the length of the ribbon. Most commonly available on the market in tape lengths of 5m, sometimes 40m. If you want to create a soft lighting in the bedroom or living room, choose a strip length of 5 m or more with a density of 60 LEDs per 1 m, such as IEK ECO LED LSR-3528. If you want accent lighting, take the short strips of tape with an LED density of 30 pieces per 1 m or less, such as LS5050-30LED-IP68-RGB-eco-5m. And in this case you need to cut it. Cutting strip is made with scissors or a knife. only in specially marked places. They look like yellow dots. pins to connect (the figure shows the place of the cut LED strip). Cutting pitch for direct connection ribbon should be a multiple of 1 m. For single-row ribbon, the step of cutting should be a multiple of three LEDs, for double-row ribbon. six.

Connecting the segments of the LED strip. It can be done in two ways. The first. using connectors. They do not require special skills in use. You just need to move the lock (clamping plate), and then slip the connector onto the LED strip contact, and then put the lock in place. The connector wire is then connected to the contacts on the power supply.

The second method is soldering. You need a soldering iron, rosin and a good light. Before soldering, clean the tip of the soldering iron so that it is free of carbon and dirt. The working temperature for the soldering iron is between 210 and 260°C. Before soldering the pads of the LED strip should be tinned, and after a short time. solder. The base of the strip is very thin, so it is not recommended to keep the soldering iron on one contact for more than 10 seconds, otherwise you can burn the strip. After you finish, you need to clean the soldering point with any sharp object to get rid of the solder residue. Soldering is more reliable, because the LED strip, your own hands soldered to the power supply, will not lose the quality of contact with it, what is sometimes wrong with connectors.

Connecting the strip to the power supply. Most modern models of power supply leads to connect to a network of 220 V, one of them is provided with a plug. A reduced voltage cable of 12, 24 or 36 V is coming out of the power pack. To avoid confusion, remember that red means “” and black (or blue) means “-. But even if you reverse the polarity, the diodes just won’t light up when you turn them on. Wrong polarity can’t hurt them. just reverse it.

If you are going to connect several sections, you should not connect them in series, i.e.е. to each other. This would overheat the first part of the ribbon and not give enough voltage to the second part. As a result, both ribbons will not work as they are supposed to. The correct way to connect is parallel, ie.е. you connect the wires coming out of the power supply to the inputs of two strips of ribbon at once. You connect the first segment as usual, and run the individual wires from the power supply unit to the second segment. So, each section is connected independently.

The power supply is connected to the 220V network, and you need to connect the controller to it. At the output of the controller there are wires of appropriate size, to which the contacts of the LED strip are connected. Correct wiring can be checked by matching the emitted light to the included color of the diode.

LED strip. a modern element of decor, which will serve not only for interior decoration, but also for accent lighting. The devices are durable and environmentally friendly, consume little power and take any shape, emit directional and uniform light in a wide color spectrum. In the section of our site you will find many options for LED lighting and tools and equipment for installation. Choose and order now!

How to connect the LED tapes. schematic

How to cut a normal LED strip 12?

LED ribbons belong to the so-called LED devices. At its base this system has only an electrical circuit. 12V tape is not only flexible, but also elastic. Like its counterparts, it is made up of individual segments, usually with three LEDs each. Verify this fact you can yourself, removing a particular part of the tape and look closely. Along the backlight between the individual segments is the distribution of voltage on the strip.

Due to the fact that the coating has a thin layer, the strip can be cut, clearly controlling where there is a line for the trimmer. This is done simply by using a box cutter. If you, when cutting this type of product, break the rules and do not do it on the right line, it will lead to the fact that one side will stop its work.

With the release of such tapes manufacturer itself clearly distributes the line with a dotted line, where you need to make the cut.

How to cut the LED-tape

Now about how to properly cut the LED-tape of different voltages and types.

12 volts

On the 12 volt LED strip between each group of 3 bulbs are marked with a cutting line.

You can clearly see the cutting points every 3 LEDs.

Such tape has a thin coating, which allows the use of an ordinary office knife or scissors. The main thing is the accuracy of the work. Tape is cut strictly along the dotted lines, otherwise part of the diodes will fail, and such a luminous device will remain only to throw out.

Sticker tape 220V

Using LED strips for street lighting Models rated for voltage of 220 V, are available without an adhesive backing and placed in an airtight shell. They heat up during operation, so it is not recommended to use them indoors. Used for outdoor illumination of buildings in well-ventilated areas.

Attach such a model can be one of three ways:

- Mounting on the aluminum profile with clips;

- fixing with the help of mounting pads, clips, nails;

- gluing on the double-sided adhesive tape.

For fixing on the adhesive tape, it is cut into strips 3-5 cm long. One side is glued to the cloth every 5-7 cm. Then the design, separating the free surface of the tape from the protective film, is secured in the desired location.

When using the LED outdoor strip 220 V the most reliable option. fixing on clips.

LED strips that just won’t stick!

Self-adhesive on the back of the LED tapes, usually you need a smooth surface for reliable sticking. Rough surfaces or too many grooves will limit the contact between the surface and the 3M tape backing. Less contact means less adhesion, which causes LED strips to fall off or peel off.

LED strip backing also does not adhere well to certain finishes. If the surface is glossy or oily, the strip is likely to slip too much or not adhere. In such situations, you will need to find other mounting options.

The environment around the LED strip, also affects the stickiness. Very hot climate will lead to failure of the adhesive material. It may work at first, but after one very hot day, the strip will fail as the surface temperature rises. Humidity also adversely affects the LED strips, causing them to lose their ability to bond.

What happens if you cut the LED strip?

Is it possible to cut the LED strip in any place? To maintain the performance of all segments of the LED strip only need to cut it in places provided for this strip. If you cut anywhere between the LEDs in the strip, the LEDs from the cut segment of the LED strip will not work.

Waterproof LED strip can be cut into segments of three LEDs or six (depending on the operating voltage of the tape DC12V or DC24V), but do not forget to seal the place of the cut.

How to cut the LED strip 220v?

Cut the LED strip at 220 volts can only be in special places. is a break in the flexible carrier board with a length of 1.5-2 cm, containing only the conductive bars under the silicone sheath. You have to cut in the middle of this break.

The easiest way. just throw the base of the garland on the ledge, securing it with clamps at the edges and middle of the ledge. In this case, if you want to be able to move the whole garland together with the curtain, it is recommended to add hooks to the curtain rod and fix the garland with them.

What happens if you connect the LED strip wrong?

What happens if you reverse polarity? The ribbon just won’t light up! What’s worse, if you mix up the input and output of the power supply: you connect the part that should go to the tape to the 220. In this case, all the sparkling and the power supply unit can explode.

How does the LED strip: LEDs in series connected to each other, fed from source of voltage, and the strength of the current limits the resistor (current-limiting) Due to this, when one LED burns out, not all the LEDs stop shining, but only 3-6.

Why cut the LED strip?

The desired brightness is achieved by selecting the type of device (size of LEDs, their number). Therefore, before installation, the roll is cut into pieces of the required length, to which the wires are connected for connection.

Here are a few basic places where you can stick the LED strip at home: the outside surface of furniture, especially beds and kitchen furniture; stairs; wallpaper (especially with dirt-repellent properties);