How to drill properly How to properly drill metal and concrete. Drilling tips for various materials.

How to drill correctly

In this article, we will tell you how to properly drill various materials with a drill: metal, tiles, concrete, glass, wood. Working with wood, metal, concrete and tiles has its own subtleties. If you follow some principles, then the holes will turn out to be smooth and of high quality.

Drilling concrete

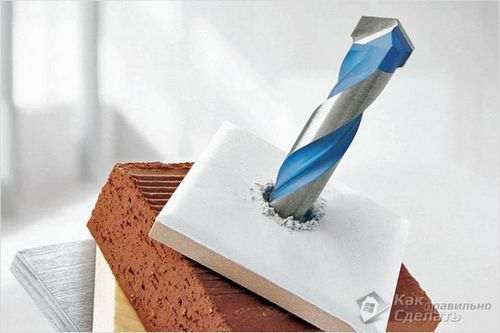

Drill bits with victorious tips Holes in concrete can be needed for a wide variety of purposes. The need for them may arise during routine repairs. For example, holes in a concrete wall are required when installing a toilet and other plumbing, for installing shelves and sliding doors. There are tons of examples when you need to use a drill to work with this material. Concrete has its own special properties, therefore, work with it is also carried out according to certain rules.

How to drill concrete? For this purpose, you need to purchase drills with victorious tips.

It must be remembered that a drill is used in working with concrete only for drilling small holes (up to 12-13 mm). If you need to make a larger hole, it is better to use a hammer drill.

Drill breakage and jamming are the most common problems when drilling in concrete. Drills can also become clogged, so they must be cleaned and sharpened regularly.

Drilling is done as follows:

- First, the point is marked at which the hole will be made.

- Then you need to make a small depression at this point with a conventional drill.

- Is the deepening ready? So it’s time to change the conventional drill to an asymmetric one. It will allow you to work more efficiently.

- If the hole is made for a dowel, then it must exceed its size. Because concrete dust will significantly reduce the headroom.

- It is better if the drill used in the work has a built-in level. Anyone who has already drilled concrete knows how difficult it is to keep the tool in an even position at all times. Especially if the work is long.

- During operation, the drills can be regularly moistened with plain water. This makes the process easier.

Drilling metal

To properly drill metal, you need to know the properties of this material. It is very hard, difficult to mechanical stress and requires drills of a certain strength. If the drills are bad, the job will not work. It is not recommended to save on tools, because a poor, low-quality tool can destroy the material.

Drilling thin metal sheets is a real flour for most craftsmen. Steel tends to break free, which can lead to serious injury. To prevent this from happening, the steel sheets must first be fixed. To do this, you can make a special device that will clamp the steel.

When cutting a blind thread, various debris often gets into the hole. To eliminate this phenomenon, you need to pour a little paraffin or wax inside.

How to drill a brick wall

Drill brick with a drill. A simple process. An impact drill is used for work. If drilling is hammerless, the drilling process can take a long time. It is very important that the tool runs at high power. Quantitative indicators of revolutions per minute are also important. Indicators of more than 2,000 revolutions are considered the most acceptable.

Of course, a puncher is used to perform better work. If it is not at hand, then high-power drills are used. You don’t need any to drill a hole. Then special knowledge. The main thing is to follow a number of simple recommendations, which were mentioned above. Sometimes you can stumble upon a burnt stone. It will be quite difficult to form a cavity in it. Such a brick is determined by the dust generated during operation. It becomes a pronounced black hue.

To form holes in burnt rocks, you need to turn on the drill at low speed and set the percussion function. The instrument must be pressed very hard for the impact function to work properly. It is also important during work to ensure that the drill does not overheat. A severely overheated drill will cause the edges of the drill to wear out quickly. For such purposes, a diamond-coated drill is most often used. This is how the grip is most effective. This leads to significant savings in physical strength and energy.

Sometimes there are situations when a hole has to be made of a significant diameter. For example, this could be a ventilation outlet. It will be very difficult to organize such work with an ordinary tool. You will need powerful equipment and large crowns.

How to drill wood surfaces

Wood is the easiest material to drill. But there are also certain features of the technological process that must be observed so as not to spoil the surface and not to break the equipment. The speed parameters depend on the type of wood flooring. Loose specimens are easy to drill. The following types of equipment for wood can be distinguished:

- Flat or feather;

- Twisted, they are single-spiral;

- Crowns, also called core drills;

- Cylindrical nozzles of the Forstner type.

Choosing a drill. As a rule, for small holes (less than 1.2 cm), metal tooling is used, if a larger diameter is needed, you will have to fork out for a specialized wood drill.

For large holes, ring crowns must be used. For drilling blind areas, Forstner-type crowns are perfect.

Particular attention must be paid to drilling the timber. Despite the fact that it is very convenient to fix, its thickness often becomes a negative factor that complicates work. If the timber is of a standard size, then, as a rule, drills up to 25 mm are taken. The drilling process always takes place at low speeds.

Selection principles

Most cases involve the use of punchers. This tool always has more power in stock, it allows you to punch even very thick walls. With this tool, you can always drill large areas in diameter. It is advisable to use it in the following situations:

- When you need to make a hole up to 10.12 mm;

- When you need to drill many holes. over, the size of each of them is supposed to be large enough;

- When working on coatings that contain foam.

All drills should be aware that drills can be classified according to their impact power. Some models can be used for drilling concrete pavements, others are designed for use with specific attachments. It is important that the alloy from which the attachments are made is of high quality. High quality alloys. A guarantee that the drill will not fail for a long time.

Working with a punch in different modes

Drilling mode

It is recommended to start drilling at a low speed without pressing the surface too hard. After starting the engine, it should run in idle mode. This is necessary so that, in the event of vibrations, extraneous noise or smoke, react in time to a malfunction and prevent more complex consequences in the form of injuries, damage to building structures, complex tool breakage.

In the technology of performing work, much depends on the characteristics of the material. For example, there are often questions about how to drill metal with a hammer drill. Experts recommend using only high-quality drills that are specifically designed for such operations from trusted manufacturers. In addition, the surface must be properly prepared. The hole is made in stages with a gradual expansion of the diameter to the desired size.

Impact drilling mode (drilling)

The hammer drill has become a common designation for the drilling mode among most manufacturers of construction tools. Particular attention during the execution of work should be paid to prevent skewing of the nozzle. It is also important not to put additional pressure on the rock drill, this will not increase the motor power or speed up the work.

This function is not always used. For example, before drilling tiles with a hammer drill, it is important to turn off the impact mode and prevent the drill from sliding over the surface, which often causes scratches.

Impact mode

To work in impact mode (the toggle switch rotates to the position indicated by the hammer), special chisels are used. During operation, the perforator must be clamped with both hands. In the process, the chiseling speed can be adjusted depending on the characteristics of the work performed. It is necessary to constantly monitor the tool, since situations often arise in which the drill inside the structure stumbles upon the reinforcement. If the hole becomes full of crumbs, it is enough to remove the drill in idle mode to clean it (you can also use a construction vacuum cleaner).

How to work with a puncher: 7 nuances that are important to know

Even small repairs, not to mention professional construction, are not complete without the use of a hammer drill. It is with its help that you can make a hole in a stone wall or a depression in a concrete structure. Therefore, both the home craftsman and the builder should know how to work with a puncher.

Also, such a tool allows you to quickly and easily drill the required number of holes in ceramic tiles, brick, wood, metal. And additional nozzles will allow, for example, to drill the floor, compact the material, hammer in the rod and even tighten the screw.

Depending on the application and the availability of additional accessories, the rotary hammer can be used for a wide variety of construction operations. But how to do it correctly to prevent the tool from breaking down?

For what materials can the rotary hammer be used:

- Is it possible to tighten screws, self-tapping screws with a puncher? Whenever possible, many professional builders prefer to use a power tool that is capable of performing the functions of several types of equipment. The puncher is one of them. For quick and convenient screwing in screws or screws, special nozzles are used. Among them there are models with a limiter, which guarantee control of the recession of fasteners.

- Is it possible to interfere with the solution with a perforator? It is possible, and quite effective at a low viscosity of the solution (for compositions of high viscosity, it is recommended to use a stirrer nozzle and work at minimum speed). Additional arguments in favor of this use can be that the speed of rotation of the tool shaft can be easily changed. In addition, according to the principle of its operation, the perforator differs little from the construction mixer.

3. Can a puncher drill wood? Using a puncher, you can get enough quality holes. To do this, you need to use the power tool in drill mode and use special drills. The drilling speed is determined depending on the material and hole diameter.

4. Can a puncher drill tiles? The main problem in working with ceramics is that they can crack if mishandled. That is why, when using a hammer drill, it is necessary first of all to turn off the percussion mode, and it is better to start drilling at low speeds with a gradual increase in speed.

Five. Can a puncher drill metal? Provided that a special drill is used, it is possible to create holes with this tool in almost any material. In most cases, they have a cylindrical shank and a spiral design. The material for their manufacture is high strength steel (often based on cobalt alloys). versatile in use will be drills equipped with carbide inserts on the cutting edge.

Rock drill tips

There are several rules for operating rock drills that must be followed.

- During work, do not press too hard on the tool to prevent damage to the drill. Power and performance will not increase from this in any case.

- A common mistake is the desire to perform the entire operation in full at one time. The drill needs to be cleaned periodically.

- The choice of equipment is determined by the type of work performed and the specific features of the tool itself. For example, when using one type of rotary hammer, an adapter is required to replace the nozzle, and the second has a quick-release design.

- Mechanical damage or systematic overheating of the equipment is not allowed. When choosing, you should pay attention to the models in the aluminum case, which, due to the nature of the material, always cool better.

- When working with the hammer drill, it is recommended to wear rubber gloves, which will help to dampen vibration, despite the fact that the tool itself is equipped with special inserts for this purpose.

What not to do with a hammer drill

The hammer drill can even be used as a concrete mixer. Many craftsmen use this tool to mix grout or tile adhesive. But hammers, despite their large size, are not very suitable for this. They do not have reduction gears like slow speed drills. Therefore, during mixing of thick and viscous mixtures at low speed, the rotary hammer motor experiences greater loads than when drilling concrete. And this negatively affects its durability.

It should also be remembered that chiseling without rotating the chuck is an auxiliary function of the punch, and not the main one. The design of the tool is not designed to last long in this mode. If you have to carry out large volumes of dismantling work or cut a new opening in the wall, then it is better to take the appropriate tool: a jackhammer and a diamond circular saw.

Chiseling mode

The hammer drill can work as a jackhammer, that is, in chiseling mode without rotating the chuck. To do this, you need to switch the toggle switch to the position indicated by the icon with the hammer, and fix the nozzle in the form of a chisel or lance in the chuck. In this mode, the tool can be used to dismantle brickwork, widen openings, or knock tiles off walls and floors.

Impact drilling mode

The hammer hammer mechanism allows you to quickly and efficiently drill holes in concrete, brick or stone. Impact mode cannot be used when drilling metal or ceramics.

Hold the hammer drill perpendicular to the surface during hammer drilling. Do not skew, as this can damage the tool and accessories.

Work rules: tips

When working with tools, you must follow the safety rules and general recommendations:

- 1) When performing work, protect the respiratory system, dust is harmful.

- 2) If you are working outside, then you need to put fences 2.5 meters.

- 3) When working at a height of more than 1.5 meters, use a strong base of the forest or goat.

- 4) When working with a tool, the revolutions must be turned on smoothly, and in no case should it be turned off when it is in the body of the wall.

- 5) When drilling through plaster, you must carefully study the communications plan so as not to hurt anything.

- 6) It is strictly forbidden to drill through the decorative coating.

- 7) Choose the right drills for each surface.

- Wet the drill with water so that it does not overheat.

Which attachments to choose

A specific nozzle is used for each material:

- Concrete, brick, stone drill with carbide plate or victorious;

- Tile, glass cone drills with diamond dusting;

- Metal spiral drill with a cylindrical cone;

- Wood, drywall for holes of different diameters, drills are used: feather, ballerina, screw, saw crowns for wood;

- Foam concrete drills.

Is it possible to do without a drill and punch

Make a hole without a drill and hammer drill, but not in a concrete wall. This will require a bolt or punch.

The working end of the tool is applied to the place where the hole will be. On the opposite side of it, you need to hit hard, rotating the tool after each turn.

Drilling of rolled steel

Drilling holes in metal is one of the types of machining to obtain through and blind holes of the required diameter. The essence of the process consists in fixing the workpiece, marking and processing with manual or automated tools.

Drilling at home

At home, hand and power drills are used. Twist drills are most often in demand.

Drilling equipment

The type of equipment is chosen depending on the tasks. Drilling machines are radial drilling, vertical drilling, coordinate drilling. With their help, they perform:

- Through and blind holes with cylindrical walls;

- Polyhedral, oval and other holes;

- Internal thread;

- Fine finishing;

- Reaming an existing hole.

Which is better: hammer drill or hammer drill?

This question is often asked by inexperienced people who purchase a tool for the home. In principle, professionals do not have such doubts, since they certainly know that behind the external similarity there is a great difference that predetermines the capabilities of these two tools.

The drill is originally intended for drilling holes in materials of low density. In wood, plastic, soft metals. The addition of the percussion function has significantly expanded the capabilities of this tool, allowing everything else to be easily drilled into masonry and structures made of low-grade concrete. At the same time, like hammerless drills, with the proper equipment, they are able to work with fasteners. For all their versatility, the drills have rather modest dimensions and are much cheaper than perforators. Thus, the main reasons for the popularity of impact drills among domestic consumers include their versatility, compactness and affordability.

Accordingly, rock drills are heavier and more expensive. If you compare tools with identical power, the weight and price advantage of the hammer drills will be obvious. For example, a thousand-watt two-speed drill Makita HP 2071 weighs 2.4 kg and costs about 5000 rubles. With its help, you can drill holes with a diameter of up to 40 mm in wood, up to 16 mm in steel, and by connecting the impact function, drill into concrete with a 20 mm drill.

For a perforator similar in power M akita HR 4010 C will have to lay out three times more and weighs 6.3 kg. In terms of functionality, a hammer drill is significantly inferior to a drill, since it only hammers or drills with a blow, and these two modes are unacceptable for making holes in wood and metals. But in terms of drilling concrete, the designated perforator is out of competition, since it will pull not only a large-diameter drill (up to 40 mm), but also a drill bit (up to 105 mm). In addition, this tool will easily replace a jackhammer and will greatly facilitate the work of installing niches and openings, laying communications, chipping off old ceramic tiles, etc. Of course, such a hammer drill is intended exclusively for professionals and is unlikely to be useful in everyday life.

However, among the hammer drills there are light weights: for example, the Makita HR 1830 weighs only 1.7 kg, and is inferior in price to the Makita HP 2071 hammer drill. Both of these tools work in the mode of drilling and hammer drilling. over, with the help of a drill, you can arrange technical holes of a much larger diameter in concrete (without taking into account hardness), and in wood, and in steel.

A natural question arises: what is the difference then? First of all, the difference in power consumption: for the compared hammer drill, the power consumption is 440 W, and for the drill 1010 W. And this is the corresponding load on the network and the cost of paying for electricity on the one hand and an indicator of performance. With another.

But the main difference lies in the purpose, in particular in the main object of the application of efforts. For a drill, drilling concrete is an additional option, and in the hammer drilling mode, the tool works for self-destruction (more on that below). A hammer drill that easily breaks a monolith will not provide high precision drilling of holes in steel, wood and plastic. The reason for this is the design features of the percussion mechanisms of drills and perforators and the used cartridges for fixing the equipment.

In impact drills, the impact is generated mechanically. Everything is extremely simple there. Two toothed ratchets in drilling mode without impact rotate interlocking teeth, as a whole. When the impact function is turned on, the internal ratchet (located closer to the engine) moves back, and the external one begins to count its teeth with its own. As a result, impact energy is not generated as such: the impact force is predetermined by the height of the teeth and the pressure exerted on the tool by the user, and the frequency of impacts is the number of teeth and the rotation speed.

This is where the self-destruction mentioned above comes from. No matter how strong and wear-resistant the material used for the manufacture of ratchets is, sooner or later the teeth will merge and the impact mechanism will finally fail.

The nature of the impact in rock drills is completely different. The crank mechanism converts the rotation from the engine into reciprocating movements imparted to the piston. That, in turn, activates the striker, but not directly, but through an air gap, which reduces the load on the piston, thereby contributing to the durability of the tool as a whole, and reduces recoil. Such an impact mechanism is three times more effective and, of course, more reliable than a drill ratchet. In the presented model range of Makita rotary hammers, the impact energy ranges from 1.3 to 19.7 J (models HR 1830 and HR 5210 C, respectively).

Some conclusions can already be drawn from the above. For example, that if intensive work is coming up on drilling concrete, then the impact drill will die pretty soon, and the heavy one will not overcome at all. And it is true. But do not be fascinated also by the versatility of three-mode rotary hammers, which are declared by manufacturers as jack of all trades. As a rule, these are instruments of light (up to 4 kg) and medium (5-8 kg) class. These rock drills, and heavy ones too, are equipped with SDS keyless chucks. Plus and SDS. Max, designed exclusively for special drill bits, blades, etc. Whose shanks have a well-defined shape (the presence of grooves and their number). Consumables for rotary hammer drills are much more expensive than conventional drills, and the use of the latter is not possible due to the specifics of the cartridges. To expand the capabilities of rotary hammers, manufacturers quite often complement their models with additional cam chucks, which are mounted in standard SDS-type holders by means of special adapters. At the same time, the tool becomes more cumbersome, and the runout of the chuck increases significantly, which does not benefit the quality. Replacement chucks are an alternative for more accurate drilling. In this case, the main SDS chuck can be easily dismantled, and in its place, thanks to the adapted tip, a conventional cam chuck is installed. For cylindrical drills. An example puncher Makita HR 2811 FT with removable SDS chuck. Plus. It should be noted that such an arrangement is not so common yet and significantly affects the price of the instrument.

So, answering the first question, we have already noted its incorrectness. Both drills and rotary hammers are equally good, but only in the area for which they are intended. The hammer drill is ideal for drilling holes in wood, metals, plastics, brick and lightweight concrete. In addition, it can be used to work with fasteners, and at low speeds as a mixer. The hammer drill is preferable where you often have to drill and hammer concrete (and reinforced concrete) of varying degrees of density, but it will not provide precision drilling in metals and wood. Rock drills, which are equivalent in power to impact drills, are significantly superior in weight and cost. When working with concrete, rock drills are much more reliable, practical and more durable than impact drills. The versatility of impact drills will come in handy in a domestic environment, and hammer drills are more professional. But if you live in a building made of glass and concrete, then, in addition to a hammer drill, it will be useful to have a hammer drill, if not the most expensive and powerful, at hand.