How to cut cellular polycarbonate

If you plan to cut cellular polycarbonate at home, then you should understand that this type of building material has a porous structure, as a result of which the work process can be very specific. If the thickness of the material does not exceed 1 cm, then in this case you can do only with a clerical or construction knife with a retractable blade. When cutting cellular polycarbonate along the stiffeners, you will need to do the work in several stages.

Starting cutting should be carried out on the outer surface, after which the sheet of cellular polycarbonate is turned over and a similar action is performed, only on the other side of the building material. When it became necessary to cut the polycarbonate sheet across the stiffeners, the algorithm of actions will already include 3 stages. Thus, as in the previous version, the product is cut from both sides, after which the inner partition is carefully cut.

When a polymer product is more than 1 cm thick, then you will need to use a hacksaw for metal or wood, while the teeth must be divorced. If you have an electric tool, for example, an angle grinder or a jigsaw, you can give preference to them, but at the same time the speed of the selected tool should be at a minimum level.

Preparation and marking of sheets

Before you start cutting polycarbonate for a greenhouse or any other structure, you must first carry out preparatory work and make the appropriate markings on the material.

The first step is to completely clean the place where you plan to cut the polymer material. All debris and excess items must be removed. This is necessary not for reasons of cleanliness, but so that nothing distracts from the process during work. After the surface is prepared, it is necessary to put a sheet of plywood or fiberboard on it. Only then can the cutting site be considered as flat as possible.

It is worth putting a sheet of polycarbonate on the workplace. In the event that the material has a laminated surface, a mirror or a special coating, then this side should look up. Until the material is cut, the protective film must remain in place.

Initially, the preliminary marking should be applied to a blank sheet of paper as a diagram with respect to scale. After that, you will need to transfer all the markup from the paper sheet to polycarbonate. For measurements at home, it is best to use a tape measure or a metal ruler. A black marker is used for marking. If you plan to work with large-sized polycarbonate, then many experts recommend putting a board with a width of 10 cm on the polymer material and moving only along it. This approach will eliminate damage to polycarbonate.

How to cut polycarbonate roofing sheets

In the place where it is planned to cut the sheet, it is required to put wooden boards about 4 cm high and 10 cm wide on the right and left sides of the cut mowing line.In this case, the ends of the boards must necessarily look out from both sides of the polymer material.

Movement should be carried out on the board in the same way as at the time of drawing the corresponding markings. This is the only way not to damage the material, carrying out all the work at home.

How to cut polycarbonate with a jigsaw

In order to cut the polycarbonate evenly, you can use an electric jigsaw. This option is considered an alternative to a construction knife and an angle grinder. In this case, it is important to choose the right file. In order to be able to cut polycarbonate as smoothly as possible, you should use a straight file or with wavy teeth. The rest of the options are not recommended, since it will be extremely inconvenient to cut the product, in addition, burrs and cracks may remain.

The process of working at home begins in a similar way. the first step is to prepare a place suitable for cutting. It is best to use a new file that is installed in an electric jigsaw before cutting. The fixation must be reliable, otherwise the file will constantly fly out of the device.

The connected electrical device is brought from the end of the polycarbonate sheet according to the cut mowing line applied. To make work at home as comfortable as possible, you can initially apply notches.

The base plate of the power tool must be pressed against the material. In addition, it is necessary to monitor the downforce, as there is a high probability that the polycarbonate will be damaged. The tool is slowly and carefully guided along the markings left. If you plan to cut wavy parts, then it is best to initially practice somewhere in order to cut accurately and evenly.

When the work at home is completed, the electric jigsaw should be disconnected from the electrical network, remove the plastic shavings. If there are excess elements, they are cut off with a knife.

How to properly cut polycarbonate with a hacksaw

Very often, in order to cut polycarbonate, a hacksaw is used, designed for working on metal and having small and frequent teeth. This option allows you to cut the building material into square or rectangular pieces. If we compare the process of work, then it is necessary to cut polycarbonate according to the same step-by-step algorithm as when working with a construction knife.

Before you start cutting polycarbonate sheets at home, many experts recommend that you first take into account some of the nuances, among which the following points should be noted:

- when cutting, the hacksaw should be located at an angle of 30 degrees;

- in the presence of a workbench or a clamp, it is recommended to securely fix the polycarbonate sheets, which will greatly facilitate the cutting process.

It is worth cutting the material as carefully as possible so as not only not to damage the sheet, but also not to injure yourself.

How to cut polycarbonate at home with a knife

Many people believe that it is better to cut polycarbonate with a knife, since this tool is considered the most affordable, while it is suitable for both honeycomb and monolithic material. Regardless of what type of knife will be used at home, in order to cut polycarbonate the blade must be sharpened well in any case. It is important to take into account the fact that a dull knife will leave a large number of burrs and irregularities on the building material.

It should be understood that cutting material at home with a construction knife will be much more difficult and longer than using an electric jigsaw or an angle grinder. Also, the inconvenience lies in the fact that the knife is great for sheets of a small area and polycarbonate should have a thickness of 6 to 8 mm, no more.

The step-by-step algorithm of the work carried out is as follows:

- The first step is to prepare a site for work at home. It is important to properly prepare the place and apply the markings.

- Many experts recommend trying the knife on that part of the polycarbonate that will not be used in the future for the construction of the structure. This is necessary in order to check how sharp the knife is and whether it is convenient for them to cut. If necessary, the blade can be replaced or sharpened.

- A thick ruler made of metal is applied to the applied mowing line of the cut. If this tool is absent, then you can use a building level or a flat wooden board.

- Attach a knife blade from the end of the cut line. If you plan to cut thick polycarbonate at home, then the tool should be in a perpendicular position relative to the plane of the sheet. For thin materials, the angle of inclination can vary from 30 to 45 degrees. A knife is inserted into the end of the sheet as accurately as possible, thereby making a notch.

- The knife must be guided from the left notch along the cut mowing line. In order not to disturb the cutting, it is recommended to use a ruler when working at home.

It is important to keep the cutting speed as low as possible. In this case, the most important thing is to be accurate. The knife should not go beyond the line outlined with a marker, otherwise it will not work perfectly to cut the sheet. Do not be afraid to leave too much, if necessary, all this can be cut off quite easily.

How to cut polycarbonate

A feature of polycarbonate is the fact that in order to cut it at home, you can use any construction tool.

In this case, the following is perfect:

- clerical or construction knife;

- electric jigsaw;

- angle grinder (angle grinder);

- a circular saw;

- hacksaw designed for metal work.

If we consider industrial equipment, then here you can use a milling machine, which has numerical control and a special laser of several types.

It is worth considering the fact that there are a number of construction tools that should never cut polycarbonate. This is due to the fact that there is a high probability of damage to the sheet, as a result of which the quality will suffer greatly.

Many experts recommend refraining from using:

- A hacksaw designed for woodworking. as you know, such a model has rather large teeth, so that the material is not cut, but torn during operation. Ultimately, the cut will have a large number of cracks, nicks and burrs.

- Construction scissors or metal scissors. this option is perfect for thin monolithic polycarbonate. Cellular polymer material will be deformed on both sides.

Choose the right tool before cutting polycarbonate.

How to cut solid polycarbonate

If necessary, you can carry out the process of cutting monolithic polycarbonate at home. A circular saw with small teeth is perfect for these purposes. In order not only to cut polymer material, but also to achieve the best possible result, many experts recommend giving preference to teeth that are equipped with special solid inserts. Thanks to this approach, it is possible to prevent unwanted material heating. If you plan to cut a sheet with a thickness of up to 2 mm, then in this case it is recommended to cut at the same time from 10 polycarbonate sheets. As practice shows, cutting several sheets at the same time is much easier and more convenient than one.

It is important to understand that if you cut a single polycarbonate sheet of small thickness, then the material may crack during operation. In this case, it is best to use a guillotine cutter, but this method also has a significant drawback. the edges of the cut will turn out to be rough. If necessary, you can use a band saw up to 2 cm wide.

Electric jigsaw

A household, most ordinary electric jigsaw is also quite suitable for working with polycarbonate sheets, only you need to install a file with fine teeth on it, otherwise the material will tear, not cut. This tool, like the angle grinder, is quite easy to use, but in order to be completely confident in the quality of work, it is advisable to also practice in advance. An electric jigsaw is very much in demand, especially when you have to cut monolithic polycarbonate of complex decorative shapes or make roundings.

Note: If you have to cut thin sheets, experts recommend folding the canvases of 10-12 pieces, and placing a layer of cardboard under them and then cutting everything at the same time.

When it is necessary to cut only one sheet, the risk of cracking increases significantly. To prevent damage to the material, you need to work only with a very well sharpened tool. There are craftsmen who use scissors when working with polycarbonate. This is also perfectly acceptable. The main thing is that the tool used does not violate the structure of the canvases.

How and how to cut polycarbonate at home?

Cloths of polymer plastic, more familiar to everyone under the name polycarbonate, are becoming more and more popular every day. And it is no coincidence: the relative cheapness and excellent properties of the material brought it to one of the first places in sales. It is also of great importance that almost anyone can work with it, if there is a desire. But since this is a relatively new material, not everyone knows how to correctly and how to cut polycarbonate at home in order to get a high-quality cut and not spoil the material.

Hacksaw

Beginners are usually interested in: is it possible to cut and how to cut cellular polycarbonate with a hacksaw or a hand saw? In the event that there is no experience, it is advisable not to use these tools: the blades along the cuts can crack. It is best to work with power tools. But both beginners and experienced professionals definitely need to fix polycarbonate sheets well in order to prevent vibration and stress in the material, which is also fraught with bad consequences.

Tools

Laser cutting

In addition to the listed methods, you can also cut with a laser. But, to work with a laser machine, you need to have the appropriate skills. In addition, not every master has such a tool, therefore, laser cutting of polycarbonate is available only to those who deal with polycarbonate professionally. But, if there is an opportunity to perform the work with a laser, you must definitely use it, since this guarantees:

- high speed of work;

- lack of defects;

- excellent cutting quality;

- cutting accuracy: when working with a laser, the dimensional accuracy is maintained up to 0.05 mm;

- when working, you do not need to fix the sheets.

Angle Grinder

The very first tool that almost everyone has and that can work with polycarbonate is an angle grinder. over, it is not at all necessary to use an expensive tool: even an inexpensive and small angle grinder will do all the work perfectly. To make even cuts, you need to set the circle 125, intended for metal. The only thing you need to pay attention to is experience, since the tool is distinguished by high revolutions, and if you did not have to work with it before, it is advisable to practice on scraps from this material before cutting the polycarbonate. Where can I get them? Contact the craftsmen who are engaged in the manufacture of polycarbonate structures.

Stationery knife

Perfectly cuts polymer plastic canvases and a stationery knife. over, even beginners can cope with this. The main thing is that the knife is of good quality, and the work is not carried out in a hurry. the blade of such tools is very sharp and you can not only make an incorrect cut, but also get seriously injured. The stationery knife is suitable for honeycomb sheets with a thickness of 4-6 mm, but with 8 mm it is already quite difficult to work with. On thicker sheets, cutting polycarbonate is almost impossible, therefore, experts recommend using a knife only where you need to trim the material, and even then, on sheets up to 10 mm.

How to cut correctly?

Before cutting polycarbonate, specialists prepare the workplace well beforehand. It is necessary:

- Remove all foreign objects from the site: branches, pieces of planks and boards, even small pebbles. Ideally, the place should be clean. This is necessary so that there are no dents, scratches and other damages on the polycarbonate canvases. It is best to pave the work area with sheets of chipboard, fiberboard or other suitable material for this purpose.

- Using a marker and a long ruler or other object on the panels, you need to mark up. If you have to move along the canvases during this, it is necessary to lay a wide board and walk only on it so that dents do not appear on the polymer surface.

- Before cutting polycarbonate to size, it is necessary to put boards under both sides of the markings applied with a marker, the size of which should not be less than 4 × 10 × 220 cm. will move on them.

- If the cut is made on an even mowing line, you can work with an angle grinder, rounded parts go through with an electric jigsaw, and if you need to make a slight adjustment, a clerical knife will do.

- If the work is performed on material with a laminated or mirror surface, it is very important to correctly position the canvas in the workplace: the laminated or mirror coating must be turned up. What is the best way to cut this type of polycarbonate? With the same tools as other types of material, but using a hacksaw is not permissible: mirror or laminated layers can peel off.

- When working with canvases of cellular polymer plastic, if the cut is made along the length of the sheet, the marking can be omitted: the honeycombs themselves will serve as a guide. Thanks to this, it will not even be possible to walk on the surface of the material.

- After completing the sawing work of honeycomb blades, it is necessary to blow out all the seams with compressed air in order to remove dust and chips that have got inside.

And most importantly, before cutting polycarbonate with an electric jigsaw or an angle grinder, you need to wear safety glasses to protect your eyes from micro particles and dust. And one more thing. you always need to remember the popular wisdom, which says that before you cut it off, you need to measure it seven times. this will help save both money and time.

Polycarbonate. what it is

Polycarbonate is a hard transparent or translucent plastic that is more durable than glass. less weight.

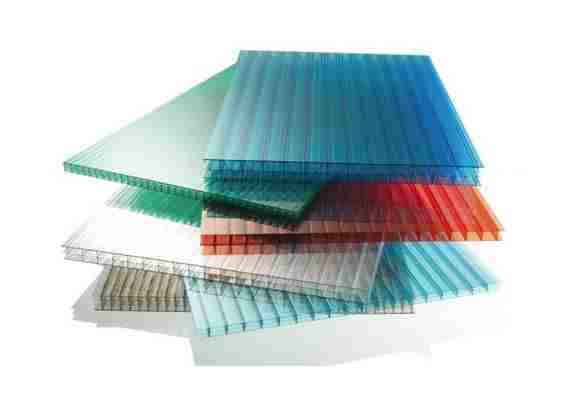

There are two main types of this material.

- Monolithic. is a solid sheet of polycarbonate.

- Cellular (honeycomb) polycarbonate. hollow cells with partitions are located in it between the solid upper and lower layers of material. A sheet can have one, two, three rows of cells, sometimes even more. The walls of the cells also play the role of stiffeners.

Types of cellular polycarbonate

Table. The main dimensions of polycarbonate sheets.

How to Cut Lexan Polycarbonate Sheet

| 6.05×2.05 | Monolithic | 2, 3, 4, 5, 6, 8, 10, 12 |

| 6×2.1 | Cellular | 4, 6, 8, 10, 14, 16, 25 |

| 12×2.1 | Cellular | 4, 6, 8, 10, 14, 16, 25 |

Cutting polycarbonate with a hacksaw

A hacksaw for metal with small and frequent teeth is sometimes used to cut polycarbonate sheets into straight square and rectangular pieces. The process is similar to cutting with a construction knife, so if you decide to use a hacksaw, then check out the corresponding step-by-step instructions above.

Hacksaw for metal

When doing this, take into account two nuances:

- hold the hacksaw at an angle of approximately 30 °;

- fix the polycarbonate sheet as well as possible; if there is a workbench and a vise or clamps, then use them.

But it will be more convenient and, most importantly, it will be better to cut the material using an electric jigsaw or a construction knife with a retractable blade.

Stages of cutting and installation of polycarbonate

Cutting polycarbonate with a knife

The knife is the most affordable tool suitable for cutting solid or honeycomb polycarbonate. For such work, office or construction knives with retractable and replaceable blades are used. It is better to take a construction one, as it has a comfortable handle and a more reliable blade locking mechanism. It’s a good idea to cut polycarbonate with a boot knife.

Shoe knife

Regardless of the type of tool, it must be well sharpened. a dull knife will not only significantly slow down the process, but also leave a lot of burrs on the material. The construction knife is best for working with small sheets, cutting and adjusting them to size.

Replaceable blade construction knife

But, compared to an electric jigsaw or “angle grinder”, cutting polycarbonate with a retractable knife is time consuming. It is not very convenient for them to work with sheets of a large area. It should also be borne in mind that clerical and construction knives are suitable for cutting polycarbonate up to 6-8 millimeters thick, but no more.

It is advisable to use a clerical, construction or boot knife exclusively for cellular polycarbonate. Solid sheets of similar thickness are too hard to cut with this type of tool.

Prepare the site for work. Detailed instructions on how to do this are outlined in the section above. Mark the polycarbonate with a black marker.

First you need to prepare everything

Try the knife on scraps of material or that part of polycarbonate that will not work. you need to check the sharpness of the tool. If it is not enough, replace the blade (for office and construction knives) or sharpen (for a boot knife).

Polycarbonate can be fixed with electrical tape

Attach a rule or a thick metal ruler to the cut line. If they are not available, use a flat board or building level. When working with sheets of a large area, your assistants should keep the rule and the sheet itself. so the accuracy and quality of cutting will increase.

Alternatively, you can mark the cut line with the same tape

Move the knife blade to the end of the cut line. When working with thick polycarbonate, hold the tool perpendicular (or nearly perpendicular) to the plane of the sheet. If the polycarbonate is thin, then it is permissible to hold the knife at an angle of 30-45 °. Slowly insert the knife into the end of the sheet to leave the initial notch there.

Open with a knife

Guide the knife from the notch along the mowing line of the cut. A rule or ruler will help you to follow the pattern.

When cutting with a knife, it is convenient to use a long ruler or rule

Cutting speed should be low, accuracy is more important here. When working with rounded elements, wind the knife on the “turns” carefully, avoiding burrs or cuts behind the line drawn with a marker. Do not be afraid to leave too much. trim after.

When cutting polycarbonate with a knife, use a ruler or rule

If the cut polycarbonate sheet does not separate from the rest of the material, run the blade again along the cut line of the mowing line. It is forbidden to break or bend the material. there is a risk of cracks and other defects.

Trim any burrs, if any. Trim any excess to fit the sheet. If the cellular polycarbonate was cut, then glue the ends with construction tape or electrical tape so that dust and debris do not get into the cells.

If the thickness of polycarbonate (only monolithic!) Is less than 30 mm, it can be cut with large scissors

Job is done

How to cut polycarbonate?

One of the advantages of this material is that tools for working with it can be found in almost every home, and therefore it will not be difficult to cut polycarbonate at home.

The following tools are successfully used for marking and cutting polycarbonate:

- stationery / construction knife;

- electric jigsaw;

- angle grinder, better known as “angle grinder”;

- a circular saw;

- hacksaw for metal.

From industrial equipment, CNC milling machines and special types of lasers are suitable for these purposes.

Polycarbonate Cutting Tools: Hacksaw, Circular Saw, Band Saw

Along with this, there are tools that cannot be used in any case for working with polycarbonate, otherwise there will be a risk of damaging the sheet and getting extremely unsatisfactory results.

- A hacksaw for wood. its teeth are too large, they not so much cut the polycarbonate as they tear. As a result, you will have a lot of nicks, burrs and cracks at the edges.

- Construction scissors or plastic scissors. they are suitable exclusively for thin monolithic sheets of material. Otherwise, when squeezing polycarbonate (especially cellular) from both sides, the sheet is deformed near the cut.

A hacksaw cannot be used

Now let’s take a closer look at the preparation and the cutting process itself with the most popular tools.

How to cut polycarbonate at home?

At the moment, polycarbonate is one of the main materials used in the construction and arrangement of private households, personal plots and greenhouses. Working with it begins with cutting, and not only the appearance, but also the strength of the polycarbonate structure depends on how correctly it is done. Therefore, it is extremely important for every summer resident or owner of a private house to know how and with what tools to cut this material.

Cutting Polycarbonate Angle Grinder

The next most popular tool after the knife is the angle grinder, better known as the “angle grinder”. It is well suited for sawing large sheets of polycarbonate with straight lines. If you need to make a cut with rounded elements, for example, cut out the end wall of an arched greenhouse, then it is better to use a knife or an electric jigsaw.

angle grinder

To cut polycarbonate, use metal cut-off wheels, preferably those that are designed to work with aluminum. This is due to the fact that when using them, the temperature in the cutting zone will be lower than when using a wheel on steel. Accordingly, the risk of melting the edges of the polycarbonate sheet will also be less.

To make the chances of melting even less (and at the same time to reduce the likelihood of burrs) will help the use of an “angle grinder” at low speeds.

For safety reasons, use an angle grinder with a guard. In addition, under no circumstances use cutting discs of the wrong main and bore diameters or saw blades from a circular saw. this is dangerous.!

Prepare a sheet and a platform for work as described in the instructions in one of the previous sections of the article. When working with an angle grinder, fit props and plank scaffolding to the right and left of the cut mowing line. Do not remove the protective film from the sheet.

The sheet should be located on props

Test the Angle Grinder on cuts or unnecessary pieces of polycarbonate. This will give you some practice and a little experience with a similar material and an angle grinder. After that, it will be much easier and safer to correctly cut the main sheet.

Marking before starting cutting is mandatory

Turn on the angle grinder, let it pick up the required number of revolutions and move the cutting disc to the end of the sheet along the cutting line of the cut.

Start the cutting process. Slowly slide the “Angle Grinder” cut-off wheel forward on the cut-off line. Control the position and do not rush, otherwise there is a risk of leaving a large burr. When cutting cellular polycarbonate along the stiffening ribs, the cutting line should be positioned so that the “angle grinder” cut-off wheel does not cut into the walls of the cells. Wear protective goggles to keep plastic shavings out of your eyes.

Start cutting polycarbonate with an angle grinder

When finished cutting, turn off the angle grinder and de-energize it. As a rule, the sheet is cut off immediately and completely; additional work with a knife is not required.

Completion of the cutting process

If you are cutting cellular polycarbonate, remove any plastic shavings and dust from the cells after the process is complete. To do this, use a jet of compressed air, vacuum cleaner or fan.

Cover the edge of the honeycomb polycarbonate sheet with construction tape.

You can cut with a circular saw in a similar way. Choose fine-toothed saw blades designed for metal or plastics. Immediately before starting to insert the disc, let it gain the required number of revolutions. The base plate of the tool, which needs to be pressed against the sheet, will help you to increase the accuracy of cutting.

Cutting polycarbonate with an electric jigsaw

The choice of an electric jigsaw as a tool for cutting polycarbonate sheets can be called a kind of compromise between the cutting speed of the “angle grinder” and the safety (as well as relative simplicity) of working with a construction knife. In addition, the jigsaw is great for sawing semicircular / round elements and parts of complex shapes.

Using an electric jigsaw to cut polycarbonate

The main thing is to choose the right file. First, notice the shape of the prongs. Straight or wavy prongs will give you an even, clean cut. exactly what you need. With adjustable teeth, the opposite is true. they are designed for working with wood, therefore an electric jigsaw with such a saw will not cut, but tear the polycarbonate, leaving a lot of chipping, burrs and other defects in it.

Second, pay attention to the number and size of the prongs. They should be frequent and shallow. These properties are determined by the TPI parameter. the number of teeth per inch. In our case, give preference to files with TPI from 9 to 13 and more.

Thirdly, ask the seller what material this or that file is designed for. You need those canvases that are designed to work with metal, plastic or plexiglass. Choose specialized files whenever possible. they will give a clean cut with a minimum of defects.

File for working with acrylic glass, plastic and polycarbonate

Mark out the polycarbonate sheet and prepare the work area.

Place the file in an electric jigsaw. It is advisable to use a new and sharp blade. Fix it carefully and adjust. if it is not properly fixed, the file will vibrate and leave defects on the polycarbonate.

Move the jigsaw connected to the power supply to the end of the sheet along the cutting line of the cut. For greater convenience, make a notch in this place in advance with a sharp knife with a retractable blade. Do not remove the protective film from the sheet until the cutting process is complete.

Cut polycarbonate for 4 m greenhouse Kremlevskaya

Press the base plate of the jigsaw against the material. Make sure that the force applied to the tool is not excessively large, otherwise the polycarbonate along the mowing line of the cut will bend. It is advisable that your helpers or clamps hold the sheet, not allowing it to move or vibrate.

Turn on the electric jigsaw and let the saw speed up. As soon as it does this, start cutting into the material along the cut mowing line, slowly and carefully guide it forward, pressing the base plate of the jigsaw against the plane of the polycarbonate. Take special care in curved sections. It is a good idea to pre-practice cutting rounded parts on polycarbonate cuts and waste. a good idea that will give you experience and simplify your business.

Start cutting an element of complex shape with a jigsaw. Finish cutting polycarbonate with a jigsaw. If you do not want to stand on the material, even if you have a scaffold board, then first make a cut on one side, then on the opposite

After completing work with the electric jigsaw, switch it off and unplug. Clean the cells of the polycarbonate sheet from chips using a vacuum cleaner or a jet of compressed air. Cut off the excess with a knife and clean the edge of the sheet from defects. Cover it with construction tape to protect the cells from dirt and dust.

When working with several thin sheets of polycarbonate, you can significantly save time by cutting several sheets at the same time in a stack. Before starting cutting, make sure that the sheets do not move relative to each other.

How to cut polycarbonate at home: basic tools

Benefits

- Maximum speed of manipulation. Minimum investment of time and effort.

- This option, how to cut monolithic polycarbonate at home, guarantees the absence of failures and defects.

- Accurate cutting is maintained as the laser controls dimensional accuracy down to 0.05 mm.

- During sawing, the sheets do not need to be secured, which makes the task easier.

However, despite all the visible advantages and luxurious characteristics, such equipment is very expensive. Of course, one-time use is not worth the expense. It’s another matter if you have grandiose plans for the manufacture of greenhouses. your own workshop, in which you will regularly make various polycarbonate coverings. It should be understood that when working with an industrial laser, you cannot do without the appropriate skills, which are almost impossible to learn on your own.

Stages of cutting and installation of polycarbonate

Preparatory stage, cutting schemes

First, you need to remove all debris from the site for work. This must be done mainly so that excess debris does not disrupt the process and does not leave dents, scratches or other traces on the back of the sheet.

Place a chipboard or fiberboard plywood sheet under the prepared polycarbonate sheet. The cutting area is now as flat as possible.

Bring and place a sheet of polycarbonate on the prepared workplace. If it is covered with a laminate or has a mirror (UV) coating, then put the sheet upside down with this side. It is not necessary to remove the protective film from the sheet until the material is cut.

Draw preliminary schematic markings on paper, observing to scale.

Transfer the layout from the paper to the polycarbonate. To measure correctly, use a tape measure, a metal ruler and a black marker to draw cutting lines.

Small addition to the above

When it comes to how to cut polycarbonate for a greenhouse at home, you can also use cutting materials that are practiced in metalwork! For example, a cutter.

Having decided to start cutting polycarbonate sheets, a person who has no experience doubts how you can cut polycarbonate with a hacksaw. We answer the question: it is possible with a primitive hand saw. The whole trick lies in the fact that without experience you can easily achieve the appearance of cracks along the mowing line of the cuts.

Remember. if you decide to use a hacksaw. the fastening of the sheets plays the most important role here! They must be secured in such a way as to avoid any vibration and stress. Then the hacksaw won’t let you down.

How to cut polycarbonate for a greenhouse at home. Cutting rules

The most modern and popular material for creating a greenhouse is polycarbonate. It is a polymer plastic sheet that holds the record for sales. And this is not surprising, because this material has such important properties as: durability and good light transmission. To make the greenhouse durable, you need to choose a suitable frame and cut the polycarbonate sheets correctly. And how to cut polycarbonate at home? We will tell you how and with what tools to do it yourself.

Stationery knife

The knife is the most affordable of all tools suitable for cutting solid or honeycomb polycarbonate. As a rule, clerical or construction knives with retractable and replaceable blades are used. If you have a choice, then it is better to take a construction one, since it has a comfortable handle. and the blade locking mechanism is more reliable.

Stationery knife is the most affordable cutting tool

A few things to consider when doing carving:

- The tool must be of excellent performance to cut polycarbonate effortlessly.

- Note! Cutting polycarbonate should be done without haste as the blade is sharp. Here you can not only spoil the polycarbonate, but also injure yourself.

Important! Stationery knives are only suitable for cutting non-thick sheets, approximately 4-6 mm. Working with thicker ones on your own at home will be difficult to work with. By and large, the knife is useful where you only need to quickly trim the edges.

Angle Grinder

It is in the first place among other tools, because almost everyone has an angle grinder. At the same time, it is absolutely not necessary to buy an expensive tool. Even an inexpensive angle grinder will do its job perfectly and make even cuts. To do this, you need to set the circle 125, which is for metal. Just before you start cutting, you need to practice on unnecessary trimming, since the tool makes sharp turns and you can damage the material out of habit.

Current recommendation: Angle grinder is a very good cutter for polycarbonate, but if possible, it is better to use angle grinders with safety shrouds for more precise cuts. You can not take cutting wheels with an unsuitable diameter, both the main and the landing. The use of circular saw blades is prohibited!