Adjusting the carburetor chainsaw Oleo-Mac 941c

When you purchase the chainsaw, the carburetor is factory-adjusted for reasonable operating conditions. But in the course of use, the engine (ICE), fuel pump, carburetor, as a result, you need to perform their repair, maintenance and options. With all this the role of a carburetor. limitation of low and high engine revolutions.

The main aspects that allow you to find the need to adjust the carburetor:

- The engine does not start, it stops and does not respond to the gas pedal;

- Lack of idle speed;

- High fuel consumption, GIS doesn’t develop power;

- Wear piston group, soot on the spark plugs, black exhaust fumes, incomplete combustion of gasoline.

The following are the prerequisites for failure of carburetor options:

- Breach of fixation of screws regulating low and high revolutions of the engine, because of strong vibrations or mechanical influences;

- If the piston system of the GIS is worn;

- Clogging of air or fuel filter, nozzles, fuel duct, breakage of inlet valve.

Malfunctions and methods of their elimination

Common defects can be:

- Clogging of filters or jets, corrected by cleaning;

- Damage of the diaphragm (playing the role of a pump), solved by replacement;

- Failure of the gaskets, you need to replace them with new ones after disassembly of the carburetor body parts;

- Jamming the valve (the needle that cuts off the fuel supply to the carburetor), you need to assess its condition to determine the ability of its upcoming operation or replacement;

- Violation of the contact lever of the choke with the gas pedal, you need to restore, repair or replace the node.

It is not uncommon for some of these problems to appear after the chain saw has been idle for a long time. To restore performance requires complete node service and pre-starting operations.

Main problems and malfunctions of the carburetor.

Strainer. There are two problems with this element most often:

In order to find out the cause of the breakage unscrew the fuel filter cover to remove the strainer. If it is just dirty, you can rinse it in gasoline or blow it out.

If the strainer is visibly damaged it is imperative that a new strainer be fitted. There may also be damage to the fuel supply pipe (when repairing the practice of checking this element).

The carburetor starter mechanism almost always fails to work because of clogs. Should use acetone or the same gasoline for flushing.

Blowing out clogged carburetor parts with compressed air is an acceptable and comfortable repair practice.

Throttle body, carburetor component bundles, inlet or outlet piping. all these parts are subject to depressurization. You can check probably a simple method. put soapy foam on the problem area.

Description

Oleo-Mac chain saws are reliable, high-quality products that can be used both in the workshop and on the farm. Production of chainsaws of this brand is made with high quality, reliable materials and modern technology. Many buyers highlight the versatility of household chainsaws Oleo-Mac, which is their main advantage in comparison with competitor models.

Oleo-Mac 937 chainsaw

Oleo-Mac products have been on the market for more than 40 years. During this time the construction features and design of the products have changed significantly.

Modern developments by Oleo-Mac improve the quality and reliability of products. The company’s chainsaws and other machines are continually being improved to maintain global sales.

The first chainsaws like the Oleo-Mac 937 had basic components and could only be used for domestic purposes. New models offer a wider range of applications and greater functionality.

Advantages of modern Oleo-Mac chain saw models:

- Quick start system.

- Cooling system and automatic oil supply.

- Modern air intakes with re-cleaning system.

- Reliable emergency stop system.

In addition, many models are equipped with a system of protection against accidental start. Oleo-Mac models are characterized by a modern, ergonomic design that makes the user comfortable and safe while working.

Basic Oleo-Mac chainsaw equipment:

Saw bar cover Fuel mixing container Chainsaw assembly keys

Depending on the year of manufacture and model of the machine, this equipment may vary slightly.

Advantages and disadvantages

- There is no toothed stop in the basic package;

- Some owners complain about the quality of the saw chain;

- Needs high quality fuel and lubricants.

Technical characteristics of each model vary.

The entire line of chainsaws is divided into 3 types:

Their technical and construction features are designed for small domestic tasks, such as cutting firewood or limbing.

Oleo-Mac 936 chainsaw

Oleo-Mac GS 370 chainsaw

Oleo-Mac GS 35C chainsaw

These models have small size and power. Household Oleo-Mac chain saws weigh less than 5.5 kg.

Characterized by medium-performance specifications. Weight of the devices is up to 6 kg, but their functionality is greatly extended. Manufacturer specifies that such saws can be used for cutting big diameter logs and working with frozen wood.

Oleo-Mac 941 CX chainsaw

Oleo-Mac 947 chainsaw

Oleo-Mac 952 chainsaw

Most semi-professional chainsaws are equipped with a quick start system, which allows to work at minus temperatures.

This class of chainsaw has a guide bar longer than 45 cm. and is designed for time-consuming work. As a rule, such devices weigh more than 6 kg. and equipped with a powerful engine.

Oleo-Mac GS 650 chainsaw

Oleo-Mac GS 720 chainsaw

Oleo-Mac GS 820 chainsaw

A more detailed list of technical specifications is listed in the instructions for use for the device, on the official website of the company or in the online store. Before buying a particular Oleo-Mac model, it is worth paying attention to the purpose of further use.

Manufacturer: Italy, China. Oleo-Mac chain saws are marketed as European products. In addition, EmakSpA has several subsidiaries in China. Thus, the Italian company reduces the price of their devices and makes them more affordable for Russian buyers. In most cases it significantly affects the quality of the products.

To avoid buying low-quality products, the manufacturer recommends choosing Oleo-Mac equipment in specialized stores.

To avoid the purchase of a chainsaw manufactured in China or assembled in China, it is recommended to study the technical characteristics of a particular model, pay attention to the original appearance and functionality. Of course, the cost of the original saw and the fake will be significantly different.

Adjusting the Ural

It is little different in that it should not be carried out at high revolutions, but make sure that the chain picks them up quickly, but smoothly, without moving on the bar.

In any case it is necessary to take the regulation especially seriously, because if it is done incorrectly, the saw won’t stay with you for a long time. Take care of your own tools and if you are not sure yourself, call in a specialist.

READ How to Set the Angle of Sharpening for Band Saw Blades

No matter which one, even a good friendship, needs attention and care. Then the chainsaw will be your faithful assistant for a long and lasting years.

When you buy the HUS365 chainsaw, you must be prepared for the fact that after a month of use you won’t want to deal with a single saw other than this brand. This is due to its reliability, accessibility, and, most importantly, ease of operation.

Adjusting the carburetors on Oleo-Mac chainsaws 941c, 936

There is no difference in correction. Oleo Mak 937, 941c, and nine hundred and thirty-six chainsaw carburetor models are the same. We explored the step-by-step adjustment in detail using the example of the 937 model, so no matter which of the listed duster is adjusted with a similar approach.

carburetor adjustments

For clarity, chainsaw carburetor options can be viewed as follows. After viewing no adjustment questions should arise, even for beginners.

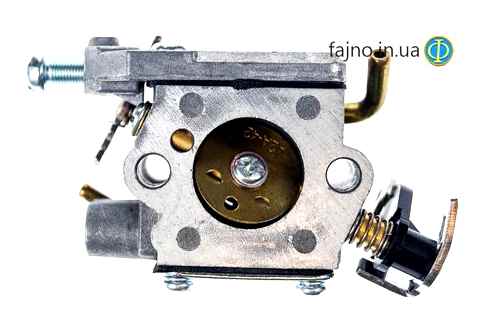

Carburetor Repair Kit

To repair the carburetor for you will come in handy repair kit, the composition of which is as follows:

Adjustment Aspects

When adjusting carburetors for Oleo-Mac chainsaws, the following aspects usually appear:

- Inconsistent auger markings. Depending on the model, equipment supplier or other reasons markings may be different from the outlined. In such cases, it is recommended that you carefully study the annotations that come with the device.

- After the option it is necessary to switch off the chainsaw and let it cool down for 10-15 minutes to check its work from a cool start.

- If you have no experience or the right knowledge, it is not recommended to adjust the screw H. This is due to the possibility of establishing a bad fuel-air consistency, which can lead to wear of the piston group, malfunction at start-up and engine operation.

- On all the steps it is necessary to control the revolutions of the engine with the tachometer. An oscilloscope or multimeter with this function can be a substitute for a tachometer.

READ STIHL Mower carburetor adjustment

Step by step adjustment

Let’s look at an example of adjusting the carburetor on a chainsaw Oleo Mak 937. The principle of adjusting the other duster is actually similar, because this method is applicable to the following models: 941c, 936. With other, less popular models (for example, Oleo Mak three hundred and sixty-two or Oleo Mak 35) similarity is not checked. but probably no severe differences.

Before adjusting the carburetor for the Oleo-Mac chainsaw, a number of criteria must be met:

- untainted air and fuel filters;

- Check the condition of the jets, make sure they are good and unstained;

- Evaluate the integrity of the diaphragms: no damage, no cracks;

- check if there is enough fuel in the chamber.

Disassembly is not required for standard carburetor adjustment. There are screws on the outside to make all the necessary adjustments:

Although the manufacturer recommends only adjusting the S screw, in practice this is not enough. Before adjusting all three screws should be turned to the stop and then unscrewed 1.5-2 turns.

- Engine starts, warms up for 3-5 minutes at medium speed.

- tachometer is plugged in.

- Working at low speed is adjusted with the L screw. You need to reach 1-1,500. RPM. engine without reversing the chain, and when the gas pedal is pressed, the revolutions do not drop. If a fault is found, the screw should be unscrewed until the effect is eliminated.

- The high speed of the motor is adjusted with the H screw. When the gas pedal is pushed to the maximum, they keep the acceleration under control, it is fundamental that they do not exceed a very permissible value. It is recommended to set it 5-10% below the highest speed so as not to provoke increased wear on the gasoline engine.

- The carburetor is fine tuned with the S screw. When the chain is idling, turn the screw counterclockwise as far as it will go. If the gasoline engine is stalled, the screw should be unscrewed clockwise until a measured operation is obtained.

- After carrying out the procedures, the chainsaw is tested under real working conditions. Do the options again if necessary.

READ No oil in chainsaw chain

Carburetor adjustment

Proper adjustment of the fuel system directly affects the economy and performance of the chainsaw. Adjusting the carburetor is one of the most important maintenance items.

The service manual for this tool lists a certain sequence of adjustments to be made after servicing the air intake filter and warming up the power unit at medium speed.

Traction and fuel economy are restored to pre-set levels after the fuel system has been adjusted. If the machine won’t start or won’t perform at the proper operating level, it could be a clogged jets or water in the carburetor.

Benefits of the Oleo-Mac chainsaw range

This manufacturer’s products have an optimal ratio of cost to quality in all parameters.

The Italian Oleo-Mac brand chainsaws are characterized by

- ergonomic design;

- high quality of materials;

- exemplary craftsmanship;

- reliability and long service life.

The models supplied to the domestic market of chainsaw equipment do not require extensive pre-sales preparation. Ready to go after filling up the gasoline cartridges and installing the flat top.

Design Features

Despite the possible difference in design, the carburetors of chainsaws work on the same principle, so the sequence of adjustment of different models does not differ significantly.

Prestige chainsaws from top manufacturers come with technically advanced carburetors with built-in compensators and automatic choke control. Such revisions contribute to the operator’s comfort, but do not affect fuel efficiency and other operating parameters.

The list of optional equipment includes a booster pump designed to enrich the mixture before starting the power unit. Many models of professional-class chainsaws are equipped with a heated carburetor devices, which are included in the transfer tool for winter use.

Preparing for self-adjustment of fuel system

The procedure for adjusting the carburetor is described in the instruction manual supplied with the machine. A screwdriver for adjusting the screws marked L, H, and T is supplied in the factory. Some manufacturers equip their chainsaws with a carburetor, which requires a special key for adjustment.

Proper adjustment of the fuel system presupposes warming up the power unit to operating temperature and pre-cleaning the air intake filter. Saw is in a position that allows easy access to the fuel system.

Complete set

When buying a chainsaw Oleo-Mac 936, the customer receives a standard kit, which comes with any saw.

It should be noted that with all of the above, the customer gets a 3-year warranty on the chainsaw.

Adjusting the carburetor

For clarity the carburetor adjustment on the chainsaw can be seen in the example below. After watching it there should be no questions about adjustment, even for beginners.

Modification

In addition to the usual 937, you can also find on the market a modification with the PoverSharp badge, which is even applied to the tire. It is not fundamentally different, but the set includes a special tool for sharpening the bar. It’s a plastic cover with a sharpening stone inside.

You put it on the end of the bar and press the stop and the chain can be sharpened in a few seconds without taking it off. But users do not like this sharpening stone: They say it produces lots of spark and not enough power. Better to turn it the old-fashioned way, with a file or take it to a repair shop.

Oleo-mac chain saw repair (oil pump, carburetor)

(oil pump, carburetor) Service website. Group

Q: I bought an Oleo-Mac 941 cx chainsaw a year ago, good saw, works great. Passed the running-in period and it has a slight malfunction.

When the engine is warmed up and, sawing limbs, trunks then when you switch the lever to the stop position the engine is not shut off and continues to run for a few seconds from 10 to 20 seconds.

On initial start, when the engine is not too hot it stops right away. The service center said that’s the way it’s supposed to be.

I don’t know if that’s right or not. May be after running-in a lean mixture comes in and needs to be adjusted with the L and H screws?

Answer: Wrong! Most likely, the spark plug does not match or the fuel is bad.

This is called “glow ignition” when the fuel mixture is ignited spontaneously from the glow plug electrodes instead of the spark.

It will not put the engine out of operation at once, but with time. definitely.

When you turn off the engine you are not shutting off the fuel, you are interrupting the supply of spark to the spark plug. So it has absolutely nothing to do with the carburetor. Oleo-Mac 941c chainsaw, carburetor adjustment, carburetor repair. The reason could be the fuel.

Use 92 gasoline from a trusted gas station. Either the spark plug is “very hot” t.е. has a low wick number.

I’m sorry, it’s not under warranty. Try changing the fuel and plug, I think the problem will go away.

Give it about 20 seconds. 30 at idle. It’s good for the engine anyway.

Question: I have an Oleo-Mac 941c chain saw, almost new, assembled it myself out of the box.

It was fine at first, but then it was used by construction workers, how. don’t know.

In general, the cord stopped retracting all the way. I solved this problem by taking apart the housing and wrapping an extra lap around the spring. now retracts and sits in the socket a little taut), but there was another problem. runs for about a minute, even a little less, and then stops.

It feels like there’s no gas, but the tank is full. I loosened the tension on the chain. didn’t work, what else can I do??

Answer: If the saw stops when idling. Just turn the idle speed screw clockwise.

And if under load, then you need to adjust the carburetor. You should also check and clean the air filter.

It might be the problem. If nothing changes, you have to adjust the carburetor, the idle speed screw won’t make any difference. You need to ask for a service.

A chainsaw is a highly technical piece of equipment and should be serviced from time to time. Cleaning, filter replacement and, of course, carburetor adjustment will help your chainsaw last as long as it should. In this article we will consider the issue of carburetor adjustment. How and why is it done?

New chain saws come from the manufacturer with their carburettors already set. This is called standard adjustment. But for a normal process, you need to lower the maximum engine speed, to adjust the carburetor. After the running-in period, the chainsaw needs fine-tuning to achieve maximum engine performance.

This is also the signal for cleaning and adjusting, as increased fuel consumption negatively affects the performance of the exhaust system. To put it simply, the chain saw begins to smoke a lot and the muffler becomes clogged with soot and this in turn leads to a loss of power. With a lack of fuel in the mix, engine parts are poorly lubricated and premature wear occurs. Poor mixture can also cause the engine to seize up due to overheating (this is one of the reasons why ).

Adjustment is necessary if the engine does not keep idle speed, stops or does not develop full power.

Carburetor tuning should be done with clean air and fuel filters.

Advantages and disadvantages

- No toothed stop is fitted as standard;

- Some owners complain about the quality of the saw chain;

- Needs high quality fuels and lubricants.

The manufacturer tried to achieve an acceptable quality-price ratio in all models. The entire lineup has the following advantages:

- quality parts and materials;

- ease of operation;

- Fuel consumption is lower than that of analogues of other brands;

- Easy assembly;

- quick start in winter.

Some models use technology that other brands do not. That’s why Oleo-Mac saws are so popular around the world. But no matter how high the demand, it is not always possible to meet it. This reveals the main disadvantage of. Despite the popularity of products on the territory, the company can not properly supply all the stores with spare parts and consumables. In addition, the saws of this brand are sensitive to the quality of gasoline and oil.

Order online

940C 16″, 936 16″, GS 35-14″, GS 35-16″, 937-16″, 35-16″ PowerSharp, 35-14″ PowerSharp, 937-14″ PowerSharp, 937-16″ PowerSharp, 941C-16″, 941CX-16″, 925-10″, 932C-14″, GS 260-10″, GS 44-16″, GS 650-18″, 962-18″, 947-18, 952-18″, 985HD-30, 965HD-18″, 956-18″, 971-20, GS 720 20″, GS 820-30″, 981-25

- Blog

- About our service center

- Served brands

- for diagnosis and repair

- Delivery

- Spare parts

- Contact

Repair and service of garden equipment.

Specialized Service Center. providing comprehensive warranty and post-warranty maintenance of gardening and municipal equipment from world manufacturers! We carry out sale of spare parts with delivery across all Russia!