The principle of operation of the internal combustion engine

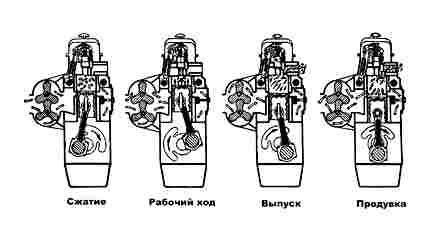

The working cycle of a two-stroke engine consists of intake and exhaust, which occurs in one revolution of the crankshaft, while a 4-stroke has the following cycles – intake, compression, working stroke, exhaust. And they take two turns of the flywheel. In an engine with 4 strokes, intake and exhaust are carried out in the form of different processes, in a two-stroke they are combined with the compression of the fuel mixture and the expansion of the working gases. The principle of operation of a two-stroke engine:

- The first measure is compression. The piston moves from the bottom dead center, while the purge port closes first. The waste exhaust gases are discharged through the exhaust port. At this moment, a vacuum area is formed in the crank chamber under the piston crown, where the enriched fuel mixture is supplied from the carburetor (injector). This portion of fresh air pushes the remaining exhaust gases into the exhaust manifold. At the moment of the highest position of the piston, the mixture is ignited from the spark plug.

- The second cycle is a working stroke or extension. The temperature and pressure of gases in the combustion chamber increases sharply, under its action, the piston begins to move to the bottom dead center, doing useful work. The increased pressure in the crank chamber shuts off the intake valve, preventing exhaust gases from entering the carburetor. Through the system of exhaust ports, the exhaust gases go into the muffler, and through the purge port, a fresh combustible mixture begins to flow into the combustion chamber. At the lowest point, the action of the second measure ends and the process repeats.

A two-stroke diesel engine works on the same principle, only it does not have a spark plug, and the fuel is ignited by compression. Therefore, the compression ratio in diesel internal combustion engines is much higher than gasoline.

Two-stroke engine: device and principle of operation, differences from a four-stroke

Internal combustion engines are built on the same principle – the energy of fuel combustion is converted into kinetic energy of rotation of the crankshaft. There are two types of motors – two-stroke and four-stroke. Both have their own advantages and disadvantages, let’s try to figure out what the differences are..

Lubrication system and fuel preparation

The operation of a two-stroke engine requires effective lubrication of moving parts. There is no centralized separate lubrication system with an oil pump, like in four-stroke engines, so oil is added to gasoline in a ratio of 1:25 – 1:50. The resulting composition, being in the piston and crank chambers, lubricates the connecting rod bearings, cylinder walls and piston rings. When the air mixture ignites, the oil burns out and is removed along with the exhaust gases.

The engine oil must be special – for a two-stroke engine, usually it is marked 2T on the canister. The use of regular automotive oil is unacceptable for a number of reasons:

- Oil for two-stroke engines must have good solubility in gasoline;

- Possesses excellent lubricating properties, improving engine performance and reducing friction;

- Corrosion protection of rubbing parts of the piston group;

- Two-stroke oil should burn out without residue, without forming carbon deposits and soot. High ash content of conventional oil leads to coking of piston rings.

The two-stroke engine can be supplied with lubricant in two ways. The first and the simplest one is to mix it with fuel in the right proportion. The second is a separate lubrication system for a two-stroke engine, when a composition of fuel and oil is prepared immediately before entering it in a special pipe. In this case, a separate oil tank is installed, and its supply is carried out using a special plunger pump..

This system is widely used on modern motorcycles and scooters. In addition to ease of use (now there is no need to add oil to the tank by eye every refueling), there is a serious saving of oil, because its injection depends on the engine speed. At idle, the oil ratio can be as low as 1: 200.

Tuning two-stroke engine

Any two-stroke motor has a boost capability. An increase in power with the same volume is justified in sports, and in everyday use the engine becomes more elastic and more economical. The main ways of revision:

- Increase the diameter of the outlet and keep it open as long as possible. This allows the maximum amount of gases to be released. This increases the traction capacity of the engine and its torque..

- Provide efficient purging. To do this, you can increase the diameter of the inlet window, then the combustible mixture will not linger in the crankcase and timely injection into the combustion chamber will be ensured.

- The use of a swirl diffuser on the carburetor, which at the same time delivers a larger amount of the fuel mixture. Together with it, it is advisable to use an air filter of zero resistance..

- Installation of the exhaust resonator, the calculation of which is made for a specific engine size. Such a device returns part of the fuel mixture back into the cylinder through the outlet..

- Modification of the connecting rod-piston group, its lightening and careful balancing. Valves and channels must be lapped in and free from burrs (seizures), retarding and swirling flows. This reduces the filling of the cylinder and reduces the power..

- Application of injection injection systems and variable valve timing. This allows for more accurate metering of the amount of fuel supplied and to reduce the loss of the combustible mixture during cylinder purging..

- Installation of pressurization systems. Typically, these are compressor blowers, and a traditional turbocharger can be installed on a two-stroke diesel engine. With its help, the amount of air entering the cylinders increases, respectively, and the amount of fuel can be increased..

Features of the two-stroke motor

A two-stroke engine completes a full cycle in one revolution of the crankshaft, which allows obtaining a higher specific liter power than a 4-stroke engine at the same engine speed. However, the efficiency of the two-stroke will be lower due to the imperfection of the valve timing mechanism, the inevitable loss of the fuel mixture during the purging process and the incomplete working stroke of the piston..

The two-stroke engine gets very hot because a lot of heat energy is released during operation. Sometimes additional cooling may be required. Two-stroke engines with a large number of cylinders are rarely used in motorcycles, the most commonly used single-cylinder air-cooled engine.

When operating on a two-stroke cycle, the piston makes fewer movements per stroke, and the load on the auxiliary gas distribution, lubrication and cooling systems on the crankshaft is lower or absent altogether. Therefore, the wear of the piston group will be lower. If this is not a decisive factor for light vehicles, then a low-speed two-stroke diesel engine can have several times longer resource than all other ICEs. Therefore, they are widely used in diesel locomotives, generators, marine engines..

The two-stroke gasoline engine picks up speed at maximum power faster. This is actively used by motor sportsmen, especially in cross-country disciplines, when an instant response to the throttle is needed. In addition, it is easier to maintain, cheaper and lighter than a four-stroke.

The fuel consumption of a two-stroke will be 25-30% higher, noise and vibration will also be higher. The engine cannot fit into tough environmental standards, even if we use injection and pressurization systems. High air consumption requires the use of special air filters.

Operation and causes of engine breakdown

Most often, two-stroke motors are found in motor vehicles, boat engines, lawn mowers, chain saws and other devices where a light and reliable engine is required. Nevertheless, even such a simple engine can fail due to violation of the operating rules..

- Poor quality of gasoline. Poor fuel often leads to knocking. This is most often noticeable at low rpm with podgazovki. The resulting shock loads lead to breakage of the piston baffles, excessive loads on the crankshaft bearings. Detonation can occur due to engine overheating, piston deposits and a lean mixture.

- Poor quality of parts from which the motor is assembled. This is especially true for Chinese manufacturers, who often allow defects in the production of components. This leads to early failure of the piston, crankshaft, cylinder and other parts, and then overhaul. Usually a simple compression measurement helps to assess the piston condition..

- Low quality engine oil. Fuel-oil mixture for two-stroke engines is very important. It will depend on its quality how smoothly the engine works, the purity of the exhaust, the absence of overheating and unnecessary noise. Bad oil leads to the formation of a layer of carbon deposits on the piston, in the main and connecting rod bearings, to scuffing on the cylinder walls and the piston skirt, the passage section of the muffler decreases due to carbon deposits. Oils for two-stroke engines should be used synthetic or semi-synthetic, the use of mineral water is undesirable.

- Overheating on an air-cooled two-stroke engine is not uncommon. This is caused by prolonged operation with a fully open throttle, or a malfunction of the cooling system. Overheating can be short-term, when there is a loss of power and maximum speed, after reducing the load and cooling the engine, everything returns to normal. A wedge occurs due to very strong overheating, when the thermal gap between the piston and the cylinder is reduced so much that the friction forces tightly grab them together. After it, repair of the CPG is required.

- Carburetor not tuned. The fuel mixture is too lean or too rich. Driving on an over-rich mixture is fraught with high fuel consumption, loss of power and sludge formation. A lean mixture can cause knocking and a decrease in maximum engine power..

To prolong service life and delay overhaul, a two-stroke boat or motorcycle engine should be properly run-in. For this, the proportion of oil mixed with gasoline should be slightly higher than that established for normal operation. Let the engine run on such a mixture in partial power mode for several hours, which is equivalent to 500-1000 km of run for a scooter and a motorcycle..

Yet, due to the toxicity of the exhaust, two-stroke engines are gradually being replaced by modern four-stroke engines. They continue to be used only where high power density is required with minimal weight and simplicity of design – motor vehicles, chainsaws and trimmers, aircraft models and much more..

How To Mix 2 Stroke Oil (Oil and Gas)

Requirements

A quality oil that can be poured into a gasoline trimmer must meet a number of requirements and standards to ensure reliable operation of the device and its performance. The oil should:

- provide an increase in wear resistance for various elements (in particular, the gearbox is especially susceptible to this);

- ensure the formation of smoke and exhaust gases is as low as possible;

- do not allow premature ignition;

- mix well with gasoline when exposed to low temperatures;

- have good viscosity and flow characteristics in various temperature ranges;

- be as safe as possible in terms of environmental impact.

As mentioned, two-stroke engine oil will differ from four-stroke engine oil. It has higher power, which is why fuel for it is obtained by mixing a certain amount of gasoline and oil. For each lawn mower, the ratio will be different. You can find out its meaning in the instructions for the device. These proportions must be observed with maximum accuracy. When adding additives, take into account the type of motor.

If mineral oils are used, mixing should be somewhere in the ratio of 1: 25, 30 or 35, depending on the type. If we are talking about a synthetic analogue, then the proportion will be 1: 50 or 80. That is, a certain amount of oil dissolves in the volume of gasoline.

Choosing a lawn mower oil useful tips from professionals

If the instructions for the tool have been lost, and there are difficulties with choosing the right oil, then it is recommended to stop your choice on the following two options:

- Semi-synthetic – they are cheaper than synthetics, but more expensive than mineral water. Suitable for equipment, both Russian and foreign. They have low smoke parameters, and adequately “take care” of the structural elements of the motor. Manufactured by ferrying petroleum products and hydrocarbons

- Synthetic – expensive types of lubricants that are suitable for all types of equipment. If you use synthetics for your trimmer, then the engine of the tool will work like a clock.

When choosing and buying oils for dilution with gasoline, you may come across the fact that some letter designations are indicated on the cans. These designations are an API classification, which will be useful to find out who wants to fill the tool with a lubricant that is suitable for the parameters. Let’s consider all types of oils according to API classification for two-stroke engines:

- TA – intended for air-cooled units with a volume of up to 50 cm3. These include mopeds, lawn mowers, trimmers and lawn mowers. Optimal solution for lawn mowers and trimmers

- TB – used for refueling engines of units such as mopeds, chainsaws, scooters and motorcycles. The engine displacement of such equipment ranges from 50 to 200 cm3. This type of oil is also suitable for trimmers

- TC – intended for dilution with gasoline and filling in motorcycles, snowmobiles and other types of land equipment

- TD – serves for refueling outboard motors, hydro scooters and boats

API classification is an American standard that is used in Europe. However, when choosing, there are additional designations on oil cans for two-stroke engines, for example, FA, FB, FC, FD and others. This is the smoke emission classification of oils developed by the Japanese JASO standard. If such designations are found on the selected oils for trimmers and chainsaws, then their decoding must be taken into account:

- FA – used in countries where the legislation provides for the minimum emission of smoke into the atmosphere. Emits an imperceptible fog of smoke during operation

- FB – Designed for use in countries where there are strict restrictions on the emission of smoke into the atmosphere. Virtually no white smoke

- FC – smoke emitted into the atmosphere is transparent and invisible to humans

- FD are smokeless oils for 2-stroke internal combustion engines that do not emit smoke, but still have improved chemical properties. They are usually used for mixing with gasoline and refueling boats, boats and yachts.

If the container with the lubricant has the designation “self mix” and “pre mix”, then they mean – self-mixing with gasoline (the first option, which does not require shaking), and the need for forced dissolution (the second option).

Knowing the classification of oils by their types, it will not be difficult to choose the best option for your brand of lawn mowers. On the market you can find a variety of brands of oils for two-stroke engines, but it is better to pay special attention to such companies:

- Stihl – produce mineral and synthetic, and semi-synthetic of this brand are rare

- Shell Helix Ultra – Recommended by Specialists

- Motul

- Oleo-Mac

- ECHO

- Hammerflex

- Lukoil is a Russian oil that costs 3 times cheaper than foreign analogues, but at the same time has excellent quality indicators

Product prices are not indicated as prices vary. There are many other brands, and if you still want to find the perfect trimmer lubricant for yourself, then it is recommended to watch the test in the video clip below..

From the video, we can conclude that it is not always useful to buy expensive oils, since they may turn out to be of unsatisfactory quality, which can be seen in a real example..

Two-stroke trimmer oil

To cut grass in the country or in the field, you will need gasoline trimmers. They run on gasoline, unlike their electric counterparts. Far from many masters know how gasoline and oil for trimmers, petrol and lawn mowers are diluted. Step-by-step instructions for preparing the fuel mixture in the trimmer will be useful not only for beginners, but also for specialists who may be refueling chainsaws incorrectly.

Varieties

The oil that is poured into the engine may differ in the production method. According to this criterion, it happens:

- mineral – this type is obtained during the processing of petroleum products;

- synthetic – it is obtained by processing or synthesizing gas;

- semi-synthetic – this type has better characteristics due to the introduction of synthetic-based components into it.

Lawnmower oil refers to formulations intended for use in air-cooled engines that have a combustion chamber volume of 50-200 cubic centimeters. In addition, any two-stroke oil can differ from analogs in additives that give it certain additional characteristics. They are of the following types.

- Antiwear. The main task of the oil will be to reduce wear of parts during the operation of the device..

- Antioxidant. They do not allow oxidation to occur and make it possible to maintain the performance of the oil for a long time..

- Anti-corrosion. Their task is to prevent corrosion from forming on the engine parts..

- Friction modifiers. These additives can significantly reduce the coefficient of friction.

Two-stroke oil from different manufacturers may differ in the combination of additives used, which means that their properties will differ.

Recently, when purchasing oil for dilution with gasoline, users very often come across the fact that special letter abbreviations are applied to the cans. These designations are made within the framework of the API classification. Consider what types of oils exist in accordance with it..

- The TA is used for air-cooled lawn mowers with an engine displacement of no more than 50 cubic centimeters. It can be used not only for mowers, but also for mopeds, lawn mowers and other types of machinery. For a petrol trimmer, this is the optimal solution..

- TB is used to refuel a chainsaw, scooter, moped or motorcycle, the engine of which does not exceed 200 cubic centimeters. Can also be used for refueling petrol trimmers.

- TC is suitable for thinning with gasoline and pouring into a snowmobile, motorcycle and other types of equipment.

- TD is intended for refueling boats, yachts and gyro scooters.

But in addition to this classification, other letter designations of the FA-FD type are often found. It should be said that the API is an American standard that is used in Europe. But there is a discrepancy between European and American smoke emission regulations. For this reason, additional letter designations should also be taken into account..

- FA can be used in countries where minimum exhaust gas emissions are required by law. Barely noticeable smoke may be emitted when using oils with such markings..

- FB – can be used in countries where the restrictions on the emission of smoke and gases are much stricter. In this case, the smoke will practically not be emitted..

- FC – a transparent smoke appears here, which the human eye cannot notice.

- FD is a special category of oils for 2-stroke engines, they do not create smoke at all. They have increased chemical properties. Usually this oil is used for mixing with gasoline and subsequent refueling of boats and yachts..

In addition, oils come in two more categories:

In the first case, this will mean that it is necessary to carry out self-mixing, which does not require shaking, and in the second case, it will be necessary to do it too..

Choosing a lawn mower oil

For trimmer engines, it is necessary to choose oils marked “2T”, which are used for internal combustion engines with a volume of 50 to 200 cm 3 and are air-cooled. First of all, when buying oil, you should pay attention not to the price, but to the protective properties of the material, since small savings can subsequently become a real headache for the owner and, as a rule, high costs.

Two-stroke lawn mower oil

secrets of 2 stroke engines oil x gas mixture

The main factor in determining the quality of trimmer oil is the base number. It is this component that excludes oxidation of rubbing parts and slows down their destruction. During operation, the oil gradually loses its alkalinity and becomes oxidized. The optimal acidity level (Ph) should not be less than 8-9 units.

The viscosity of lawn mower oil also has a big impact on how a gasoline tool works. This indicator determines the ability to operate the trimmer at different temperatures. For example, summer brands of lubricants thicken even with a slight decrease in temperature. Due to the use of lawn mowers exclusively in the spring-autumn period, oil with summer marking would be an excellent option..

The flash point for trimmer oil must be more than 225C, otherwise the oil will burn out quickly and the piston group will be subject to intense wear.

Selection Tips

Now let’s try to figure out how to choose a quality gasoline trimmer oil. The main feature to look out for is the base number. This moment excludes the oxidation of parts in which friction is observed, and slows down their deformation as much as possible. The more this compound is used, the faster it loses its alkalinity and becomes more oxidized. The optimal indicator of acidity (PH) is a value of at least 8-9 units..

The second important factor, which also has a serious impact on the performance of a gasoline trimmer, is the viscosity of the oil. This characteristic determines the ability to use the device at different temperatures. Summer brands of oils begin to thicken already with a minimal decrease in temperature.

But given that such trimmers are usually used in autumn and spring, it is best to use just oil with summer markings..

The third point, the importance of which should not be underestimated, is the flash point. This indicator should not be less than 225 degrees. Otherwise, the composition will burn out very quickly and the load on the piston group will begin to increase, which will cause its accelerated wear. Also, 4-stroke oil is not suitable for 2-stroke. Namely, the latter type of motors is used in the vast majority of lawn mowers..

If we talk about manufacturers, then you can make a small rating that will allow you to navigate the formulations offered by various manufacturers. For example, Stihl offers quality synthetic and mineral oils, which have already proven themselves as an excellent solution at any time of the year..

Shell Helix Ultra oil is considered very good. Experts note its high characteristics and excellent indicators of alkalinity and viscosity. In addition, the products of such brands as Oleo-Mac, Motul, Hammerflex, Echo are considered worthy. If we talk about the products of domestic brands, then you should pay attention to Lukoil oil. Its price is several times lower than foreign counterparts, but at the same time it has high quality and good technical characteristics..

In general, the ideal solution would be a synthetic or semi-synthetic oil labeled TB or TA..

What to look for when choosing an oil?

Modern two-stroke engines of the lawn mower are fueled with a mixture of AI-92 gasoline and oil marked “2T”. Using fuels with a higher octane rating will increase the flash point and therefore burn out the lubricant..

Undoubtedly, the best trimmer oil is the one recommended by the manufacturer, but the owner does not always have the opportunity to purchase exactly the “branded” lubricant. Experts recommend Shell Helix Ultra, based on Pureplus technology, which improves the basic properties of the lubricant.

For gasoline trimmers of the German manufacturer Stihl, it is necessary to use oils Stihl HP Ultra, Stihl HP, Stihl HP S. A budget substitute can be Vityaz products, which in their properties are most similar to the recommended material.

We deal with the choice of gasoline for lawn mowers AI-92 or AI-95

How many people, so many opinions, which applies not only to the choice of oil for the trimmer, but also gasoline. Similarly, in order not to make a mistake with the choice, it is recommended to use gasoline of the brand recommended by the manufacturer (indicated in the manual for the tool). However, everything is not so simple here, since at each gas station, the brands of gasoline are only called the same, but they have a completely different composition. You need to figure it out and come to a common conclusion about which brand is better to pour gasoline into a two-stroke engine for your trimmer.

Manufacturers recommend using A-92 gasoline for their equipment, and some models require the use of A-95 grades, which do not contain ethyl alcohol. It is not recommended to use AI-90 and lower gasoline, as they will cause rapid wear of engine parts. When buying gasoline of one brand, you cannot be 100% sure that it corresponds to reality. The result is the following picture:

- The manufacturer recommends pouring fuel into the AI-92 trimmer

- The summer resident uses only gasoline of this brand, but buys it at gas stations, where the price is lower or where necessary

- This negatively affects the internal parts of the engine, since at one gas station it is really high-quality AI-92 gasoline, and at the second – at best, if it is AI-80, not AI-76

As a result, the engine suffers, and after a couple of years of operation of the new trimmer, it becomes necessary to overhaul it. In order not to have to analyze the quality of fuel or buy only expensive gasoline, it is recommended to refuel at only one filling station. At filling stations, gasoline is poured only into metal cans, not plastic.

There are manufacturers producing special purified fuel for two-stroke engines. If this option is chosen, then you do not need to choose the best gas station, the brand of gasoline and control its shelf life..