How to remove clutch at the echo trimmer

Modern technologies and technology allow you to produce the best and optimal technical solutions that become effective assistants when arranging a summer cottage or personal plot. Green lawn and other stands can grow rapidly, to put the house mowl is used to put in order and haircuts of lawns, which is differently called a motorcycle or a trimmer, a benzo-core.

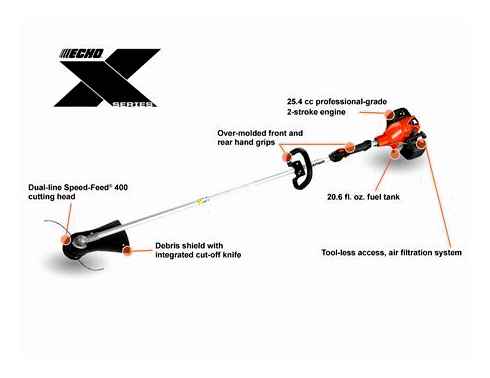

Traditional braids for grass are inconvenient and unsafe in use, require significant expenditures and their own forces that will help to save law mowers that combine functionality and practicality in their design. In the photo Benzosos, you can see various high.tech devices that have a complex of operational characteristics, including parameters such as increased performance and long service life.

A convenient and reliable trimmer for grass is a technical device consisting of individual mechanisms, details and elements that can be worn out, become unusable and damaged during intensive operation.

Even when conducting a regular technical inspection, care and care procedures, such devices and their individual parts require repair and even replacements, all repair procedures can be carried out independently.

Types of clutch breakdowns

Types of malfunctions do not depend on the chainsaw model, since the structure and principle of the clutch operation is the same on almost all modern power units. Chainsaw operators know that a slight problem from this node requires immediate active actions. The breakdowns are inevitable, since the clutch collides with not the most intensive operation of the tool with a large load. Often problems are related to:

Fixing an Echo trimmer that starts but dies.

- the wear of the node as a whole (it may burst the spring or the mechanism will begin to slip);

- Damage to the spring (the chain will rotate, the engine to work, but unstable);

- Sticks formed on the clutch fist due to a large load or overheating (it is enough to listen to the node during its operation, an extraneous noise indicates a malfunction).

Whatever the reason for the poor work of the coupling and related components, you need to dismantle the clutch to carry out its repair

Please note that repair work does not always give the desired result, so sometimes you need a clutch replacement on a chainsaw. All of the listed manipulations can be “crank” yourself, without turning to the specialists of service centers for help

How to remove clutch on a chainsaw?

It is not necessary to consider instructions for such a type of work for a single model, because for everyone one universal is used, which allows the dismantling of this unit on modern benzo tools.

If there are any distinctive nuances, then they relate to separate traction details. For example, some brands create one spring with two sections in the design of this node, which must be taken into account when the component is completely replaced (it must be replaced when the spring is damaged, due to which the circuit will rotate, and the engine will demonstrate unstable operation).

To dismantle the clutch, we adhere to such an algorithm.

- We dismantle the entire headset. Also remove the cap placed on an air filter and clutch.

- Manually stop the crankshaft so that it does not rotate. It is more convenient to do this, using a rope that is threaded through the candle hole, while removing the candle itself. Do not forget that for this you need to reliably fix the piston in one position. Alternatively remove the starter cap and entrust a couple of bolts into the rotary mechanism of the ignition system.

- Using a special key, which is usually included in the tooling of the tool, unscrew the clutch (you need to unscrew with movements against the course of the clockwise). No need to be afraid to make efforts, usually the fasteners of this node on modern chainsaws are strong.

- Remove the drum and the leading star.

After that, you can install new spare parts (which needed to be replaced). Twisting fasteners, we make movements along the time of time. Do not forget about the crankshaft where the starter is placed. It needs to be stopped.

When assembling, we adhere to the same algorithm of actions, but in the reverse sequence.

By screwing the knot manually, use the brake of the SAW ELREANT to fix for fixing. Tilt the tool forward, try to start it, remove the unit from the brake.

Speaking about the complete replacement of the clutch, do not forget that experts recommend changing the knot after two replacements for the guide. You need to take into account when servicing couplings and such nuances:

- On some saws there is a washer located in the gap between the clutch and an asterisk (sometimes a motor and asterisk), this must be taken into account during repair work;

- Disassembleing the tool, dismantling the clutch, try not to damage the special spring of the oil pump (the drive of this node), do not try to put it in its original position, otherwise this will cause the causes with the supply of lubricants.

Before operating the saw on which the clutch was repaired, check the unit for the serviceability of the engine, the reliability of fixing the bolts, test the lubricant system.

The main malfunctions of gasoline and electric trimmers

In the lawn mower and an electric trimmer for grass, if you do not consider breakdowns associated with the bar and the mowing head, the malfunctions mainly happen in the engine area.

Damage of gasoline trimmers

Typical breakdowns of a gasoline trimmer for grass, which are most often faced with the owners of this unit, are as follows:

- engine breakdown;

- problems with the carburetor;

- problems with the supply of fuel;

- muffler malfunction;

- gearal breakdown;

- The starter broke;

- Air filter problems;

- Broken a buckshot on a gas tank.

Malfunctions of electric trimmers

Since the device of an electric coser is much easier than a motirmer, then there are few reasons for its failure.

It should be noted that the elimination of some of them is best entrusted to the specialist.

Basically, the trimmer for the grass ceases to work normally in the following cases:

- Electric cable malfunction;

- The control button is faulty;

- burned engine winding;

- Contact joints break on the engine.

Possible malfunctions of a trimmer gearbox for grass, a gas mowing gearbox, and gearbox Motokos

Knowing the internal device of the lawn mower and the principle of its operation, you can easily eliminate the malfunctions with your own hands. Some breakdowns are most often found and they are distinguished as the main.

- The engine malfunctions should be sought if the lawn mower does not work or does not even start. It is also worth paying attention to this part of the braids for grass, if during operation unusual noises are heard or strong vibration is felt. Clotting of the air filter can also lead to problems with the engine.

- If the fuel does not enter the combustion chamber, then you should look for the cause in the suction of the fuel filter. It is also worth looking at it if the tool does not work at low speeds.

- The starter’s grille was clogged. the reason for the engine overheating and its termination. The starter can also fail when the cord tears when it is too sharp.

Malfunction. the knife does not rotate, the coil.

The reason is the wear of transmission elements.

The data transmission of the gasoline consists of a lower gearbox, shaft and upper gearbox (cup). Consider them in more detail.

The gearbox consists of a housing and a gear pair that are susceptible to wear.

This is due to the lack of lubrication in the gearbox.

Do not neglect this procedure during the operation of the lawn mower.

Lubrication control will extend the life of the gearbox.

There are sets of gears for these reducers on sale, but their cost exceeds 60-70% of the cost of the gearbox, moreover, the process of their replacement is laborious, a simple solution will be-replacing the gearbox with a new.

The transfer of traction from the engine to the gearbox is provided by a hard shaft, at the end of which there are slots. Due to the lack of lubrication in the gearbox, slots can be worn out. In this situation, only replacing the shaft with a new. Please note that there are 3 types of shafts (7 slits, 9 slits and “square”). The length of the shaft, as a rule, on such models 152mm. The replacement is very simple. we dismantle the old shaft. install the new.

How to disassemble a gearbox on a trimmer

It is believed that there is no universal lubricant for a trimmer gearbox for grass, but this is not exactly. In fact, a suitable lubricant will be the one in which the subsequent components are located:

From time to time, in the midst of saturated work on mowing the grass, your trimmer for grass begins to make nasty, grinding sounds. This complains the gearbox on the lack of lubrication. a more actively loaded node of the device. And soon, these “warnings” may follow the junction of the drive

What lubricant should be used for a trimmer gearbox for grass?

In the process of work, the mechanical part of the trimmer for grass is loaded with contact efforts on the teeth, resistance reactions from adhering grass (sometimes with dirt), dynamic, shock loads due to a constantly changing torque. The lubricant for the gearbox of the trimmer for the grass should fully consider these features, so the selection of the brand should be strictly individual.

The following factors are taken into account:

- Manufacturer’s brand. Each trademark is not unreasonably focused on lubricants of its own manufacture (you can talk about cheap Chinese products later). This applies to manufacturers such as Husqvarna, Stihl, Huter, Makita, etc. The exception is trimmers for domestic grass: for example, the caliber in the user’s instructions does not indicate a lubricant brand at all

- Break of lubrication. As you know, all lubricants are divided into three groups. high.speed (colloidal systems containing various additives), plastic compounds of universal use and hard lubricants softening during operation.

- Good adhesion to the surface of the parts of the gearbox, as a result of which the lubricant is not squeezed into the gaps or outside the node.

- The intensity of lubrication consumption by the gearbox. Here you have to focus on their own experience and recommendations of specialists, since some manufacturers of trimmers, hoping for their own service centers, do not give clear recommendations at all regarding the period of the reducer between two lubricants.

This Echo Trimmer Won’t Start Because Of Poor Handling

- What do the numbers on the chain of the chainsaw

- What gasoline to fill in the chainsaw of Partner

- AL-KO Classic 3 AL-Ko Classic Review.82 se.

- Gasoline lawn mower L 5300S

- Rotor Rotor Kr 2 1m

- Which is better stihl or echo lawn mower

- How much oil is needed in gasoline for a chainsaw

- Husqvarna 128r Lawn mowed Carburetor adjustment

How to disassemble a motorcade gearbox.lawn mowers.Benzotrimer

How to disassemble a gearbox from motorcycles.lawn mowers.Benzotrimer.

The consumption of the lubricant also depends on the temperature at which it retains its lubricant. When heating the gearbox to 40 ° C, it is believed that its working conditions are satisfactory, and there are enough lubricants.

- STIHL FS 38 Dismantling and Assembly

- Is it possible to cut along

- How to start a stihl 180 chainsaw correctly

- How to remove a carburetor from a Chinese chainsaw

- Gasoline lawn mower mtd Optima 42 PB

- How to choose a end saw with a length

It is believed that there is no universal lubricant for the gearbox for grass, but this is not entirely. In fact, a suitable lubricant will be the one in which the following components are present:

- Anti.sympathetic supplements, which include toxic lead;

- Solid lubricants with the presence of graphite or disulfide of molybdenum (the latter is preferable, since the lubricant is completely preserved for the large range of the speed of the shaft);

- Only mineral (inorganic!) oils, with a high degree of cleaning.

The mentioned requirements are fully met by Gear Grease Oregon or Champion EP-0, domestic compositions Oleo-Mas, Litol.24, or Ammol 158, as well as those recommended by the manufacturer of a particular model of a trimmer for grass.

How to lubricate the gearbox of a trimmer for grass?

In the upper part of the case, where the gear unit is installed, there is a technological hole that, when operating the trimmer for the grass, is drowned out with a screw. This screw is twisted, and 1.52 ml of grease is introduced into the hole using a nose available on a tube. If the lubricant was purchased in another packaging, then a regular disposable medical syringe is suitable for this operation.

After that, the screw is installed in its former place. This procedure, regardless of the user’s recommendations, should be performed every 1015 hours of operation of the trimmer for grass in working mode. Other reasons for updating or replacing the reducer lubrication are the independent performing of small regulatory work (for example, cleaning and washing the gear of the gearbox before the start of the summer season), repair of the node, preserving the trimmer for grass for the winter period, etc. D.

If the reducer node is disassembled, it is recommended to completely remove the remaining lubricants from the surface of the parts, even if it does not have traces of oxidation and pollution. And only then apply a new grease. After applying the lubricant, it is recommended to handle the shaft several times manually, and make sure that the grease is evenly distributed over all the details of the gearbox.

-

Trend

- Strong heating of the gear unit. There are two reasons. new not dead gears or lubrication: inappropriate, low quality or completely absent. If the problem is in the lubricant, it should be replaced by another. And the new gears should be running in for a short time without significant loads and interruptions so that the details have time to cool down.

- The shaft seals during movement, a knock and backlash appeared. Such signs report about the wear of the bearings. It is necessary to disassemble the gearbox and install a new part. The destruction of the bearing is caused by poor lubricant or its absence, as well as an increased load of the trimmer for grass or getting metal objects into its planting nest, which occurs due to damaged anthers. To remove and install a new bearing, you will need a special puller or a hammer with a wooden bar. You need to beat carefully so as not to spoil the planting nest. Its preliminary heating is allowed only in the most difficult cases.

- With kosbe, the gearbox hangs or flies from the bar. This means. its case is damaged, it is necessary to install a new part. If the defects are insignificant, you can pull the breakup with a metal clamp.

- If the transmission mechanism does not hold on the bar, this means that the docking area is worn out. It is necessary to replace the rod of a new one or pin the mount with electrical tape if it is partially damaged.

- The knife on the shaft does not rotate or stops with an increasing load. The reason is the wear of one of the gear or teeth. It is necessary to change worn.out details for new.

- Unscrew the screw, fastening the pulley using the starter cover using a screwdriver;

- Remove the spring and antennae;

- Carefully remove the pulley (rotate your head or work by putting on glasses and gloves earlier);

- Determine why the trigger is out of order;

- If the spring is almost completely destroyed, it is replaced;

- Когда пружина выйдет из крючка, установите ее на прежнее место, согнув перед ней антенну (на фото показан процесс установки);

- By inserting the spring plate into the groove, carefully tighten it.

- Disconnect the clip of the throttle cable from the shaft;

- Get up for both ends of one of the controls of the control cable and pull to disconnect it;

- Repeat these actions to disconnect the second control cable connector;

- With the help of a hexagon, unscrew two bolts with which the muffler cover is attached;

- Raise the muffler cover and lift it to the upper edge to disconnect from the engine cover;

- Loosen, but do not remove a bolt with a loop, fastening the main shaft to the engine;

- Take the engine and pull it to remove it from the main shaft;

- When the engine is removed, make sure that you do not pull the still connected throttle cable;

- Manufacturer’s brand. Each trademark is not unreasonably focused on lubricants of its own manufacture (you can talk about cheap Chinese products later). This applies to manufacturers such as Husqvarna, Stihl, Huter, Makita, etc. The exception is trimmers for domestic grass: for example, the caliber in the user’s instructions does not indicate a lubrication brand at all.

- Break of lubrication. As you know, all lubricants are divided into three groups. high.speed (colloidal systems containing various additives), plastic compounds of universal use and hard lubricants softening during operation.

- Good adhesion to the surface of the parts of the gearbox, as a result of which the lubricant is not squeezed into the gaps or outside the node.

- The intensity of lubrication consumption by the gearbox. Here you have to focus on their own experience and recommendations of specialists, since some manufacturers of trimmers, hoping for their own service centers, do not give clear recommendations at all regarding the period of the reducer between two lubricants.

- Anti.sympathetic supplements, which include toxic lead;

- Solid lubricants with the presence of graphite or disulfide of molybdenum (the latter is preferable, since the lubricant is completely preserved for the large range of the speed of the shaft);

- Only mineral (inorganic!) oils, with a high degree of cleaning.

How to disassemble the upper gearbox of a trimmer for grass

Repair and lubrication of the gearbox trimmeraph often, saturated use of motorcosa gearboxes can begin to heat up or make sounds unusual for its usual work, for example, rattle. This indicates that the mechanism needs to be lubricated. Trammers for grass and chainsaw gearbox trimmer for grass trimmer for grass stihl video How to disassemble a gearbox. How to lubricate the gearbox of a trimmer for grass? How to disassemble the upper gear gearbox. If this does not do this, then more severe obstacles will arise (for example, the gears will be rapidly worn and it will be useful to change them), directly to jamming. Other breakdowns also appear with the transmitted mechanism. Reducer repair and lubrication can be performed without the help of others. for this you just need to familiarize yourself with the features of these work and stock up on some available tools.

Dismantling and repair of the upper gearbox Motokos Trimmer for grass

Dismantling and repair of the upper gearbox Motokos (trimmer for grass) online store of spare parts for garden equipment.

Upper and lower gearbox trimmer for grass

About gearboxes on trimmers, lower gearbox and upper gearbox (bell) about how to understand what they are excellent.

How to disassemble the upper gearbox of a trimmer for grass

Repair and lubrication of the gearbox trimmeraph often, saturated use of motorcosa gearboxes can begin to heat up or make sounds unusual for its usual work, for example, rattle. This indicates that the mechanism needs to be lubricated. Trammers for grass and chainsaw gearbox trimmer for grass trimmer for grass stihl video How to disassemble a gearbox. How to lubricate the gearbox of a trimmer for grass? How to disassemble the upper gear gearbox. If this does not do this, then more severe obstacles will arise (for example, the gears will be rapidly worn and it will be useful to change them), directly to jamming. Other breakdowns also appear with the transmitted mechanism. Reducer repair and lubrication can be performed without the help of others. for this you just need to familiarize yourself with the features of these work and stock up on some available tools.

Dismantling and repair of the upper gearbox Motokos Trimmer for grass

Dismantling and repair of the upper gearbox Motokos (trimmer for grass) online store of spare parts for garden equipment.

Upper and lower gearbox trimmer for grass

About gearboxes on trimmers, lower gearbox and upper gearbox (bell) about how to understand what they are excellent.

Repair of a trimmer gearbox for grass, its lubrication and replacement with your own hands

Regularly using motorcycles, its owner may notice an increase in the temperature of the gearbox or the emergence of new uncharacteristic sounds in it, which were not previously heard. These signs report that the mechanism requires lubrication. If you ignore them, after a while new, more significant problems will appear.

So, without lubrication of the gear, they wear out much faster and soon require replacement. In some cases, the part jams when working. It should be understood that the damaged transmission mechanism can cause damage to other details of the structure.

Make a repair of a trimmer gearbox for grass, as well as lubricating the part is quite feasible with your own hands if you know how such procedures are performed correctly, as well as have the desired tool and materials.

Reducer is a device for transmitting rotation to the cutting part from the engine shaft. Its second purpose is to convert the angular speed of rotation of the output shaft into lower or higher speeds.

In the first case, the device is called a “demultipliter” and is used on trimmers with powerful engines, in the second. “multiplier” and installed on low.power tools.

The gearbox is always placed in the lower part of the rod of gasoline and electric brands of different brands, whether it be “champion”, Huter or other brand.

The reducer device looks as follows. The main details are the shaft-sheet (for transmitting movement from the motor) and the gear installed on the driven shaft (to rotate the cutting unit). To reduce friction during movement, rolling bearings are placed on the support points of the shafts.

They are protected by special washers, allowing to preserve the lubricant and prevent the penetration of dirt inside the seat. All parts are placed in a duralumin case with a special technological hole for entering lubrication.

It is necessary so that you do not have to constantly disassemble the knot to make lubrication.

Thus, in the design of the gearbox, depending on the model and brand that released the technique (for example, Sterwins, “foremen”), it includes several gears that are linked to the teeth for transmitting rotation and moving at high speed. Due to significant friction, they are strongly warming up.

Important! In the absence or lack of lubrication, gear overheating occurs, followed by their breakdown, after which it becomes necessary to replace damaged elements. To avoid such unpleasant consequences, it is necessary to use the lubricant in time and treat it with a gear node.

Features of different types of gearboxes

Electro and benzos manufacturers install various models of gearboxes on their equipment. Usually they differ from each other in the shape and dimensions of the seat, which is performed in the form of a circle (popular diameter. 24, 25.5 and 26mm), square or sprocket.

Another difference between the gearboxes of Chinese and European brands are types of transmissions. They are conical, worm, spiroid, combined, wave, planetary, cylindrical. Typically, worm gearboxes are used on benzocoses.

Typical malfunctions. causes and elimination

With intensive operation, the gearbox may be damaged. Most of the malfunctions of this node are typical for different brands of trimmers and are eliminated the same.

Most of the gearbox malfunctions, the owner of the trimmer for grass can eliminate independently. It is only necessary to have a suitable tool, spare parts (it is recommended to use the original ones. for a specific motorcosa model), and also know how to disassemble the gearbox in order to change the damaged element to a new.

The reducer lubrication algorithm

To lubricate the gear mechanism of the gearbox, there is no need to disassemble the node. for this, a special hole is provided in the upper part of the case. In addition to the gear, it is necessary to carefully lubricate the elements such as the bearing node.

The wear of its compacted walls leads to the fact that the lubricant comes out of the seat and the vibration of the technique begins. This problem is relevant for Chinese trimmers. The decision would be to replace the “native” bearings with high.quality details.

The flywheel is also subject to lubrication. during operation, the part is covered with fragments of grass, creating additional resistance during kosbe.

Important! It is necessary to lubricate the dog’s reel dog, since when starting it touches the grooves on the flywheel. This leads to its wear, as well as to the appearance of mechanochemical corrosion due to the fact that the details are made of various materials (flywheel-aluminum, dog-steel).

Solid lubricant or oil are placed inside through a hole protected by a screw. At the same time, the following actions are performed:

Starting analysis

The starter mechanism is dismantled to install new parts instead of broken in the following order:

To change the spring, the work should be done carefully and carefully: it can accidentally explode under the influence of the force caused. Even if the video is carefully removed, the spring strip breaks very quickly from the coil and can injure the hand with sharp edges.

Immediately putting a spring plate in your place is not always possible. This often slides, so the samples should be repeated until the desired result is achieved.

The shaft of a trimmer for herbs at idle is spinning.

The problem is that a coil or disk is spinning on hot or cold at idle (depending on what is installed on the braid) in the general shaft at idle!

This happens on a new trimmer after the engine shakes properly, the turnover at idle can grow! Some manufacturers even write in the passport after 5 tanks to come to the service and adjust the carburetor! Few people do this. You yourself can adjust the carburetor starting by decreasing the idle, this is done only on a hot trimmer for the grass!

We twist the screw a little bit, with pusions! As soon as the revolutions stabilized by the muffle engine, we are waiting for it until it cools down and start the engine if this problem is not, I congratulate the given moment is resolved! If at full gas a trimmer for grass is buried or stalls, then we twist the screw a little with extensions until the speed on full gas is not normalized. The main thing with the speed of full gas cannot be overdoed, otherwise you can burn the piston!

If the trimmer for the grass is not new, with a carburetor this moment was tried and it works normally for the grass for the grass, but it is very difficult for a cold, as if some fasting is most likely a problem in the adhesion or rather in the clutch spring, or the bushings that are damaged that are damaged He is being held!

Here I can advise replacing the clutch assembly if the pads have already been wiped on it for 23! (As a rule, replacing the clutch solves this problem) If only the case is not in the carburetor!

How to replace a clutch in a trimmer

Today we will figure out how to replace the clutch in the trimmer with our own hands. For example, take a trimmer for Echo grass, which our wonderful neighbor provided to us. He asked not to give his name, but we still thank him.

So, how to replace the clutch in the trimmer:

CAREFULLY! Before the launch, operation or maintenance of the engine or equipment, study the operating manual to avoid injuries or damage to property. Contact the authorized workshop if you are not sure of any procedure or have additional questions

Get the plastic case at the end of the spark plug on the end of the wire and pull with an effort to disconnect it

Get the plastic case at the end of the spark plug on the end of the wire and pull with an effort to disconnect it.

Disconnect control cables

Remove the muffler cover;

Remove the casing from the clutch cover

During the assembly

Separate the shaft from the engine

Remove the clutch

During the assembly

Please note that a larger puck passes under the clutch node, and a small puck is higher; Make sure the clutch is installed in place with an arrow up;

To collect the device, follow these instructions in the reverse order.

With love, Gardeniumpro and may strength arrive with you.

What lubricant should be used for a trimmer gearbox for grass?

In the process of work, the mechanical part of the trimmer for grass is loaded with contact efforts on the teeth, resistance reactions from adhering grass (sometimes with dirt), dynamic, shock loads due to a constantly changing torque. The lubricant for the gearbox of the trimmer for the grass should fully consider these features, so the selection of the brand should be strictly individual. The following factors are taken into account:

The consumption of the lubricant also depends on the temperature at which it retains its lubricant. When heating the gearbox to 40 ° C, it is believed that its working conditions are satisfactory, and there are enough lubricants.

It is believed that there is no universal lubricant for the gearbox for grass, but this is not entirely. In fact, a suitable lubricant will be the one in which the following components are present:

The mentioned requirements are fully met by Gear Grease Oregon or Champion EP-0, domestic compositions Oleo-Mas, Litol.24, or Ammol 158, as well as those recommended by the manufacturer of a particular model of a trimmer for grass.

The shaft of a trimmer for herbs at idle is spinning.

The problem is that a coil or disk is spinning on hot or cold at idle (depending on what is installed on the braid) in the general shaft at idle!

This happens on a new trimmer after the engine shakes properly, the turnover at idle can grow! Some manufacturers even write in the passport after 5 tanks to come to the service and adjust the carburetor! Few people do this. You yourself can adjust the carburetor starting by decreasing the idle, this is done only on a hot trimmer for the grass!

We twist the screw a little bit, with pusions! As soon as the revolutions stabilized by the muffle engine, we are waiting for it until it cools down and start the engine if this problem is not, I congratulate the given moment is resolved! If at full gas a trimmer for grass is buried or stalls, then we twist the screw a little with extensions until the speed on full gas is not normalized. The main thing with the speed of full gas cannot be overdoed, otherwise you can burn the piston!

If the trimmer for the grass is not new, with a carburetor this moment was tried and it works normally for the grass for the grass, but it is very difficult for a cold, as if some fasting is most likely a problem in the adhesion or rather in the clutch spring, or the bushings that are damaged that are damaged He is being held!

Here I can advise replacing the clutch assembly if the pads have already been wiped on it for 23! (As a rule, replacing the clutch solves this problem) If only the case is not in the carburetor!

Launcher of the starter and gearbox

The gearbox conveys the rotational moment from the engine shaft to the cutting tool, its gears during operation should be absolutely clean and necessarily lubricated with special lubricant.

Conducting a technical inspection on their own once a season will get rid of the need to carry out the repair of the gearbox or its replacement, with the acquisition of an expensive new node.

The starter is necessary to bring a trimmer for grass to working condition, its diagnosis is to check the tension of the lace of the starter coil with the teeth of the coil, which are often destroyed at a sharp launch.

A non.working starter in a benzocos is not subject to repair, it must be replaced with a working unit, as part of a mandatory inspection or a set of repair measures.

Separate attention and care require cutting elements that must always be cleaned of dirt and mowed grass after operation. Regular inspection and thorough preparation of the device for work will help to avoid expensive and costly repair time, always be sure of the operation of the lawn mower.

The cost of repairing a gasoline lawn mower

| No. p/n | Name of work | Price |

| one | Technical diagnostics | 450.00 rub. |

| 2 | Battery replacement | 300.00 rub. |

| 3 | Replacement of the switch | 750.00 rub. |

| four | Wheel replacement | 300.00 rub. |

| 5 | Corps replacement | 2 250.00 rub. |

| 6 | Replacing the impeller | 300.00 rub. |

| 7 | Replacing the cap | 150.00 rub. |

| eight | Replacing a tension roller | 750.00 rub. |

| 9 | Replacing a knife | 150.00 rub. |

| ten | Replacing the axis | 600.00 rub. |

| eleven | Replacing the wheel bearing | 300.00 rub. |

| 12 | Replacing a height regulator on each wheel | 300.00 rub. |

| 13 | Replacing the gearbox | 750.00 rub. |

| fourteen | Replacing the variator belt | 300.00 rub. |

| fifteen | Replacing the cutting belt | 450.00 rub. |

| 16 | Replacing the transmission belt | 300.00 rub. |

| 17 | Replacing the handle | 900.00 rub. |

| eighteen | Replacing the gase cable | 300.00 rub. |

| 19 | Replacing the cable of the self.propelled gun | 300.00 rub. |

| twenty | Replacing the brake cable | 300.00 rub. |

| 21 | Replacing the central regulator of the haircut height height | 1,200.00 rub. |

| 22 | Replacing the engine pulley | 600.00 rub. |

| 23 | Replacing the pulley of the self.propelled gun | 750.00 rub. |

| 24 | Repair of a self.propelled gun | 750.00 rub. |

| 25 | Removing/installation of engine | 750.00 rub. |

| 26 | RED RELEASE/Installation | 1 050.00 rub. |

| 27 | Checking performance | 450.00 rub. |

| 28 | Bulkhead | 3 500.00 rub. |

| 29 | Service of benzogasonocosils | 4 350.00 rub. |

| thirty | Service of the blower of the floodplain | 2 250.00 rub. |

| 31 | External cleaning of dirt | 600.00 rub. |

| 32 | Restoration of thread in the housing | 600.00 rub. |

| 33 | Production of a bolt | 1 500.00 rub. |

| 34 | The editing of the crankshaft | 1,200.00 rub. |

Published on May 24, 2018

Dismantling and repair of the upper gearbox Motokos (trimmer for grass)

Online store of spare parts for garden equipment-https: // Benzozapchasti.com.UA rental technique. https: // Tehprokat.com.ua

Watch our new videos on the new generation of the new generation VIULY analogue Yuotube https: // Viuly video.IO/R/K585255A74CD13B

If there are questions about the repair of the upper gearbox motorcosa. ask, I will answer.