How to convert a battery Screwdriver for lithium-ion batteries

Often, owners of nickel-cadmium-powered screwdrivers want to convert their batteries to lithium-ion batteries. They are attracted by the advantages that can be purchased by such a rework of the battery pack:

- Lighten the weight A screwdriver that requires fewer batteries for the same values of battery capacity and voltage;

- Get rid of the memory effect, which is not found in lithium-ion batteries;

- Reduce battery charging time.

In addition, with a certain assembly scheme, you can double the charge capacity, and hence the operating time of the Screwdriver from one charge. The advantages, of course, are obvious, but this solution has its drawbacks, which you also need to know in order to weigh the pros and cons. Of the negative aspects of adapting the screwdriver battery for lithium ion banks, it should be noted:

- Higher cost of lithium-ion type batteries;

- The need to maintain the battery charge level strictly within the range from 2.7 to 4.2 V, for which it will be necessary to additionally install a charge-discharge controller board in the battery box;

- Large sizes of batteries such as Li-Ion, which will require wit and imagination to place them in the battery case Screwdriver;

- Inability to use the tool with such batteries at low temperatures.

But if the decision to replace nickel-cadmium batteries is still made, then you need to proceed further in the following sequence:

- Determine the number of lithium-ion batteries and their electrical characteristics. For example, for the Most common Screwdriver operating from a battery with a nominal voltage of 14.4 V, it is better to take 4 lithium-ion cells, the total maximum voltage of which will be 4.2×4 = 16.8 V. It must be borne in mind that immediately after starting work on new batteries the voltage on them will drop and will be equal to 14.4-14.8 V. If the capacity of the battery box allows, you can take 8 such cans, forming 4 pairs of them with parallel connected batteries. This will allow to increase the battery capacity by 2 times.

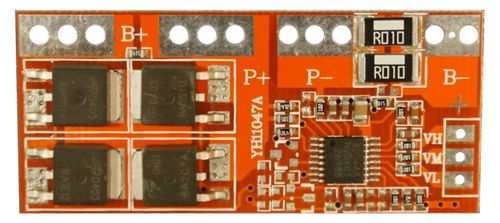

- Pick up a controller board for 4 batteries. Its parameters must correspond to the discharge current and the rated voltage of the selected batteries. In this case, the operating discharge current should be 2 times less than the maximum permissible value of the battery discharge current, which is usually equal to 25-30 A. This means that the board should be designed for a current of 12-15 A.

The controller board must be designed to work with the required number of batteries and designed for their operating discharge current

Disassemble the battery box. Screwdriver and remove all nickel-cadmium cans from it. Cut the entire chain with pliers or side cutters, leaving only the top element with contacts for connecting to the tool. The thermistor can also be removed, since overheating of the batteries will now be monitored by the controller board.

Here are the chains of old cans, you need to leave only an element with contacts for connecting to a screwdriver

Assemble a circuit of lithium-ion batteries, soldering them in series, and connect the controller board according to the diagram, observing the polarity.

Polarity must be observed when connecting the control board to the lithium-ion battery string

Place the assembled structure in the battery box. Li-ion batteries are best placed horizontally.

It is better to place lithium-ion batteries in the battery case Screwdriver horizontally

- Close the battery with a lid, installed a battery with contacts on old-type batteries on the horizontally laid batteries.

It may turn out that the Assembled structure will NOT be able to charge from the old charger. Then you need to install an additional connector for a new charge.

Typical battery malfunctions Screwdriver

Despite the fact that screwdrivers are equipped with different types of batteries, they all have the same design and similar malfunctions. The most common failures of this device are as follows:

- Loss of capacity by one or more batteries;

- Mechanical damage to the battery pack circuit (separation of the plates connecting the banks to each other or to the terminals)

- Drying out of the electrolyte;

- Decomposition of lithium in Li-Ion cells.

Loss of battery capacity. This is the most common defect in batteries. Its essence is that the loss of the charge capacity of at least one battery does NOT make it possible to fully charge the rest of the banks. Receiving a low-quality charge, the battery quickly discharges.

Such a malfunction may be a consequence of the memory effect or the drying out of the electrolyte in the cans due to their heating during charging or under load. This defect in batteries of any type can be rectified by yourself without contacting a service center. In this case, you can try to repair faulty elements or replace them. It will NOT be possible to restore only lithium ion battery cells that have lost their capacity as a result of lithium decomposition. Such banks can only be replaced with new ones removed from an idle battery pack.

A malfunction of the battery The screwdriver can be caused by the loss of capacity of one or more batteries, so it is easy to fix it by replacing them with new or known working

how to properly solder battery banks Screwdriver. : Replacing nickel-cadmium batteries with lithium-ion batteries. Diagnostics of malfunctions of the battery Screwdriver

Before proceeding with the repair of the battery, you need to diagnose it and identify the cause of the malfunction. This requires:

- Fully charge the battery. Previously, a nickel-cadmium or nickel-metal hydride battery needs to be discharged to zero to avoid the manifestation of the memory effect.

- Disassemble the battery case by removing its cover. It can be screwed or glued to make disassembly a little more difficult. In the second case, to remove the cover, you need to walk along the glued joint with a sharp scalpel or knife, and then, gently prying it off with a thin screwdriver, disconnect the cover.

The cover of the battery pack can be fixed to its body with screws or glue

By visual inspection, determine the presence of mechanical damage, open circuits, as well as swollen or leaking battery cells.

After disassembling the battery packs, the contents are visually inspected for obvious defects

Measuring the voltage on each battery with a multimeter. For batteries such as NiCd or NiMh, it must be in the range of 1.2-1.4 V, and for lithium ion cells. 3.6-3.8 V. It is better to write the measured value on each bank with a pencil to avoid confusion.

By measuring the voltage on each bank, you can find all the faulty elements

Load the battery by connecting an ordinary car light or resistance to the output contacts.

By connecting the lamp, we give the batteries the opportunity to work in order to show the voltage drop under load

- I held the battery under load, again measured the voltage on each bank and find the batteries on which the maximum drawdown occurred. This is the defective item.

Battery repair DIY screwdriver

Most of the defects of the battery pack A screwdriver can be eliminated by yourself if you know the cause of the malfunction and methods of dealing with it.

Fault definition

Repairing a screwdriver battery is a replacement for a faulty can. All banks cannot fail immediately, therefore, when the unit is not being charged, the reason lies mainly in the failure of only one battery cell. To repair the battery, you should find this faulty item.

It is possible to determine the malfunction of a failed bank by performing the following manipulations:

- Initially you need to charge the battery to full charge.

- We disassemble the device case, after which the voltage of each can is measured using a multimeter. The voltage value should be between 1.2 and 1.4 volts, and for lithium-ion. 3.6-3.8 Volts.

- When taking measurements, you can sign the values on each jar with a pencil.

- After taking measurements, you should reassemble the battery, after which discharge it to a complete loss of charge.

- We proceed to disassemble the case again, and again we check the voltage readings on each element.

- If in any bank the voltage drop exceeds the threshold of 0.5 Volts and above, then this indicates the failure of this element.

This popular method is used by many to find a faulty battery cell. There are also other types of battery malfunction testing, but the above is the most popular.

After the faulty elements are found, they begin to repair them, which is quite realistic to do at home on your own.

How to repair a screwdriver battery

The question of repairing a screwdriver battery is one of the most relevant among the owners of this type of tool. The reason for this is the rather high cost of batteries for screwdrivers, which fail over time. If the battery on the screwdriver has become unusable, you should not rush to dispose of it. In this case, you can repair the battery of the screwdriver, and what is required for this, we will find out further.

What operations does the repair process consist of?

The process of repairing the device is the removal of a faulty can, which is possible by using side cutters, and to connect the battery, you will need to use a soldering iron and accessories for it: rosin and tin. Instead of the removed jar, the fast solder follows. However, before carrying out work with soldering, it is important to know the following:

- Soldering must be done quickly so that the block does not have time to warm up.

- To solder a new can, use the same size connection plates.

- When soldering, it is important to control the correct connection of the pros and cons.

After replacing the faulty can, we check the quality of the soldering, and, if necessary, remove the remaining flux. Banks must be assembled, then placed in the device case, and assemble the case.

Replacing cans in a screwdriver battery

To repair the battery, you need to purchase cans of the same voltage. They can be taken either from an old and faulty battery, or you can purchase new ones. The cost of new nickel-metal hydride cans is quite affordable, and usually does NOT exceed 100 rubles per can.

At home, you can replace a faulty element with a soldering iron and tin. In production, such a connection is carried out using spot welding. Buying such a device for repairing a screwdriver battery is irrational. After the defective element is replaced, you can assemble the battery and check the quality of the repair, for this you need to put it to charge until it is fully charged. After that, and a few hours after the device has cooled down, you will have to disassemble it again and measure the voltage on each bank. Voltage values should correspond to 1.2-1.3V.

Screwdriver battery: design and types

Despite the external design differences between screwdriver batteries, inside these devices have the same structure. Each device is based on a set of small cylindrical elements, which are interconnected in a sequential way. Such elements are called banks, which external image is shown below.

Such banks are made of various materials, which affects the cost of the screwdriver. These materials include:

- Nickel metal hydride (Ni-MH) elements. The nominal voltage of each cell does not exceed 1.2 Volts. Here are the number of such cans, the final nominal value of the battery voltage depends.

- Lithium-ion. The voltage of each jar is 3.6 volts, so it takes 2 times fewer jars to achieve the same rating with metal hydride.

Rarely enough, you can already find another type of battery for screwdrivers, which have the abbreviation Ni-Cd. This means that nickel-cadmium cans are installed in such a device. They are already almost ousted from the market by more modern and better performing types of batteries. Lithium batteries are currently the most popular. The main advantage of lithium devices is the absence of self-discharge, lighter weight, and a large number of cycles for charging and discharging. These advantages are reflected in the cost of products, the price of which is 3 times higher than nickel-metal hydride.

Repair and replacement of battery elements of a screwdriver

It should be noted from the outset that all types of batteries, both nickel-metal hydride and lithium-ion, are subject to repair. Not many people know how to repair a screwdriver battery, therefore very often faulty batteries become a prerequisite for buying a new tool.

It is not possible to repair a bank that does NOT hold a charge, and therefore it will have to be disposed of after being removed from the circuit. It is irrational to repair the battery with a screwdriver in which more than 4 faulty cans are found. In this case, it is easier to purchase a new battery entirely, or find a used device.

In conclusion, it should be noted that most screwdrivers are equipped with two batteries, so if one fails, then the second will have to be used more intensively during its repair. This will allow the tools not lying idle, and you can try to repair the product at a convenient time.

Screwdriver repair: checking and replacing battery cans

The most expensive and important part of a screwdriver is its battery. Therefore, when the electrical storage fails, you DO NOT want to buy a new tool. How to check the battery and make repairs in the event of a battery malfunction can be read below.

Screwdriver battery repair work

So, during the checks, non-working batteries were identified. What to do in this case? There are two ways out. Attempt resuscitation elements or simple replacement of a broken cans.

Checking the storage batteries

So, let it turn out that with the help of preliminary checks, the presence of faulty elements in the drive was established. Then it is necessary to disassemble the battery and remove the sequentially connected batteries. Banks. As mentioned above, the battery consists of 10-12 such cells with a voltage of 1.2 V.

First, a visual inspection of the joints of the elements is carried out for violations. They can degrade the overall battery performance.

After inspection, you should measure the voltage of each cans. The voltage of one cell does not have to be less than 1.2 V. When carrying out measurements, the battery cells should be disconnected from the connections with all kinds of sensors. The measuring device is connected to the battery poles. Banks with reduced voltage must be replaced. If, during a simple measurement, no faulty elements were found, you should measure banks under load.

Screwdriver battery design and types cans

Regardless of the country of manufacture of the screwdriver, all batteries have the same structure. Rows of batteries connected in series are placed inside the battery. Batteries or cans. The resulting battery voltage is created by summing the voltage of each battery. Banks have the same parameters. Dimensions and tension. Batteries differ only in power.

The screwdriver battery itself has four contacts:

- Two power contacts are used to charge and discharge the batteries;

- The third contact (control) is connected to a thermal sensor built into the battery. It serves to protect the charger from overheating;

- The fourth contact (service) equalizes the charges in all batteries.

Screwdriver batteries are assembled with the following types of storage elements, which have their own advantages and disadvantages.

Ni-Cd. Nickel-cadmium batteries, voltage. 1.2 V.

- Low cost;

- Prevalence;

- NOT afraid of low temperatures;

- Can be stored discharged.

- The manufacture of THESE batteries is considered hazardous and are therefore manufactured in third countries;

- Possess memory effect;

- Self-discharge;

- They have a small capacity;

- They have a small number of cycles (charge / discharge). Not live long with constant use.

Ni-MH. Nickel-metal hydride batteries, voltage. 1.2 V;

- Produced in environmentally friendly production, high quality branded products;

- Possesses low memory effect;

- Low self-discharge ability;

- High capacity and high cycle count.

- High price;

- During long-term storage in a discharged state, some of the characteristics are lost;

- DO NOT function long at low temperatures.

Li-Ion. Lithium-ion batteries, voltage. 3.7 V.

- Is absent memory effect;

- There is no self-discharge;

- High storage capacity;

- There are a large number of charge-discharge cycles;

- A small number of batteries are required to generate sufficient voltage in the battery, which reduces the weight and size of the battery.

- Very high price (almost 3 times more than other types of batteries)

- After 3 years, capacity is lost due to decomposition of lithium.

At its core, a battery is a constant current source. By converting a chemical reaction into electrical energy, it can release stored electricity into a circuit. When charging, the current flows in the opposite direction, thereby charging the drive.

Any battery operates on the principle of electrolysis. This means that its design includes two mandatory elements. Anode and cathode, which are in the electrolyte. As a result of a chemical reaction, an electric charge is created at the poles. The battery voltage is determined by the potential difference across the poles.

Resuscitation storage elements

Immediately it is worth making a reservation, trying reanimate ion batteries are useless. This type of battery cannot have a memory effect, and therefore, the reason for their failure lies in the decomposition of lithium. But first it’s worth finding out. The control circuit may be defective. Two methods can be used here.

- The control scheme should be changed. If the batteries are working, then you need to repair the circuit itself.

- The battery is supplied with 4 V with a current of approximately 200 mA using an adjustable charger. Voltage rise on bank up to 3.6 V indicates the health of the element and, therefore, either the control circuit or another battery is to blame for the malfunction.

For resuscitation screwdriver battery batteries are used in two ways:

- Recovery of performance cans by compression or compaction.

- Supply of high voltage and current to the storage element. In this case, it will be possible, although NOT to completely eliminate the lost capacity and get rid of memory effect.

However, these methods cannot completely solve the problem of battery failure. They will only delay the inevitable. Sooner or later, you will have to change banks anyway.

The first stage of verification

Voltage and current measurements are taken while charging the electrical storage. The readings are taken periodically after a certain period of time. With increasing time, the increase in voltage decreases.

So, half an hour after the start of charging, the voltage value will be 13 V. If you measure it after another half hour, then the voltage will be 13.5 V. After 2 hours after the start of charging, the voltage will already be about 14 V. This indicates that the maximum has been reached. In a fully charged battery, the voltage has a value of 17 V.

You can assess the quality of the drive by measuring the current during the charging process. If the battery is in good condition, then it is characterized by a steady rise in current of 1 hour during the charging process. The passage of the current value of the 1 A mark indicates the normal functioning of the drive.

The battery installed in the screwdriver can be checked with a tester or voltmeter by measuring the voltage between the poles. No load voltage will correspond to no-load voltage. So, if for 12 cans with a nominal value of 1.2 V, the operating voltage will be 14.4 V, then the open circuit voltage will increase to 17 V. A decrease in this value means that some of the cells in the battery are inoperative or the drive is NOT fully charged.

Based on the results of the first check, you can get an initial impression of the health of the battery cells. This will help determine the need to disassemble the battery.