Segment or rotary mower; which is better for a tractor, for grass

What is a segment mower for a tractor, what are its features. Characteristics of popular models, prices, selection criteria.

How to do it yourself

Taking on such a complex matter, you need to have experience not only with iron or a similar material, but also have the skills of welding, working with autogen and much more. Therefore, you need to think several times before taking on such work, because you cannot return the expended energy and nerves later.

If you nevertheless decided on this, you feel confident in your ultimate success, then you can safely get down to business. Material for your future segment mower can be found in numerous landfills, of which there are plenty in our country. Any scrap metal that can later be used to design a mower will do. When all the material has been found, you can start working.

There are the main stages of designing a homemade segment mower:

- Metal bars are taken, the dimensions of which will be the following parameters – 15/15/120 mm. Next, you need to drill 12 holes in each bar so that the M8 bolts fit under them.

- Next, a metal rail with cutting elements is made, the length of which will be no more than 90 cm. It is important to know that the teeth should be on both sides.

- Next, you need to connect and fasten the entire structure together with bolts and sliders so that so that the cutting element is in the middle of the bars.

- At the bottom of the structure, it is necessary to install wheels, which makes it possible to set the height of the future grass cut.

It is also important to know that all homemade equipment is an amateur solution to the issue, therefore, no one can guarantee its safety for you and those around you. Therefore, before the first start, carefully check the tightness of all connections, tighten if necessary.

Carefully inspect the surface on which you will be working. There should not be pets, children, so God forbid a tragedy does not happen. A person who has taken up the manufacture of a homemade mower must have considerable knowledge and skills so that the result of his actions is not only positive, but also safe.

If you do not have such skills, then it is better not to tempt fate, but to purchase models, which are presented in a wide range in specialized retail outlets. So, for example, take a closer look at the manual gasoline grass mower, which is described in more detail in this article.

KSF-2.1

Segment mower KSF-2.1 is an excellent solution for farms and individual villagers. Thanks to its design, it allows you to harvest hay in unlimited quantities, without spending a lot of time and resources.

- Weight – 190 kg;

- Dimensions (l / w / h) – 50cm / 180cm / 255.5cm;

- Width of the mowed surface – 2.1 m;

- Area of the treated surface – 1.7 hectares / h;

- Speed – 9 km / h;

- Power – 7500 W;

- Height of the mowed grass (min) – 4 cm;

- Height of the mowed grass (max) – 6 cm.

If you want a cheaper model, then follow here and read a review of the homemade segmented mower for the Neva Tiller, which can be assembled literally from scrap materials that can be found in every home.

Principle and device of work

The segment tractor mower is designed for mowing grass in large and small cultivated areas. This invention is indispensable for rural enterprises, and ordinary villagers too. After all, the cattle needs to be fed with something, and the feed, in fact, lies under the very feet and it remains only to properly mow it. You can, of course, resort to the good old manual braid, but it is very long, dreary and not suitable, for example, for agricultural enterprises.

Therefore, many do choice towards the segment mower, which is hooked up to the tractor. Unfortunately, no alternative transport or invention has yet been invented that would replace tractor technology. Although this regret may be in vain, because the tractor has always been considered the main driving force in the rural economy, with the help of which almost all work on plowing, cultivating or harvesting hay was carried out. The segment mower is no exception, which is completely meaningless without a tractor as a driving force. If you are confused by this fact, then you can purchase a simpler model such as a hand-held electric mower at a very affordable price.

In the process of movement, the grass will fall between the segments of the mower, thereby rolling over the cutting blades, and, in fact, cut off. The grass cut in this way is laid in an even layer back to the ground, which is extremely convenient for its subsequent harvesting.

The design of a segment mower for a tractor does not look particularly complicated, which does not mean that it is ineffective to work with it. On the contrary, as practice shows, this method of mowing grass is one of the most beneficial, especially for large cultivated areas.

The segment mower includes:

- Bearing beam;

- Cardan transmission;

- Transport traction;

- Cutting mechanism;

- External engine;

- Lifting the apparatus.

Features of the segment mower on.

Therefore, more and more people are asking the question – is it possible to make a mower with your own hands? And, as the experience of other people shows, this idea does not seem so unrealizable.

Segment or rotary mower – which is better for a tractor, for grass

Rural life has its own special way, which not everyone can get used to. It means constant work that does not stop even for a day. There are no days off here, like city dwellers, because you actually feed yourself with your own hands, keeping cattle or doing work in the garden.

Such a monotonous life at first glance allows you to feel confident, because only you are responsible for your life and your success, without looking back at your bosses, stock quotes and other things that are insignificant in rural life. From how a rural man looks after his garden, house, and his cattle, depends on its survival in these conditions, which can only be endured by a truly strong and whole person.

Still some twenty years ago, for a person living in rural areas, no special tools (for example, a Makita gasoline self-propelled lawn mower) and technology (such as a honda lawn mower) were invented to facilitate his everyday life. All that he could count on was in his own calloused hands and a simple list of auxiliary tools, known since ancient times.

One of these innovations is a variety of tractor mowers designed for cutting grass. They had their own varieties and types of designs, which were due to different tasks. There are two main types of mowers for tractors – rotary and segment. Today we will take a closer look at segment mowers, and you can read about self-made rotary mowers for a tractor here.

Features and prices

It is important for every person who decides to buy a segment mower for a tractor to know main models, their technical characteristics and approximate prices. Let’s consider some of the most popular models among buyers.

Principle and device of work

The segment tractor mower is designed for mowing grass in large and small cultivated areas. This invention is indispensable for rural enterprises, and ordinary villagers too. After all, the cattle needs to be fed with something, and the feed, in fact, lies under the very feet and it remains only to properly mow it. You can, of course, resort to the good old manual braid, but it is very long, dreary and not suitable, for example, for agricultural enterprises.

Therefore, many do choice towards the segment mower, which is hooked up to the tractor. Unfortunately, no alternative transport or invention has yet been invented that would replace tractor technology. Although this regret may be in vain, because the tractor has always been considered the main driving force in the rural economy, with the help of which almost all work on plowing, cultivating or harvesting hay was carried out. The segment mower is no exception, which is completely meaningless without a tractor as a driving force. If you are confused by this fact, then you can purchase a simpler model such as a hand-held electric mower at a very affordable price.

In the process of movement, the grass will fall between the segments of the mower, thereby rolling over the cutting blades, and, in fact, cut off. The grass cut in this way is laid in an even layer back to the ground, which is extremely convenient for its subsequent harvesting.

The design of a segment mower for a tractor does not look particularly complicated, which does not mean that it is ineffective to work with it. On the contrary, as practice shows, this method of mowing grass is one of the most beneficial, especially for large cultivated areas.

The segment mower includes:

- Bearing beam;

- Cardan transmission;

- Transport traction;

- Cutting mechanism;

- External engine;

- Lifting the apparatus.

Features of the segment mower on.

Therefore, more and more people are asking the question – is it possible to make a mower with your own hands? And, as the experience of other people shows, this idea does not seem so unrealizable.

Advantages and disadvantages

In addition to the ability to use in any weather conditions, segment mowers KSF-2.1 have a number of other advantages, for which they are appreciated by many business executives:

- High productivity achieved by a relatively high speed of work and a large width of simultaneous capture – more than 2 meters.

- The light weight of this mounted mowing equipment allows you to work with it even on small types of transport devices.

- Low power consumption of the device will help save money and does not affect the increase in the cost of hay while reducing the volume of the workpiece.

- Simple operation without connecting the hydraulics does not require additional service personnel, except for the tractor operator.

- The cost-effectiveness of purchasing the device itself and spare parts for it, which are available everywhere.

- High-quality work at high speed and a long service life – by the end of the operating period, it will be enough to change the cutting blade, and the mower is ready for the mowing season again.

Segment mower KSF 2.1

Segment mowers of the KSF-2.1 type are produced by the Lyubertsy plant "Selkhozmash" (Russia, Moscow). This enterprise is the successor of the Ukhtomsky plant and the successor of its long-term business – the manufacture of hay harvesting equipment of various types and designs.

Specifications

Technical characteristics of the segment mower KSF-2.1:

| Specifications | Unit measurements | Indicators |

| Total weight of the device | Kg | 190 |

| Transport dimensions, lengths / widths / heights | mm | 500/1800/2555 |

| Drive power | kWh | 7.5 |

| Work progress speed, up to | km / h | nine |

| Capture of the cut strip | mm | 2100 |

| Cutting height | mm | 40-60 |

| Productivity, max. | Ha / h | 1.7 |

| Tractor required traction | – | 0.6-1.4 |

| Required PTO frequency | rpm | 540 |

Features of operation

The mower is attached to the tractor by fixing the longitudinal rods of the tractor attachment device, setting the distance from the ground to their rear ends of about 40 cm and lifting no more than 65 cm.This is done to prevent lateral displacement of the mower frame relative to the central axis of the traction unit.

When working with the device, you should follow the rules that contribute to its long-term and safe operation:

- The mower cutterbar must be covered with a protective cover.

- The stopping of the tractor must take place with the simultaneous actuation of the power take-off shaft.

- All adjustment and cleaning work with the mower itself and especially with the cutting tool is carried out with a complete stop and a plug of the tractor.

- The device is transported with a protective shield put on its teeth.

Segment mower KSF 2.1

Segment mowers of the KSF-2.1 type are produced by the Lyubertsy plant "Selkhozmash" (Russia, Moscow). This enterprise is the successor of the Ukhtomsky plant and the successor of its long-term business – the manufacture of hay harvesting equipment of various types and designs.

Device

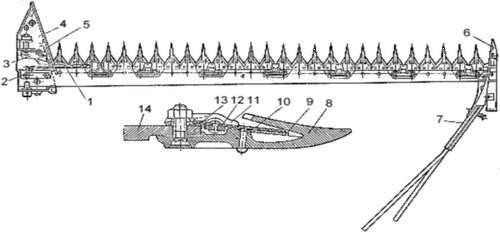

KSF-2.1 mower consists of the following main structural units and parts:

- A frame on which the rest of the working tools are taken on the base and which is fastened for installation to the tractor hitch.

- A pull rod designed to connect the working cutting tool with the device frame.

- A cutting blade with sharp segments (fingers).

In operation of the mower, the blade with knives is set in a forward-reverse motion parallel to the ground surface. In this case, the stems encountered on its way fall on the fixed segments of the canvas and are immediately firmly pressed against them by the movable blades. The grass is cut in a similar way to the work of conventional shears, leaving behind a strip of already finished mowing.

Mower scheme KSF-2.1

1 – knife head; 2 – guides of the knife head; 3 – knife head cover; 4 – inner shoe; 5 – branch bar; 6 – outer shoe; 7 – field board; 8 – finger; 9 – finger insert; 10 – knife segment; 11 – knife clamp; 12 – the back of the knife; 13 – friction plate.