What file to sharpen the chain of the chain of the chain of Stihl 180

There are many reasons why the cutting elements of gasoline and electric saws occur. The main one is in the natural process. Sawing wood, which has a softer structure than metal, still leads to a gradual dulling of the cutting edges of the teeth. It is simply impossible to avoid this, but the speed of lowering the sharpening level can be reduced if you use high.quality circuits released by conscientious manufacturers.

The following factors belong to other reasons for the accelerated dullness of the chainships:

incorrectly exhibited chain tension; the use of low.quality oil, which does not fall into the compounds between the links, and thereby does not carry out high.quality lubrication

It is especially strictly contraindicated in using the development as lubrication; It is important to consider the type of sawing wood, otherwise the chain can be torn very quickly. Especially for working with high solid wood, chains with winning attacks on teeth should be used; falling under the cutting parts of extraneous materials, for example, metal, stone, plastic, sand, glass, earth

A slight hit of the earth or sand onto the tool chain accelerates the dullness of the edges by 10 times; Long.term operation of the tool without a break. During sawing, the cutting parts are subjected to such a negative influence as heating. The higher the metal temperature, the faster the teeth is dull, so experts recommend taking breaks in the tool (approximately every 2 hours a break for 10-20 minutes); The wrong choice of the chain for the technical parameters of the tool at this moment should also be paid special attention, otherwise this will lead not only to the rapid dullness of the links of the tool, but also to reduce the engine resource.

Another important point that inexperienced sawmen do not pay due attention: the sharpening of the chain of the ribbon should be performed only and solely after it cools.

It is interesting! Tip for novice sawmills: before working as a chainsaw, it is recommended to add additionally the chain with motor oil. You probably noticed that new products have some lubricant. In the process of lubrication of the chain, it is carried out through a special channel of the oil pump, but it will not be superfluous, if before work, you will additionally apply a lubricant directly from the bottle or from the syringe.

Options for doing work

It is important to know how to sharpen a chain of chainsaw at home, so as not to delay the process of working with lumber and not break the tool. Sharpowing the electric saw chain with your own hands is no different from the editing of the cutting element of a saw with a gasoline engine

You can choose one of the available ways:

- The editing of teeth using a file is the most common and easy way that allows you to sharpen directly at the place of work.

- You can focus the teeth using the PowerSharp system.

- Using a special sharpening machine. this method is used by service centers, but it can quite be used at home.

- With the help of corner grinder (corner grinder). In this way, inexperienced users are unlikely to be able to use, as it is rarely used and requires certain skills.

STIHL chainsaw angle

It is important to withstand the angle of sharpening of the rear angle of the upper blade, you can only do this using the template. In other ways, this is extremely difficult to achieve, t

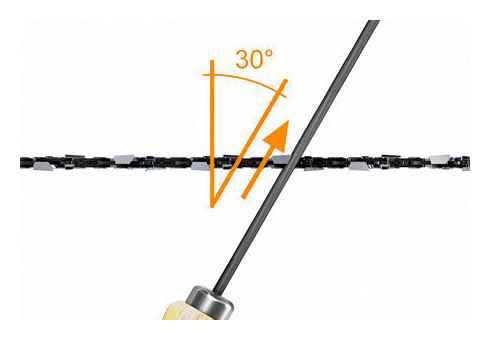

to. Its value ranges from 50 to 60 °. The angle of the front edge can be changed, depending on what type of sawing you will produce. The stronger the wood breed, the smaller the angle, otherwise the edge will bend. Optimal angle values 10 12 ° with longitudinal sawing, and 25 30 ° with the transverse method. Its performance depends on which angle of the edge is used in a particular case.

The editing of the chain with a file

Sharpening of chains of chainsaws is carried out by two types of files: round and flat. A round file should correspond to the diameter of the rounding of sawing teeth of a particular chain. For example, for sharpening the chainsaw of Stihl 180 with your own hands, you will need a file with a diameter of 4 mm. For other chains of this type, files can be used with a diameter of 3.8 to 4.8 mm. For circuits that are used on professional saws, we use sufilies with a diameter of 5.2 to 5.5 mm.

For proper editing the chain of use only a round file is not enough, because, in addition to sharpening the teeth, it is necessary to adjust the limiter of the depth of the cut. If you miss this important point, then the chain will not be able to bite to the desired depth into the body of the sawing material, and this will significantly reduce the speed of the work and will affect the engine resource. For this type of sharpening, you must use a flat file.

In time sharpening, protect your hands with dense gloves, and eyes. glasses.

Useful tips

The following recommendations will come in handy:

- First, install the tool on an even and stable surface. a table or bench is well suitable. If you are in the forest, then just find a wide chock or stump. Check the teeth throughout the circumference for the presence of chips and other defects: it may turn out that some teeth have broken.

- Give the saw brake to working condition. this action will block the movement of the chain along the tire. Make sure that the cutting element on time sharpening is stretched. It is recommended to place a stand in the form of a log or a regular piece of a branch under the tire. so when pressed, it will not fail. You can purchase special clamps to hold the tire in a stationary position.

- In the process of sharpening the movement of the file, the tooth is carried out from the inside to the outer edge of the edge, scrolling the file around its axis. In this case, the tool must be moved parallel to a special mark located on the circuit. This label serves as an indicator of the correct angle of sharpening of the cutting edge. For the convenience of the process itself, the tooth that you process should be located in the center of the tire.

- All sharpening work must be carried out in protective clothes and gloves, t. to. The cutting edge of the teeth is very acute, so there is a high probability of injury. For uniform sharpening, manufacturers recommend that the same number of file movements for each tooth, in practice, such a recommendation can be applied exclusively to teeth that do not have damage.

- For lighter sharpening, the file can be used paired with a special powers, on which the marking of permissible angles is applied. With the help of such tags, the teeth can be sharpened not only for the transverse, but also for the longitudinal sawing of wood. The use of the holder will also be useful to people who, unlike professionals, have no proper experience in this matter.

Sharpening of the chain of the chain of the Stihl MS 180

85 was then. As the seller said: “The file of the file is one chain = one file”, and it turned out. with a new chain in the kit I buy one file and there is enough it to exude the chain completely. As you can see in the photo, the template to the file is screwed up with “lambs”, holds on “dead”. to crank the file around its axis (it has to be uniform), you need to preliminarily loosen the nuts. For comparison, the Oregonovsky template is attached to the file simply with spring brackets “if only I didn’t fall off”. I saw a neighbor, not conveniently.

So, when you exuded the chain completely and installed a new one, you disassemble the structure:

, Take a pre.purchased new file:

and collect the structure in the reverse order:

Probably 90% of the circuits have an angle of sharpening is 30 degrees, the remaining 10 degrees (but I have not seen something of such chains), theoretically, the more than the wood-the less the angle of sharpening should be. Both of these corners are drawn on the template. The angle of sharpening of the cutting edge itself is not adjusted by anything. just press the template with a file to the tooth shelf from above and you can be sure that the corners on all teeth will be the same. The sharpening technology is as follows: do not meditate on the chainsaw itself (without removing the chain from the tire), put the file with the template to the hidden edge of the tooth so that the file is horizontal (withstand the angle of 90 degrees with respect to the tire), press the template to the tooth shelf, the devil on the template With an angle of 30 degrees, place parallel to the edge of the lifted tooth and at the same time press the file to the hidden surface. The progressive movements of the file in advance (namely, forward, and not forward-forth) correct the tooth. The cutting edge of the lifted tooth should be on the opposite side of you. Visually control the sharpening edge. If the chain is slightly blunt, two or three movements are enough and the tooth is sharpened, we proceed to the next. First, we sharpen the teeth on one side of the chain:

Then we turn the saw with a tire in the other direction and sharpen the teeth on the other side:

As you can see, in the sharpening of the chain with your own hands, with the help of this non.cunning device, there is nothing complicated. If I saw a large amount of firewood at a time, I undermine the chain through one or two sawing of the saw. This procedure takes no more than 5 minutes. at this time and the back with hands rests and the saw cools a little. Someone will certainly say: “And in a fig so often? Well, you can exude the whole chain “.I will answer: with a constantly acute chain, fuel consumption decreases, the load on the entire saw decreases. accordingly its wear decreases and the resource increases. You can cut without straining in the full bus, which I do. lay on a pack of firewood, immerse the tire into firewood completely, “on the very tomatoes” and so the saw to the ground, then I move to the other side of the pack, immerse the end of the tire at the beginning of the saw and I also definitely sprinkle a pack from the other side. Then I will be a muffled saw, I throw off the cut firewood, I conquer and again in the full tire. When constant sharpening the chain in a manual chain, I have enough to cut 100m3 firewood! You think it is not enough? How many cubes you will cut until the teeth are completely wear if you carry to the service center for sharpening? I think much less. Yes, I don’t take off the chain from the saw at all, well, except for transportation, so that the tire does not stick out, I don’t turn the tire (I don’t see the point-the friction location “chain-nine-outlets” is rubbed to each other, why turn the tire so that the scrays are wrapped up changed and began to rub them again?). Limiters in front of cutting teeth in the entire life of the chains have to be undermined a couple of times, I take the usual flat (suitable and triangular section) a file and grind. Somewhere there was a template to control the height of the limiters, but something was lost somewhere-today before writing a review, I also wanted to get it down, but I did not find it. By and large, if you know the size (and, as a rule, it is indicated in the table on the chain box), you can use the usual caliper for control, it is not so often that you have to undermine the limiters to bother. It seems that I painted everything in detail, take a file with a template, a saw with a chain and learn to sharpen ourselves. There is nothing complicated. A bonus will be a bunch of saved time, an increased resource of the chain and saw, saving money and the pleasure of sawing constantly sharp chain. Thank you for your attention :-).

PS: I almost forgot, for all the time you use a saw (since spring 2011.) exuded just 2 chains, literally the day before yesterday put a new (which in the photo above), sawed by the two (according to my calculations) of about 200m3 wood. Photos of the chains deputed to the limit (part of the cutting teeth even broke off on the Oregonovskaya)::

STIHL circuits instructions for chainsaws

The normal and productive work of the chainsaw can only be ensured with the proper operation of the saw headset and, above all, the saw chain. The fundamental rule for any owner of a chain saw should be the condition of work only by a sharp chain. Never use stupid chains for sawing. So that the chain on your saw is always in the lock, we recommend that you learn to hide it correctly. Only a properly sharpened chain can always provide effective, safe and accurate sawing. Professionals know that even the power of the chainsaw engine does not affect the performance of work as a sharpened chain.

A file for a chain

You need to understand that the usual round, and even more flat or triangular file, will not work out the chain, since the file for the chain should have its own parameters. Although here it is worth making a remark- a limiter of depth can be stuck and with a simple flat file.

File parameters for sharpening circuit

The most important parameter of the file for sharpening the chain is its diameter. It is important because, depending on the chain step, the file of a certain diameter is used. Below I give a table, which indicates which file is suitable for a chain with one or another step.

In addition, it must be borne in mind that most files are sold without a handle. It should be purchased separately. This of course does not concern the sets of files in which for the most part files are equipped with handles.

Auxiliary devices for sharpening circuit

Without a doubt, an experienced chainsaw user will be able to sharpen a chain without various auxiliary devices and devices, which is called “by eye”. But for this you need to have experience that you must first get. And this is much more convenient to do using various devices that will sharpen the chain correctly. Let’s look at the most popular of them.

Control caliber

- Control the distance to the depth limiter

- Check the angle of sharpening of the cutting teeth of the chain

- Clear the groove and measure its depth

- To the front angle of the tooth

That is, with the help of a control caliber, you can, after you pre.sharpening, determine whether it is done correctly. It will be useful to measure the measurement before the sharpening of the chain. STIHL production.

Clime holding

This simple device allows you to sharpen the chain at the required height and at the right angle. She fits tightly to the tooth and limits the depth of the file of the file. And thanks to the risks applied, you can control the necessary angle. It is necessary to choose a holder based on the step of the engine.

Combined template

Unlike the combined caliber produced by the Shtil, the tent from Husqvarna allows not only to measure, but also directly sharpening. Templates also need to be selected by the chain step.

Guide for the holders

Despite the risks inflicted on the holder, sometimes it is not easy to withstand the angle for sure, especially an inexperienced user. Therefore, STIHL offers a special guide FF1, which on the saw tire allows you to accurately withstand the necessary angle of sharpening.

Sharpet template

In addition to combined templates, Husqvarna also produces ordinary templates, which allow you to observe the correct angle when sharpening the teeth of the chains of chainsaws.

Clamping holder 2 in 1

When properly sharpening the chain, two operations must be performed: sharpening cutting teeth and sharpening the depth limiter. STIHL offers a universal solution- a clamping holder for two files, which at the same time you perform both operations.

STIHL FG4 SHIP

This sharpening device is installed on the tire, accurately withstanding the required angle, and also allows you to check and rule the limiters of the cut depth on the circuit.

STIHL FG 2 circuit sharpening device

When using this device, the chain from the chainsaw must be removed. This is one of the most accurate devices with which you can sharpen a saw chain for a gasoline saw.

Clamp

In the field of the clamp, it allows you to clearly fix the tire for accurate sharpening.

Chain parameters

The main geometric parameters of the saw chain are a step, profile height and shape of the cutting tooth, the thickness of the leading link, the number of links. A step is half the distance between the centers of three sequentially walking rivets.

It is customary to measure it in inches, and everyone has a symbol (see. Table 1). Saw chains in height of the tooth profile are divided into low and highly profile. So, for powerful STIHL chainsaws, it provides for Rapid chains with a higher tooth, and for less powerful. Picco chains with a lower tooth. The number of links determines the length of the circuit, depends on the power of the engine installed in the saw, as well as the type of work performed and corresponds to the size of the tire.

The thickness of the leading link is measured in millimeters (mm) and must correspond to the width of the groove of the tire used (s/and. Table 2). The last figure of this thickness is stamped in the form of a convention on each leading link of the chain.

Additional recommendations

First of all, you must remember, is that before making direct sharpening, it is necessary to determine its level, starting from the most “stupid” cutter, since it is a kind of guideline in this process.

The chain lubrication scheme

It is also important to remember that you do not need to get involved in manipulation too much and deeply grinding your chain. Since in this way you simply violate its direct functionality, and its immediate strength and the link of the link will decrease

It is also important that most experts recommend, after direct sharpening, blowing the circuit itself by using the air of compressed. And after such a process, place it in oil for several hours, but it should be clean.

The procedure for adjusting the STIHL MS 180 carburetor:

In the instructions for MS 180 it is described how to standardly configure idle on a chainsaw:

We turn the blanket of the idle speed against the sentry until it does not go tight, then we turn it off for two clockwork clockwork. Voila! Tun.

If your saw has too low idle speeds, then we carry out the following actions:

If you have high speeds and the chain does not stop spinning:

- We turn the blanket adjustment screw counterclockwise until the chain stops moving.

- We rotate the screw even on a hollow against the sentry.

If you fail to independently adjust the idle speed, you must contact a specialized service center.

How to determine the need to sharpen?

Everything is very simple, when using a chainsaw, look at the sawdust received from the work, if they look non.standard and look like dust, the chain is most likely to be sharpened or completely changed. It all depends on the duration and correct operation. Please note that you need to check the suitability of the chain on dry trees, do not use wet wood.

If it is sawed in the longitudinal direction, you can determine the wear of the chain by detecting rude defects on the surface of the cut of wood and tears in the site of the saw. Other noticeable signs include:

During the transition to the upper edge from the workplace of the chainsaw, you notice a different radius rounding;

If there is a cut of a chainsaw in the process, it can vibrate, noise increases;

The resistance increases at the first attempts to begin sawing wood.

Be careful when working with not sharpened chains, otherwise you will be overheated by the chainsaw and the appearance of defects on the cylinder.

How to sharpen a chain of chainsaw?

If you do not want to change the chain several times a year, the sharpening procedure can be done independently using simple devices. The main methods include:

Machine. Usually there are masters or special service centers, so the procedure, although effective, is not so accessible. The machine is also used for those chains that have severe wear;

Corner grinder. It is better not to try without experience, sharpening corner grinding requires certain knowledge. Otherwise, you will damage the chain;

File. The easiest and most popular sharpening tool, small sizes allow you to carry a file with you and sharpen right at the place of work.

How to find out when you need sharpening?

To determine whether the teeth of the chain or not, it is possible by some characteristic features. Of course, it all depends on how intensely the chainsaw is used. It is worth taking a closer look at what chips it leaves. Its homogeneity and square forms indicate sharp teeth. If the chain is hidden, then it usually leaves wood dust, and the sawdust itself resembles the needles that the manual hacksaw “produces”.

If the speed of the cut is reduced, then this is also considered a sign. You feel an increase in the load on the tool itself and the appearance of vibration. Beginners do not always manage to notice some of these signs. Therefore, they should pay more attention to the quality of the chips. Sometimes it is a brown shade, which is already guaranteed to indicate that it is time to sharpen the chain.

How to determine that a chain of a chainsaw is time to sharpen

Frequent work with a chain saw leads to a rapid blunt of cutting teeth, and when abrasive particles (for example, land), this process is accelerated. Sometimes you have to restore the cutting ability of the saw several times within one working day: with timely sharpening, less steel will have to be removed each time, which will increase the service life of the entire cutting headset in the complex. We list the most characteristic signs of a chain of chain:

- – the saw does not crash into the wood itself, requiring significant pressure on the motor unit;

- – instead of large chips, the saw chain throws small sawdust;

- – the appearance of the smoke and smell of burning during sawing, despite the impeccable operation of the oil pump and sufficient tension of the chain;

- -the saw “leads” aside due to the uneven wear of the cutting teeth;

- – When sawing, the chain “beats” and “jumps”, which can be caused by a small distance between the vertices of the depth limiters and the corresponding cutting edges.

The best Chainsaw Chain sharpening video ever

In addition, special lines are applied to the cutting links of the STIHL chains. this is a marking of wear. With the wear of the chain to such lines, it is necessary to replace the chain.

Where to order restoration of chains for a chainsaw?

Service conducts high.quality repair of chainsaws and carries out saws. Services are available for all types of chain devices. If the sharpening does not make sense, the chain is too much damaged or poor.quality, the master will not do the work, saving your money. Modern models sharpening machines allow guaranteeing the accuracy of completing tasks. The cutting edge will be fully restored for further effective operation. For issues of ordering services and for consultations, call workshop managers.

Sharpening of the saw chain in the presence of appropriate knowledge and skills is not complicated, but it requires compliance with certain rules. Consider the most useful and necessary.

With prolonged operation, the saw has to periodically undermine its cutting part during the day, since all cutting teeth should first have the same values, angle of sharpening and position of the depth limiter.

To do this, we first find the shortest tooth, take it for the beginning of the reference and, during the sharpening process, adjust to its length all other cutting teeth of the chain. If it is in the right row of teeth, then we fix the guiding tire in the vice of the end star to the left, if in the left row, then we turn the tire with an end star to the right. Then we place this tooth in the sharpening area and turn on the circuit brake. We sharpen the sharpening with a round file of a certain diameter depending on the chain step

Read also: What to do the battery in the car

For this reason, two types of saw circuits are produced. transverse and longitudinal, differing in angle of sharpening.

When working with a file, 20-25% of its diameter should protrude over the upper line of the cutting tooth. Remember that the file grinds the metal only when moving from itself, and with the reverse movement it should be lifted. In addition, the file must be periodically slightly rotated around its axis to prevent uneven wear. After two or three servings, check the uniformity of the removal of steel from a wiped tooth. If the earnings occurs in places, then you either use the wrong file, or lead the file too high or too deep. You need to grind the cutting edge until the light strip disappears on it.

After receiving a high.quality cutting edge of the lifted tooth, first turn off the brake, move the chain to the next tooth from the same side of the tire and set the brake again before sharpening. Stop the rest of the cutting teeth from this side to the same length, then turn the tool 180 ° and sharpen all the teeth on the other side in a similar way. Recall that all of them need to grind to the length of the initial tooth. If the cutting teeth of one row turned out to be longer than the other, then align them by performing one or two additional sharpening movements.

Compliance with the above recommendations helps to obtain the correct and identical values of the front angle of cutting and angle of sharpening with the same height of all cutting links in the chain.

Now it is necessary to configure the depth limiters, since the difference in heights of the upper points of the cutting edge and the cut limiter limiter as the teeth grinded decreased, and in the same way, because the teeth had to be aligned.

To check this value, it is convenient to use a supporting caliber corresponding to the chain step and determining the depth of cutting (see. Table 1). It is a template for monitoring the position of the cutting depth limiter, it is applied to the cutting tooth, and if the cut depth limiter protrudes above the upper plane of the caliber, then this surplus should be removed with a flat file. You can’t touch the sharpened cutting tooth with a file. Calculate the number of supplies with a file when processing the first depth limiter and approximately the same amounts of the depths of the other cutting teeth, not forgetting to correct the front edge of the limiter to reduce vibration and reduce the risk of return.

Note that manual sharpening of the chain saw justifies itself to maintain the productivity of the tool with its intensive use during the working day. over, StiHL offers a large selection of auxiliary devices that facilitate and increase the effectiveness of such sharpening. These are special guides, various sharpening devices, control calibers, etc.D. After 3-4 sharpening manually, we recommend that professional mechanized sharpening of the saw chain in a specialized service center for a high-performance guarantee and excellent quality of the saw.

Application

Table 1. Dimensional row of saw chains

Even the popular Stihl is not eternal: once the teeth of the chainsaws wear out, which is easy to install by the nature of the formed chips. With a blunt cutting edge, the chips are small, because the working edge does not cut, but wives wood. Naturally, the efforts spent by the operator increase sharply. It’s time to sharpen the saw. How to do this correctly. choose the optimal technology, establish which angle of sharpening of the tooth should be and how to check it?

External signs of a dent of a chainsaw

Among the most popular chainsaws are the instruments of the Austrian company STIHL, in particular, the STIHL-180 (if accurately, then STIHL MS-180-14 ’’). Suitable for sharpening flat file 150 mm. For storage chain. Such a chainsaw can be cut, and with the average branches in diameter, the power of 1500 watts quite allows. Despite the quality steel that the indicated trademark (Chinese fakes do not consider!) uses for the manufacture of teeth, independent sharpening will require dexterity and time.

Attention should be paid to the following external signs of the cutting chain of the cutting circuit:

- A conical section appeared on the working coal of the tooth.

- When moving from a working angle to the upper face, radius rounding visually differs.

- At the time of the initial feed, even with its relatively low intensity, the introduction of the working edge of the tooth in the thickness of the wood is carried out with great resistance.

- At the stage of the installed cut, the chain of the chainsaw begins to vibrate, and the noise level of the chainsaw increases noticeably.

- When sawing in the longitudinal direction, the surface of the cut has gross tears and chips of wood. When and how to sharpen the chain of the chainships. What tools are used for independent sharpening at home with a file. The chips itself are becoming much smaller in size.

A trial test is carried out on dry.resistant, and in no case on wood with high humidity. The frequency of sharpening depends on the main direction of sawing. If it is performed mainly in the axial direction, then the sharpening will have to be performed much more often.

What is included in the sharpening kit?

In the absence of a special machine, you will have to get by with a file for sharpening the chain of the chainsaw (more precisely, not one, but two). The video sharpening the chain of the chainsaw is visible, regularly turn the file to avoid. POLMARS POSICS DOLMAR 5.2mm reviews. STIHL STIHL STIHL 4.8 mm reviews. Reviews. A special template is also needed, with which you can control the current value of the angle of sharpening. Thus, the base set of sharpening equipment includes:

- Round file with section diameter 4.5 5 mm.

- A holder with special positioning lines, with which the tool can be placed with the necessary accuracy on the upper face. The holding is equipped with a area that is based on the surface of the cut depth limiter.

- Flat file, which is sharpened the limiter itself.

- A hook that removes sawdust formed during sharpening.

It should be noted that manual sharpening is effective only when the signs of the ditling of the chainsaw are set very promptly, and wear is relatively small. Otherwise, more complex and expensive specialized machines will be required. Manual type machines of the dimensional row FUG are suitable for work with teeth of the chainsaw of the Stihl-180. Sharpet of the chain of the chain of the chain. Their advantage is that it is possible to sharpen the teeth, the wear of which turned out to be sharply uneven.

The diameter of the file for sharpening the chain of the chain

The diameter of the file for sharpening the chain of the chainsaw is very important in the process of selecting the tool. The incorrectly chosen file will spoil the chain, which is why there will be problems in the process of sawing. The saw can get stuck inside the tree, break and lead to a breakdown of an expensive tool. The diameter directly depends on the chain step. When sharpening, 4 of the main sizes of diameters corresponding to their step: step ¼ ”. a diameter of 4.0 mm; Step 0.325 ″. 4.8 mm; Step 3/8 ″. 5.2 mm; Step 0.404 ″. 5.5 mm. For some types of chains, files with a diameter of 3.2 mm are also used.

There are three ways to sharpen a chain of a chainsaw:

- Using a file. Two types of files are used: with a round section, the diameter of which corresponds to the diameter of the rounding of the edge of the saw tooth, and with a diameter of 4, 4.8, 5.2 and 5.5 mm for sharpening the chain of chainsaws of household purposes and professional. For proper sharpening, it is necessary to sharpen the cutting edges of the tooth and adjust the limiter of the cut depth. If you do not adjust, the chain will not be able to plunge into the sawed material to the desired depth, which will slow down and lead to overheating of the motor. The action is performed by a flat file.

- Using an electric sharpening machine. often the method is used in service centers in the processing of a large number of tools, requires professional skills. The principle of operation of the machine is one: the chain is clamped by the reference with the guide, which is located on the rotary platform. The latch holds the tooth and is able to move horizontally. An emery is installed at the angle at an angle. The depth of immersion and angle of sharpening are regulated. The process is carried out under the control of the operator.

- Using a corner grinding machine (corner grinder). Not a common and not safe way. The corner grinder is clamped tightly and turns on. The edge of a sharpened tooth is brought to the rotating disk. This method of sharpening differs from a similar action by a file, t.to the angle of sharpening is difficult to control. The disadvantage of the method is the probability of cutting the fastening element of the links of the chain. This can lead to a break in further work.

Take a sawing kit using the recommended tool, do not invent new methods and tricks that will lead to financial costs and injuries.

Files for sharpening chains of chainsaws Stihl Stihl

There are different files for sharpening chains of chains of chainsaws Stihl Stihl on the market. Despite the external differences, they are all branded. Some of them are components for sharpening machines and are sold in packs several pieces. They have no handles, so it is inconvenient to use without the basis. Files sold in individual packaging can be included in the set or sold on their own. There are 2 options for them. with a sharpening template and without it. In addition to the files, STIHL also produces a number of auxiliary devices: sawing calibers; sharpening mandrels; Templates (holdings) of different types; clamps. Opal calibers are designed to verify the depth of sharpening, clean the grooves and check the corners manually. The mandrel is a plate with guides applied on it, indicating the angle of sharpening. Moving in accordance with the guides is easier to withstand the right degree of angle. It is attached using magnets on a metal tire. The clamp works on the basis of the holding and allows you to sharpen the cutting and restrictive bones of the link in one stage.

Files for sharpening chains of chainsaw stihl

ЖЕРТВА ФЕРЗЯ и МАТ ПЕШКОЙ Анны Музычук! Шахматы Для Всех

Than and how to sharpen

For tightening the chain, use a file, corner grinder or special workers. Each method requires compliance with a certain technology.

Sharpening by means of a file

To sharpen the motor.rope circuit, a set of flat and round files is used, as well as a special hook with which the motorizedopia is cleaned of sawdust. The use of such a set requires special skills, so without them it is better not to sharpen the road circuit yourself. Before sharpening the engine circuit, the tire should be fixed. The selection of files should be carried out in accordance with the type of chain, using its step as the main criterion. With the help of flat files 4-12 mm wide, a control tooth is removed. With the help of round files with a diameter of 3-6 mm, the cutting tooth is sharpened.

The sharpening process consists of the following steps:

- First, the circuit brake is installed.

- Then the template is installed so that the “arrows” show the “nose” of the tire. You need to make a note with a chalk on the tooth, the first to be processed.

- The file moves with movements “from itself” in the direction of the arrows show.

- A control tooth is removed using a flat file and overlays. The movement of the tool in this case can be carried out in any direction.

When performing work, the following requirements must be fulfilled:

- Sharpening should be done so that the file for one fifth of its length protrudes above the cutting edge.

- The movement of the file should be carried out in one direction, and not back and forth.

- The cut limiter must be undermined every two to three sharpening of the teeth.

Description of the sharpening process using files

The first where the editing of the saw chain begins on the saw is the installation of the tool on an even platform or table. In forest conditions, for this, a large.diameter chock is well suited. Next, you need to examine the saw chain for any defects, it can be cracks, completely fragmented teeth. After inspection, you need to install the brake in working condition, thereby blocking its movement along the bus.

The chain during sharpening with a file should be stretched.

It is advisable to lay a stand under the tire, you can use logs as it, a piece of a branch of suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the tire during the sharpening of the circuit.

The circuit is sharpening is carried out by the movements of the file from the inside of the tooth outside. In this case, the file should be located parallel to a special mark on the chain. This label is applied by the manufacturer of circuits to specify the standard angle of sharpening.

The hidden tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process you need to advance the chain along the tire, without forgetting to install the brake in the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of rough material, otherwise it is quite easy to injure yourself, t.to. The working surface of the teeth is very acute.

Ideally, manufacturers advise to conduct the same number of movements with a file for each tooth, but in practice this is not always possible, t.to. teeth have a different degree of damage to the working edge.

To facilitate the sharpening of a saw chain using a file, special holders can be used, with the markings of the angles applied to them. Markings are made not only for standard transverse cut, but also for longitudinal.

The holders are also convenient to use if you do not have sufficient sharpening experience. Experienced masters for sharpening do not use holders, but can only use special devices that support the file.

Another device designed for sharpening is a manual machine for editing saw chains. As a sharpening tool, it uses a regular file that can independently replace. The machine is mounted directly onto the tire, it also has the ability to adjust the angle of tooth sharpening and a special emphasis that holds the pulled tooth.

Hand machine for sharpening, perfect for beginners. Along with electric models for sharpening, manual has its own undeniable plus in the form of a low price. Depending on the manufacturer of a manual machine, their appearance may vary, but everyone has one principle.

The cut depth adjustment is carried out using a flat file, so that there is a difference between the upper cutting edge of the tooth and a height limiter.

As can be seen from the figure, the depth limiter is flowed in such a way as to bring the clearance indicator to the factory value. Below is a table, which contains the main values of the angles, as well as the clearance for the most common types of circuits.

Read how to choose a tree current

As a rule, the size of the gap is adjusted using a special dick. It is installed on the circuit during sharpening, after which the depth limiter grows.

Using a manual machine

When the cutting edge of the chain completely loses its original shape, its sharpening with a file takes over a lot of time and labor too much. In such situations, machines for sharpening the motorcycle chain are used. Sharpening with a hand machine consists of the following actions:

- First you need to slightly loosen the screw that controls the clip of the circuit.

- The chain is installed in the guide groove so that the links look in the direction of the sharpening stone.

- The required angle of sharpening is set, taking into account the goals of using the circuit.

- Sharpening is performed using one of two ways. One of them consists in sequential processing of incisors with a constant change in polarity. The second consists in the processing of each second cutter: first, left.handed incisors are hidden, then right.handed, or vice versa. In the latter case, there is no need for a constant change in polarity, so the sharpening is made much faster.

Character characteristics of the teeth

The teeth of the chain have several important parameters. Such parameters include:

- The device of the cutting link (consists of the base, attached to the chain, the spatula of the teeth with two cutting edges, the depth limiter, which controls how deeply the blade crashes into a tree, the end and upper blade), the cutting effect is not performed by the chain itself, but the links, that is, that is, the links, that is,. teeth. They move to the chains, as on the basis of wood, and a tree cuts the link;

- The angle of the end blade, which allows the chain to cut the tree (precisely because of this corner, wood chips are formed during the cutting).

Read chisel for woodcarving: what a tool and how to choose

To conduct the proper sharpening of the chain, the owner needs to know:

How to properly flood the chain depends on these two parameters. The softer the metal metal metal on the chainsaw, the more carefully you need to handle the file when manual sharpening. The upper edge of the file during the tightening process should be located at an angle of 90 ° in the vertical plane and 30 ° or 10 ° in horizontal.