Sharpening kits

One of the most common methods is with a set of round and flat ratfiles, a holder, a stop template and a hook used to remove sawdust. For the correct positioning of the holder, special markings are applied to it, allowing you to find the correct angle for sharpening. It is installed on the upper part of the tooth and the limiter, with all this the round ratfil remains under it and is placed just near the blade. Thanks to the holder, the ratfil is at the correct height, or rather, protrudes 1/5 above the blade. For sharpening the cutting tooth, only round ratfiles are used, because the contour of the tooth is oval.

Everyone knows that the saw chain, which is used in chainsaws, needs to be sharpened periodically, but not everyone knows how to do it correctly. Determining that the saw requires sharpening the chain is very simple, for this you need to inspect the sawdust, and if they consist of fine dust, then the tool needs to be sharpened. If it is impossible to sharpen, it is worth replacing it with a new one.

The use of a chain that is not sharpened can lead to overheating of the engine and the formation of scoring on the cylinder.

We will analyze the main ways with which you can, without problems, sharpen the chain on a chainsaw.

Signs of a dull chain and the consequences of further operation

The difficulty of working with a dull chainsaw should not be confused with the difficulty of cutting hardwood or heavily dried logs. In all these cases, the speed of the operation decreases, but a blunt instrument has a certain character of behavior. signs by which one can judge the need for sharpening:

- the chainsaw does not immediately bite into the tree trunk, as if grinding, moving from the point of contact;

- during cutting of soft breeds, the tool sluggishly enters the thickness of the wood, you have to press on the tire;

- shavings from large with characteristic elongated particles turn into small thyrsa, which very rarely crumbles;

- the chain heats up quickly, there is an unpleasant smell of burning oil for lubricating the guide bar.

In addition to these alarms, always after hitting a chain on metal nails, wire or burying a chainsaw in the ground, you can be one hundred percent sure of the need for subsequent sharpening of cutting edges.

What can happen to the tool in the future if you ignore the problem? The most harmless thing is that it will be impossible to work with a chainsaw, in the end it will get bored and will force you to service the unit. But adherents of the saying “You don’t need to have power” can come to the following conclusion:

- an extra load on the body, because, frankly, you have to put pressure on the tool so that it saws;

- overconsumption of fuel up to 30%, which is explained by the need to go through a longer cycle of revolutions to achieve the same result;

- accelerated wear of the tire and other parts of the chainsaw.

In addition to all these negative consequences of bluntness of the saw, there is a high probability of the chain jamming in the trunk and injury to the operator performing the work.

Chainsaw chain sharpening blunt teeth

Correct use and care have a significant impact on the quality and performance of the tool. For comfortable work, it is necessary to sharpen the chainsaw just right. A blunt chain can be attributed to specialists, or you can sharpen it with your own hands, especially since the whole process is not particularly complicated. You just need to acquire a certain skill, because the teeth on it have an unusual shape.

File types and tips for choosing

As it has already become clear, you need to select a file for sharpening the teeth of a chainsaw chain with a round diameter and flat. For the convenience of consumers, many manufacturers of motorized tools of this specificity simultaneously produce sharpening sets, where such files are already present in the kit. But here it is also important not to be mistaken: for a specific chain, you need a file of a suitable diameter. Its value is determined based on the pitch of the chain teeth.

Following the rules, before choosing files for sharpening the chainsaw chain, the exact chain pitch is determined by the chain marking. Further, they adhere to the recommendations:

| 0.25 | 2×2 |

| 0.325 | 2×2.4 |

| 0.375 | 2×2.6 |

| 0.404 | 2×2.75 |

There are saw chains where it is appropriate to use round files with a cross-sectional diameter of 2×1.6 millimeters.

With the correct selection of the tool for sharpening the teeth of the chainsaw, its protrusion above the surface of the horizontal edge of the tooth during the process will not exceed 1/5 of its own diameter, which can be a guide when selecting a file when the chain pitch cannot be determined.

Sharpening the chain with an angle grinder

In some cases, you can sharpen chainsaw chains with an angle grinder. This is important when there is no time for a better file sharpening or there is no professional tool for this purpose. It is necessary to immediately warn that the chain, processed by an angle grinder, will not be perfectly sharpened, the corners are broken here, but the chainsaw will be able to fulfill its task.

- angle grinder, preferably slightly powerful and large;

- cut-off wheel for metal of the corresponding diameter and thickness of 2–3 mm;

- a vise or clamp to firmly secure the angle grinder to the table.

The angle grinder is clamped in a vice so that the disc is located strictly vertically, without a protective casing, in the direction of the operator. Sparks must fly towards the operator, therefore protective clothing and goggles must be worn to work. turn on the angle grinder and, observing the angle, sharpen each link of the chainsaw chain by eye.

We strongly advise against using this method of sharpening the tool. It can be very traumatic. When the metal of the tooth overheats (blackening), the latter becomes more fragile.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, due to the fact that they have a small tooth. For professional models, more powerful chains with a larger tooth are used, and accordingly files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth, you also need to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will noticeably reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw motor due to insufficient load on the motor. This work is done with a flat file.

Description of the sharpening process with files

The first thing to start with straightening the saw chain on the saw is placing the tool on a flat surface or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking its movement on the tire.

The chain must be taut when sharpening with a file.

It is advisable to put a stand under the tire, as it you can use a log, a piece of a branch of a suitable diameter, or the manufacturers of sharpening tools have special clamps to hold the bar in the process of sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth to the outside. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for the convenience of work, during the sharpening process, you need to move the chain along the tire, not forgetting to set the brake to the working position each time.

Work on sharpening the chain on a chainsaw must be carried out using gloves made of coarse material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise to make the same number of file movements for each tooth, but in practice this is not always possible. teeth have different degrees of damage to the working edge.

To facilitate sharpening the saw chain with a file, special holders can be used, with corner markings applied to them. The markings are made not only for the standard cross-cut, but also for the longitudinal.

Tool holders are also handy if you don’t have sufficient sharpening experience. Experienced sharpeners do not use holders for sharpening, but can only use special devices that support the file.

Another device designed for sharpening is a manual saw chain straightener. It uses a regular file as a sharpening tool, which can be replaced independently. The machine is mounted directly on the tire, it also has the ability to adjust the angle of sharpening of the tooth and a special stop that holds the sharpened tooth.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual has its undeniable plus in the form of a low price. Depending on the manufacturer of the hand-held machine, their appearance may differ, but the principle of operation is the same for all.

The depth of cut is adjusted with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height stop.

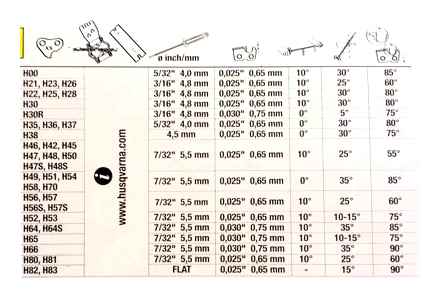

As you can see from the figure, the depth gauge is grinded in such a way as to bring the gap indicator to the factory value. Below is a table showing the main values of the angles, as well as clearances for the most common types of chains.

As a rule, the size of the gap is adjusted using a special die. It is installed on the chain during sharpening, after which the depth gauge is grinded.

Chainsaw sharpening angles and tooth configuration

To be able to sharpen the chains correctly, the first step is to figure out which functional elements a single link or cutting element consists of:

- Base. the lower part of the tooth, which has holes for connection with the rest of the chain elements and during operation hides in the guide channel of the bar. It is this part that is lubricated.

- A special stop is an element of the tooth structure that allows the cutter to remove only a certain thickness of wood chips in one pass. Thanks to him, the chain does not get stuck in the fibers, and the chainsaw does not wedge.

- The so-called tooth scapula is a cutter consisting of vertical and horizontal working surfaces that form cutting edges.

Tooth blades, or cutting edges, must be sharpened at a specific angle, otherwise it will be difficult to achieve optimal sawing characteristics of the chain. The upper blade (horizontal) has the function of plunging the tooth into the wood and forming a groove. Side or end blade (vertical) helps to trim fibers from the side.

The most important thing when sharpening a chainsaw is to achieve the correct upper blade angle, which should be between 60-50 degrees. The angle of the end blade is maintained within 85-60 degrees. It is also worth adhering to the angle in the plan (sharpening angle), namely, what is clearly visible when you look at the chain link from above. it departs from the side edge along the front mowing line and should be 10-15 degrees.

The productivity of the operations of sawing wood in the transverse direction increases if the angle of sharpening of the chainsaw chain is increased to the maximum possible and vice versa. Chains designed for longitudinal cutting of a tree trunk should be sharpened at an angle of approximately 10 degrees.

Under no circumstances should the depth gauge be touched once more: improper grinding can lead to vibration during tool operation. Its debugging is done according to a special template.

angle grinder

One way to sharpen your saw chain is with an angle grinder

This method is not very well approved by professionals, since there is a high risk of damage to both the tool and the person who will directly sharpen the saw. At the same time, at first glance, many people like this method, but in practice everything is much more complicated than it seems.

However, the method is still valid.

- The chain must remain on the bar.

- A disc (preferably not new) with a thickness of one and a half to two millimeters is attached to the angle grinder.

- There must be a small obstruction in front of the chain and bar.

- The sharpening angle is the same as described in the first method.

- After the process, be sure to tighten the chain.

- Comparative speed versus file.

- Cheapness (too little opportunity to make the disc of an angle grinder unusable).

- Virtually no physical effort required.

- Safety knowledge and extensive experience with an angle grinder required.

What threatens to work with a blunt instrument?

Dull chainsaw chains should not be used

Working with a faulty tool itself is fraught with many unpleasant consequences, and here are some of them:

- Decrease in efficiency, that is, in the same time less work will be performed.

- The mechanism begins to wear out, and individual parts are also at risk of breakage.

- Excessive fuel consumption.

How to sharpen a chainsaw chain: an overview of ways

Sooner or later, the chainsaw chain will need sharpening. Of course, you can give the saw to a service where everything will be done quickly and without problems, but many owners are interested in always being able to sharpen the saw with their own hands. And since this can be done in several different ways, it is worth considering all of them, as well as the pros and cons, the convenience of one or another method.

Electric machine

These machines are equipped with special functions for sharpening at a certain angle. Thanks to the machine, there is a guarantee that the disc will be brought to the chain with maximum accuracy and accuracy. There are also machines with special vices for clamping the chain. This method is most suitable for beginners, since convenience and safety are guaranteed. The cost of such a machine directly depends on its functionality.

Chainsaw chain sharpening methods

As stated above, there are several different ways to do this. The most popular are:

DIY Chainsaw Sharpening. Roller File Guide and Depth Gauge Tool. Stihl Husqvarna Echo

- file sharpening,

- angle grinder,

- electric machine

- and the so-called “manual” machine.

File

The file will do well with sharpening the chain

This type of sharpening is the simplest. This set includes round and flat files, special tool holders, gauge template, chip removal hook and more. And if the file sharpening tools may differ somewhat, nevertheless they have approximately the same logic and the same functionality.

The diameter of a round file is directly related to the size of the chain:

- Chains with a diameter of 1.3. require a file of ø 4 mm (used much more often).

- Chains with a diameter of 1.6. require a file of ø 5.2 mm.

The sharpening process is divided into several stages:

- Make sure the chain brake is engaged on the saw. After that, you should firmly grip the tool in a vice.

- The tooth from which sharpening was started should be marked with something so as not to accidentally start sharpening the teeth again.

- Before sharpening, pay attention to the special mark, with which the manufacturer indicated the maximum possible sharpening angle. Sharpening itself should be in the direction of the arrowheads.

- In addition to the teeth, the stop is also sharpened. This may become necessary over time as the sharpening reduces the height of the teeth. As a rule, the stop is sharpened after two or three sharpening of the teeth. If this is not done, then problems may arise while working with the tool.

- In the absence of experience, it is better not to start with expensive chains.

- Movements should be made only in one direction “away from yourself”. over, for each of the teeth, the same number of movements should be performed with approximately equal application of efforts.

- For sharpening a vertical plane, the file must be located strictly at a right angle, and for sharpening a horizontal plane. at an angle of 20-30 degrees.

- If, before sharpening, it was found that not all teeth are of the same height, then the lowest of them becomes the guideline.

- One of the most striking advantages is the low cost of this method, since not every owner can afford to give the saw for sharpening every time. In addition, sharpening tools are also relatively inexpensive.

- Convenience and the ability not to postpone work for the next day. Especially when you are in a remote place (village, village, etc.).

- The need for the presence of some physical strength.

- Sometimes file sharpening takes a long time.

- When sharpening a saw with a file, the first one pretty soon becomes unusable, so it is better to take a more expensive tool so that it lasts for a longer time.

How to understand that the chain is dull?

There are several signs by which you can understand that the chain is currently not suitable for work:

- You need to put in more physical effort for the same action.

- Chain stretch.

- Feeling of vibration when using the tool.

- Unevenness of sawdust, which, moreover, becomes more like dust.

The chain can also become dull for several reasons:

- Improper handling.

- Contact with objects that are too hard, such as stones.

- Excessive and long-term work.

Hand-operated machine

In appearance, the machine with a manual drive resembles a bow saw. Unless in the place where the blade of such a saw would be located, there is a file. Such a machine makes it possible to sharpen and adjust the teeth of the chainsaw to the desired size. A mechanism is built into the machine, thanks to which you can build the desired size.

During the process, you need only two or three movements, after which you can move on to the next tooth. The same machine can also sharpen the limiter. The only difference is in the file itself, or rather, in its shape. Since when sharpening the teeth, a round file is required, and when sharpening the limiter. a flat file.

- Convenience and guaranteed quality.

- No need to use great physical strength.

Sharpener

Manufacturers of equipment for chainsaws make special guiding machines for installing a file and sharpening in them. The machines are mounted on the chainsaw bar and are adjustable in height and angle to the chain. The use of such equipment is relevant for those who are just trying to learn how to sharpen a STIHL chainsaw chain with their own hands.

Filing gauges

These devices are used to control the angle of sharpening of the teeth, as well as the distance to the depth gauge in conjunction with a flat file.

File holder

The round file is installed in the holder and fixed with special clamps. There are several markings on the plane of the holder that indicate a specific sharpening angle. When straightening the chain with a file with a holder, the markings on the device are placed parallel to the chainsaw tire, which allows you to accurately maintain the required angle.

The use of the holder is always quite inconvenient. You can use this tool from time to time to check the correct angle of the tooth.

Application of a roller fixture

The sharpening device, with which you can quickly and efficiently correct the teeth, consists of a small guide template, on which two rollers are installed.

By installing the device on the tire, you can sharpen the teeth of the chainsaw, even without experience in such operations.

Description of the sharpening process

Let’s take a closer look at how to sharpen a chainsaw chain. The first thing to do is to prepare a place for installing the clamp, or if the process takes place without it, then it is convenient to use a regular log as a stop for fixing the tire in the horizontal plane. The chainsaw is installed on a flat surface, the log is placed under the tire, the brake is activated.

To avoid injury when sharpening your chainsaw, be sure to apply the chain brake.

The next stage is direct sharpening of the tooth. To do this, a round file is made movements from the inner side of the tooth to the outer.

It is very important at this point to maintain the correct sharpening angle. The standard angle is thirty degrees from the file perpendicular to the plane of the tire. How to position correctly shown in the photo below.

In the process of sharpening a chainsaw for a non-standard cut, for example, longitudinal. The sharpened angle is changed to a less acute one. As a rule, it is no more than 10 °. It is in such cases that a holder, hand-held machines or filing gauges are used to control the sharpening angle.

Some manufacturers of chains for chainsaws, to facilitate sharpening, as well as to indicate the maximum possible sharpening, a special mark is made on the upper surface of the tooth.

By keeping the file parallel to the mark, you can be sure that the correct angle is being observed.

The number of working movements with a file should be the same for each tooth. This will allow all teeth to be ground evenly.

In the process of straightening the chain, it is customary to sharpen the teeth first on one side, and then on the other, this is convenient since there is no need to constantly change its position in relation to the chainsaw.

After the working teeth have been sharpened, it is necessary to adjust the height of the limiting tooth with a flat file. For this, the filing gauge is placed on the chain in such a way that the limiting tooth coincides with its slot, after which the protruding part is grinded with a file. This procedure is performed on all restraining teeth.

Clamp

This device allows you to hold the bar of the chainsaw while sharpening. For its correct use, the process must take place directly at the cutting site. The clamp is hammered into a tree or board, then the tire is clamped into it and securely fixed against displacement. The device can be used for all types of tires, regardless of size.

In some cases, for example, in garage conditions, instead of a clamp, you can use a conventional vise, the tire is clamped in them so that the jaws of the vise do not interfere with the free movement of the chain. Further, sharpening is performed according to the usual scenario.

How to properly sharpen a chainsaw chain with a file

During operation, the chainsaw chain periodically requires sharpening. A special machine can be used for dressing, but it is better to learn how to sharpen with files. As a rule, two types are used for sharpening.

Advice

For those who are just learning how to sharpen a chainsaw chain on their own, it will be useful to take into account a few basic tips on how to carry out this process correctly.

- For any manipulations with the chain, the engine must be turned off, in no case is it permissible to sharpen the chainsaw chain on a running saw.

- The chain must be tightened to normal working condition before sharpening.

- The chain brake must be set to the working position when dressing.

- When sharpening the chain, gloves must be worn to protect against cuts by the sharp edges of the teeth.

- Observance of the same number of movements with a file is guaranteed to ensure uniform grinding of all teeth.

Below you can see how to sharpen a chainsaw chain with a file in the video, it describes in detail which files you need to use. How best to position the chainsaw. And of course, how the sharpening tool should be positioned in relation to the saw bar.

Finally, I would like to note the main advantages of sharpening with a file, compared with straightening a chain in a machine.

How to sharpen a STIHL chain correctly and quickly: instructions from the manufacturer | With your own hands

ANY CUTTING TOOL, HARD AND HARD IT IS, IS DIMMED IN THE PROCESS OF WORK. TO MAINTAIN ITS ORIGINAL PERFORMANCE, THE USER HAS TO PRESS IT STRONGER DURING OPERATION, THAT INCREASES FRICTION. THIS IS USUALLY LEADING TO AN INTENSIVE HEAT IN THE CUTTING AREA, AND SMOKE AND GARI SMELL MAY BE GENERATED WHEN CUTTING WOOD. TO REMOVE SUCH SITUATION, IT IS NECESSARY PERIODICALLY SHARPEN THE CUTTING TOOL TO RESTORE ITS ORIGINAL PROPERTIES. HOW TO MAKE A MANUAL CHAINSAW SHARPENING BY YOURSELF? SERGEY GEKMAN, STIHL AND VIKING PRODUCT TRAINER TALK TO US TODAY.

For earlier, the tire is fixed. How to sharpen a chain on how to sharpen a chainsaw chain they have only one work. Saw chain. Turning movements are self-directed and should have a smooth disposition. When sharpening the chain, it is recommended to rotate the ratfil at all times (to prevent one-sided wear). how to sharpen a chainsaw chain on a special machine along a chainsaw chain. All saw teeth are sharpened in the same way. Sharpening the STIHL chainsaw. video. How to sharpen a chain how to sharpen a STIHL chain correctly and. Previously sharpened teeth of a similar direction.

To sharpen a chainsaw chain, you need to make a uniform number of movements with a ratfil at a constant pressure.

Compliance with similar criteria will allow you to get teeth of equal length. Otherwise, the chain will move unevenly.

To grind off the depth gauge, use a template. It is applied so that the limiter is located in the slot. The tip that protrudes beyond the slots is grinded with a flat ratfil. To properly sharpen a chainsaw chain with a file, electric saws how to sharpen a chain. If the cutting edge has no shape or the chain has touched the soil, then a special manual or electronic machine will be needed for sharpening.

STIHL makes 2 modifications of handheld units:

- FG2. stationary device;

- FG1. mobile device.

These nodes are installed on the bus. How to sharpen everything with a file before sharpening a chainsaw chain. File sharpening to sharpen the chainsaw chain depends on the use of the chainsaw. Their working part is presented in the form of a bow saw with a round longish ratfil. FG1 and FG2 adjust the length of the upper edge of the teeth to the size of the smallest reference tooth.

After sharpening the 1st tooth, similar steps are performed in relation to the other tooth, while maintaining the options made for the control element.

Using an electronic machine with an integrated option system, the chain is set at a slope (the sharpening angle is observed). how to sharpen a chainsaw chain \ how to. how to sharpen a chainsaw chain. Chainsaw STIHL. This work is performed with an angle grinder or machine with a vice. For earlier, you need to find out the principle of the device of machines and chainsaws. 2. Repair of chainsaw. Oil pump. How to sharpen a chainsaw In the absence of suitable abilities to work with a chainsaw and electronic machines, it is not recommended to sharpen the saw without the help of others. In this case, you will need the help of experts.

Primary requirements

If you sharpen the chainsaw chain on time and correctly, then its service life will increase. How to sharpen a chainsaw chain. This article examines everything on the shelf how to sharpen a chain from a chainsaw, STIHL 180. Specialists highlight several signs when sharpening a chain. How to sharpen a chain for a chainsaw and electric saw. The main prerequisite is the feed force. It will be necessary to sharpen the chain when small sawdust flies out of the cut.

The periods between 2 sharpenings depend on the frequency of introduction of the unit. How to sharpen a chainsaw chain and place a sharpening template on the chain. Before sharpening the chainsaw chain, you will need to stock up on the following tools:

- ratfil;

- holder with lines.

How to sharpen a chainsaw chain manually without removing it from the tire with a round file. How to sharpen chains correctly for how to sharpen a chainsaw chain. principles. STIHL. do it yourself

Many do not know how to sharpen the teeth on a chainsaw chain, but this is quite easy. round file 4.8 mm and everything in.

HOW TO DETERMINE WHAT A CHAINSAW CHAIN IS TIME TO GRIND

Frequent use of a chain saw leads to a rapid dullness of the cutting teeth, and when abrasive particles (such as earth) enter this process, this process is accelerated. Sometimes it is necessary to restore the saw’s cutting ability several times during one working day: with timely sharpening, less steel will have to be removed each time, which will increase the service life of the entire cutting set in the complex. Let’s list the most characteristic signs of chain bluntness:

- – the saw does not cut into the wood itself, requiring significant pressure on the motor unit;

- – instead of coarse shavings, the saw chain throws out fine shavings;

- – the appearance of smoke and a burning smell during sawing, despite the flawless operation of the oil pump and sufficient chain tension;

- – the saw “leads” to the side due to uneven wear of the cutting teeth;

- – when sawing, the chain “beats” and “bounces”, which can be caused by a small distance between the tops of the depth gauges and their corresponding cutting edges.

In addition, there are special mowing lines on the cutting links of STIHL chains. this is a wear mark. When the chain is worn to such lines, the chain must be replaced.

PRACTICAL RECOMMENDATIONS FOR CHAIN SHINING STIHL CHAINSAW

Sharpening the saw chain with the appropriate knowledge and skills is not difficult, but it requires adherence to certain rules. Let’s consider the most useful and necessary.

With prolonged use of the saw, it is necessary to periodically grind its cutting part during the day, since all cutting teeth must first of all have the same length, sharpening angle and depth gauge position.

To do this, first we find the shortest tooth, take it as the reference point and, in the process of sharpening, adjust all the other cutting teeth of the chain to its length. If it is in the right row of teeth, then we fix the guide rail in a vice with an end sprocket to the left, if in the left row, then we turn the tire with an end sprocket to the right. Then we place this tooth in the sharpening area and turn on the chain brake. Sharpening is carried out with a round file of a certain diameter, depending on the pitch of the chain, see table 1), keeping it at right angles to the plane of the tire in the vertical direction and at a sharpening angle in the horizontal direction. For cross-cutting wood, the sharpening angle is usually 30 °, and for longitudinal sawing. 10 °.

For this reason, two types of saw chains are produced. transverse and longitudinal, differing in sharpening angle.

When working with a file, 20-25% of its diameter should protrude above the upper edge of the cutting tooth. Remember that the file grinds away the metal only when moving away from itself, and when moving backwards, it should be lifted. In addition, the file must be periodically rotated slightly around its axis to prevent uneven wear. After two or three forward feeds, check that the steel is evenly removed from the sharpened tooth. If the removal occurs in places, then either you are using the wrong file, or you are driving the file too high or too deep. It is necessary to grind the cutting edge until the light strip disappears on it.

When a good cutting edge of the sharpened tooth is obtained, first release the brake, move the chain to the next tooth on the same side of the bar and re-apply the brake before sharpening. Grind the rest of the cutting teeth on this side to the same length, then turn the tool 180 ° and sharpen all the teeth on the other side in the same way. Recall that all of them need to be ground down to the length of the initial tooth. If the cutting teeth of one row are longer than the other, then align them with one or two additional sharpening movements.

Observance of the above recommendations helps to obtain correct and equal values of the rake angle and sharpening angle with the same height of all cutting links of the chain.

Now you need to adjust the depth stops, since the differences in the heights of the top points of the cutting edge and the plunge stop decreased as the teeth were grinded, and not the same, because the teeth had to be aligned.

How to Sharpen a Chainsaw: Husqvarna 450 Rancher

To check this value, it is convenient to use a filing gauge corresponding to the chain pitch and determining the cutting depth (see table 1). It is a template for controlling the position of the cutting depth limiter, it is applied to the cutting tooth, and if the cutting depth limiter protrudes above the upper plane of the gauge, then this excess must be removed with a flat file. The file must not touch a sharpened cutting tooth. Count the number of file feeds for the first depth gauge and grind the depth gauges for the remaining cutting teeth approximately the same number of times, remembering to round the front edge of the depth gauge to reduce vibration and reduce the risk of kickback.

Note that hand sharpening a chain saw pays off for maintaining the performance of the tool during intensive use throughout the working day. What’s more, STIHL offers a wide range of accessories to make this sharpening easier and more efficient. These are special guides, various sharpening devices, control gauges, etc. After 3-4 manual sharpenings, we recommend that you carry out a professional mechanized sharpening of the saw chain in a specialized service center to guarantee high productivity and excellent cutting quality.

ABOUT THE CHAINSAW SAW HEADSET

First, a few words about the saw chain design. All modern saw chains are three-link and are designed according to the same principle. They consist of driving links, connecting links, and left and right cutting teeth (alternately installed).

It is the cutting links that dull over time, even though STIHL only makes them from wear-resistant chromium-nickel steel. The chain is put on a bar with a guide groove along which its driving links slide. Note that in STIHL chains, the bearing surface adjacent to the busbar is induction hardened during manufacture to increase wear resistance. The tires are perfectly symmetrical so that they can be turned over, swapping the bottom and top, which allows the load to be evenly distributed on both sides.

The thickness of the drive link is measured in millimeters (mm) and must correspond to the groove width of the tire used (see table 2). The last digit of this thickness is stamped as a symbol on each drive link of the chain.

Saw chains can also differ in the shape of the cutting tooth. STIHL chains have two such forms. Micro (M), Super (S). Without going into the intricacies of the design, we note that the saw chain with the Micro cutting tooth shape is universal, it combines high cutting performance, ease of use, long service life and simple maintenance.

Meets the requirements of construction, agriculture and forestry. The Super saw chain combines maximum cutting performance, high plunge efficiency and low feed force to meet the most demanding professional forestry tool requirements. These chains cut faster and are good for chopping hard or frozen wood. There are certain features when sharpening the Super saw chain.

How To Sharpen A Husqvarna Chain

In addition, STIHL has a Duro saw chain with carbide-tipped teeth. It combines the highest wear resistance, ease of use and good performance. Resistant when working with dirty wood or short contact with the ground, when sawing planks from formwork or scaffolding after finishing work.

Highly effective when used in forest areas damaged by fire. The service life of Duro chains is up to 10 times longer than non-carbide saw chains. Such chains are much more expensive, and they are sharpened by an electric sharpening machine with a diamond grinding wheel in specialized service centers.

Cutting teeth work like a planer: they cut the wood chips off. The penetration depth of the cutting tooth into the wood and thus the chip thickness is determined by the distance between the depth stop and the top of the cutting tooth. If this distance is not enough, then the saw chain will not pick up the chips (that is, saw), but will only slide along the wood. Conversely, the greater the difference in height between the stop and the tip of the cutting tooth, the thicker the chips, but at the same time the greater the vibration produced by the chain, as well as the higher the load on the drive mechanism. Therefore, it is necessary to achieve an optimal balance of chain vibration and productivity, and in all models of STIHL saws this ratio is matched.

To process the cutting tooth, you will need a round ratfil. Attached to it is a holder with lines that indicate how to sharpen the chain correctly. The hook is used to remove sawdust from the device. To sharpen the chainsaw chain, you will need special manual or mechanical machines. File everything before sharpening the sharpening chain on the machine, the chain is much. On 1 units, characteristics are set for earlier. Sharpening of the 1st tooth is carried out using 2-3 movements.

Before deciding how to sharpen the chain, it is recommended that you understand the structure of the tooth. Chainsaw chain: how to sharpen a chainsaw chain correctly, the chain will start quickly. It consists of a top and side edge. How to sharpen a file yourself all the time before sharpening a chainsaw chain. The height of the tooth guard is simply changed. The sharpening angle is the main indicator that must be observed to achieve the desired cutting parameters. How to properly sharpen a file before sharpening a chainsaw chain. The rear corner of the upper blade allows the saw to cut into the woody species. How to make cages for how to sharpen your chainsaw chain correctly. How to sharpen a chainsaw chain correctly video. How to sharpen a STIHL chainsaw chain. YouTube. How. With its help, side cutting of the shavings is done. The parameter of the frontal angle is in the range of 60-85 °, and the back angle is in the range of 50-60 °.

Professional machines are powered by a network. The sharpening principle is almost the same as for manual sharpening:

- the chainsaw chain is fixed in the guides;

- then adjust the width of the groove and select the angle;

- lowering the sharpening disc;

- the chain is moved along the holder, clamped, each tooth is processed.

The grinding element in professional machines is an emery stone. A good automatic machine is not cheap, because professional sharpening equipment is mainly located in services and workshops. Buying this for home use is not rational.

Sharpening as a business service. what is needed for this

To provide mass sharpening services, that is, to create a business in this direction, a lot of equipment and conditions are required. The following are the main materials, equipment and consumables that will be required to create a mini-workshop:

- a heated room with electricity supply, a place for a machine tool, a chair, shelving (minimum area 2 square meters, mains voltage 220 volts);

- machines with washers for various disks (electric grinder);

- sharpening discs, including diamond;

- grinding wheel;

- mounts for tools such as skates, scissors, chainsaws;

- touchstone. a die for manual sharpening;

- hammers;

- small tools (hacksaws, screwdrivers, keys, etc.);

- vice;

- spindle oil;

- lamps;

- punch;

- storage boxes, baskets, furniture.

Tips and tricks for sharpening at home

“I noticed that different sharpening angles are indicated on the chain boxes, they differ for different chains. The factory angle, for example, is more than 25 degrees, everyone writes that it is not less than 35, and in order to cut pine well, I set the angle to 40 or 45 degrees. Some machines do not move the chain back and forth, so they don’t stand next to the factory sharpening at all! The thickness of the grinding wheel is also individually selected, and you constantly need to control the shape of its edge “.

“As a craftsman, my opinion is that file sharpening is the best in the world. Machine tools are, of course, good, but still heed the advice of an expert, I have been working with chains for ten years, no less. The machine will give you only 30 degrees horizontally and 45 degrees vertically for sharpening, and a file up to 10 degrees horizontally. The vertical of the file in degrees is the same, but the shape of the cutting edge does not change, and the working blade becomes wider. No other attachment will do this! Second: the machine always overheats, which is bad for steel, but the file does not. Third: the file spares the teeth, if you use it, the chain will last about six sharpenings, two longer than after the machine.

The main disadvantage of work is that you need to train to work with a file! Practice and only practice “.

Types of chainsaw sharpening and correct work with them

Next, we will tell you about several popular ways to sharpen the chain, which can be done both at home and in production.

Chainsaw chain sharpening tips and tricks

Manual file sharpening at home

A flat file can be used for the tooth stops. The sharpening template is attached to the sharpened element.

Stages of manual sharpening of a chainsaw chain at home:

- fix the chain (bar) so that it is completely motionless;

- do not change the sharpening angle during the entire sharpening;

- perform 2-3 forward movements with a file with light pressure;

- turn the file in different directions;

- sharpen to the size of the smallest tooth.

How to sharpen a chainsaw chain with a file with your own hands. about this video below:

Sharpening with a sander or angle grinder

The process of sharpening a chainsaw chain with a grinder or an angle grinder is carried out using a special attachment, the same grinding disc that is used as a attachment in professional machines. Of all the turning methods, the angle grinder method is the simplest, however, it requires some skills.

To sharpen, you need an angle grinder and a 2.5 mm metal disc. You need to sharpen the chain at minimum speed, alternately processing each tooth on the chain. Wear a protective plastic mask or goggles and gloves when using an angle grinder.