Transmission

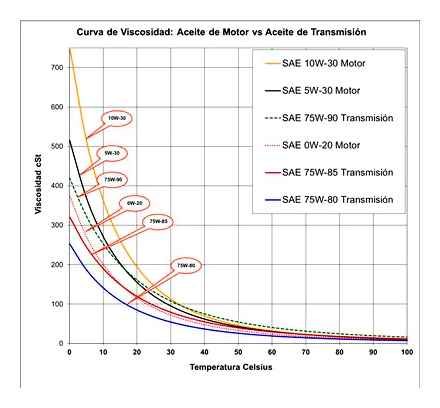

Transmission oil for the walk-behind tractor is used for the gearbox to work normally. It is poured into the gearbox. There are several options for transmission oils for this type of equipment, but it is recommended to use SAE 85w90.

This oil has a good viscosity of 16.5 mml / s. This product allows you to work even at low temperatures, because it solidifies at 25 degrees. This is a very solid indicator, especially considering that walk-behind tractors are practically not used in winter. Therefore, this stock will definitely be enough for you.

If you still have not decided what kind of oil to fill in the box of the walk-behind tractor, choose SAE 85w90.

What type of oil is best for a walk-behind tractor engine

It is good when a new single-axle tractor is purchased along with the documentation. Then everything is simple. take a look at the technical data sheet. There are mandatory instructions for changing the oil. Any more or less responsible manufacturer will indicate both the replacement schedule and the filling method, and even recommend the most suitable brand of oil. But this is the ideal. And in fact, very often you need to brainstorm on your own, look for information, ask more experienced owners of motoblocks. As a result, you can hear or read completely ineffective and not sensible advice and spoil your precious technique.

The choice of oil begins with determining the design of the engine. it is two-stroke or four-stroke. Two-stroke motors are not found in walk-behind tractors at all. They are mainly mounted on small, weeding cultivators. And for the most part, both gasoline and diesel motoblocks use ordinary engine oil intended for four-stroke engines.

For automotive four-stroke engines, there are three types of oils in nature: mineral, semi-synthetic and synthetic. But in the field of gardening equipment, namely, in walk-behind tractors, only two types of oil are used:

- Semi-synthetics. It costs a little less. Perfect for a walk-behind tractor in the summer. It thickens in winter. Therefore, if you use a single-axle tractor all year round, attaching a snow plow and other winter attachments to it, then semi-synthetic oils will not work.

- Synthetics (mineral). These oils are versatile in terms of temperature. Used for a walk-behind tractor both in winter and in summer.

It is very easy to “calculate” its winter appearance by the marking of the oil. The lettering of the brand must contain the Latin letter “W”. It denotes the season. winter (winter. in English)

Our recommendations for the highest quality brands of mineral oils for a walk-behind tractor:

- Motor oil brand 10w30. Made on the basis of paraffin, natural ingredients. Does not form precipitation at the bottom of the crankcase. The admissible negative temperature is 20 degrees below zero. The number 10 indicates the rate at which the parts are lubricated and coated. Number 30. viscosity at maximum engine heating. 30 is a universal indicator, it is used at different ambient temperatures. Ideal for new, not run-in engines. In addition, a viscosity of 30 will provide an opportunity to save fuel consumption by 2%.

- Brand 10w40. This oil can be used in even more severe frost. The allowed limit is 30 degrees below zero. But its viscosity is higher, so there will be more carbon deposits, which threatens with high fuel consumption. This oil will also be relevant when pouring it into a uniaxial tractor in a very hot summer: 35-40 in the sun. A reading of 40 also means this grease is good for worn out motors.

- Engine oil 0w30. The temperature range of this oil is very wide: 25 degrees of heat and 35 degrees of frost. In winter, it absolutely does not thicken, very quickly lubricates all elements of the engine, does not form carbon deposits and sludge. In summer, there is a limitation on the upper temperature up to 25 degrees Celsius.

Why you should follow the manufacturer’s recommendations?

The instructions for the cultivator must indicate the type of oil that is optimal for a particular engine. To determine the required viscosity, as well as to compile a list of recommended manufacturers and brands of lubricant, motorcycle tool manufacturers conduct numerous tests, analyzing the effectiveness of protecting rubbing parts with one or another material. Therefore, the instructions of the manufacturer must be strictly observed.

However, as we have already said above, in some cases it is possible to deviate from them. In particular, the range of lubricants is regularly updated, new products appear that may well suit your equipment. In addition, if the engine is worn out and actively consumes oil, then you can try to increase the viscosity by 1 level.

The main thing is to observe the service intervals and regularly monitor the quality and quantity of lubricant in the engine of your cultivator.

Transportation

- drain fuel and oil

- clean the uniaxial tractor from dust and dirt

- check the tightness of the fasteners and tighten if necessary

- check the completeness of the walk-behind tractor

a single-axle tractor must be securely secured against horizontal and vertical movements, while the gaps between the walk-behind tractor and other objects must be at least 50 mm. Transportation by motor transport on highways at a speed of no more than 60 km / h is allowed, on unpaved roads. no more than 30 km / h. It is prohibited to throw and tilt a single-axle tractor.!

What kind of oil to pour into the box of the eel walk-behind tractor

For the “Ugra” walk-behind tractor, there are the following types of maintenance:

daily maintenance maintenance after the first 50 hours and every 100 hours of operation maintenance during storage

Engine maintenance is performed in accordance with the requirements of the engine operation manual. Maintenance should be carried out without fail when the walk-behind tractor is not working! All work must be performed in a specially designated place that provides free access to the elements of the walk-behind tractor. Be careful and careful, observe the safety measures specified in section 2.2.3 of the “Ugra” walk-behind tractor operating manual.

How to change the oil in the gearbox of a motor cultivator

Maintenance of the gearbox of the Neva MK200 cultivator should be performed every 250 hours of operation. It is better to change the oil in the gearbox immediately after the work of the equipment, since during this period it is easier to drain the oil. In order to change the oil in the gearbox of the motor cultivator, you should perform the following steps:

- Place the cultivator in a vertical position

- Place a container of at least 2 liters under the gearbox

- Unscrew the breather plug, clean it from dirt

- Unscrew the oil drain screw, drain the oil from the gearbox

- After draining the oil, screw in the oil drain screw with gasket and tighten the screw. Dispose of oil at a waste oil collection point.

- Fill in fresh gear oil of 1.15 liters of the appropriate grade and operating temperature through the hole for the breather plug

- Screw in the breather plug.

Oil for a diesel walk-behind tractor. features of choice

When choosing engine oil for a diesel walk-behind tractor, you should follow the instructions in the operating instructions. However, if the instructions for use have been lost, then you will have to study the formulations on the market more carefully.

Diesel engine oils are classified into the following categories. To determine the type and conformity of the composition for a specific walk-behind tractor, special markings indicated on the container with grease will help:

- API CJ-4. formulations with this marking are designed specifically for motoblocks with a capacity of 10 liters or more. from. and more. The composition of these lubricants has a high viscosity, which guarantees the correct operation of all elements of the motor unit;

- API CI-4. these oils should be used for engines equipped with different types of injection and pressurization. Such oils have good dispersing properties and high thermal oxidation stability;

- API CH-4. lubricants with this marking fully comply with all modern requirements and quality standards. Among the advantages of these compositions, one should highlight the ability to fill them in diesel engines running on fuel, the percentage of sulfur in which exceeds 0.5%;

- API CA. formulations of this type are optimal in cases where diesel fuel contains a small amount of sulfur. Oils with such markings protect the walk-behind tractor engine from the formation of harmful deposits on its walls;

- API CB. the use of oils of this oil reduces the risk of corrosion of motoblock bearings;

- API CC. such oils will be the best option for a turbocharged engine without a supercharger. These compounds help walk-behind tractors to withstand prolonged loads and work properly in difficult conditions;

- API CF-2. oils of this group show themselves well when used in motoblocks that are subject to heavy loads.

After purchasing a suitable engine oil, you can proceed to pouring it into the motor of the walk-behind tractor. The procedure is quite simple:

- Place the unit in a horizontal position first;

- Place a wide container under the drain hole in the engine and remove the plug by gently prying it off with a screwdriver;

- Wait until the old oil is drained from the motor, and screw the plug back into the hole;

- Fill the engine with at least 2 liters of new lubricant.

Remember that the oil in new walk-behind tractors should be changed three times with an interval of 5 hours of moderate use. After that, it is required to replace it no more than 1 time in 25 hours of operation of the walk-behind tractor.

Oil change in the gearbox of the Neva walk-behind tractor

It is also worth talking separately about changing the oil in the gearbox of the Neva walk-behind tractor. This should be done every fifty hours of operation. It is also important to check the oil level. A straight wire is suitable for this. You put it in a container of oil and it should be 25-30 centimeters wet. What kind of oil to fill in the gearbox of the Neva walk-behind tractor, you will learn from the operating instructions. Most often these are transmission TAD-17I, TAP-15V and others in accordance with GOST 23652-79.

Motoblocks “Neva”, as well as motor-cultivators MK100 and MK200 are equipped with mechanical gear-chain gearboxes housed in aluminum cases. The MK70 motor cultivator has a mechanical chain reducer in a steel case. In order for the gearbox to serve for a long time, it is necessary to regularly carry out maintenance of motor vehicles. For diagnostics and troubleshooting, please contact authorized service centers.

THAT during storage of an unconserved walk-behind tractor (up to 3 months)

- By external inspection, check the condition of the V-belt transmission belts, the absence of leakage of gasoline and oil (once a month)

- Start the engine and run at idle mode for 3-5 minutes (once a month)

- Change the oil in the gearbox (once every 18 months)

Land cultivation equipment operating manuals

Insufficient amount of the second can also be the reason. With old oil, smoke and exhaust gases of a characteristic white color can come from the equipment. After checking and starting the unit, you can go directly to work with the Salute walk-behind tractor. If the soil is rather hard and the weight of the walk-behind tractor is not enough, then you can use special weights on the wheels, which have the shape of a vessel and are covered with wet sand, pebbles or something heavy to increase the mass.

COMPLETE MAINTENANCE GUIDE For KUBOTA BX Tractors, Step By Step, Every Fluid Filter

They are fastened using conventional bolts, which are usually supplied in the kit. Therefore, it is better to process the same area with a walk-behind tractor in several passes, gradually increasing the processing depth. Working on a walk-behind tractor does not require special training, however, it should be noted that when working with each trailed implement, certain skills are required. During soil cultivation, the space between the cutters and the gearbox housing can become clogged with stones, wire and other objects.

In this case, to avoid damage to the V-belts, turn off the engine and remove objects that are stuck in the cutters.

Tags: ray MB-1, aliexpress manual pump, oil change in the walk-behind tractor

Participate in the discussion can only registered users.

Daily maintenance of the walk-behind tractor

- Remove dirt, dust and oil from the outer surfaces of the walk-behind tractor with a rag.

- Check the reliability of fastening of the available parts of the walk-behind tractor and, if necessary, tighten it: assembly units and parts must be fixed.

- Visually check the condition of the wiring. no exposure of the wiring is allowed!

- Visually check the condition of the V-belt transmission belts. no stratification of belts is allowed!

- Check the reliability of the attachment of the mounted (trailed) unit, it must be securely fastened and fixed.

- Check the tire pressure when working on wheels: operating rate. 1.8 2 kgf / cm².

You will need: rags, electrical tape, tire gauge.

Running in an Oka walk-behind tractor with a Lifan engine

Before starting field work, it is necessary to run in the engine to avoid damage to moving parts and mechanisms.

Before starting the break-in, it is necessary to fill the tank with fuel and check the oil level. Correct running-in of the engine of the Oka walk-behind tractor begins immediately after the first start and lasts more than 30 hours. During this period, it is impossible to give heavy loads and work more than 2 hours a day, open the throttle more than ¾.

Soil cultivation should also take place in a gentle mode. in several passes with a depth of no more than 10 cm in one pass. After the break-in period (20-30 hours worked in a gentle mode), it is necessary to completely drain the used oil and pour fresh oil into the crankcase.

single-axle tractor Oka. operating instructions

When purchasing any Oka model, the first step is to familiarize yourself with the operating instructions for the motorized device, which contains the following sections:

- The device of the unit (as well as the device of its constituent parts: gearbox, carburetor, etc.).

- Assembling the Oka walk-behind tractor, according to the descriptions and diagrams.

- Specifications of the selected model.

- Instructions for the first start of the engine (Lifan, Honda or any other).

- The procedure for the correct running-in of the power plant.

- Maintenance.

- Troubleshooting the Oka walk-behind tractor.

How to increase the speed on the Oka walk-behind tractor

Oil for single-axle tractor Oka

| Volume | Oil type | |

| Crankcase | 1,3 | Automotive motor oil for carburetor engines M-53 / 10G1 or M-63 / 12G1, or any oil that meets API requirements: SF, SG, SH and SAE: 10W-30, 15W-30 |

| Walk-behind tractor reducer | 1.8 | Transmission oil TAD-17I, TAP-15V and others GOST 23652-79 |

The frequency of oil change in the Oka walk-behind tractor

| Gearbox oil change intervals | During break-in first oil change after 25 operating hours After every 25 operating hours Check the oil level in the gearbox. Add up to 1.5. 2 L every 50 hours of operation. Change gearbox oil | |

| The frequency of oil change in the engine of the Oka walk-behind tractor (excerpts from the operating instructions of the main engine manufacturers) | Briggs Stratton (brigs) | First 5 hours. Change oil. Every 8 hours or daily. Check oil level. Every 50 hours or every season. Change oil. |

| Honda (Honda) Lifan (Lifan) | Checking the oil level. with every use. Change of oil. the first month or after 20 hours of work, thereafter. every 6 months or after 100 hours of operation | |

| Robin Subaru (Subaru) | Checking the level and adding engine oil. each time the engine is used (add oil to the maximum mark). Engine oil change: First change after 20 hours of operation; later. every 100 hours of operation | |

Changing the oil in the gearbox of the Oka walk-behind tractor

| operations and specifications | Tools, fixtures, materials |

| Drain gasoline from fuel tank and engine oil | Capacity |

| Install a container to the right of the walk-behind tractor | |

| Unscrew plug 1 (Figure 6) and, tilting the single-axle tractor to the right, drain the oil from the gearbox into the placed container. | |

| Place a single-axle tractor on wheels and fill the gearbox with oil of the brand indicated in the table above, in a volume of 1.5. 2.0 liters. | Funnel, container, oil, rags |

| Screw in the plug 1. Fill the fuel tank with gasoline and oil the engine |

What kind of oil to fill in a single-axle tractor OKA

What oil to pour into the engine and gearbox of the Oka walk-behind tractor should be known to every owner of this technique. Butter. it is a key factor for the perfect operation of the motor and gearbox, under load conditions, when working the land. After all, work is on the ground. hard work, and motor vehicles work under extreme stress.

Therefore, the oil in the walk-behind tractor needs to be changed much more often than in the car. The most correct advice on the choice of oil is the recommendations of the manufacturers of the walk-behind tractor and the engine to it. Therefore, we turn to the user manual for Oka and to the operating instructions for the engines used.

Manufacturer of motoblocks MB-1 Oka. JSC Kaluga engine, Kaluga, st. Moscow, 247

Official website of the manufacturer of the Oka MB-1 walk-behind tractor. http://www.kadvi.ru

Operation manual for single-axle tractor Oka MB-1D1 (2, 3) M and its modifications download

Oka motor-block engine oil recommended by manufacturers.

| Motoblock engine make | Manufacturer’s Recommended Engine Oil | ||

| summer | winter | service class | |

| Robin Subaru (Subaru) | SAE 10W-30. in temperate climates | SAE 5W-30. in cold regions | Automotive engine oil; class SE or higher (SG, SH or SJ recommended) |

| Honda (Honda) | SAE 10W-30 is recommended for use at all temperatures. If you wish to use seasonal oil, select the appropriate viscosity grade based on the average temperature in your area. | SG, SF. | |

| Lifan (Lifan) | SAE-30 | SAE-10W-30. all-season | |

| Briggs Stratton (brigs) | Briggs Stratton recommends the use of synthetic oil when operating in temperatures below 0 ° C. If you do not have synthetic oil, you can use Briggs Stratton 10W-30 non-synthetic oil, part number 998208 Note: Synthetic oil that meets the ILSAC GF-2 certification mark, API and API service symbol labeled “SJ / CF ENERGY CONSERVING” and above can be apply at any temperature. Change synthetic oil as usual. Air cooled engines heat up faster than car engines. Using non-synthetic thickened oil (5W-30, 10W-30, etc.) at temperatures above 4 ° C will result in high oil consumption. If using such oil, check the oil level more often. | SF, SG, SH, SJ or above | |

| DM-1-01 (JSC Kaluga Engine) | М63 / 12Г1 or М53 / 10Г1 GOST 10541-78, oil corresponding to API requirements: SF; SG; SH and SAE: 10W30; 15W30 | ||

| DM-1K Instruction from OJSC “Red October” | M10GI, M12GI TU 38.10148-85 M63 / 12G1 or M53 / 10G1 GOST 10541-78, | ||

For more information about oil in the motoblock gearbox, see here.

Video. preparation of the Oka walk-behind tractor for work

Oil level

How to know if you need to add oil:

- Place the single-axle tractor level on the ground or on a solid platform so that it is convenient to open the gearbox and fill in the lubricant. To do this, the gearbox must be in an inclined position.

- Check the lubricant level. To do this, insert a probe or any suitable diameter metal rod 65-70 cm long into the hole on the gearbox. If the measurement result shows that there is at least 30 cm of fluid in the gearbox, no top-up is required.

- If there is not enough liquid, add it to the desired level, checking with a dipstick.

It is advisable to check the oil level before each work shift, as well as inspect the gearbox housing for leaks. After work, measurements are not carried out, since some of the liquid ends up on the parts, and the result will be unreliable. This simple operation should not be neglected: lack of lubrication can lead to parts breakage.

How much oil to fill in the gearbox of the walk-behind tractor?

If you have a question about the amount of oil to be poured in, you should follow a simple algorithm:

- a single-axle tractor must stand on a flat surface with wings parallel to the ground;

- A wire with a length of 70 centimeters can act as an oil dipstick;

- When bent, the wire should resemble an arc in shape;

- The wire is pushed into the tank to the bottom to control the oil level.

If the lubricant is 30 centimeters of wire, no more top up. If it is dry, you need to fill in at least two liters of grease.

For gasoline engines

For motoblocks running on gasoline, it is recommended to pour the following types of liquids into oil containers:

- SA. for work with low loads;

- SB. for work with medium mechanical stress;

- SC. used in engines without PCV valves;

- SD. works in engines with PCV;

- SE is a lubricant for use in engines manufactured since 1980;

- SF. a higher quality analogue of the previous oil;

- SH. used in many engine systems.

SB category has good anti-corrosion properties. The product provides high quality lubrication of cylinder walls and bearings. SF reduces oil sludge in 4-stroke and 2-stroke engines.

Classification of grades of oils

To increase the service life of a gasoline or diesel engine, you need to make the right choice of engine oil. Failure to replace it in a timely manner reduces the service life of the engine. How to choose it, in what quantity, how to pour it into a uniaxial tractor. let’s talk about this in more detail.

The kit of each mini-tractor or walk-behind tractor includes instructions and a product passport. In the instructions, the manufacturer lists the suitable grades of fuel and lubricating fluids that can extend the life of the equipment. The engine oil performs the following functions:

With air cooling, the grease settles on the walls of the hot cylinder. These deposits contaminate engine parts and make lubrication difficult. Therefore, antioxidant additives are present in the lubricant. They clean the cylinder walls from carbon deposits and extend the service life of the walk-behind tractor. Different climatic zones require the use of different oily fluids. They differ in viscosity, composition and purpose.

Algorithm for changing the oil in the walk-behind tractor

Before using a new lubricant, it is important to clean the gearbox of the used compound.

Change the lubricant immediately after using the equipment, before the oil has cooled down. You can quickly change the oil with your own hands according to the following scheme:

- single-axle tractor is installed horizontally;

- Two plugs are installed. Through one, the already used composition is drained, the second is used to fill in new oil;

- The lubricant filling cap is unscrewed. A wide container is installed under the drain hole;

- The drain cover is unscrewed until all the used oil drains out;

- The drain cover is screwed up to the stop with a spanner wrench;

- The funnel is inserted into the filling hole and new oil of the appropriate grade and temperature is added;

- The lid is screwed on. With a special probe, you can check the amount of the poured agent.

Commercial Truck Diff and Gearbox Oil Level- Eaton, Spicer, Rockwell

For details on the specifics of the replacement procedure, see the introductory video.

If the equipment is operated under normal conditions, the oil in the gearbox changes once every hundred hours of operation of the walk-behind tractor. When working around the clock, replacement is done every fifty hours. In this way, various breakdowns of agricultural machinery can be prevented.

Oil for walk-behind tractor: for engine, gearbox, transmission

Many new owners of motoblocks are interested in issues related to the use of oils for agricultural machines. Let’s look at what formulations are suitable for lubricating certain mechanisms of the walk-behind tractor, and how to use them for stable operation and extending the life of the unit.

What kind of oil must be poured into the gearbox

In the question of which oil to pour into the gearbox of the walk-behind tractor, the most reliable will be to rely on the manufacturer’s recommendations. They are set out in the instruction manual, and if it is lost, the text can be easily found on the Internet. In general, any gear oil can be used to lubricate the gearbox. It is undesirable to mix oils in order to avoid conflicts between additives. In rare cases, substances can, when mixed, turn the entire lubricant into an emulsion, which is fraught with damage to the gearbox or at least thorough flushing. Therefore, before adding new oil, you should check for the presence of the old.

Motor-block reducer device

The gearbox is one of the most important components of the walk-behind tractor. It is available on absolutely all models, without it the equipment will not work. The function of the gearbox is the uninterrupted transmission of torque from the engine to the wheels through a V-belt transmission. In addition, it provides a change in the speed and direction of movement of the agricultural unit. Simply put, it provides movement and control of equipment.

The gearbox consists of a system of shafts and sprockets connected by a chain. The shafts take the rotation and are transmitted by the chain. The input shaft is equipped with a lever and a fork that shift the mechanism. Bolt-on plastic housing protects parts from dirt and dust.

Motoblocks are irreplaceable helpers in the household

All parts are made of metal and require lubrication. With a lack of lubrication, the load on the contacting parts increases sharply, which can lead to their rapid destruction. Timely oil change in the gearbox will ensure their serviceability and smooth operation of the mechanism as a whole.