The disk on the corner grinding dump was biting, how to unscrew the nut

Corner grinder. an indispensable tool for various types of work. The worse when the tool fails and the disk is bustling. In this case, it is not possible to remove the nozzle, since the nut jam. There is a slight way to twist the closed mount by heating, which we will talk about in the article.

Problems most often occur when working with strong materials. When starting, the angular grinder operates at a speed of 6000–12000 revolutions per minute. In contact with the surface to be treated, the disk receives a strong resistance. His work slows down a little, while the motor continues to twist in the same mode.

This leads to a sharp screwing of the locking nut into the spindle thread. It is no longer possible to twist it with the usual key.

How to eliminate the clamp

There are several simple ways that are used in the first place:

- Insert a metal rod into the holes and try to scroll with light hammer blows. The main thing is not to disrupt the holes and do not break the button.

- Heat the fasteners. When temperature changes, the technical parameters change slightly, and the expansion occurs.

- We grind the disc with another corner grinder until the nut is unscrewed.

These methods are effective, but not always. Therefore, there are more correct options for delivering angular grinding grinding from the clamper clamp.

The corner grinder bites the disk: two harmful “folk” advice to get out of the problem and one correct

Get one most read article by mail once a day. Join us in and

Sooner or later, every owner is faced with a problem like the jammed nuts and a bite of the disk of a grinding machine. A similar situation puts many citizens at a dead end. On the Internet, you can find a “million” recommendations of varying degrees of usefulness in this regard. Consider the three most popular “folk” options and we will figure out why it is better not to use them. And also talk about how to prevent jamming and what approach in the treatment of the problem will be the only true.

“Folk” harmful advice

The problem of the vast majority of tips on the corner grinder from the people is that they all violate the safety of working with the tool in one way or another. Is it necessary to say that if the road is life and health, then it is better not to violate TB? After all, among other things, at the workplace, the implementation of such amateur performances may end with a minimum of deprivation of a bonus from the sanction of the safety engineer.

Harmful advice: to break and hire a disk. The essence of this method boils down to breaking a jammed disk with a corner grinder with a suitable tool as much as possible. After that, a sheet of tin is taken, the thickness of which will be a plus or minus equal to the width of the old disk. Tin is clamped in a vice, after which the residues of the disk is an angular grinder simply erased about it.

The problems of the Council are primarily a huge danger of this method for both the employee and for all others. The scattering fragments of the disk can apply very serious injuries. Especially in the absence of protective funds. The second problem. this method is extremely demanding on the skill of an employee. The third problem is that many modern discs are just not possible to hide because of a metal ring-building ring on the inner ring.

You can try to warm up the nut, but the effect may be the opposite. |

Harmful advice: warm up a clamping nut. The essence of this method is to heat the clamping nut due to friction about wood. After that, she allegedly should unscrew much easier and faster.

How to Use an Angle Grinder

Problems of the Council Metal expands in all directions. And this means that with a greater degree of probability, the nut will be delayed even more, which will make its subsequent unscrewing an even more difficult task.

How to remove a stuck disk from a corner grinder?

Many masters recommend when working with a corner grinder to make disks-laying. It is believed that an ingenuous product from cardboard can protect the tool from too strong tightening the clamping nut. In most situations, it really works. If there is no desire to mess with cutting out, then such gaskets can even be bought in a construction store. However, it is much more important to know and remember the only correct recipe for biting. All that the master needs to have is a suitable key for corner grinder.

Of course, there are different situations. And sometimes even the key ceases to help. This happens when the nut is delayed to the limit or licks as a result of previous unsuccessful attempts to remove with the key. In this case, the problem will only be solved in the most radical way. cut the nut entirely with the help of another angular grinder.

And here is an interesting video from our channel:

If you want to know even more interesting about the tools, then it is worth reading about what the Canadian screwdriver is: when it appeared, and why some consider it the best.

CAN ANGLE GRINDERS CUT WOOD?? (Tricks TipsCutting Wood With Grinders)

How to unscrew the nut on a corner grinder if you eat

I tried to stop the button, take a standard key and crush, knock with a hammer. to no avail.

I took it home, stalled the button, tried to use the gas key. it doesn’t go and that’s it, I only scratched the nut. At the same time, I remembered how often I had heard about cases when a nut on a corner grinder is unscrewed with great difficulty.

How easy it is to unscrew the nut on the corner grinder (corner grinder) if it was clamped

First of all, it should be broken to the ground that remains of the broken detachment disk.

This is done very simply, you just need to take the pliers. At the same time, we use protection products. glasses and gloves, as metal fragments will fly.

The result should be the following:

Next, we find a piece of metal, the thickness of which is less than the disk of the corner grinder.

Next, you need to turn on the corner grinder and with the help of this piece to hide the rest of the disk between the nuts.

After everything is standing, we unscrew the nut inside not even with the key, but with our hands.

This is how it is done, very simple and fast. over. safe for bearings of corner grinders. Because if the nut does not unscrew, many are immediately arm themselves with a hammer and try to unscrew the nut, tapping it.

What to do so that this is not repeated

If you do not want to fall into this position, before squeezing a new disk, you can put a puck under the nut. from plastic, paper or cardboard. In this case, the nut will be unscrewed without effort.

Today, a cutting stone or disk can not often be found in proper quality, therefore, when they break, it often turns into a problem.

Naturally, improper operation may be the reason. But now you already know how to unscrew the nut on the corner grinder.

If there are questions or something is not clear, then you can look at everything on

How to prevent re.clamp?

In order not to fall into such a situation, carefully read the following recommendations of experienced craftsmen:

- When twisting the disc nut, you should not make unnecessary efforts, pressing the key, since at the time of rotation the nut will drag on to the desired level;

- Before putting a new disk, place a cardboard or plastic washer under the nut; It can be cut out by any improvised material;

- The side of the abrasive disk with a glued label should touch the support flange, not nuts; Subject to this condition, the metal ring of the circle will protect it from jamming;

- weld a regular hexagonal nut to the flange, which can be unscrewed with a simple wrench.

Cutting stones or disks for corner grinders are not always of good quality and accurate size. This can lead to a situation when the nut jams. But if you have such a case, do not despair. Useful tips of experienced craftsmen and their own ingenuity will always help you out in difficult times and tell you what to do in this situation.

About how to unscrew the nut on a corner grinding of a corner, watch in the video below.

How to unscrew the nut on the disk of the corner grinder, if it was bitten

Get one most read article by mail once a day. Join us in and

When working with a corner grinder, everything can happen. Worst of all, when the cutting disk is bitten. In this case, unscrewing the clamping nut on the tool can be very difficult. First you have to deal with the jammed disk. Few people know, but there is one simple and effective way to solve this problem.

Most often, the jamming of the corner grinder occurs in situations when work is carried out with strong materials at high speeds (from 6,000 to 12,000 revolutions per minute). At such revolutions, the disk enters into severe resistance to the surface, its work slows down, while the motor continues to spin in the same mode. All this leads to the fact that the detector’s nuts are sharply screwed into the spindle thread, after which it will not work to unscrew it in the traditional way.

The easiest way to twist the jammed nut is to warm up. To do this, it is tightly applied to the tree, after the angular grinder turns on. Several minutes of friction and the fixer nut will warm enough in order to become a rather malleable and soft. In the future, it can be unscrewed with a regular key. This becomes possible due to the fact that when heated, the metal tends to expand.

As a more “traditional” alternative to the method described above, you can choose the path of direct mechanical impact. To do this, we set up a strong metal rod into the hole and try to unscrew the nut with the neat beats of the hammer. This method is bad in that if you are too strong, there is a risk of breaking the thread or break the button.

How do you not try to unscrew the clamped nut

Squeezed nut on a corner grinder is always unpleasant. This problem deprives the opportunity to work with the tool, and its solution takes a significant amount of time. All this is reflected in the mental state of a person, as a result of which we begin to be nervous and perform not quite logical actions. I want to say that there are a number of ways to unscrew the clamped nut on a corner grinding, which is not worth using (well, of course, if you are dear to your power tool, and soon you do not want to buy a new corner grinder).

- There are holes on the nut that serve to unscrew it using a special key, and also provide ventilation and counteract it with excessive heating. Some “comrades” instruct the openings of any core or hairpin, after which they beat it with a hammer. By their logic, this method will help unscrew the clamped nut. Perhaps this will happen (and that is not a fact), but this is what the load on the gearbox will be crazy. this is definitely. The result is an ambulance of one of the main structural elements of the corner grinder.

- A similar situation occurs when the same nut is welded on top, but larger, and with the faces. After that, they clamp the lock and try to unscrew it with a heftybide or take a large shoulder. The result may be a broken latch and licked teeth in the gearbox.

- Someone is trying to warm the nut with a gas burner or cutter. This method very rarely helps, and the chemical properties and strength of the metal you definitely violate. If you need to unscrew the nut in any way, it is easier to take another corner grinder and cut off two parts from the opposite sides. So it will weaken and accurately give in.

A simple way to unscrew the clamped nut

And now, let’s look at the most gentle way to unscrew the clamped nut on the corner grinder. I will not say that this method is a panacea from such a problem, but of all the existing opportunities it is the most optimal. To get started, you need to find a piece of metal, up to 1 mm thick. I recommend taking a plate that will be even thinner, about 0.8 mm. It must be squeezed in a vice. The dimensions of this product do not play a special role. What will be at hand, then take. The main parameter is the thickness. If you take the metal thicker 1 mm, then nothing will come of it. Next, you need to break off the remnants of the disk. Most likely, a piece flew away from him. To do this, you can use your hands or ordinary pliers. It is necessary that one nut is left, and the residues of the disk is not visible. You should get the same as in the photo. Only a small part of the abrasive disk that is clamped between the two nuts remains. We need to extract her. Next, you need to carefully insert the metal plate between two nuts, where we have a piece of disk left. Thus, we begin to cut. Now you understand why the metal should be thinner than the disk closed in the corner grinder. After a while, the remnants of the disk will just stand. You will feel it right away, after which you need to turn off the corner grinder. After performing such manipulations, the nut on the corner grinder is unscrewed even with your hand. It is very important to clamp the sheet of metal in a vice. In no case do not hold it in your hand. The most important thing is safety precautions. Yes, and during this process, the nut is very heated, take into account this.

If you want to learn more about the tools for working on wood and about crafts performed with their help, be sure to read the material on this link.

Tips

If you had to apply a gas key, you need to remember the very powerful shoulder of such a key and the effort that is served on the parts of the “corner grinder”. If you act inadvertently, you can disrupt the spindle lock or damage the gearbox.

All manipulations with the disk of an angle grinding machine must be done with completely disconnected power supply (the fork should be removed from the outlet). Any unexpected pressing of the start button will cause the electric motor turning on, and the speed of rotation of the rod is very high. In this case, injuries cannot be avoided.

Working with “corner grinding” involves a large amount of waste in the form of metal or wooden chips and dust. Before starting work, it is necessary to put on special protective glasses: they will protect their eyes from the fragments of the very cut.out circle in case of jamming and destruction.

Glasses are necessary not only as an element of security. If the eyes are protected, you can pay more attention directly to the work of the “corner grinding”, ensure the right cut or the choice of the right mode of operation. This will allow the most efficient use of consumables (cut.off circles), minimizes the emergence of emergency situations with biting a disk or its destruction.

A protective mask that completely covers the face is remarkably replaced by the glasses. this is especially relevant for a master with weakened vision, wearing dioptric glasses, which do not put on protective glasses.

The “corner grinder” disk can be installed both “from itself” and “to yourself” depending on the direction of rotation and, accordingly, the stream of chips. This does not have a fundamental difference. However, the “corner grinder” with a circle “on itself” when biting a disk tends to jump out of the cut, and not on the one who uses it. This is especially important when working with powerful tools, but a small corner grinder can pose a serious danger.

A specially mounted extension cord with a plug, better without grounding, will help to quickly stop the work of a machine that has escaped from the hands.

“Corner grinder” is a gross processing tool and strive to obtain an ideal surface as a result of its work, the main thing is to make a rough cut, which later, if necessary, can be processed in other ways.

For work without clamps and jamming, it is better not to cut long metal blanks to the end, leaving 1-2 mm of metal in the cut: they will easily be broken after, it will practically not affect the quality of the workpiece.

Small blanks are best placed in a vice or pressed with a clamp to the workbench or other reliable horizontal surface. The quality of the cut and safety depends on the density of pressing.

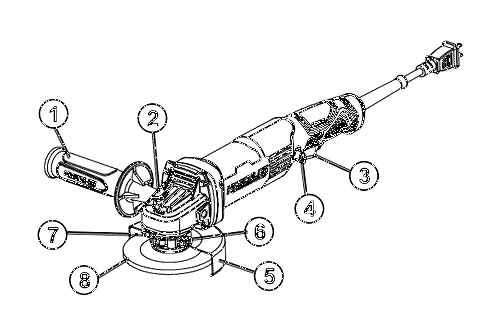

To change the disk on the corner grinding, it is necessary to unscrew the fastener.

The fasteners, as a rule, goes with special grooves, and you can unscrew it only by the corresponding key, which is usually included in each corner grinder.

On some corner grinder, ordinary nuts are installed as fasteners, which can be unscrewed with an open key.

To unscrew the fasteners in its grooves, you need to install the angular grinder key.

On the other side of the corner grinder, press the stop button to fix the rotor in a stationary state.

Next, you need to turn the key against the watch arrows.

So the fasteners are unscrewed, then the old disc changes to the new.

After installing the new disk, first the fastener is twisted with the hands, and in the end it is tightened with a key.

Now the corner grinder is “charged” with a new disk and you can start work.

How to remove without a key?

Judging by numerous reviews, the corner grinder disk can be dismantled using a large pipe key, which is popularly called gas. The master first needs to be diluted so that you can completely grab the flange. During the turning of the gas key with the flange clamped in it, the spindle is held by any metal object. According to the reviews of households, this method is considered very effective. If he did not help, then experts advise a nut to “tap” a metal rod or thin chisel. The spindle is also fixed. The nut will move out if you lightly tap on the flange at the very edge. Blows should be performed in the direction in which the disk is spinning. According to experienced masters, this method cannot be called safe. The fact is that you can damage the flange, namely the holes into which the pins of the track key are inserted.

I hope my article today was clear and useful. Now you know how to quickly and just unscrew the clamped nut on a corner grinder. The most important thing is to be neat and not succumb to emotions. It is better to think twice than to buy a new power tool or spend money on repairs.

If you are not yet familiar with the article of my colleague “Wooden toilet in a private house”, then you can read it by this link.

Write in the Комментарии и мнения владельцев how often your nut on a corner grinder is clamping?

Why the problem appears

And when the process of pulling the flange for fixing is completed, we have a freelance situation on our face. Such factors will be affected by its appearance:

- Huge disk size.

- Very high power tool capacity.

- The dimensions of the rotor.

- Sudden increase in cutting depth, t.e. The resistance increases.

In this case, you should remove the disk from the corner grinder, but it can be very difficult to do. Here you need to take additional measures.

How to replace the disk in normal mode

With regular work with an angular grinding machine, you should constantly replace circles, which are the most ordinary consumable. If the tool is already inconvenient to work, then a worn circle with an abrasive coating should be changed.

note, that it is necessary to check the shutdown from the electric network to avoid injury.

Step.by.step instruction of actions

So, the circle should be fixed on a spindle head using a ticked nut, which has a M14 thread. The standard configuration has an aniletic wrench with special protrusions for a hook with flange openings for fixation. In order to perform the unscrewing of the nut, you should fix the spindle. This will require a special latch, which is located on the back of the corner grinder. When you click the button, then you can fix the gearbox with cobbled, and exclude the possibility of its rotation.

Now you need to insert the key into the hole. With one hand you will hold the latch, and turn the second with the key against the direction of the stroke of the clockwise and shift the nut. The direction of movement of the circle is usually clockwise, however, it is worth mentioning that there are models that can have everything differently. In any case, unscrewing is performed in the opposite direction of rotation. When the nut is shifted, it can be unscrewed without great efforts with a hand. It remains to remove the latch and the old circle, remove the lower flange. After intensive work with such a tool as an angular grinder, inside the casing you can find the layering of burnt outpan and abrasive. Use a steel brush to cleanse and remove the remains.

After the lower flange is cleaned, set it in place, and combine the spindle grooves with grooves for the flange. Put a special gasket on top. If your model of the device does not have additional gaskets, then such useful washers can be made independently of plastic or even dense cardboard. Next, you should correctly put the disk on the corner grinder and close it with a similar gasket.

note, that the installed gaskets make it possible to easily unscrew the nut, even if you have a disk or it broke.

With your hand, tighten the upper lock counterclockwise (against rotation), and support the cutting disk. In this case, you should definitely clamp the spindle lock and twist the flange to a tangible resistance. With the help of an an ebony, you should reach a nut with a slight effort, but you should not excessively tighten the mount, since otherwise you can pull the circle and it will begin to warp. After that it will be possible to work calmly. But periodically, problems begin to appear and unscrew the disk on the corner grinder just fail. How to remove a disk from a corner grinder with a key and not only, we will consider further.

Locksmith’s advice: how to promote a corner grinder if the disk was clamped and torn

Get one most read article by mail once a day. Join us in and

On the one hand, corner grinder. The tool is not very cunning. On the other. requiring increased attention. The worst thing that can happen during work is the jamming and rupture of the disk. The worst thing is that it is extremely difficult to extract a working panel in this situation. Especially if you do not know how and what to do to solve a problem spontaneously arising.

What will be needed: hammer, pliers, lubrication WD-40, thin screwdriver

If a disk torn in a corner grinder and jammed a fixing nut, then to the deepest regret to solve the problem with “jewelry” methods will no longer be possible. Ahead is a rough and painstaking, but not too difficult job. Having prepared everything you need, we take the pliers in our hands and begin the most barbaric (but the only effective way) break out with pieces from the working area, a torn disk. It is best to remove the panel with small fragments.

When the bulk of the disk is removed, it is necessary to do a thinner work and carefully remove all the scraps from under the fixing nut. It will not work to tear everything out with the use of only pliers, but as many strokes should be removed as it turns out. Immediately after this you need to take a shovel, squeeze it in a vice. We apply a corner grinder so that the rib of the shovel cleans the groove in which the disk fragments remain. The angular grinder is turned on at the lowest speeds.

As a more elegant alternative to the rib of a shovel, you can use a suitable fragment of sheet metal and a conventional screwdriver. If fragments are not amenable, then they can be well lubricated WD-40. In addition, you can just try to unscrew the ticking nut. To do this, you need to heat it. The easiest way to do this leaning it against a tree and turning it on for a couple of minutes. The heated nut should easily succumb to the regular key. Of course, a torn disk before that will still have to be broken out.