About the carburetor device

The carburetor serves to mix the combustible mixture with air in compliance with predetermined proportions. If the exact dosages are NOT followed, the correct operation of the engine is jeopardized. When a large amount of air enters during the mixing of the components, and there is not enough fuel, then such a mixture is considered “lean”.

Over-saturation must not be allowed, since with a large amount of fuel in comparison with air, malfunctions or engine wear are also possible. Carburetor adjustment is necessary Not only before the initial introduction, but also when any deviations in its operation are detected. Before starting work with the chainsaw, do not forget to run it in.

The carburetor design contains a standard set of elements, but it may vary slightly depending on the manufacturer. Components:

- The foundation. It is a special tube that visually resembles an aerodynamic structure. Air passes through it. In the transverse direction, a damper is located in the middle of the pipe. Its position can be changed. The more it is Pushed into the passage, the less air enters the engine.

- Diffuser. This is the tapered part of the tube. With its help, the air flow rate increases exactly in the segment from which the fuel comes out.

- Fuel supply channels. The fuel mixture is contained in the float chamber, then passes into the nozzle, from which it flows into the sprayer.

- Float chamber. It is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain an optimal level of fuel fluid in front of the entrance to the channel where the air comes from.

Looking for models that are cheaper, but reliable and time-tested? Pay attention to Russian-made chainsaws.

Or Explore foreign chainsaw manufacturers such as Stihl.

How to adjust the carburetor on a chainsaw and properly adjust the idle speed with your own hands

For self-tuning of the carburetor, you need to familiarize yourself with its device and remember the order of work, which are carried out to adjust the parts responsible for the correct functioning of the component parts of the device and nearby parts. It is necessary to carefully handle objects for adjusting the chainsaw system, and also to determine the correspondence of the set parameters to the maximum permissible values.

Final check at idle speed

Before this procedure, it is necessary to make a full adjustment of the components of the carburetor when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct parameters are achieved during the adjustment, you will notice that the carburetor design exactly matches the following criteria:

- When connecting the idle cold mode, the chain does NOT move.

If violations are noticed in the above parameters or the device was not completely adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

How to properly manage factory dust

Carburetor adjustment is divided into two main steps. The first is called basic. It is produced when the engine is turned on. The second is performed when the engine is WARM.

How to adjust the maximum RPM

To limit this figure, you need to use the screw marked H. To increase the number of revolutions, turn it clockwise, and to decrease them in the opposite direction. The maximum frequency should not exceed 15000 rpm.

If you make this figure higher, the engine of the device will work for wear, which will lead to problems in the ignition system. When turning this screw, the ignition processes of the device must be taken into account. If the slightest glitches appear, then the maximum speed value must be reduced.

How to properly adjust China-made dust. adjustment instructions

In order to correctly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, then turn on the engine. Subsequently, you will have to leave it to work for several hours in order to accurately set your own parameters. Sometimes work is performed once after ten minutes of engine operation, however, many Chinese-made models require special handling.

Adjustment procedure:

- Activities start in idle mode. With the help of the adjusting screws, you need to achieve a systematic set of revolutions by the engine, therefore, you should first let it run at low speeds. The deviation from the norm is the movement of the chain along the tire. In this case, it is necessary to adjust the extreme screws to the optimal position so that the chain remains stationary.

- The transition to average speed turns is carried out. Sometimes the engine will smoke. This defect can be eliminated by tightening the screw to supply a leaner fuel mixture.

Before buying, rated chainsaws for reliability and quality.

Take a look at:

The main stage

The engine starts at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed must move clockwise. It is released only when the engine comes into stable operation. It is necessary to check that the chain does NOT move during this process.

In idle mode, the engine may stall (the reason is here). In this case, immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

Checking acceleration work

A little research needs to be done. Device acceleration is initiated. The serviceability of the engine should be assessed during the maximum revolutions. When the engine is functioning correctly, then when you press the accelerator, the speed rises quickly to 15,000 rpm.

What you need to have to set up and adjust a chainsaw with your own hands

Every carburetor owner must have the right tools to adjust this system. There are three adjusting screws, which are located on the body of the device. They have their own markings:

- L. screw for low speed correction.

- H. screw for adjusting high speed.

- T. regulates the idle speed, in most cases it is used for experiments.

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before the repair, and turns off when you start work (see How to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning the screw T as far as it will go (see Chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully position the device, and unscrew the chain in the opposite direction. We need a tachometer. It determines the presence of a malfunction in the carburetor. When the screws are turning, the sound should be Perfect and absolutely even. If squealing notes are noticed, then the mixture is oversaturated.

How the carburetor is adjusted?

The chainsaw setting algorithm is quite simple and consists of the following steps:

- Warming up the engine to operating temperature (the settings must be made only to warm up the engine, this will allow you to get a more accurate adjustment).

- Adjusting the engine for smooth operation at low rpm.

- Setting the carburetor for the correct supply of the fuel mixture at maximum speed.

- Fine adjustment of the carburetor for idling.

- Chainsaw check in all modes.

Almost all carburetor models have three adjusting screws.

- The screw (T) is responsible for fine tuning in idle mode.

- Screw (H) setting for maximum speed.

- Screw (L) regulates the formation of a mixture at low speeds.

By tightening the screws (L) and (H), the fuel supply and the mixture becomes leaner, respectively, the speed increases.

Now let’s look at how the correct adjustment of the chainsaw carburetor goes in more detail.

Adjusting the carburetor of a Chinese chainsaw

Carburettors installed on Chinese-made saws are made similarly to European ones and have the same adjustment screws.

The adjustment of the carburetor of a Chinese chainsaw is carried out according to the algorithm presented above, and differs in that during the initial adjustment of the screws (L) and (H) x it is necessary to turn it out two turns. Further The carburetors of the Chinese saw are regulated in the same way as the European ones. As an example, we recommend looking at the article on how to adjust the carburetor on a Carver chainsaw.

Saw carburetor setting can be explored in the view below. In that. The wizard shows how the step-by-step adjustment of the Champion chainsaw, made in China, is performed without using a tachometer. Carries out after adjustment check in various modes.

Tools

To adjust, you will need the following tools: a tachometer, screwdrivers, in rare cases, a special key. Let’s analyze their purpose, the need for availability and cost.

| Tool | Appointment | recommended | |

| Screwdriver set (slotted screwdriver) | Most chainsaws require a simple flat-blade screwdriver to turn the adjusting bolts. | 300. 700 rubles | necessarily |

| Special adjusting key | For example, to adjust the carburetor on a Husqvarna Chainsaw you will need a special key, it is available only in certified service centers authorized for repair by the manufacturer. This measure is aimed at reducing breakdowns due to improper settings by inexperienced users and topics who are engaged in repair, and not having official permission to do so. | Out of stock | Depends on the chainsaw |

Process description

- If the carburetor of the chainsaw is NOT adjusted, and it will start the chainsaw, then the adjustment starts by setting the screws (L) and (H) to the standard setting. This is 1/5 turn of the screws until completely tightened.

- After that, you need to start the engine, let it run a little and warm up.

- The next step is to set the low speed mode. Optimum low engine performance can be achieved by adjusting the screw (L) and idle speed (T). To do this, first the screw (L) is tightened until the maximum engine speed is obtained, then it is released by 1/4, and the idle speed is normalized with the screw (T).

- After adjusting the work on the “bottom”, the thrust and maximum engine speed are adjusted. To do this, slowly tighten the screw (H) and check the speed according to the readings of the electronic tachometer. It is unacceptable to allow exceeding the maximum engine speed declared by the manufacturer!

An important step is to check the saw in all operating modes after adjustment, for this you need to let the chainsaw cool down, and then start it according to the cold tool start algorithm. If the saw starts up normally and is idling smoothly, you need to check how to cut. If in the process of checking deficiencies in the power of the chainsaw are found, then it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the thrust in operation.

Situations in which adjustment is necessary

New chainsaws are supplied by the manufacturer with adjusted carburetors. This is called standard adjustment. But for the normal passage of the running process, it is required to reduce the maximum engine speed, adjust the carburetor. After running in, the chainsaw needs fine tuning to achieve maximum engine efficiency.

With excess fuel in the mixture, engine parts are poorly lubricated and premature wear occurs. Also, a poor-quality mixture can become a prerequisite for engine jamming due to overheating (this is one of the reasons why the chainsaw does not start).

Adjustment is necessary when the engine does NOT idle, stalls, or does not develop full power. Carburetor tuning should be done with clean air and fuel filters.

How to properly adjust the chainsaw carburetor

During the operation of the tool, situations arise when it is necessary to adjust the carburetor of the chainsaw. Within the framework of the article, we will figure out when to configure, how to do it correctly and whether it is worth adjusting it yourself, or is it better to give it to a specialized service. The carburetor is an important unit, the service life of the saw depends on how correctly it works.

Summing up

Adjusting the carburetor of a chainsaw, although it looks simple, requires a careful and responsible approach. The article describes the entire setup process in detail, but if there is no experience in adjusting the chainsaw, then you should contact a specialized service for the repair of construction tools, this will help save time, nerves and money.

DIY chainsaw carburetor adjustment

Chainsaw carburetor adjustment ensures efficient operation of the tool at full power while conserving fuel. Adjustments should be made with clean fuel and air filters. For a larger number of carburetors, the adjustment is carried out with three screws: for maximum and minimum revolutions and idle speed adjustment.

Screws H and L adjust the ratio of the mixture of gasoline and air, determined by opening the throttle valve of the carburetor. When the screws are unscrewed, the mixture is enriched, and the revolutions fall accordingly, when the screws are tightened, the mixture becomes leaner. the revolutions grow.

The designation H refers to the maximum speed screw that controls the main jet, L. To the minimum speed screw that controls the idle jet. The S screw is used to fine-tune the idle speed. Sometimes, for ease of adjustment, the number of available carburetor adjusting screws is reduced.

Chainsaw carburetor tuning is divided into two stages. basic (factory settings), carried out with the engine off. And the final produced on a running engine warm up. The exact value of the angles of rotation should be taken from the operating instructions for the particular chainsaw. Failure to follow manufacturer’s instructions may result in engine damage.

Basic carburetor adjustment.

The adjusting screws for maximum H and minimum L turns are slowly turned clockwise until they stop, then turned back 2 turns, other settings are also possible

Checking and adjusting idle speed.

We look for the highest idle speed, for this we slowly turn the screw L in different directions. After finding the position of the highest engine speed, it is necessary to return the screw L by 1/4 turn counterclockwise. If the chain rotates at idle speed, screw T or (S) should be turned clockwise until it stops.

Checking and adjusting the maximum speed.

The maximum number of revolutions is changed by screw H. When screwing it in (clockwise rotation), the revolutions increase when it is turned out. Decrease. Chainsaw engines have the highest rotational speed of 11500 rpm. Up to 15,000 rpm. A higher speed is NOT provided by the ignition, in addition, it becomes dangerous for the engine. The rpm limit can be determined by misfiring. If they step, turn the screw H slightly counterclockwise.

If engine operation is NOT checked at accelerated and maximum revolutions, then the chainsaw adjustment cannot be considered complete.

When the throttle trigger is smoothly pressed, the engine should confidently and quickly gain speed from idle to maximum (from 2800 rev. To 11500-15000 rev. Depending on the unit). If revolutions are gained slowly, with a delay, screw L must be slowly Unscrewed counterclockwise, but no more than 1/8 of a turn.

After adjusting the acceleration and maximum speed, the saw should be checked again at idle speed. The engine must run steadily, the chain does not have to move. Chainsaw tuning should be repeated if this condition is not met but with the exception of the basic adjustment step.

Current setting

Experienced process operators may notice that the chainsaw’s internal combustion engine has started to perform worse. Sometimes it is enough to alternately return the screws H and L to one side or the other with a small step of 1/5. 1/6 turn and immediately check the result of the carburetor adjustment in real operation. This is one of the easiest ways to get a good setup.

The material contains information on how to adjust the carburetor of the chainsaw and check the result of the adjustment.

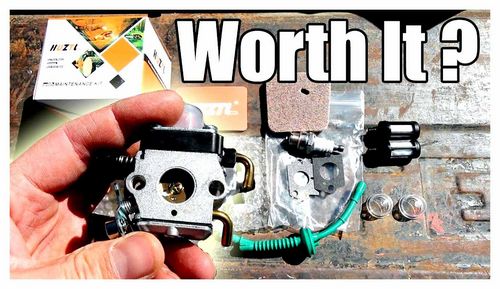

Features and differences of carburetor adjustment on a Chinese chainsaw

The carburettors for Chinese chainsaws are mostly copied from the original Stihl design. Therefore, the tuning algorithm for the original and Chinese versions is almost the same.

Non-original products are inferior because they use low-quality alloys, strong plastic parts (membranes and gaskets), the sizes of the calibrated holes are not precisely supported, etc.

For educational purposes, we recommend that you look at interesting things in the Chinese Stihl MC 660 chainsaw. The chainsaw is completely disassembled, assessing the condition of the components, including the carburetor. Also, the author disassembles the carburetor and shows an example how to clean it from dirt.

How much is

The product of the Chinese assembly of the Stihl MS-660 chainsaw is highly popular for its reliability, safety and ease of use. Users note the low noise and vibration level during the operation of the unit, a long service life and the ability to operate in winter conditions. A significant disadvantage for many professional lumberjacks and land owners is the price of the tool and spare parts for it. Sometimes you have to wait a long time for the necessary parts, which negatively affects the logging process.

Customizing the carburetor for the Stihl MS 660 chainsaw

All Stihl MS 660 chainsaw carburetors are factory-installed. This provides the best settings for the combustion engine in all modes. The settings are extremely rare. Make sure you need it before setting up. Engine failure can be caused by other reasons:

- Clogged air filter.

- Clogged with spark plugs and muffler.

If there are problems or they are resolved and the combustion engine is not working properly, start tuning.

Stihl Ms 660 Carburetor Adjustment

The Stihl MS 660 chain saw has three adjusting screws:

- Aircraft for idling.

- H for adjusting the fuel supply at high speeds (main screw).

- L to adjust the proportions of fuel and air (screw quality mixture).

The L and H propellers are located near the aircraft at some distance from them. They are all marked on the case.

Specifications

The Stihl MS-660 professional chainsaw is equipped with a 51 cm replaceable tire and a spare chain. Parts are quickly replaced, which makes it possible to work with thick trunks and then cut branches.

The Chinese chainsaw has the following specifications:

- Power. 7.1 HP (5.22 kW)

- Engine volume. 91.6 cm³;

- Saw chain pitch. 9 mm;

- Chain thickness. 1.6 cm;

- The number of links in the chains. 72, 90, 162;

- Fuel consumption. 0.4-0.8 l / h;

- Fuel tank capacity. 0.83 l;

- Oil tank capacity. 0.36 l;

- Tire length. 40, 50, 90 cm;

- Weight with full filling. 7.3 kg.

Specifications may change slightly as the manufacturer makes changes and modifications to their products.

What carburetor is installed on the Stihl MS 660 chainsaw

The carburetor of the Stihl MS 660 chainsaw is of a membrane type, which allows it to work even in an inverted position. The company has more than half a century of chainsaw production, so each unit is perfect enough.

Non-original products from other manufacturers most often have an identical design.

Chainsaw Stihl MS 660. one of the most powerful in the world (7.1 HP), professional grade.

Therefore, the carburetor on it is distinguished by increased throughput, sufficient for such an engine size, and reliability.

Stihl Ms 660 Carburetor Adjustment

Stihl does NOT use third party spare parts to assemble chainsaws. Therefore, the original Stihl MS 660 chainsaws have Carburetors from this company. Chinese chainsaws may include Carburetors from Walbro, Rezer, Kimoto, Cingcong, and other unknown manufacturers.

Standard or standard setting

Screws H and L Tighten clockwise to the end, counting the number of turns. Their number is recorded or memorized. If the carburetor does NOT start the engine, this data will allow you to return to the original factory settings.

- Screws H and L are loosened clockwise every 1 turn.

- Starting and checking the engine by ear or tachometer.

- If the revolutions fail (choke) when you press the throttle, the screw H is loosened by another 1/4 turn.

- If the engine is idling while pressing the throttle, return screw L. 1 1/4 turn.

Each Stihl MS 660 chainsaw that has worked for some time has its own characteristics, including the compression ratio in the cylinder. Therefore, the settings are individual. By turning the screws 1/4. 1/3 H and L to one side or the other, they achieve optimal performance of the chainsaw engine at medium to maximum speeds.

Stihl chainsaws characteristics

| model | Working volume (cm 3) | Power (kW / hp) | Weight, kg) | Specific gravity (kW / kg) | Standard tire (cm) | standard chain | Start aids | Chain tensioner | engine’s type | |

| Petrol-powered saws for sawing wood and for maintenance of the land | ||||||||||

| MS 170 | 30.1 | 1.3 / 1.7 | 3.9 | 3.0 | 35 | 50. 3/8 “R.1.3 | In front | 2-stroke | ||

| MS 180 | 31.8 | 1.5 / 2.0 | 3.9 | 2.6 | 35 | 50-3 / 8 “P-1.3 | – | In front | 2-stroke | |

| MS 180 C-BE | 31.8 | 1.5 / 2.0 | 4.2 | 2.8 | 35 | 50-3 / 8 “P-1.3 | ErgoStart | swift | 2-stroke | |

| MS 181 | 31.8 | 1.5 / 2.0 | 4,3 | 2.9 | 35 | 50-3 / 8 “P 1.3 | – | lateral | 2-MIX | |

| MS 181 C-BE | 31.8 | 1.5 / 2.0 | 4.6 | 3.1 | 35 | 50-3 / 8 “P 1.3 | ErgoStart | swift | 2-MIX | |

| MS 192 C-E | 30.1 | 1.3 / 1.8 | 3.3 | 2.5 | 35 | 50-3 / 8 “P-1.3 | ErgoStart | lateral | 2-stroke | |

| MS 211 | 35.2 | 1.7 / 2.3 | 4,3 | 2.5 | 35 | 50-3 / 8 “P-1.3 | – | lateral | 2-MIX | |

| MS 211 C-BE | 35.2 | 1.7 / 2.3 | 4.6 | 2.7 | 35 | 50-3 / 8 “P-1.3 | ErgoStart | swift | 2-MIX | |

| MS 230 | 40.2 | 2.0 / 2.7 | 4.6 | 2,3 | 35 | 50-3 / 8 “P-1.3 | – | In front | 2-stroke | |

| MS 231 | 40.6 | 2.0 / 2.7 | 4.9 | 2.4 | 35 | 50-3 / 8 “P-1.3 | – | lateral | 2-MIX | |

| MS 250 | 45.4 | 2.3 / 3.1 | 4.6 | 2.0 | 35 | 50-3 / 8 “P-1.3 | – | lateral | 2-stroke | |

| MS 250 C-BE | 45.4 | 2.3 / 3.1 | 4.9 | 2.2 | 40 | 55-3 / 8 “P 1.3 | ErgoStart | swift | 2-stroke | |

| MS 251 | 45.6 | 2.2 / 3.0 | 4.9 | 2.2 | 35 | 50-3 / 8 “P 1.3 | – | lateral | 2-MIX | |

| MS 271 | 50.2 | 2.6 / 3.5 | 5.6 | 2.2 | 37 | 62-0.325 “- 1.6 | – | lateral | 2-MIX | |

| MS 291 | 55.5 | 2.8 / 3.8 | 5.6 | 2.0 | 40 | 67-0.325 “- 1.6 | – | lateral | 2-MIX | |

| MS 390 | 64.1 | 3.4 / 4.6 | 5.9 | 1.7 | 45 | 66-3 / 8 “- 1.6 | – | lateral | 2-stroke | |

| Petrol saws for forestry | ||||||||||

| MS 201 | 35.2 | 1.8 / 2.4 | 4.0 | 2.2 | 35 | 50-3 / 8 “P 1.3 | – | lateral | 2-MIX | |

| MS 241 C-M | 42.6 | 2.2 / 3.0 | 4.7 | 2.1 | 40 | 55-3 / 8 “P-1.3 | decompressor | lateral | 2-MIX M-Tronik | |

| MS 260 | 50.2 | 2.6 / 3.5 | 4.8 | 1.8 | 37 | 62-0.325 “- 1.6 | decompressor | lateral | 2-stroke | |

| MS 261 | 50.2 | 2.8 / 3.8 | 5.2 | 1.9 | 37 | 62-0.325 “- 1.6 | decompressor | lateral | 2-MIX | |

| MS 261-VW | 50.2 | 2.8 / 3.8 | 5.4 | 1.9 | 37 | 62-0.325 “- 1.6 | decompressor | lateral | 2-MIX | |

| MS 361 | 59.0 | 3.4 / 4.6 | 5.6 | 1.6 | 40 | 60-3 / 8 “-1.6 | decompressor | lateral | 2-stroke | |

| MS 362 | 59.0 | 3.4 / 4.6 | 5.9 | 1.7 | 40 | 60-3 / 8 “-1.6 | decompressor | lateral | 2-MIX | |

| MS 362-VW | 59.0 | 3.4 / 4.6 | 6.0 | 1.8 | 40 | 60-3 / 8 “-1.6 | decompressor | lateral | 2-MIX | |

| MS 440 | 70,7 | 4.0 / 5.4 | 6,3 | 1.6 | 50 | 72-3 / 8 “- 1.6 | decompressor | lateral | 2-stroke | |

| MS 440-W | 70,7 | 4.0 / 5.4 | 6.5 | 1.6 | 50 | 72. 3/8 “- 1.6 | decompressor | lateral | 2-stroke | |

| MS 441 | 70,7 | 4.2 / 5.7 | 6.6 | 1.6 | 45 | 66-3 / 8 “-1.6 | decompressor | lateral | 2-MIX | |

| MS 441 C-M | 70,7 | 4.2 / 5.7 | 6.6 | 1.6 | 45 | 66-3 / 8 “-1.6 | decompressor | lateral | 2-MIX M-Tronik | |

| MS 660 | 91.6 | 5.2 / 7.1 | 7.3 | 1.4 | 50 | 72-3 / 8 “-1.6 | decompressor | lateral | 2-stroke | |

| MS 880 | 121.6 | 6.4 / 8.7 | 9.8 | 1.5 | 90 | 108-0.404 “-1.6 | decompressor | lateral | 2-stroke | |

| special saws | ||||||||||

| MS 150 TC-E | 23.6 | 1.0 / 1.3 | 2.6 | 2.6 | thirty | 64. 1/4 “R. 1.1 | ErgoStart | lateral | 2-MIX | |

| MS 192 T | 30.1 | 1.3 / 1.8 | 3.1 | 2.4 | thirty | 44-3 / 8 “P-1.1 | – | lateral | 2-stroke | |

| MS 201 T | 35.2 | 1.8 / 2.4 | 3.7 | 2.1 | 35 | 50-3 / 8 “P-1.3 | – | lateral | 2-MIX | |

| MS 192 C-E Carving | 30.1 | 1.3 / 1.8 | 3.3 | 2.5 | thirty | 64 1/4 “H 1.3 | ErgoStart | lateral | 2-stroke | |

| saws | ||||||||||

| MSE 160 C-BQ | 1.6 | 4.1 | 35 | 50-3 / 8 “P-1.3 | swift | |||||

| MSE 180 C-BQ | 1.8 | 4.2 | 40 | 55-3 / 8 “P-1.3 | swift | |||||

| MSE 220 C-Q | 2.2 | 6.2 | 45 | 66. 3/8 “- 1.6 | lateral | |||||

Checking and subsequent replacement of defective membranes

Stihl 180 chainsaw carburetor membrane repair kit

Repair and adjustment of the carburetor of the Stihl 180 chainsaw

Stihl 180 is a German chainsaw designed for gardening, firewood, site clearing and other woodworking. Many people love it for its compactness and ease of use. The tool combines seemingly opposite qualities. power and maneuverability. German designers have tried to create this sample, but the MS 180 Stihl also has drawbacks that users face in various operating modes. Like all mechanisms, it tends to fail. What to do in such cases and is it worth contacting the workshops?

Carburetor repair and cleaning without spare parts

There are situations in life in which it is simply vital to repair the dust, and the necessary components are at hand. For such cases, there is the following method: Take out the carburetor, remove the membranes, and then put the rest in acetone and let it soak. Acetone will remove debris that interferes with the passage of various liquids. This method will NOT hit your. but it is not reliable. Such a repair will not ensure the long operation of the chainsaw, since outdated membranes have NOT been replaced.

Stihl 180 chainsaw carburetor tuning

Common malfunctions of the Stihl 180 carburetor

Faults that can be solved by repairing the carburetor: It is worth noting that diagnostics may not always correctly indicate the problem. There are times when the same “symptom” arises for different reasons. And sometimes the diagnostics can also give false information, as a result of which you will NOT be able to correctly eliminate the cause of the breakdown. Paying due attention to diagnostics, but do not overestimate its importance.

The tool does NOT keep idling, and sometimes the revolutions “walk”. Most likely the idle jet was forgotten. It is urgent to clean it, otherwise the saw will NOT be able to perform its functions. Another possible cause is a malfunction of the fuel system.

Sometimes this problem is solved by cleaning the valve, which limits the fuel tank. This valve regulates the output of gasoline and the passage of air. Don’t forget to adjust the carburetor by changing the amount of air that is supplied to it. details about this operation can be found in the instructions included with the brand new chainsaw.

The carburetor of the Stihl chainsaw, and not by disassembling, can only be adjusted for the number of idle revolutions produced. It is impossible to increase or decrease the fuel supply in various modes. Manufacturers have limited access to this adjustment, removed special screws. If faults are found in this system, it is possible, with experience, to increase the gap between the needle valve and the wall.

The saw does not start. The solution is the same as in the previous paragraph.

The tool began to consume more fuel, while its power was significantly reduced. Gasoline consumption and power are subjective concepts. To accurately determine THESE indicators, one cannot do without visiting Special firms specializing in this tool.

Well, if these two indicators are visible “on the face”, then follow these steps:

Check if the chain is blunt. A dull chain has a lower efficiency, and therefore the saw consumes more fuel.

Examine the fuel tank. Perhaps it has formed small mechanical damage, through which gasoline imperceptibly leaves.

Inspect the muffler carefully.

Clean the cooling system and exhaust system.

The unit stalls immediately after operation or warming up. Experts call it hot.

The most common reasons are:

- Lack of air entering the carburetor. Replace inlet and outlet valves.

- Breakdown of the cooling system (overheating). It is possible that foreign objects have entered the pipes with cold air, which will need to be removed.

- Chainsaw stalls when position is changed. This only applies to tilting to the side, in the vertical state the saw functions normally. This problem even applies to serviceable chainsaws, because during the development the designers made a small mistake. The fuel system of the Stihl 180 has a special design, in which the fuel cannot come out of the tank on its side. Sometimes the problem lies in the clogging of the fuel pump.

The procedure for parsing, as well as tuning the carburetor of the Stihl 180 chainsaw In order to carry out a high-quality repair of the carburetor, you will need to remove it. This is not difficult to do, but you need to be extremely careful. To begin with, prepare the workplace: install lighting, lay out all the necessary tools. Understand that the carburetor is the main saw unit where the fuel and gasoline flows intersect. For stable operation, they must be cleaned of foreign debris.

Therefore, before the main work, you need to do the following:

- Remove and clean the muffler.

- Make sure there are no problems with fuel supply and combustion.

- Check the serviceability of the air and cooling filters.

The main stages of work (removal of the carburetor)

The best option would be to watch the tutorial. Fortunately, there are dozens of them on the Internet. There they will tell you everything in detail and professionally. As the saying goes: “It’s better to see once than hear a hundred times.” (In our case, read it.) Schematically, this process can be written as follows: remove the protective cover, remove the rods and, finally, Unscrew the unit to work with it.

Stihl 180 chainsaw performance

| model | MS180 |

| Engine displacement (ml) | 31.8 |

| Max power (hp) | 2.0 |

| Max speed (rpm) | 14000 |

| Weight (without tire, chain, oil and fuel) (kg) | 3.9 |

| Fuel tank volume (ml) | 250.0 |

| Oil tank volume (ml) | 145.0 |

Reliability of Chinese Carbs Purchased on Aliexpress

In conclusion, I want to say that the native Stihl Carburetors, which are produced by its subsidiary, are almost the most durable and reliable. If you want your instrument to work properly for a long time, you should take care of it. Do not forget to clean the air filter and lubricate the chain with tested oil. When storing the saw for a long time, be sure to remove all gasoline and chain oil from the tank.

Successful work with wood and less damage to your Iron second!