Stihl 180 ignition adjustment

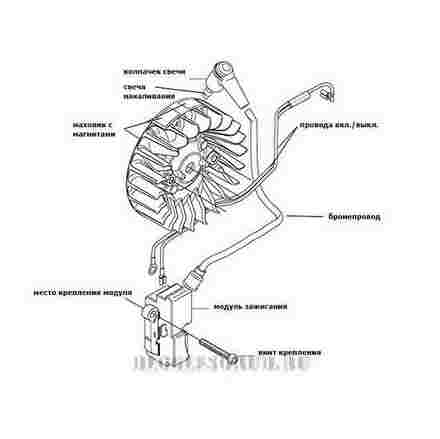

On the Shtil MS 180 chainsaws, an electronic ignition system is installed, the adjustment of which is reduced to setting the gap between the flywheel and the ignition coil of the Stihl 180 saw. To adjust, remove the starter, loosen the two screws securing the ignition coil and install a strip cut from a plastic bottle between the flywheel and the coil contacts tighten the fastening screws.

To check the clearance, it is necessary to turn the flywheel and check if the contacts of the coil do not touch it.

Common breakdowns Calm 180

Common malfunctions on a chainsaw calmness include:

- Breakage of the starter cord;

- Drive sprocket wear;

- Leaks in the chain oil supply system;

- Wear of the oil pump worm gear;

- Air leaks through oil seals into the engine crankcase;

- No spark on the spark plug;

- Lack of fuel supply in case of malfunctions in the carburetor (we will not dwell on them, since the repair and adjustment of the chainsaw carburetor is a wide enough issue and will be discussed in a separate article);

- Breaking the eyelet of the seat under the engine control lever.

Now we will consider the malfunctions in more detail and start with the repair of the oil pump.

Device description and technical parameters

Calm 180 has a standard configuration. However, like all modern chainsaws. Its components:

- Anti-vibration front and rear stick.

- Saw bar with chain.

- 2-stroke single-cylinder engine.

- Fuel and ignition systems.

- High quality plastic housing.

Chainsaw calm 180, technical characteristics:

- Gasoline engine that runs on a mixture of fuel and oil in a ratio of 1: 50. It has a capacity of 2 liters. from.

- The saw weight is approx. 4 kg.

- The saw is equipped with an easy start system.

- The capacity of the fuel and oil tank is 250 and 140 ml, respectively.

- Saw bar is 14 inches (35 cm) long.

- Automatic chain lubrication.

Chain lubrication

This usually occurs due to a clogged lubrication system. We clean the oil pump from dirt. The oil supply to the chain can be adjusted. To do this, turn the screw to the side. which is next to the leading sprocket. To check the oil supply, the saw must be started. We bring the tire to any unnecessary surface and give revolutions for the movement of the chain, where an oil trace should remain.

This problem does not affect the operation of the chainsaw. But the bar and the chain must be lubricated, otherwise it will lead to more serious damage.

Chainsaw engine breakdown

During operation, parts of the cylinder-piston group of the saw fail due to friction forces, high temperatures and loads. If the tool does not reach full power at startup and stalls at idle speed, a possible problem may be damage to engine parts. To disassemble the power unit, unscrew 4 bolts and remove the cylinder. The owner is required to carefully inspect its internal work surface for the presence of chips, nicks and cracks.

Even the slightest damage to the “mirror” of the cylinder can negatively affect the compression of the chainsaw engine and its performance.

Cylinder-piston group of the Stihl MS180 chainsaw

When diagnosing an internal combustion engine, we also perform a visual inspection of the piston and compression rings. Made of aluminum alloy and cast iron, respectively, they are more exposed to abrasion loads than a steel cylinder. In case of breakage and excessive wear of the piston rings, it is necessary to replace them.

If, upon visual inspection, the ovality of the cylinder working surface is observed, it will need to be bored. To do this, we measure its diameter in a larger size, select the piston and perform the subsequent machining.

The Stihl MS 180 is a fairly reliable saw, but if used improperly, using poor-quality lubricants or due to operator negligence, malfunctions may occur. To repair a saw with your own hands, you must have certain knowledge and a special tool, in the absence of which repair is impossible. Do not forget that the Stihl 180 chainsaw is a technically complex tool and it is better to maintain it in a service center.

Despite the many varieties of modern building materials, wood remains the most demanded. In this regard, chainsaws are in great demand among fellers, owners of their own houses and summer residents.

Among the huge variability of the model range, the most popular among both amateurs and experienced foresters for many years has been the calm 180 chainsaw, which is distinguished by its simple maintenance, repair and operation. The Stihl company was founded more than 9 centuries ago and began production of gasoline chain saws back in 1926. Thanks to many innovations, simplicity and durability, the tools of this manufacturer are in demand on the world market of woodworking equipment.

Starter malfunctions and their elimination

What other malfunctions happen to the starter? One of them is the failure of the return spring, the restoration of which is impossible and the part will need to be replaced.

It is recommended to do this in the service center, because the process is quite complex and requires some practice.

Saw starter

The main cause of breakage is a broken cord. It is necessary to remove the saw cover, unscrew the 4 screws securing the starter. Replacing the cord is not particularly difficult. The condition of the remaining parts of the starter can be checked immediately. Before assembling, we lubricate the moving elements and clean them from dirt, oil leaks. You can change the entire starter.

About the chainsaw and its inoperability

Chainsaw. The installation itself is not that difficult. But having the smallest initial knowledge is extremely important in order to find and eliminate any defect.

Modern electronics has progressed so much that it has revolutionized the world of instruments. Saws of our days are light and at the same time powerful, equipped with electronic ignition systems ESZ.

Not so long ago, saw ignition systems were cam-type. This carried a lot of disadvantages: severity, complexity, high cost, and much more. And the main drawback of the archaic ignition system is the difficulty of the plant. Some saw model systems could not generate enough spark at all to flash at crankshaft speed.

Modern systems are nearly fail-safe. Saw models are lightweight and durable, the reel is made more professionally and will serve its life almost flawlessly. However, there are also problems, but in most cases they can be corrected on their own.

Consider the main types of chainsaw malfunctions associated with the flywheel and ignition system.

As a rule, the most common ailment of modern chainsaws involves the absence of a supply spark. This also directly depends on the shift in the clearance (gap) between the bobbin and the flywheel.

Common installation failures are always associated with internal combustion engines. Problems arise in the fuel ignition system, the fuel intake module, in the internal elements of the engine itself.

As for other units of the chainsaw, malfunctions arise there, as a rule, due to failures of the brake mechanism, poor lubrication, etc.

If startup difficulties are associated with the engine, then the following symptoms are most often observed:

- the motor does not develop the necessary power;

- does not start at all;

- starts, but quickly stalls;

- functions unstable.

As always, experts recommend identifying fault factors in a way of elimination. In other words, you need to go through the chain, diagnosing each node, each link.

The gap between the ignition coil and the flywheel of the chainsaw

Internal combustion engines are installed not only on cars or motorcycles. They are widely used in various tools, for example, such as a chainsaw or a trimmer. In the event of their malfunction, poor start-up, it is often enough to establish the correct clearance between the flywheel and the ignition coil.

Ignition module

Inoperability of the SZ chainsaw is the most common reason why the engine of the tool does not start. It is recommended in most cases to start troubleshooting from here.

Here’s what to do:

- first of all, carefully check the spark plug by carefully throwing off the armored wire from the head and unscrewing the plug from the socket using a special key;

- the second is to check the spark supply by jerking the starter when the armored wire cap is put on the candle;

- clearance check is the main topic of our article (more details below).

So, a malfunction of the spark plug will clearly indicate its phlegm. A wet spark device for igniting the fuel-air mixture indicates that there is an excess of fuel in the system, the carburetor is incorrectly tuned, or there are problems in the SZ.

The candle is checked only after drying. That is, it must be thoroughly cleaned with a napkin, the insides of the internal combustion engine should be dried, the supply should be blocked, and then the starter should be started a couple of times so that excess combustible mixture comes out.

Then the spark device is put in place and everything is checked again.

In general, a spark device can tell a lot about the entire ignition system. If black carbon is observed on the candle, then this indicates violations in the communications of the gasoline mixture supply. Here either the ratio of gasoline and oil has been violated, or the carburetor needs to be readjusted. In some cases, this also happens due to low-quality oil.

A dirty candle is cleaned of black carbon with a needle or some other sharp object. Then the electrode is cleaned with emery paper (zero) until a metallic sheen appears. The spark device is returned to its place, everything is checked again.

The next step: checking the spark supply. The spark device skirt is brought up to the cylinder and the starter motor is started. If a bluish spark jumps at a distance of 2-3 mm, everything is fine. A spark distance of 0.5-1 mm is already considered a malfunction. There may be no spark at all, and this is also a big problem. Perhaps this is a wire break.

And now we come to the topic of our article. The chainsaw may not start due to a violation of the gap between the ignition and the flywheel magneto. This very gap should be within 0.2 mm. It is very simple to check: a special gasket is placed between the flywheel and the bobbin. If it comes in normally, not too loose and tight, then the gap is normal.

The saw flywheel itself is round, and checking the clearance with a conventional feeler gauge is impossible. It would be more qualified to set the gap according to a special template, but it is not always possible to acquire it. And not everyone can afford to buy a template that is not cheap for a single use.

However, instead of a foreign template, you can use a cut-out strip from a plastic container for 1-2 liters from under the juice.

- the ignition fixing bolts are loosened;

- a plate is inserted between the flywheel and the bobbin;

- the bolts are tightened.

Advice. It is recommended to cut the plastic tape where there are no embossed irregularities.

How to check the magneto of a chainsaw

Magneto, babin, module is an ignition coil. It may have absolutely nothing to do with tool failures, and the reason is lurking only in the gap or in another. But in some cases, it is she who becomes a factor in violation.

To check the babin itself, you should, as in the above case, use it by excluding the components from the chain. Or in other words:

- visually assess the condition of the bobbin case for cracks and other visible defects;

- check the cleanliness of the current communications of various nodes and elements;

- diagnose the insulation and serviceability of the armored wiring, the reliability of fixing the fasteners, the absence of rust, etc.

- visually assess the condition of the spark device cap;

- checking the condition of the candle;

- circuit breaker diagnostics, which is especially important for Chinese-made chainsaws.

Again, as in the above case, certain points are excluded from this chain, thereby finding the cause of the problem.

Babin herself is investigated like this.

- The resistance of the magneto is measured. However, this option is not always applicable, since it is necessary first of all to know the resistance parameters. In addition, for the formation of the required HE pulse, it is necessary to separate the indicators of various semiconductor elements. A sign of a malfunction, as a rule, is the ringing of the circuit through the BB wire and minus. Should show either “open circuit” or high resistance.

- The check can be carried out as follows. use a device that checks for the presence of a spark. It is installed in the open circuit between the BB wire of the bobbin and the candles. The disadvantage of this method is that the device is so very expensive, it is used mostly in serious repair services.

- “Dedovsky” method of verification, which will save on an expensive device. It is used at your own peril and risk when there are no other options. The method of checking is reduced to the fact that the cap is thrown off the candle, a carnation is inserted into it. The candle is re-inserted. The stud should be 6-7 mm from the cylinder. The chainsaw starts up. A spark is examined: it should be bright blue, if not, then this is a sign of a malfunction.

The “grandfather’s” method of checking a bobbin has many drawbacks. First of all, this applies to electrical components in the system, which can easily deteriorate. The distance between the cylinder and the stud may differ depending on the different models of the tool.

As for tuning the magneto, it boils down to examining the groove on the flywheel. UOZ for most of the current models of saws does not need to be adjusted. But it is possible to determine its exposure only by the angle between the mark after the groove on the flywheel and the magnets installed, again, on the flywheel.

Competently and accurately set the gap between the magneto and the flywheel. that’s what is more important.

How To Gap An Ignition Coil On ( chainsaws/strimmers/mowers/etc ) quick tip!

You should be aware that the bobbin on chainsaw systems is installed in the fan fuselage near the flywheel. The coil, in contact with the flywheel magnet, produces energy for the spark.

Replacing the coil itself will be much more difficult, since the installation location is too inconvenient. The installation of a new bobbin should be carried out so that the base of the coil is at a distance of 1-1.5 mm above the flywheel magnets.

In some cases, it is recommended to also check the crankshaft bearing for play.

Major malfunctions and their elimination

If you cannot start the saw the first time, there may be several reasons. The most common problem is with the spark plug:

- electrode wear or damage to the ceramic insulator;

- loose fitting of the removable cap (if any);

- sparkling along the ceramic winding, which is indicated by a brown residue on the outer shell;

- cracks in the cap of the candle (a saw with such a problem will continue to work, but it may hurt the user when touched).

If no problems were found with the spark plug, it is recommended to inspect the wires coming from the coil. They can be cut off or have other mechanical damage. There may be wire breaks inside the insulation, so sometimes these violations cannot be detected by visual inspection.

The cause of the breakdown may lie in the shutdown switches. It’s easy to check them. To do this, disconnect the wires from the module, and then check the ignition. If a spark appears after shutdown, the switch must be replaced.

Chainsaw ignition system. device, check and adjustment

The ignition system of a chainsaw is a series of parts that generate a spark when the engine of the tool is started. In most cases, the ignition system is a fairly reliable unit, but sometimes, for various reasons, some of its parts fail. Let’s explore the features of repair and adjustment of the main elements of the chainsaw ignition system.

How the ignition of a chainsaw works and how it works, their main malfunctions and elimination

Gasoline saws are necessarily equipped with an ignition system. It is necessary for timely ignition of the fuel mixture in the engine cylinder. Therefore, it is so necessary to install the ignition on a chainsaw and its periodic adjustment, since the tool simply will not start without a spark.

How to set the ignition on a chainsaw?

Quite often, owners of chainsaws are faced with a problem in which the engine of the tool does not start. One of the main reasons for this breakdown is a malfunction of the ignition system, namely, a failure of the factory settings of the unit.

First of all, the owner of the saw will need to unscrew the protective rubber cap and check the spark plug under it. It is possible that it is flooded with oil, which prevents the flow of current to the candle. In such cases, the problem lies not in the ignition system, but in the fuel system, namely, in the depressurization of the channels.

However, if the spark plug is completely dry, then it may be necessary to install the ignition on the chainsaw. To do this, unscrew the candle and dismantle the protective cover. After that, it is necessary to measure the gap between the flywheel and the ignition coil. The instructions for each of the chainsaw models indicate the optimal clearance between these elements. In most cases, it is between 0.2 and 0.4 mm. Since the handwheel of the tool has a round shape, it will not be possible to use an automotive dipstick to adjust the gap. It is best to use a special template in the form of a spacer for this purpose. However, finding it is not easy. Therefore, many experts advise using a cut out strip from a plastic bottle as a template.

Chainsaw ignition adjustment is quite simple;

- First, loosen the bolts securing the elements of the ignition system;

- Place the plastic bottle plate between the spool and the flywheel;

- Tighten the bolts all the way.

Design features of the factory ignition system

The ignition system for a domestic or professional chainsaw initially consists of:

- magneto, or factory ignition coil;

- candles with a pre-installed cap;

- electrical high-voltage wiring, pre-connecting the spark plug to the coil;

- keys that instantly turn off the running power unit of the chainsaw.

In the device of a household gasoline tool, magneto is a kind of generator responsible for the continuous generation of alternating current with the subsequent transfer of energy to the built-in candle. The design of the magneto initially consists directly of a standard stationary winding of an inductive coil, as well as a permanently operating magnet pre-installed on the built-in flywheel.

Magneto, provided in the standard built-in ignition device for household and professional gasoline saws, are divided by equipment manufacturers into:

- contact. in the design of these nodes, the first output of the built-in factory high-voltage winding is connected to the spark plugs. In the basic design of the contact magneto, a capacitor is initially provided, which prevents overheating and gradual oxidation of the contacts of the standard breaker;

- contactless. the principle of operation of units of this type is based on the work of the built-in control coil of the factory, which, at the same time, plays the role of an element that regulates the supply of voltage. During the regular opening of the thyristor, the standard capacitor begins to actively discharge. As a result, a sufficiently high current is continuously generated in the turns of the high-voltage factory primary winding, which is inducted into the high-voltage voltage. It leads to an instantaneous breakdown at the built-in spark plug located in the cylinder of the power unit. The electrical network of the non-contact magneto operates stably in the mode of continuously generated short-term pulses generated in time with each forward movement of the factory cylinder and the corresponding rotation of the engine crankshaft.

Manufacturers of chain garden equipment use different types of factory magneto in the configuration of chainsaws. The main difference between them lies only in the principle of action. At the same time, contact and non-contact magneto have approximately the same working efficiency.

How to set the ignition on a chainsaw

The ignition of the chainsaw should be adjusted periodically. This action involves setting the correct spark plug gap between the coil and flywheel. The parameter depends on the model of the chainsaw. It is specified in the instruction manual. The average value is 0.2-0.4 mm. Having the correct gap is important to ensure that the spark appears at the right time, i.e. not earlier and not much later than the fuel supply.

Special templates will help to adjust the ignition on the chainsaw, but it is not always advisable to purchase them for one-time use. Therefore, they can be replaced with a homemade one. To make it, you need to cut a strip from a plastic bottle. The part of the container where there is no embossing is suitable. After that, you can install the ignition, proceeding in the following sequence:

- Unscrew the ignition bolts slightly to loosen.

- Flywheel magnets to ignition coil.

- Clamp the plastic plate between the flywheel and the spool and then screw the bolts back.

- Remove the strip.

- Rotate the flywheel full circle several times in a row, while you need to make sure that it does not cling anywhere.

If, during the diagnostics, any coil malfunctions were identified and it was not possible to adjust it, then the part must be replaced, since the repair is impractical.

Check the ignition coil on the chainsaw

If the preliminary actions did not help in identifying the cause of the chainsaw malfunctions, then it is necessary to check the saw’s ignition coil. Diagnostics is performed in several stages:

- Measure the resistance of the coil using a multimeter. To do this, you should know the optimal parameters, which are indicated in the operating instructions. However, due to the use of semiconductor elements in the system, an attempt to “ring” the coil will result in an Open Circuit reading. This is normal. A positive test result is a sign of a malfunction. That is, if it was possible to determine the resistance of the coil using a special tool, then it is definitely faulty.

- Check for spark with a special device. This device should be installed in the open circuit located between the spark plug and the high voltage terminal of the saw ignition coil. The readings will be visible on the display. This verification method is more often used in service centers, since the device required for this is expensive and the costs will not be comparable to the benefits rendered.

- Testing the coil with a spark plug, i.e., perform a homemade ignition. To do this, it must be turned out, and then the body must be attached to the cylinder. Now you need to pull the starter and watch the spark. But this method gives only an approximate result, since the flywheel turns faster due to the unnatural position of the candle.

If none of these methods work, or if you need to perform a check in the field, you can proceed as follows:

- Remove the cap from the candle, insert a nail without a cap into the core at a distance of 6-7 mm from the cylinder. This must be done as carefully as possible so as not to damage the part.

- Carry out the steps to be taken when the tool is manufactured. Now you need to look at the presence of a spark and its color. If there is no malfunction, then the spark will be strong and the color will be bright blue.

This method can be used as a last resort and only if there are no electronic components, while it is important to follow the rules:

- it is impossible to completely unscrew the spark plug, as this can lead to faster rotation of the flywheel, which is not the correct operating mode of the engine;

- you need to place it at a distance that corresponds to the compression model and the dielectric properties of the fuel mixture, therefore this parameter can be viewed in the instructions (a value of 6-7 mm is average).

Chainsaw ignition

In order for a gasoline saw to start running stably at idle, the fuel located in the factory cylinder of its power unit must ignite. For this, a standard ignition system is provided in the basic configuration of any branded chain tool. The ability of the internal combustion engine to make the first cold start and steadily gain momentum when the operator presses the gas trigger depends on its serviceability. The ignition of a household saw is distinguished by a simple device and a constant operating principle. Having studied their features, it will be easier for the operator to carry out maintenance and self-repair of the unit.

Chainsaw ignition adjustment

The device and principle of operation of the chainsaw ignition system

The standard ignition system for a carburetor engine consists of:

- magneto;

- spark plug;

- an electrical cable connecting them to each other;

- engine shutdown keys.

Ignition scheme of the Ural chainsaw

Magneto is a type of alternator that supplies electricity to spark plugs. It consists of a stationary winding of an inductor and a permanent magnet attached to a flywheel that rotates with the crankshaft of a gasoline engine. The moving magnetic field creates an electromotive force in the low-voltage winding, which is converted by the transformer into a voltage with a potential sufficient to generate a spark.

For contact magnets, the first terminal of the high-voltage winding is connected to the spark plug, and the second is connected to the ground through a mechanical switch. At a certain moment, a special structural element divides the contacts, which leads to a sharp increase in the voltage in the network and a spark slip in the interelectrode space of the candle.

To prevent overheating and oxidation of the breaker contacts, a capacitor is connected to the electrical circuit.

The ignition circuit of a chainsaw with a contactless magneto is based on the operation of a control coil, which plays the role of a voltage supply regulator. The electronic unit also includes a diode, a capacitor and a thyristor, which transmits a current with a voltage of a certain magnitude. When it is opened, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is inducted into a high voltage, giving a breakdown on the spark plug installed in the cylinder. The electrical network operates in a pulsed mode in time with the rotation of the crankshaft and the translational movement of the cylinders.

Ignition timing

The mechanical device and the factory setting of the magneto ensure that the discharge time of the spark plug matches the optimal position of the moving piston. For four-stroke gasoline engines, spark breakthrough must occur even before the piston reaches top dead center. this is due to the fact that the process of complete ignition of the air-fuel mixture takes a certain time. The speed of movement of engine parts is comparable to the speed of fuel ignition, so the piston, from the moment of spark breakthrough until the moment the burning gases create extremely high pressure.

There is an ignition timing for each engine. It is equal to the rotation of the crank, expressed in degrees, from the moment of breakdown in the interelectrode space of the spark plug until the moment when the piston is at top dead center. This indicator depends on many parameters, including the design features of the engine and the properties of the fuel mixture.

In practice, during the mass production of an engine at the factory, individual adjustment of the ignition of each product is not made, but the corresponding marks are set on the rotating parts, which must be aligned during installation.

When is the ignition setting required? There are the main symptoms of a system crash:

- the engine will not start;

- the motor works, but with noticeable interruptions;

- there is a decrease in tool power.

In these cases, you should not rush to contact the service center. Try to adjust the ignition yourself first.

The procedure for checking and adjusting the correct operation of the engine

The most vulnerable element of a carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of a gasoline engine. The following procedure is recommended.

-

Dismantle the spark plug and inspect it. A dry candle with a slight brown tint of the electrodes can be considered serviceable.

Spark plug carbon deposits

Chainsaw ignition coil

When installing a new electrical module on the engine, the magneto gap must be adjusted. The optimal distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

Clearance between magneto and flywheel

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

Best way to set the gap on any ignition coil, magneto, armature, part 1

With such a small gap, it will not be possible to use an available measuring tool for direct measurement. In practice, a Husqvarn saw uses a template in the form of a spacer cut from a thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

In order not to have to resort to adjusting the ignition, operate the tool carefully, avoiding knocks. In particular, this applies to chainsaws with electronic chips in the ignition system, since they are very sensitive to mechanical damage.