How to charge a screwdriver lithium battery

A lithium battery screwdriver is almost always an upgrade. Whereas Ni-Cd cells had the same charging requirements, they are now the opposite. First of all, you need to purchase or assemble a charger, specifically for the power-hungry lithium batteries of a screwdriver with a 18650 form factor. The charging scheme is applied in two stages CC / CV.

Charging the lithium battery of the screwdriver is optimal when 20-50% of the capacity remains – one stick on the indicator. The more often you charge, the more stable the voltage at the terminals and the longer the life of the energy source. The more even the voltage at the terminals, the more cycles the lithium battery of the screwdriver will withstand.

| Discharge depth,% | Number of charge cycles |

| one hundred | 500 |

| fifty | 1500 |

| 25 | 2500 |

| ten | 4,700 |

If there are 2 batteries in the screwdriver, remove one, charge to 50-60% and keep in reserve. But always charge the second one at the end of work, even by 10%. The best temperature for charging is 15-25 0 C. At minus, the battery of the screwdriver will not charge, but it can work up to 10 0.

How to charge the lithium battery of a screwdriver with a charger depends on the scheme for collecting the battery from the cans. In any case, the voltage on the charger should be equal to that declared for the device, and the current strength is 0.5 C at the first stage. On the second, the terminal voltage is stable, and the current falls, until the end of the process.

Two-stage lithium battery charging circuit

CC / CV circuit principle – constant charging current / constant voltage. How to charge a lithium battery using this scheme?

The diagram before stage 1 of charging shows a pre-stage for restoring a deeply seated lithium battery, with a terminal voltage of at least 2.0 V. The first stage should restore 70-80% of the capacity. The charging current is chosen 0.2-0.5 C. You can accelerate charging, with a current of 0.5-1.0 C. (C is the capacity of lithium batteries, digital value). What should be the charging voltage in the first stage? Stable, 5 V. When the voltage at the battery terminals 4.2 is reached, this is a signal to go to the second stage.

Now the charger maintains a stable voltage at the terminals, and the charging current decreases as the capacity rises. When its value decreases to 0.05-0.01 C, charging will end, the device will turn off, preventing overcharging. The total recovery time for a lithium battery does not exceed 3 hours.

If the lithium-ion battery is discharged deeper than 3.0 V, a “jolt” will be required. This consists in charging with a small current until the terminals are 3.1 V. Then the usual circuit is used..

How to charge lithium batteries

Lithium batteries are a galvanic pair in which lithium salts serve as the cathode. Whether it’s a lithium-ion, lithium-polymer dry cell or a hybrid battery, the charger fits everyone. Products can be in the form of a cylinder, or a hermetically sealed soft package, the charging method for them is general, corresponding to the peculiarities of the electrochemical reaction. How to charge a Li-ion battery?

Accumulators and batteries

Energy storage information website

How to properly charge lithium batteries

There are several schemes for charging lithium batteries. The two-stage charging developed by SONY is more commonly used. Devices with the use of pulse charging and stepwise charging, as for acid batteries, are not used..

Charging any type of lithium ion or lithium polymer battery requires strict voltage compliance. One cell of a charged lithium battery should have no more than 4.2 V. The nominal voltage for them is 3.7 V.

Lithium batteries can be charged quickly, not fully? Yes. You can always recharge them. Battery operation by 40-80% capacity extends battery life.

How charging parameters are monitored

Since lithium batteries operate in a narrow range of voltage variation at the terminals, they cannot be recharged above 4.2 V and discharged below 3 V. The charge controller is installed in the charger. But each battery or battery has its own breakers, PCB board or PCM protection modules. In the batteries, it is precisely the protection against one factor or another that is installed. In case of violation of the parameter, it must turn off the bank, break the circuit.

A controller is a device that must implement control functions – switch CC / CV modes, control the amount of energy in banks, turn off charging. At the same time, the assembly works, heats up.

Homemade charging circuits used for lithium batteries

- LM317 is a simple charger circuit with a charge indicator. Does not power from the USB port.

- MAX1555, MAX1551- special for Li Batteries, install in phone to USB power adapter. There is a pre-charge function.

- LP2951- stabilizer limits the current, forms a stable voltage of 4.08-4.26V.

- MCP73831 – one of the simplest circuits, suitable for charging ionic and polymer devices.

If the battery consists of several cells, they are not always discharged evenly. When charging, you need a balancer that distributes the charge and ensures that all the cells in the battery are charged evenly. The balancer can be separate or built into the battery connection diagram. The battery protection device is called BMS. Knowing how to charge devices, understanding the circuits, you can do it yourself with a circuit of a protective device for a lithium battery.

How much to charge a lithium battery

The charging time of the batteries is determined by the process of restoring capacity. Distinguish between full and partial charge.

Capacity is measured in ampere hours. This means, if you apply a charge numerically equal to the capacity, then in an hour the required voltage will be created at the terminals, and the energy reserve will be 70-80%. If the capacitance is measured in units of C, a 1C-2C current should be applied during fast charging. Fast charging time about an hour.

For a complete charging cycle of batteries from several cells connected in series, 2 stages are used – CC / CV. The CC phase lasts until voltage appears at the terminals. equal to the worker, in volts. The second stage: at a stable voltage, a current is supplied to the jar, but with an increase in capacity, it tends to zero. Charging time takes about 3 hours, regardless of capacity.

How to charge a 12 volt lithium battery

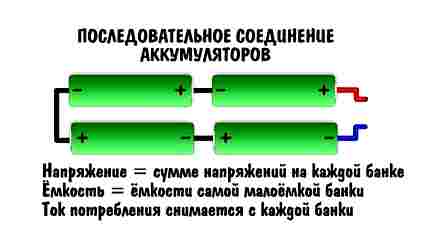

Each lithium battery is a sealed product of a cylindrical, prismatic shape, for Li-pol in a soft package. They all have a voltage of 3.6-4.2 V and a different capacitance, measured in mA / h. If you collect 3 cans in series, you get a battery with a voltage at the terminals of 10.8 – 12.6 V.The capacity during sequential charging is measured by the weakest lithium battery in the bundle.

How to properly charge a 12 volt lithium 18650 battery or Pol, you need to know. To return the container to the device, you must use a charger with a controller. It is important to have in the PCM assembly for each can, protection against under- and overcharging. Another scheme of unprotected lithium-ion batteries is the installation of a PCB – a control board, preferably with balancers, for uniform charging of the cans.

DIY: How to revive a dead 18650 (or any) Li-ion battery cell

On the charger, you must set the voltage under which the battery operates, 12.6 V. On the dashboard, the number of cans and the charging current are set at 0.2-0.5 C.

How to charge, we suggest watching the video, charging method for 2, 3 lithium 18650 batteries connected in series. Using a budget charger.

Charging options for lithium-ion lithium polymer batteries:

- Charger purchased with the device.

- Use the USB connector from electronic equipment – computer. Here you can get a current of 0.5 A, charging will take a long time.

- From the cigarette lighter by purchasing an adapter with a set of ports. Choose the one that matches the parameters of the 12V battery.

- Universal charger “frog” with a dock for installing the gadget. How to charge? There is a charge indication panel.

Experts advise using a standard charger to charge lithium batteries, the rest – only in force majeure circumstances. However, how to charge a lithium battery without a standard charger, you need to know.

Lithium battery marking 18650

There is a marking on the surface of the battery case. Here you can find complete information on the technical properties. In addition to the date of manufacture, expiration date and brand of the manufacturer, the device of the 18650 lithium batteries is encrypted, and the consumer qualities associated with this aspect.

- ICR – lithium-cobalt cathode. The battery has a high capacity, but is designed for low consumption currents. Used in laptops, camcorders and similar long-term equipment with low power consumption.

- IMR – lithium manganese cathode. Has the ability to deliver high currents, withstands discharges up to 2.5 A / h.

- INR – nickelate cathode. Provides high currents, withstands discharges up to 2.5 V.

- NCR is a Panasonic specific marking. In terms of properties, the battery is identical to the IMR. Nickelates, cobalt salts, aluminum oxide are used.

Positions 2,3,4 are called “high current”, they are used for flashlights, binoculars, cameras.

EASY FIX FOR A DEAD ‘NOT CHARGING’ LITHIUM 18650 BATTERY FROM A CORDLESS TOOL BATTERY PACK – PART 2

Lithium ferrophosphate batteries have the ability to work at deep minus, recover at deep discharge. Undervalued in the market.

By marking, you can determine that this is a lithium rechargeable battery of the letter – I R. If there are letters C / M / F – the material of the cathode is known. The capacity indicated by mA / h will be displayed. Date of issue and expiry date are located in different places.

You should know that manufacturers of rechargeable lithium batteries do not have products with a capacity of more than 3 600 mAh. In order to repair a laptop battery or collect a new one, you need to purchase batteries without protection. For use in a single copy, you need to buy elements with protection.

How to charge a li-ion 18650 battery

There is a procedure for restoring the performance of a lithium 18650 battery after a voltage drop to working. We restore the capacity measured in ampere hours. Therefore, first we connect the Li-ion 18650 battery to the charger, then we set the charging current with our own hands. The voltage changes over time, the initial 0.5 V. As a stabilizer, the charger is designed for 5 V. To maintain operability, the parameters of 40-80% of the capacity are considered favorable.

The charging circuit for a li-ion 18650 battery involves 2 stages. First, you need to raise the voltage at the poles to 4.2 V, then by gradually decreasing the current strength, stabilize the capacitance. The charge is considered full if the current has dropped to a value of 5-7 mA when the power is turned off. The entire charging cycle should not exceed 3 hours.

The simplest single-slot Chinese charger for li-ion 18650 batteries is designed for a charging current of 1 A. But you will have to follow the process yourself, switch it yourself. Universal chargers are expensive, but have a display and run the process on their own.

How to properly charge a Li-ion 18650 battery in a laptop? Connecting a set of energy sources in the gadget through Pover Bank. The battery can be charged from the mains, but it is important to turn off the power as soon as the unit has reached capacity.

How to test a lithium 18650 battery

If, when buying an expensive device, you doubt the veracity of the information on the case, there are ways to check. In addition to special meters, you can use the tools at hand.

- You have a charger, you can time a full charge with a certain amperage. The product of the time and the amperage will reveal the approximate capacity of the li-ion battery..

- A smart charger will help you. It will show both voltage and capacity, but the device is expensive.

- Connect the flashlight, measure the current strength, and wait for the light to go out. The product of time and amperage gives the current capacity in A / h.

You can determine the capacity of the battery by weight: a lithium battery 18650 with a capacity of 2000mA / h should weigh 40 g. The higher the capacity, the greater the weight. But the bunglers have learned to pour sand into the hull, for heaviness.

Recovering li-ion 18650 battery

If the battery refuses to work, it can manifest itself like this:

- Power source discharges quickly.

- The battery is dead and does not charge at all.

Any source can quickly discharge if the capacity is lost. This is what is terrible about overcharging and deep discharge, from which protection is put. But there is no escape from natural aging when storage in a warehouse decreases the capacity of cans every year. There are no regeneration methods, only replacement.

What if the battery does not charge after a deep discharge? How to restore a li-ion 18650? After the controller disconnects the battery, there is still a reserve of energy in it, capable of delivering 2.8-2.4 V voltage at the poles. But the charger does not recognize a charge up to 3.0V, everything below it is zero. Is it possible to wake up the battery, start the chemical reaction again? What should be done to raise the charge of a li-ion 18650 to 3.1.3.3V? You need to use a method to “push” the battery, give it the necessary charge.

Without going into the calculations, use the proposed circuit, mounting it with a 62 ohm (0.5W) resistor. A 5V power supply is used here.

If the resistor heats up, there is zero on the lithium battery, then there is a short circuit or the protection module is faulty.

How to recover a lithium 18650 battery using a universal charger? Set the charge current to 10 mA, and perform precharge, as written in the instructions for the device. After raising the voltage to 3.1 V, charge in 2 stages according to the SONY scheme.

Li-ion 18650 battery device

The production of lithium-ion batteries is based on the sites of Sanyo, Sony, Panasonic, LG Chem, Samsung SDI, Skme, Moli, BAK, Lishen, ATL, HYB. Other firms buy items, repackage them, claiming to be their own. They also write inaccurate information about the product on the shrink wrap. There are currently no 18650 lithium-ion batteries with a capacity higher than 3600mAh.

The main difference between batteries and batteries is the possibility of multiple recharging. All batteries are designed for a voltage of 1.5 V, the product has a li-ion output of 3.7 V. Form factor 18650 means a lithium battery 65 mm long, 18 mm in diameter.

18650 Lithium Battery Working Mode Specifications:

- Maximum voltage of 4.2 V, and even minor overcharging will significantly shorten the service life.

- The minimum voltage is 2.75 V. When reaching 2.5 V, special conditions for capacity recovery are required, With a voltage at the terminals of 2.0 V, the charge is not restored.

- Minimum operating temperature 20 0 С. Charging at subzero temperatures is not possible.

- Maximum temperature 60 ° C. At higher temperatures, an explosion or fire may be expected..

- Capacity is measured Ampere / hour. A fully charged battery with a capacity of 1 A / h can deliver 1A of current for an hour, 2A for 30 minutes or 15A for 4 minutes.

Lithium batteries 18650

It is difficult to find an area where there are no electrical appliances. Mobile sources represent rechargeable batteries and disposable batteries that power the consumer by converting chemical energy into electrical energy. Lithium-ion batteries are electronic pairs with active components containing lithium salts. The shape of the battery resembles a disposable finger battery, but slightly larger, has hundreds of charging cycles, refers to Li-ion 18650 batteries.

18650 lithium battery charger

Lithium batteries are demanding on terminal voltage parameters. The limit voltage is 4.2 V, the minimum is 2.7 V. Therefore, the charger works as a voltage regulator, creating 5 V at the output.

The defining indicators are the charging current and the number of cells in the battery, set by yourself. Each cell (bank) must receive a full charge. The power is distributed using a balancer circuit for lithium 18650 batteries. The balancer can be built-in or manually controlled. Good memory is expensive. Anyone who understands electrical circuits and knows how to solder can do DIY charging for li-ion.

The proposed charger circuit, made by hand for 18650 lithium batteries, is simple, it will turn off the consumer after charging on its own. The cost of components is about $ 4, not a shortage. The device is reliable, will not overheat or catch fire.

Charger circuit for 18650 lithium batteries

In a do-it-yourself charger, the current in the circuit is regulated by the resistor R4. The resistance is selected so that the initial current depends on the capacity of the 18650 lithium battery. What current to charge a li-ion battery if its capacity is 2000 mA / h? 0.5 – 1.0 C will be 1-2 amperes. This is the charging current..

Accumulators and batteries

Energy storage information website

Why the battery of the screwdriver does not charge

If the screwdriver is equipped with a rechargeable battery, then it must be accompanied by a charger. If at one point you find that the battery of the instrument is not charged after you put it on charge, then there may be several reasons for this:

- A defective battery, which happens quite often when the instrument is not handled properly.

- Charging malfunction. It often happens with Chinese instruments, which are much cheaper than branded products..

Despite the fact that there are two reasons for the lack of battery charging, the first step is to check the health of the battery. You can check its serviceability by connecting it to the terminals of a voltmeter or multimeter. If the device shows at least a similar value (12V, 16V, 24V), then the problem is most likely in the charger.

It is important to know! Most chargers are equipped with indicator lights (diodes) that indicate the charging process and its end. If, after connecting the battery, these elements do not show the charging mode, or do not light up at all, then the problem is in the charger itself..

Why the screwdriver battery does not charge – causes and elimination

The reasons for the absence or low level of charge, as well as ways to eliminate the malfunction, are different:

- There is no contact between the terminals of the charger and the battery. This is a consequence of the fact that the memory plates are bent. Gently fold back the plates, returning to working condition.

- Oxidation of terminals or dirt adhering to them. Contacts are cleaned and wiped with alcohol.

- Failure of one of the “cans”. Disassemble the battery pack housing by removing the cover (unscrew the screws or remove the latches). Call each jar with a tester for voltage or discharge current. With tension it is easier – it is either there or not, but this method does not always work. The discharge current is measured at a load resistor – in a faulty can, it is an order of magnitude lower than in a working one. After diagnostics, the faulty jar is separated from the serviceable ones, and a new one is installed in its place, exactly of the same type, and with the same polarity orientation relative to the rest of the elements.

Important! The most difficult part of changing a can is soldering the cans into a battery. At the plant, spot welding is used, and for DIY repairs, a soldering iron is often used. During operation, it is important not to overheat the battery, you need to work quickly.

There is another reason for the lack of charge, but it is characteristic only for nickel-cadmium batteries – the memory effect has worked, and the battery does not charge, although its resource has not yet been exhausted. In order not to bring it to this, it is important to carry out the charging correctly..

How else can you restore battery cells

If, for any reason, it is not possible to restore the battery by replacing the faulty cells, you can try to reanimate them. Just keep in mind that this cannot be done with lithium-ion cans. Only batteries with nickel-cadmium cells can be reanimated.

There are two ways to resuscitate:

- using a vise, pliers or hammer, seal the cans with a detected defect by squeezing;

- make the firmware of faulty cans under high voltage.

Elimination of the “memory effect”

Often the battery needs to recover from the acquisition of the memory effect that appears after repeated short recharges, when it is not fully charged. This disease is recognized quite simply. The battery discharges very quickly after a full charge, but after a short break it can resume its work for a short time. The problem is partially solved in the following way:

- It is recommended to fully charge the battery using a low voltage. After that, applying minimum loads, it should be discharged. Minimum loads provide a slow (smooth) discharge of the battery, which allows all of its plates and the outer layer to sink completely.

For discharging, it is best to use a 12 V light bulb that connects to the side terminals of the battery. A new charge can be made after the bulbs stop burning..

Before using the battery for work, it is recommended to repeat the above procedure 3-5 times. After that, the capacity of the battery may decrease, but using this recovery method is quite successful and can extend its service for at least some more time..

What you need to know?

When choosing one of the options that replace the screwdriver charger, you need to remember: the safety of the process will depend on the correct connection of the devices. In addition, it is important to ensure that the charging mode matches the specifications of the battery itself. Regardless of which version of the charger is chosen, you need to understand: temporary methods can save the situation several times. But it is always undesirable to resort to their use, since only original chargers give the required voltage and current values..

You cannot use chargers with a USB port from a laptop – they are not designed for this. If the battery does not charge, you can try to overclock the battery. To do this, the unit is disassembled and the cause of the malfunction is identified. After that, the unit is charged first with a large, and then with a smaller current. This allows you to bring it back to life if there is still electrolyte inside..

For information on how to charge the battery from a screwdriver without a charger, see the following video.

Restoration of cans

You should not throw away cans that have not been tested. Often the cause of their malfunction is the boiling off of the electrolyte or the leakage of distilled water. This takes place through the rubber band between the battery middle bus and its body. The electrolyte usually boils away with intensive charging..

To check if it can be restored, it is necessary to try to charge the battery, which shows a complete “zero”, with a 12 V pulse voltage passed through a resistance of 40-50 ohms. But at the same time, you need to carefully monitor so that it does not overheat. After charging, check the voltage, and if it is still not there, then the battery must be completely disposed of..

If a small voltage appears in the battery after charging, then it can still be restored. To replenish the boiled-down electrolyte, a small hole is drilled in the side surface, into which only the needle from the syringe can fit. Through this hole, water or new electrolyte is pumped into the battery with a syringe. The drilled hole is sealed with silicone, and you can try to charge it after a day.

Typical malfunctions of the screwdriver charger

Typical malfunctions of chargers include:

- Blown fuse.

- Rectifier malfunction if the device drops the voltage from 220V to 12V.

- Damage to the high-voltage transistor of the inverter.

The rest of the components, as practice shows, work for a long time and trouble-free, therefore, if you suspect a charger malfunction, you should check these three main components. You can repair the charging of the screwdriver yourself. To do this, it will need to be disassembled, which is possible if there is an ordinary four-sided screwdriver in the arsenal..

Forced retreat: energy features of the battery

As you already understood, the device of the screwdriver’s battery is no different in anything daunting. Nevertheless, a series circuit of connected batteries can have an additional component in the form of an installed thermistor (heat sensor), the principle of which is to open the charging circuit at the moment when the temperature indicators reach a critical level – overheating. At the same time, when repairing a battery, you should take into account the output rating of the battery used in the power tool, and also adhere to the identity of the typical layout..

In other words, sufficiently powerful screwdriver batteries (18 volts is a very common standard) are usually assembled from fifteen nickel-cadmium cells. Each individual capacity has an energy potential of 1.2 V. In the case when the device is supplied with a lithium-ion type of battery, the 18-volt battery consists of five cells with a nominal value of 3.6 V. As a result, Li-ion batteries are more compact and lighter than batteries of previous technologies.

How to charge a Li-ion battery in a screwdriver

Brought 6 Makitov devices for repair a couple of weeks ago.

4 screwdrivers, 1 jigsaw and 1 sander.

Straight to the box. Severe.

They told me the price of the repair. It turned out that only one screwdriver made economic sense to restore. The rest went to spare parts.

In general, by itself the time has come to replace the fleet of hand-held battery tools.

So I bought new screwdrivers with Li-ion batteries for all carpenters at once..

Guys are used to Ni-cd batteries, and Li-ion requires a very different approach. Straight to the opposite.

And, of course, it’s not just about how to charge the Li-ion battery of a screwdriver. If it is not properly discharged and / or stored, there will be little good for it either..

Therefore, I looked at a couple of dozen sites and a couple of hours of video.

Threw out all the husks and made the most “dry” without “water” squeeze.

How to charge a Li-ion battery of a screwdriver and other important rules for its use

- Remember —Li — ion is opposite to Ni — Cd!

- Put Li-ion on charge already with a residual charge of 20-50%.

- Important! Do not allow Li-ion discharge below 10-20%. This is a critical value. The smaller the discharge, the longer the Li-ion will work –

| one hundred% | 500 |

| fifty% | 1500 |

| 25% | 2500 |

| ten% | 4700 |

- Li-ion works optimally in the range from 10 to 45 ° C. Charge at a temperature of 10 to 30 ° C.

- Once every 4 months, carry out a full discharge-charge cycle to calibrate the charge level sensor in the battery controllers. That is, discharge to almost 100% and put on charge for 12 hours.

- You need to store Li-ion at a charge of 40-60%.

It is impossible to store 100% charged Li-ion, since in this case it will permanently lose 20% of its capacity in 3 months.

With proper storage – with a charge of 40-60% – Li-ion will irrevocably lose only 1% of its capacity in the same 3 months. - If the screwdriver is equipped with two Li-ion, then charge one up to 40-60% and store it as a backup. Use it as a worker once a month – charge to 100%, discharge to 40-60% and store again.

The second Li-ion is the main worker. Have a job – at the end of each day, put it on recharge, even if it is less than 10% discharged.

Use a backup Li-ion if the main working Li-ion is discharged as a result of intensive work and there is no time to wait for its charging.

That’s all. Now you know how to charge a Li-ion battery for a screwdriver.

I handed this to every carpenter, and even hung it on the notice board in the workshop.

And there may still be a question – why did I switch from Ni-cd to Li-ion cordless screwdrivers?

Here are the advantages of Li-ion batteries over Ni-cd batteries:

- at least 2 times higher specific capacity;

- self-discharge is several times less;

- no memory effect, which makes it possible to recharge at any time;

- withstands on average twice as many “charge-discharge” cycles, that is, it will live twice as long.

Are there any disadvantages?

And finally, if you work professionally with a screwdriver – do not hesitate too much – it will crumble at the same time as the Li-ion battery. So you probably won’t have to buy a separate Li-ion battery..

Just with reasonable non-vandal use, a screwdriver should be enough for a couple of years.

And, yes, one more important rule. Do not skimp on the power of the screwdriver. It corresponds to the voltage of the battery. Take with a 20 volt Li-ion battery at least. Will twist like a beast.

And buy a weak one – there will be little use from him, and there will be no joy from a penny saving either.

In general, I took screwdrivers with 25 volt Li-ion batteries. The carpenters will not get enough of it. Especially after 14 volt Ni-cd.

Look like that’s it. If you still have questions, do not agree with something – write in the comments.

- Types of batteries used to operate the screwdriver

- Battery charging features

- How long does it take to charge the batteries of the screwdriver?

- Do I need to charge the batteries before storing?

- What to do if the screwdriver battery does not charge?

How long does it take to charge the batteries of the screwdriver?

As a rule, the charging time of the screwdriver battery is indicated in the instructions for the tool. These recommendations should be carefully followed. Often the charger has a special display system to help you understand how the charging process is going. Thanks to this, you can easily determine with how much to charge the battery of the screwdriver. When charging is complete, you need to interrupt it in time so as not to damage the batteries. On average, the charger battery for a screwdriver can recharge from about half an hour to 7 hours. Practice shows that a Ni-Cd battery with a capacity of 1.2 Ah is charged with a current of 250 mA for about seven hours. Charging current is maintained using the mains adapter.

It should be borne in mind that there are two types of battery chargers – conventional and impulse. A standard conventional charger is more often used in a non-professional tool, it charges the battery in about 3-7 hours. Pulse – more suitable for professional mechanisms. Thanks to it, the battery performance can be restored in a maximum of an hour..

Tools

Among power tools, both household and professional, the screwdriver is one of the most demanded. With its help, you can not only twist and screw in self-tapping screws, but also drill holes. Mains-powered tools cannot be used always and everywhere, and the cord interferes with work all the time. Cordless screwdrivers are relieved of these disadvantages. With them, you can move freely and not depend on the presence of an outlet in the room..

An important element of every cordless tool is the battery, which allows you to work with it autonomously. This is very convenient, but sooner or later, each owner of such a power tool faces the question of how to charge the battery of a screwdriver.

Battery charging features

How to properly charge a screwdriver battery so that it lasts as long as possible?

Batteries need to be charged before using them for the first time as they discharge during storage. In order for the battery capacity of the screwdriver to become the maximum possible for the nickel-cadmium cell, it is recommended to charge it three times and then discharge it. Thus, since the new battery has incomplete capacity, it must be brought to full working capacity. After that, the batteries will need to be charged as soon as their capacity becomes minimum. Lithium-ion batteries are easier to use. They do not have a memory effect, so you can not bring them to full discharge and charge when it is convenient.

When charging, you need to take into account the optimal temperature regime of the process. It is better that the ambient temperature is above ten degrees and does not exceed forty. Batteries sometimes get warm during charging, but this should not be the case, as overheating adversely affects their performance, and they need to be cooled. It is undesirable to leave batteries in the charger. Yes, and it is better to store them by disconnecting them from the screwdriver, separately from the tool itself. If the batteries are not used for a long time, they should be recharged once a month..

It is better to buy rechargeable batteries at specialized points of sale. Correct use will help increase their service life. During operation, it is undesirable to discharge the elements completely until the engine stops. They will need to be charged as indicated by their markedly reduced performance..

Do I need to charge the batteries before storing?

If the cordless tool is not used for a long time, experts advise you to carefully consider the battery cells..

It is recommended to discharge nickel-cadmium batteries before storage, but not to zero, but to the point where the instrument stops working at full capacity. For long-term storage, to restore the capacity of the battery, it is necessary to carry out 3-5 complete cycles of its discharge and charge. During the operation of the tool, it is also advisable to ensure that the battery is not partially discharged before charging, but completely..

Nickel-metal hydride batteries have a higher self-discharge rate than previous cells. They are recommended to be kept charged, and after a long “rest” to charge for about a day. Partial discharge is preferable for this type of battery. Their capacity decreases after 2-3 hundred charge-discharge cycles..

Lithium-ion batteries, which have no memory effect, can be charged at any time, whatever the degree of discharge. These batteries have the lowest self-discharge rate at a high capacity. It is not recommended to fully discharge them, as this may disable the protective circuit. Power tools with such batteries are equipped with control electronics that disconnect the cell from the load when the temperature or voltage rises. It is recommended that these batteries be kept 50 percent charged. The number of charge-discharge cycles does not affect the capacitive characteristics of the cells, however, their life is limited by time and is about two years..

Types of batteries used to operate the screwdriver

Before purchasing new batteries for the screwdriver, you must carefully study the instructions for the device. The tools required for work can be professional, household and semi-professional. Batteries for them differ from each other in capacity, quality and price..

For certain jobs, certain types of cordless tools are also intended, designed for different loads, therefore, different batteries are needed for them. The higher the power rating of the battery, the longer it can work. For convenience, it is better to have two batteries so that you can recharge the second when working with one. Often a second battery is already included when the instrument is sold..

Various types of batteries can be used for screwdrivers. The most commonly used nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH), and more recently also lithium-ion (Li-Ion).

The most common of these are nickel-cadmium batteries, which are compact in size, large in capacity and at an affordable price. These batteries can be effectively charged over a thousand times, depending on their design, material purity, operating mode, including correct charging. However, these devices have a so-called memory effect, and if you charge them without waiting for a full discharge, the battery capacity will gradually decrease. In addition, the production of such elements is so toxic that the European Union abandoned it on its territory..

In second place in terms of frequency of use are nickel-metal hydride rechargeable batteries, representing a new generation of similar devices. From an environmental point of view, both the production and disposal of these batteries are practically safe. The advantages of batteries of this type include the fact that they have less pronounced memory effect, and the disadvantages. high self-discharge current. These batteries must be kept charged and fully recharged when not in use for more than a month..

More recently, more powerful lithium-ion batteries have been used for cordless tools. They also do not have such a disadvantage as the memory effect, which requires periodic discharge cycles to restore capacity. However, these batteries do not tolerate low temperatures well, and it is undesirable to work with them in cold weather. Despite the fast charge and high capacity, they are not very popular yet, as their price is quite high..

What to do if the screwdriver battery does not charge?

If the battery of the screwdriver does not charge, perhaps the reason is to look for its deterioration or in the malfunctioning of the charger. However, often the problem lies in the disruption of contact between the battery terminals of the screwdriver and the charger, as they unbend over time. In this case, you can disassemble the charger and bend its terminals..

In addition, after some time of use, both the battery contacts and the charger contacts may oxidize and become dirty. Even minor changes of this kind can prevent the batteries from charging properly. This usually translates into a significant reduction in both the charging time and the operating time of the cordless power tool itself. To avoid this, you need to periodically wipe the contacts of the battery, the charger for the battery of the screwdriver and the tool.

Unfortunately, battery cell performance degrades over time. So, with improper use of nickel-cadmium batteries, most often used in household screwdriver models, they quickly lose capacity. Experts sometimes advise to “overclock” such batteries. The battery pack is disassembled and problematic items are identified. After that, they need to be charged. What current to charge the screwdriver battery in this case? Experts recommend that you first charge such elements with a higher current than it should be, then discharge them and charge them again, but with a small current. If the electrolyte has not yet evaporated in Ni-Cd batteries, this “therapy” may help bring them back to life..

In addition, you can restore one battery pack from two that have partially lost their capacity by selecting from them and soldering together whole “banks”. After that, to equalize the charge, it is required to fully charge and discharge the recovered unit several times..

Also, the reason is that the battery does not charge, it may be in the temperature sensor .

What to do if the screwdriver battery does not charge

Cordless screwdrivers are more convenient to use than cordless ones. They are distinguished by their mobility, independence from the presence of an outlet “at hand”, the length of the cord. The only drawback is that you need to monitor the charge level for timely recharging. But not all types of batteries allow you to do this, and at the most inopportune moment the screwdriver stops working. And unfortunately, there comes a time when the battery stops charging.

Battery types

There are three types of tool batteries:

- Nickel Cadmium (NI-Cd). The older generation, which is still equipped with household screwdrivers. Affordable price, good ratio of size and capacity (rather compact), keep a charge in an inoperative state for a long time. The disadvantage is the memory effect. If recharged without a full discharge, then “information” about an incomplete volume is accumulated, it interferes with giving a charge until the real resource is exhausted.

- Nickel metal hydride (Ni-Mh). Improved analogue of nickel-cadmium batteries with cleaner production technology. Although the memory effect is present, it is weaker. The main disadvantage is that they are quickly discharged during storage..

- Lithium-ion. The most advanced type, which is gradually replacing other types in the segment of professional / semi-professional electric hand tools. High capacity, almost complete absence of “memory”, durability, low self-discharge in storage mode. The only drawback is the high cost compared to other analogues..

Important! The price of a 2 Ah nickel-cadmium can is approximately twice the price of a lithium-ion can.

Why the screwdriver battery does not charge – causes and elimination

The reasons for the absence or low level of charge, as well as ways to eliminate the malfunction, are different:

- There is no contact between the terminals of the charger and the battery. This is a consequence of the fact that the memory plates are bent. Gently fold back the plates, returning to working condition.

- Oxidation of terminals or dirt adhering to them. Contacts are cleaned and wiped with alcohol.

- Failure of one of the “cans”. Disassemble the battery pack housing by removing the cover (unscrew the screws or remove the latches). Call each jar with a tester for voltage or discharge current. With tension it is easier – it is either there or not, but this method does not always work. The discharge current is measured at a load resistor – in a faulty can, it is an order of magnitude lower than in a working one. After diagnostics, the faulty jar is separated from the serviceable ones, and a new one is installed in its place, exactly of the same type, and with the same polarity orientation relative to the rest of the elements.

Important! The most difficult part of changing a can is soldering the cans into a battery. At the plant, spot welding is used, and for DIY repairs, a soldering iron is often used. During operation, it is important not to overheat the battery, you need to work quickly.

There is another reason for the lack of charge, but it is characteristic only for nickel-cadmium batteries – the memory effect has worked, and the battery does not charge, although its resource has not yet been exhausted. In order not to bring it to this, it is important to carry out the charging correctly..

How to charge the battery correctly

When buying a new tool with a nickel-cadmium or nickel-metal hydride battery, the battery is fully discharged and charged (pumped over) three times before use. When using a screwdriver, the battery is not charged until it is completely discharged. Then the pumping is repeated periodically as a preventive measure..

Important! To avoid downtime, you need to have a spare battery.

When the full charge is reached, the Ni-Mh and Ni-Cd batteries are disconnected from the network (for lithium-ion batteries, this is done by the controller). During a long break in work, the battery is removed and stored separately from the screwdriver.

With careful handling, following the manufacturer’s instructions, the battery will work for a long time and will not require early replacement. And minor repairs can be done by hand.

Useful video reviews of smartphones and other gadgets on our Youtube channel