Step by step instruction. how to align the machine correctly

Beginners car enthusiasts and those who do not have much experience can be advised to use the services of professionals, both their physical help and advice.

The process of straightening with their own hands is carried out by means of the following steps:

- First of all dismantle the defective elements of the body, you also need to remove the trim and other interfering elements.

- The removed element is placed on a flat surface, it is necessary to outline the existing boundaries of the damage.

- If there are enough big dents, they should be leveled out from the edge, where all the main mechanical damages are. When using a straightening hammer to straighten the body, the dent is gradually reduced from the edge to the center. When carrying out this process, it is mandatory to use the support.

How well the body straightening process is performed, can be simply checked by placing the palm of your hand on the treated area. If there are cavities, they cannot be repaired by simply squeezing.

The process of straightening a car is usually carried out component by component, and the following will describe how to perform this process, depending on which of the elements to be straightened.

Hand tools for bodywork reconstruction

An automatic straightening tool for a car is not the only option for a high quality body repair. Manual straightening of the car is also widespread, for which such tools as straightening hammer, inertial and flange hammers, straightening file and other numerous names of tools are used.

The main difference between body repair hammers and their construction counterparts is the structure of the striker. Its surface is rounded and carefully polished, and the opposite striking side is equipped with a beak-like tip for picking up parts from the inside. Another feature is the low weight, which is needed for a more accurate repair.

An impact tool with beats made of hard plastic is preferable for auto leveling. These hammers are lightweight and do not mechanically damage the surface they are straightening. To save the car paint coating (straightening without painting), it is necessary to use hammers with rubber beats; they will take longer to work with, but they do not scratch the paint.

Types of body straightening

Body sheeting with your own hands requires the motorist specific knowledge and experience. Such repairs can be divided into three types:

-

Correction of dents. In most cases, this is the problem faced by many motorists. Any collision leads to metal crumpling, and the vehicle needs to be straightened on the hood or wing repair. Dents are the most common type of defect. They can be eliminated using the vacuum method.

Rikhtovka car with their own hands: tips and necessary tools

If the result of such a situation was the appearance of serious body defects, for example, dents, partial damage to the paintwork, then you should as soon as possible restore the original state of the machine. To carry out such work will require the preparation of some tools and special equipment.

Choice of method. Before you start the practical part of the restoration of the damaged surface, you should carefully inspect the place of work. If the dent is not deep and there are no traditional dents, there is no point in performing a traditional straightening, since the result is damage to the paint and the surface must be repainted. If scratches and other surface defects are found, then you should stop at the traditional straightening.

Levelling the surface is done by light tapping with different hammers

Alignment tools. Carrying out a bodywork restoration with straightening is a painstaking, narrow profile operation that can only be successfully carried out with experience and the right tools for it. In order to straighten the surface, you will need to prepare these tools:

- Rectifying hammers with a variety of fines;

- Rubberized hammers without inertia;

- Stamps and anvils to fix the surface;

- A blade on which the metalwork will be machined;

- Alignment spoons, which are used to remove sheets;

- Sandpaper and a sanding machine;

- Files for working with non-volumetric bulges;

- Spotter to level the structure using spot welding.

To perform a successful straightening, it is best to prepare several hammers of different types. You will also need to have a locksmith’s tool that every motorist has.

How to work. To perform the work, the part is placed on a flat surface with a covering of batting, felt or synthetic padding that suppresses shock. Smoothing the surface by light tapping with different hammers. If special tools are available, the part is securely fixed in the required condition.

In the process of straightening, it is not superfluous to protect other assemblies, for which a special magnetic attachment is used according to their shape. A reverse hammer is used for repairing dents.

Alignment of internal parts is considered as a simple work that you can do yourself, especially if it concerns the longitudinal members and beams. The biggest difficulties may occur when working with the mating elements. door opening with doors, mudguard with hood, engine shield with frame, etc.

Restoring geometry will already require professional tools and equipment.

Punching and pulling the hooks. This type of work requires a lot of time and effort because you need to remove the damaged bodywork and mark the area of the dent. You need a flat surface for tapping, such as an anvil.

You will need a flat surface for tapping, such as an anvil.

In some cases, the metal is heated to make it soft.

The second method is performed according to this scheme. Screw a self-drilling screw in the center of the problem area and hit it with a hammer to straighten the dent until it returns to its original position.

Pulling out the dent while straightening

Conclusion. If you have decided to perform the straightening of the body on your own, you should consider both the positive aspects and the inconvenience and unpleasant consequences. Even if straightening is completed successfully, it is followed by another responsible and difficult stage. painting.

Dent repairing without painting: step by step instructions with photos and description of straightening (removing) dents on the car from A to Z

The dent on the car is a weighty argument to apply to an auto-repair shop. Even careful drivers face this problem. Let’s look at three reasons why such difficulties arise: collisions with vehicles; inadequate pedestrian behavior; intentional damage, etc.д.

Remove the dent in the car service is expensive, and do not forget about the painting. However, it is possible to solve this problem without the intervention of outside craftsmen. At the same time without suggestive financial and time costs. Therefore, next we will discuss the technique of solving the problem, and select the tools.

The technology

Depending on the type of damage, there are different methods of repair. Before selecting the method of repairing defects, it is imperative to inspect the working surface and properly prepare the car body for the repair work:

- The surface is carefully washed and dried.

- The area to be repaired is degreased.

- Parts that are not damaged are removed or covered with masking tape.

- Conventional straightening.

- Paintless vacuum recovery. Performed with Paintless Dent Repair technology.

- Hot tapping.

- Aluminum restoration.

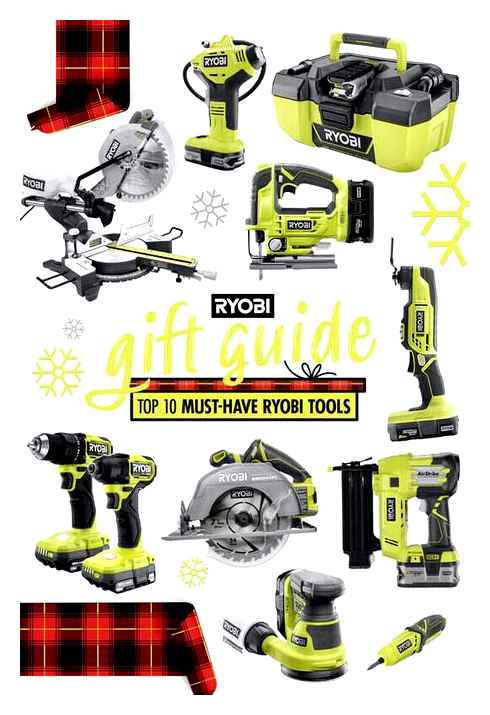

Top 5 BEST Ryobi 18v ONE Tools!

Conventional straightening

Straightening and painting is done by the customer’s own hands. Dents with a special hammer are tapped out, and complex dents are removed with special hooks. Small defects are tapped from the center to the edge, larger ones vice versa. This is done in order to avoid breaking the metal in the thinnest place.

Paintless restoration

Body repair, performed by this technology, is performed without painting the restored element. A special vacuum suction cup is applied to the dent, and the metal is leveled out under air pressure. However, if there are cracks on the surface, this method of eliminating defects is contraindicated.

Hot shrinking

In severe cases, when the traditional methods do not straighten the metal, the surface is heated with a gas burner or a construction hair dryer. Then, using the spiral motion, shape the metal to its original shape.

Reconditioning of aluminum parts

Alumina straightening is performed from the center of the defect to the edges. The defect is tapped out with hammers or pressed out with spoons. Metal straightening is not performed by a spotter, the straightening is performed from the inside of the body element. If the “cold method” is ineffective, the metal is heated to a temperature of 150-200 degrees.

Straightening. Basic steps and concepts

Dents, scratches, chips and cracks appear on the car body in case of careless driving. They negatively affect the appearance of the vehicle. One of the most susceptible parts to damage is the hood. In winter, icicles or snow that have fallen off the roof can fall on it and leave damage and dents. In summer, the body element can be easily scratched by branches. Once damaged, the hood needs to be repaired.

Spotter

The spotter is used for body repair and helps, like a reverse hammer, to tap small deformed parts. This is one of the methods of straightening cars, which is carried out with such equipment. In this regard, this miniature device has a lot of advantages over the conventional device:

- The straightening work is done with high quality.

- Working time with the spotter is short.

- No need to disassemble the car to perform auto repair.

- The unique principle of operation allows the spotter to remove mechanical damage and defects of the body, including hood, fenders, sills.

Spotting by the spotter allows the car owner, who wants to do the repair of the car by himself, to save on costs. In order to choose the right spotter, you should consider the nature of damage to the car.

Straightening tool

Body parts can be restored both with the help of the simplest tools, and with the use of professional devices and stands. Simple tools for restoring “bodywork” geometry include:

- hammers and mallets of various kinds;

- all kinds of supports (anvils, metal bars of all sizes);

- special spoons for pulling metal:

- levers and hooks;

- sanding tools.

There is also more sophisticated equipment, as well as entire tool kits. The standard set of straightening equipment usually includes:

Rack and pinion platforms, special stands are used in professional body repair. When restoring the geometry of the body element with special equipment, the impact on the damaged areas is achieved with great force and precision, the metal is repaired faster and with less labor, and the straightening is of better quality.