EGR valve. defects and symptoms

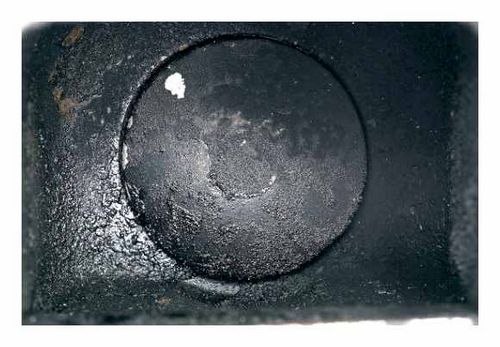

Often the exhaust gas (EGR) valve becomes covered with a mixture of soot and oil. In the photo, friends, you can see what the EGR valve looks like after thousands of kilometers of vehicle operation.

A malfunctioning EGR valve can manifest itself in different ways. Here are the signs that may indicate a malfunctioning EGR valve:

Since the EGR valve with its regulating mechanism is in the exhaust gas stream, it is the most sensitive component of the EGR system. Due to the soot contained in the exhaust gases, the EGR valve adjustment mechanism may not work properly over time. The valve may stop opening or closing normally.

Also, this valve can become dirty due to oil vapors from the oil separator, which, in combination with soot, do their evil deed over time.

As a result of incorrect operation of the exhaust gas valve in the exhaust system, the level of harmful substances can increase significantly. There may also be a delayed response from the vehicle when the accelerator pedal is depressed (throttle response). The most common symptom of a malfunctioning exhaust gas valve is a severe loss of engine power. This usually happens when the valve cannot close properly. Together with the loss of power in this case, black smoke may also appear in the exhaust pipe, which is formed due to the lack of the necessary portion of fresh air at full load.

If the EGR valve (EGR) is stuck when closed, then it is possible that when the car is moving you simply will not notice any signs of its malfunction. But if, with this type of malfunction, you take and measure the level of nitric oxide, then you will immediately find its significant excess from the norm.

A dirty exhaust valve (which also inevitably means a dirty intake system in the engine) can also lead to an increase in fuel consumption. By the way, sometimes all these signs can appear only periodically (not constantly), since the EGR valve can restore its function on its own. However, even temporary symptoms of unstable operation should not be ignored, as this clearly indicates a malfunction. This means that in the near future, problems with the exhaust gas valve will become more frequent and sooner or later this will lead to the failure of this valve.

Cleaning the exhaust gas recirculation valve

If there is a suspicion of a malfunction of the EGR valve, it should be checked first for possible contamination. If heavy soot deposits are found inside the valve, this will clearly indicate a possible reason for the incorrect operation of the EGR valve (EGR). Fortunately for us and you, in most cases, you can clean the valve and restore it to work yourself.

Before you is the EGR valve on the Lexus IS 220d car. To get to the exhaust valve to clean it, just remove the decorative cover on top of the engine and you’re done.

To do this, you must use a spray cleaner designed specifically for cleaning the EGR valves and the entire intake system of engines. As a rule, such cleaners are sprayed on the EGR valve and quite easily clean it from dirt and soot. Most often, the exhaust gas valve cleaner is sprayed with the engine running (follow the manufacturer’s instructions!) Via a hose into the engine intake tract. Thorough cleaning of the valve and the intake system of the engine usually helps to solve the problems of malfunctioning of the exhaust gas recirculation system.

Internal and external exhaust gas recirculation

Internal combustion engines (ICEs) generally have two exhaust gas recirculation systems, i.E. internal and external. The internal engine exhaust gas recirculation system does not require additional components, since it is implemented by the very design of the power unit. So, during the design of engines, engineers adjust the exhaust timing of the valves so that they remain open for a while at the beginning of the intake stroke. In total, part of the previously released exhaust gases is sucked back into the combustion chamber.

With external exhaust gas recirculation, the exhaust gases are directed to the intake channel through an external exhaust gas system pipeline (EGR-EGR system). Many diesel and some gasoline engines use an aftercooler EGR. This cooler cools the exhaust gases using antifreeze (coolant), which significantly lowers the temperature of the exhaust gases not only to reduce fuel consumption, but also to a significant decrease in the level of harmful substances in the exhaust system of the car itself (the combustion temperature decreases).

Is it possible to operate a car with a faulty EGR valve?

Short-term symptoms of EGR valve failure are generally not to be feared. But still, if, due to the operation of the exhaust gas valve, the “Engine check” icon appears on the tidy and the engine goes into emergency operation, then you need to contact the technical center as soon as possible for computer diagnostics of the entire system, as well as Get advice from a car mechanic.

If, during the diagnosis process, it turns out that the EGR valve is stuck in the open position (usually recognized by a loss of power at full engine load), then this can lead to a constant supply of exhaust gases to the intake system itself. As a result, outside the engine partial load limits, the exhaust gas recirculation itself also increases, which leads to incorrect fuel injection. Thus, under full engine load, incomplete fuel combustion occurs. This in turn leads to excessive soot formation, which, for example, in a diesel engine can clog the particulate filter. In the worst case, a malfunction of the EGR valve, which is stuck in the open position, can lead to failure of the turbocharger (turbine).

Exhaust Gas Recirculation in Diesel and Gasoline Engines

At first glance, it may seem a little strange to us that the exhaust gases from the engine do not always and DO NOT immediately exit completely through the exhaust pipe. In fact, these exhaust gases are recycled back to the engine. This technical trick lowers the combustion temperature of diesel fuel, which subsequently reduces the formation of such a harmful substance as nitrogen oxide (NOx). The recirculated exhaust gases displace fresh air in the intake duct, i.E. That low oxygen level in the exhaust gases then absorb some of the combustion heat in the combustion chamber, resulting in a significant reduction in combustion temperature. As a result, the formation of harmful nitric oxide drops sharply.

This EGR valve is vacuum operated. When the valve (inside) opens, it clears the way for exhaust gases into the intake port.

Gasoline engines also use an exhaust gas recirculation system. Here, the return of exhaust gases to the engine serves to reduce the fuel consumption of the vehicle, since the throttle valve can be additionally opened by the pressure of the returned exhaust gases. Thus, the so-called energy losses when opening the throttle valve are reduced, and this helps to reduce fuel consumption and, accordingly, leads to a decrease in the level of harmful substances in the exhaust system itself.

That is why the USR valve should be taken seriously: small but remote.

If the EGR valve stops working correctly, then certain symptoms may appear in the car that clearly indicate to us a malfunction of the exhaust gas recirculation system. Fortunately for us and you, most often it is not to say that the time has come to change the valve itself. In many cases, we can easily fix everything ourselves.

Due to the exhaust gas valve on the “tidy” the engine check is on

Another sign of a malfunction of the EGR valve (EGR) is the appearance of an engine error on the dashboard (“Engine check”). True, such an engine error is not necessarily associated with the EGR valve position sensor, which usually detects an incorrect valve position in some cars.

Malfunction of the exhaust gas valve can also be detected by other vehicle sensors, such as pressure or temperature sensors, which can transmit inconsistent values (data) to the engine control unit due to the lack of exhaust gases in the exhaust gas recirculation system. As a result, we observe that if the sensors detect a malfunction in the engine operation, then the “Check Engine” warning lamp lights up on the instrument cluster of the car.

Also, the error code itself is recorded in the memory of the engine control unit itself, which led to the appearance of the “Check engine” icon.

So, in the computer memory when the “Check engine” icon appears due to improper operation of the exhaust gas valve, an error code may appear which means that “EGR is too low”.

Including such an error may appear, meaning that “Leakage in the intake system.” This error can occur when the valve is stuck open. However, pay attention to the following, friends, that sometimes error codes associated with exhaust gases can mean completely different malfunctions in the engine, which are in no way related to defects in the EGR valve.

Causes of a defective exhaust gas recirculation valve

In case of contamination of the EGR valve (EGR) The most common malfunction is a stuck valve mechanism in the open or closed position. And this is a completely natural process. After all, the exhaust gas valve mechanism is located in the unfiltered exhaust stream, and this will inevitably lead to its failure sooner or later. Usually the exhaust gas valve has a fairly long service life. This is especially true for old cars. But what is interesting is that in more modern cars, this EGR valve fails much faster. For example, in the past, the exhaust gas valve could work for decades on cars and will quietly serve at least 200 thousand km. But modern cars today have already received new software for themselves, which is tuned to lower levels of harmful substances in the exhaust system (in connection with the new toughened environmental standards recently adopted by the EU).

As a result, the software in new cars contributes to the acceleration of exhaust gas recirculation. This is done to specifically reduce nitrogen oxide emissions. So, friends, remember that in modern cars, the resource of the exhaust gas valve has become significantly less than it was in old cars.

In addition, faulty plug contacts of the electric mowing line can lead to malfunction of the EGR valve. Also, damage to the external exhaust gas recirculation mowing line can sometimes be a prerequisite for malfunctioning of the exhaust gas valve. So, for example, the exhaust gas recirculation pipe may simply be damaged and small cracks may appear in it. Including rubber seals may be damaged, which will certainly lead to leakage of exhaust gases. Ultimately, the EGR system will not work properly.

Another common exhaust valve malfunction is associated with loss of oil in the area of the engine block head. In this case, oil vapors resulting from combustion can lead to fouling of the EGR valve.

In this case, cleaning the old, dirty exhaust valve or replacing it with a new one is only advisable if the cause of the oil vapor has been eliminated. Do not forget about the vacuum hoses, which, if damaged, can lead to malfunction of the exhaust valve. The fact is that due to damage to the hoses, vacuum will leak, which will lead to interference when opening the EGR valve.

Finally, a malfunctioning exhaust gas valve can be caused by a broken MAF sensor.

Replace the EGR valve or clean. Which is better?

On some engines, the EGR valve is readily available. But on many cars, to get to the exhaust valve, it is necessary to disassemble half of the engine. In this case, only one dismantling of the valve will cost you a tidy sum. Especially if there is a defect in the valve and you have no choice but to remove the valve from the machine. It is worth noting here that if in your car, in order to get to the exhaust gas valve, you have to dismantle many components in the engine compartment, then there is no point in cleaning it, etc. Work. In this case, it will be more expedient to simply install a new valve, since when cleaning it in the future, you may need to dismantle it from the machine again, which again will be associated with huge monetary costs.

We also draw your attention to the fact that when replacing the EGR valve with a new one in many cars, it may be necessary to re-register the new valve in the engine control unit using a computer. That is, in fact, it will be necessary to teach this new valve to work exactly as it was envisaged by the automaker.

As you already understood friends, to configure the operation of a new valve, you need special diagnostic equipment (computer car scanner). If you do not have such a device, then after replacing the exhaust valve you will have to contact a technical auto center.

How does a lawn mowers carburetor work or how it works

The carburetor adjustment of the Chinese lawn mowers is completely identical to the adjustment of the European, Russian and manufacturer’s lawn mowers. To cope with the task of adjusting the carburetor for lawn mowers and trimmers, you need to understand the principle of their operation. How the carburetor works on lawn mowers is described step by step and accessible below.

- The carburetor of lawn mowers begins with fuel supply through the channel, as shown in the diagram

- The suction of fuel into the carburetor takes place using a pulse channel connected to the crankcase. Due to the rarefaction of air, the flexible membrane moves at number 4 in the diagram above

- Fuel is supplied through valves 3 and 5. Valve 3 is an inlet valve, through which fuel is supplied to the sub-membrane space, and valve 5 is an outlet

- Further, the fuel moves along the channel and, passing through the fine filter, reaches the needle valve 14

- The needle valve is connected via a lever to the control diaphragm 18

- The needle valve is actuated by acting on the diaphragm. When it is necessary to pump fuel in order to start the engine, it is necessary to act on the soft cover of the hand pump. Upon exposure, the needle opens, and the chamber is filled with a fuel mixture

- When the engine is started (cold), the opening of the needle occurs due to vacuum with the air damper closed. This vacuum acts through the idle and high speed nozzles on the membrane 18

- The membrane acts through a lever on the needle valve, whereby the chamber is filled

- After starting the engine, the choke opens, causing the engine to run on a lean mixture as fuel mixes with air

- When the chamber is full, the fuel mixture is supplied (sucked in) through the idle and medium speed jets (when the engine is running)

- At the same time, the throttle valve is displaced from the initial position by 10-15 degrees

- When the work is carried out under load, the fuel begins to enter the chamber through the high-speed jet, and at the same time the throttle valve rotates through an angle of up to 90 degrees (depending on the pressure on the gas). In all operating modes, the air damper must be open, through which the fuel is mixed with air, and thus the mixture is ignited in the cylinder

Below is a diagram of how the lawn mower carburetor works. Based on the diagram You can not only understand the principle of operation, but also identify breakdowns and other malfunctions of the mechanism.

When using the tool, it is necessary to take into account the presence of another jet. This jet is located between the idle and full power channels. It is necessary in order to exclude a strong depletion of the mixture, which happens when the engine is running at partial load. In such a situation, the occurrence of a scuffing couple is NOT excluded. Through an additional channel (jet), fuel is sucked into the chamber, whereby the fuel-air mixture is enriched. The diagram below shows an additional jet, which is indicated by the number 1.

Having an idea of \ u200b \ u200bthe design of a membrane carburetor lawn mowers and the principle of operation, it will not be difficult to customize it yourself. The lawn mowers use adjusting screws to adjust the carburetor. The diagram above shows two adjustment screws, however most modern petrol trim models have three screws. The presence of three adjusting screws allows for more accurate adjustment, while achieving a stable and smooth operation of the internal combustion engine.

It is interesting! What’s the difference between a trimmer and a lawn mower? Many people think that the trimmer is a low-power electric lawn mower. However, the trimmer is a generic name for lawn mowers, lawn mowers and electric mowers, as they are for general purposes.

Adjusting the Husqvarna carburetor

Before adjusting Husqvarna, do trimmer maintenance (use lawn mower and engine, replace spark plug, fix minor defects).

I will definitely wash the foam air filter element. Wash the element in warm water and soap, then wring it out and dry (or replace if old or damaged).

Note: If you adjust a Husqvarna carburetor with a dirty air filter, the fuel mixture will be much leaner after cleaning the air filter (which can lead to poor performance or even engine damage).

Install a trimmer head with a cord of maximum diameter and standard length (up to the cutter blade in additional protection) to put a load on the engine when adjusting the high speed screw of the Husqvarna carburetor.

Start the mower according to the Husqvarna Manual and warm up for 10 minutes (if the trimmer head rotates at idle speed, the idle screw, i.E.

Lower, must be turned counterclockwise until trimmer rotation stops).

Carefully turn both needles (right and left) to the midpoint between fully unscrewed and fully screwed in (do not turn by the stopper! This may damage the Husqvarna engine)

There are three adjusting screws for adjusting the Husqvarna carburetor: right, left and bottom.

1) Right screw L. adjusts the enrichment of the mixture at low speed (controlled first):

Find the maximum idle speed by slowly turning the right screw to the right and left.

Then turn this screw ¼ turn counterclockwise.

Note: From the Husqvarna factory, the right screw has been completely removed (0.5 turn). He is now looking at 11 o’clock. 2) Bottom screw T. adjust the idle speed of the Husqvarna engine (if necessary): turning the screw clockwise increases idle speed, counterclockwise. decreases it.

Carburetor Trimmer Repair Tips

Regardless of the manufacturer, there is a factory defect in the carburetor parts of the lawn mowers.

For example, the tuning method described above may not give positive results with an excessively large number of turns in the springs of the screw for supplying the mixture and, as a result, the impossibility of optimally reducing the level of supplied gasoline. To eliminate this, you can shorten the spring yourself a little or, in accordance with the operating manual, purchase a new one.

Many lawn mower owners follow the fuel mixture recommendations listed there when buying oil.

So, often the information on mixing gasoline with oil indicated on the bank differs from that indicated in the trimmer passport. As a result, black carbon deposits can quickly form on the spark plug, which leads to a drop in power and an increase in fuel consumption. Then, when preparing the working mixture, you should follow the recommendations specified in the operation manual. In most cases, the proportion for a run-in ICE is 1:25. It should be noted that many tool owners prefer to prepare fuel “by eye”, which will certainly lead to rapid wear of the piston streamer in the event of a decrease in the portion of oil and the formation of carbon deposits on the spark plug with an increased amount of lubricant.

Tips for adjusting the trimmer carburetor correctly performed above will help to avoid Not only engine overheating, increased fuel consumption, but also significantly increase the service life of the second parts and tool assemblies

Pay attention to the operation of the lawn mowers in all modes and carry out regulated maintenance and repair of the tool in time.

Major problems

Malfunctions of a lawn mowers carburetor or trimmer, despite the relative ease of their elimination, sometimes require a long search by elimination. The main reasons are:

- Unsatisfactory quality of gasoline cleaning;

- Air filter clogging;

- Accumulation of deposits and carbon deposits in the compartments and passages of the carburetor.

Each of the problems has its own reasons.

Intake control lever is sticking

Jamming of the adjusting lever is a consequence of its incorrect installation, accidental bending. The contacting face will get the wrong position. This will disrupt the additional injection of gasoline.

Failure of the adjusting lever

The wear of the contact edge of the lever is a consequence of NOT completely purified fuel, into which grains of sand or particles of clay, metal, or other inclusions, and not soluble in liquid hydrocarbons, have gotten. There is a problem with fuel injection, the engine operates intermittently without load.

Adjustment diaphragm damaged

The membrane often deforms (sometimes breaks) due to the continuous operation of the lawn mower or trimmer for several hours. If you abuse this “shock” mode of operation, membrane damage occurs more often. New breakdowns will fall like a cornucopia:

- The piston will break;

- The number of unsuccessful engine start attempts will increase dramatically;

- The fuel mixture contains too little gasoline;

- Useful (thermal) power will drop sharply.

Checking the correct Husqvarna carburetor setting

The engine quickly, steadily and steadily picks up speed, and quadruples a little at maximum speed, the T-35 trimmer head should not rotate at idle.

Carburetor cannot be adjusted

The fact that the adjustment is too coarse (it is not possible to accurately set the parameters) are to blame for the springs on the adjusting screws. A lawn mower or trimmer manufacturer may supply unnecessarily thick and stiff springs. You can find others either in workshops where similar equipment is repaired, or purchased from any dealer or official representative of the company that released the motor for your trimmer or power scythe.