How to set ignition to trim tabs

Often, owners of gasoline braids are faced with the fact that the ignition does not work on their equipment. In most cases, the problem is really with this node. To fix it, you need to adjust the ignition to the trimmer. But at the same time, it is not uncommon for the ignition coil to be working properly, and the breakdown must be looked for elsewhere. The ignition system is designed in the same way on four-stroke and two-stroke internal combustion engines, therefore, troubleshooting of this unit is performed in a similar way. In addition, the technique of different brands has almost the same design of this most important component of the tool, and therefore. The adjustment process will be the same as for trimmers. Union or Foreman, and for Huter or samples of second brands.

The first way

You can check the performance of the magneto using a tester. To do this, you must perform the following sequence of actions.

- Correctly configure the tester: use the resistance measurement function and set 200 Ohms to take measurements of the primary winding.

- The first electrode of the measuring device will direct mass magneto and the second. To the output contact. If the primary winding is working properly, the indicators should be from 0.4 to 2 ohms.

- Set the tester switch to 20 kΩ to diagnose the secondary winding. Then the first probe will direct into the candle cap, and the second. On the mass. If everything is in order, the indicators will vary from 4 to 6 Kom, depending on the trimmer model, be it Patriot 547″, Husquarna 128 r or another brand. If the circuit is open, the tester will display an infinity value. And if there was a short circuit, the display will show zero.

Diagnostics of magneto

Magneto. A key component in engine ignition systems. It is a core coil that is surrounded by a primary and then a secondary winding. If this part is defective, there is no spark on the spark plug and the fuel will NOT ignite.

Typical malfunctions

Before you start adjusting the ignition of the trimmer, you need to cut off other probable causes of damage and make sure that the problem is really in this unit. To do this, it is necessary to carry out a number of actions in the following sequence:

- Inspect the ignition coil housing for damage and defects;

- Make sure that there is dirt on all nodes and elements that conduct current;

- Check the integrity and insulation of the wiring, contacts, fastening strength, the presence of rust at the joint;

- Inspect the candle cap, as it regularly comes off the high-voltage wire, and they try to restore it manually, and any unreliable connection reduces the power of the electric arc of the candle;

- Check the spark plug, since the quality of modern gasoline very quickly disables this part, but there is another possible problem. The candle is wet;

- Verify circuit breaker works.

Eliminating all Possible malfunctions, you can proceed to adjust the ignition of the coil.

Features of adjustment on different models of trimmers

The ignition system is designed in a similar way to the various brands, so the adjustment process will look the same. Differences, if any, are insignificant. They are mainly related to the disassembly of equipment. For example, removing the cover from the engine for different trimmers is done with some differences. So, on Patriot devices, you first need to Unscrew the bolts and disconnect the air filter housing with a slotted screwdriver. After that, the plastic cover will be very easy to remove. A detailed diagram and device of a trimmer of a particular model are usually shown in the instruction manual of the tool.

So, you can do the ignition adjustment for a gasoline trimmer with your own hands. This process is not difficult if you know the correct procedure. But first, you need to exclude possible malfunctions of the second units and parts, for example, spark plugs or magneto, which may be a prerequisite for the lack of engine start of lawn mowers. However, when analyzing the equipment of different brands, you need to take into account the likely differences in design, which are described in detail in the user manual.

Trimmer ignition. Principle of operation and Possible malfunctions

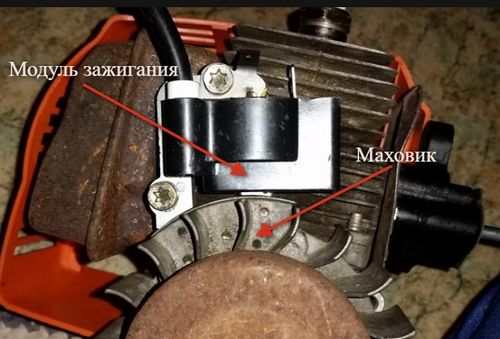

If the owner of the lawn mower wants to adjust the operation of the ignition system on his own, he follows the concepts of the principle of operation of this unit. In an internal combustion engine, it consists of a flywheel and a magneto (coil). In turn, the flywheel includes an impeller that performs the function of cooling the motor and a number of permanent magnets.

How to adjust the carburetor on lawn mowers

Before adjustment, you need to painstakingly clean the filters according to the maintenance in the annotation.

The upcoming do-it-yourself carburetor setting for lawn mowers is done with adjusting screws. There are three of them:

Right (L). Fuel Consistency Adjustment for Low RPM.

It is necessary to find the Highest idle speed. To do this, slowly unscrew the screw (L) to the right and to the left.

To adjust, turn the screw a quarter of a turn certainly counterclockwise.

Lower (T). Responsible for adjusting the engine at idle speed.

- Clockwise. Promotion;

- Counter-clockwise. Decrease.

To properly adjust the idle speed, it is typical:

- Stable cool motor operation;

- NOT overspeed of a hot engine;

- Large headroom for the trimmer head;

- Stable operation of the motor when changing position (sharp lifting or lowering of the knife).

Left (H). Consistency adjustment at high speeds. (The screw is adjusted last).

Here is the left screw (H) the overall adjustment depends on the highest speed, engine power, temperature and gasoline consumption.

The carburetor setting for lawn mowers with the last screw is done as follows:

- Open the throttle to full, with all this, give full throttle. Turn the screw clockwise until the revolutions do NOT collapse (in this case, orientate by ear).

- Return the screw as slowly as possible counterclockwise until the engine runs unevenly.

- Then they will return very little back, just after hearing measured, even work.

- For a more pleasant introduction of abilities, it is more convenient to see the work of an experienced user:

It is curious that, based on the beliefs of the creator, the setting (its correctness) is determined by the color of the candle, and not just by the speed and stability of the motor.

Correct adjustment of the carburetor with your own hands in this case. Combustion of fuel consistency without residue, the color of the candle should be light brown.

- Remove the engine cover from the engine by unscrewing all the bolts holding it. For example, on Patriot (Patriot) PT 2540 lawn mowers, to remove the cover, you will need to Unscrew the air filter housing, and remove it from the latches with a flat screwdriver. After that, the plastic case can be easily removed.

- Using a screwdriver, unscrew the 2 bolts (completely unscrew it NOT required) holding the magneto.

- Turn the handwheel so the magnets are at the top.

- Further, in order to correctly set the best gap between the flywheel and the coil, you can use a regular business card or pocket calendar. If you have neither one nor the other at hand, then, to set up the ignition, you can use a letter of A4 paper by folding it 2 times (in total, you will get a thickness of 4 sheets). This thickness will be enough to get the optimal clearance and adjust the ignition. Insert a business card or paper between the spool and the magnets.

- The magnetic field will pull the coil towards the flywheel. While holding the magneto in this position with your fingers, tighten the bolts that hold it.

- Remove the business card. After that, the trimmer ignition will be adjusted.

How to set the ignition?

You will also like the later trimmer ignition more: the piston, after the compression of the fuel, which has not ignited, goes down, and under such circumstances a spark appears. Under such circumstances, the engine either will not start, or will significantly lose power and it will be bad to gain momentum.

Alas, such difficulties with early or late ignition on two-stroke internal combustion engines are quite rare, since the flywheel with magnets is already installed in the correct position, which is completely synchronized with the movement of the piston. Additionally, the flywheel is fixed to the shaft with a key and nut. After incorrect installation of the part is excluded.

Mainly, ignition adjustment consists of setting the correct gap between the magneto boundaries and the flywheel.

Magneto is the main part of the engine ignition system and is a coil with primary and secondary windings located around the core. Often, due to a malfunction of the magneto, the spark on the spark plug is lost and the fuel does not ignite. To check the coil, you will need to use a tester, and perform the following actions.

- On testers, go to the resistance measurement mode, you need to set 200 Ohms. This method will check the primary winding.

- Connect one electrode of the tester to “mass” coils, and the 2nd. To the contact coming out of the magneto. Normally, the resistance is between 0.4 and 3.2 ohms.

- To check the secondary winding, you will need to set the device switch to 20 kOhm. Further, one probe of the device is inserted into the cap of the candle, and the second. Connects to “mass”. Normally, the resistance characteristics must be in the range from 4-6 kOhm and above (depending on the model).

When the circuit is open, the device will show infinity, and when closed. 0 (zero).

The first way

You can check the performance of the magneto using a tester. To do this, you must perform the following sequence of actions.

- Correctly configure the tester: use the resistance measurement function and set 200 Ohms to take measurements of the primary winding.

- The first electrode of the measuring device will direct mass magneto and the second. To the output contact. If the primary winding is working properly, the indicators should be from 0.4 to 2 ohms.

- Set the tester switch to 20 kΩ to diagnose the secondary winding. Then the first probe will direct into the candle cap, and the second. On the mass. If everything is in order, the indicators will vary from 4 to 6 Kom, depending on the trimmer model, be it Patriot 547″, Husquarna 128 r or another brand. If the circuit is open, the tester will display an infinity value. And if there was a short circuit, the display will show zero.

Ignition adjustment for trim tabs

On gasoline trimmers, both two-stroke internal combustion engines (ICE) and four-stroke are used. But the ignition system in them is NOT different from each other, therefore, the repair and adjustment of this fuel ignition system will be the same for different types of internal combustion engines.