Pendulum (console) machines

Cantilever band saws are the most common type of band saw equipment. Their distinctive feature is the presence of a rotary saw frame. It is hinged and can be raised and lowered up to 90 ° above the work table. They are very convenient for cutting:

- pipes;

- corner;

- channel;

- stripes;

- square.

Often cantilever band saws are used for cutting wood, frozen meat, fish, pressed panels, plywood. Their versatility and compact design determines the widespread use.

Pendulum machines are produced in two main modifications. with a swivel arm, which allows cutting metal at any angle, and fixed ones, allowing only a vertical cut. By the level of automation, they are subdivided into:

- manual;

- semi-automatic;

- automatic.

The Jet Metal Saw is a prime example of a typical jib saw. The band saw can cut metal at an angle of ± 45 ° and vertically. The workpieces are clamped with a special vice, the table can be set in two positions, the cantilever and material feed is hydraulic. Equipped with Jet bimetallic universal belt. Anchor (Corvette) installations are not inferior to them.

Hand-held machines such as the Bomar PULLDOWN are portable and powerful. They can cut metal at 90, 45 and 60 degrees. Workpiece diameter 2014. up to 230 mm (circle) and section 260 x 230 mm (rectangle).

Cantilever band saws are manufactured in a wide range of capacities and dimensions. Choosing a machine, it is easy to find a model that suits your needs.

Types and purpose of band saws for metal

We consider the types of band saws for metal. The main advantages and disadvantages of the equipment. Review of the main leaders of manufacturers. Selection Tips.

Cutting metals with a band saw is an efficient and virtually waste-free way of metalworking. Unlike gas, plasma and even laser cutting, a band saw for metal leaves a very thin cut (no more than 1-1.5 mm), does not overheat the metal, and additional processing of the cut is not required. There are several types of belt-type machines for cutting metals, differing in scope, technical capabilities, dimensions.

Vertical machines

Typically, a vertical hand-held band saw is equipped with a stationary saw unit, with the saw moving in a strictly vertical direction. Metal cutting on a band saw machine is performed by feeding the workpiece manually, the pressure and feed rate are adjusted by the operator depending on the cutting conditions.

Vertical hand-held machines manufactured by Enkor have become widespread. They are known under the brand name Corvette. The universal band saw Corvette 33 can serve as an illustration of the capabilities of the machines of this brand. In addition to steel, aluminum, stainless steel and copper, it can cut textolite, plywood, wood, OSB boards.

The Corvette band saw is equipped with a 750 W asynchronous motor. It is connected to a 220V network, which allows you to use the saw not only in industrial workshops, but also in small workshops or at home. Two gears, which determine the speed of the belt, make it possible to quickly switch to cutting dissimilar materials, which is important when used in conditions of small-scale production or in the work of repair shops.

The Corvette band saw is equipped with an inclined work table with a slope range of 0-45 0. The assembly weight of the machine is only 75 kg, which is very convenient for transportation, for example, when used in construction and restoration. The dimensions of the working table and the power allow processing parts up to 135 mm thick. To increase the degree of safety of work, the Corvette band saw is equipped with a magnetic starter, which excludes spontaneous start when accidentally touching the button.

A manual band saw of a vertical type can also be equipped with a swivel tilt frame, but most often a semi-automatic band saw can be found in a swivel design. This design allows angular cutting of metal without changing the horizontal position of the table. This is important when machining parts of a large area. It is convenient to cut channels, pipes, complex rolled products on such machines.

Vertical band saw equipment for industrial use is also produced with a movable frame that moves along a large working table. Belt machines of this type are used for the production of the same type of parts, and are equipped with a CNC.

Single Column Band Saws

The saw unit with a horizontal saw moves vertically along the support column, advancing on the workpiece and sawing it at a given speed. Hydraulic feed allows you to adjust the cutting speed over a wide range.

Double column (double column) machines

Structurally, they resemble single-column ones, but metal cutting with a band saw is provided by feeding the saw unit along two vertical guides. This eliminates the deflection of the blade when sawing large-sized workpieces and makes it possible to process parts made of very hard alloys.

Some of the best double-column machines are produced by the Czech company Bomar, for example, Bomar INDIVIDUAL, Bomar CONSTRUCTION. They are produced in an automatic or semi-automatic version, equipped with a hydraulic feed system, rotary tables, an intelligent coolant supply system.

Double-column machines are characterized by increased structural rigidity, which gives high productivity and the ability to use CNC. Thanks to this, they are widely used in the engineering industry. Often used as cutting machines.

Principle of operation

The band machine is based on the use of an endless (closed) metal band as a working tool, with teeth cut on one side. Most often, bimetallic saws are used, in which the main part is made of strong steel (spring steel or similar in elasticity and strength), and the teeth are made of tool steel or extra strong alloys.

The band saw is driven by pulleys, one of which (the lower one) is connected to an electric motor. The peculiarity of the movement of the saw towards the workpiece eliminates the ejection of sawdust or parts of the tape in the event of a break in the direction of the operator. This determines the safety of the machine when cutting both flat sheet and complex profile rolled products.

Band sawing machines are regulated by the speed of the band, which is selected depending on the type of metal. The saws themselves are made with different tooth shapes, interdental distances and sharpening angles. The design of most machines allows you to quickly change the saw band if you need to switch to another type of metal or rolled products.

saw base

Cut off two pieces of a square pipe 54 cm long and one piece 19 cm long. Cut off the ends of the pipes at an angle of 108 degrees. You need to weld these pieces so that they form the letter U, in which the corners will be equal to each other. The finished frame should be stable on the table. Therefore, all irregularities that formed during welding must be removed and sanded. The photo shows that the weld spot on the right side was cut with an angle grinder to prevent swaying.

we put the frame vertically

Here the angle should have been measured, but it was simply determined by eye. Make sure that the frame does not cover the arm of the saw that is hung on it. The angle was not 90 degrees, but 81. The frame turned out to be 54 cm high.

In this case, welding was enough to hold the entire structure. No other fastening methods were needed.

second saw holder

To hold the saw upright, a 2 cm wide steel angle was attached to the handle. Make sure the length of the steel angle is the same as the width of the saw handle. Move the angle between the saw and the frame until the blade is absolutely vertical. Now we weld the corner so that it doesn’t move. Remove the saw and weld two short pieces of steel to the corner. They will hold the saw so that it does not move left or right.

DIY metal band saw

This easel band saw for metal was made from hand held band saw.

- Plywood 0.3 cm thick

- 2.5 cm square tube

- 1.25 cm square tube

- Round tube 1.25 cm wide

- Iron corner 2 cm wide

- 10-24 slotted head screws

- Plastic insulating tape

- angle grinder with cutting disc

- Welding machine

- Magnetic holder

- Clamps

- Clamp

- Angle measuring tools

- Punch

- Drill

- Locknuts

Making a saw table

If you have 0.3 cm plywood left over from previous projects, then this is fine. Although some people use 0.5 cm, 0.3 cm is sufficient.

Cut the plywood so that you get a square piece with a side of 20 cm. Mark the middle of the square. Saw the square from one side to the center. The band saw blade will pass through this gap.

Consider the second photo. The plywood is attached to the base of the saw with three screws. Use masking tape to mark where you will be installing the screws. Check the position of the screws using a right angle. Take out the plywood and rotate it 180 degrees. Then the line cut for the saw will be in the back and the smooth part in the front, so the table will be easier to use. Punch holes in the plywood to match the threaded holes in the band saw.

Tighten the screws deeper, drown them so that the heads do not protrude from the plywood surface at all. Before hanging the plywood on the machine, make sure it is the correct size. you may need to cut it.

Consider the third photo. The blades of these saws are cut at a slight angle. It will be easier and more accurate to work if there is a gap in the table through which the saw blade passes. Also, the slit prevents the blade from sliding.

We attach the saw

We bend a rod 0.5 cm thick. This will be the holder for the saw. It was necessary to hold the bent rod with a clamp while it was welded to the frame.

Note that pieces of sheet metal were used to make the open end caps for the square pipes.

third saw holder

Cut and weld a piece of a square pipe 1.25 cm wide. Weld between the legs of the base. This keeps the saw stable and does not wobble. Where necessary they wound the electrical tape. Tape allows the saw to sit firmly in the nest. However, removing the saw from the slot to change the blade is easy enough.

In the process of testing such saws that were performed earlier, it can be said for sure that the screws are able to unscrew themselves from the plywood due to vibration. They should be put on glue when fastening.

A switch is used to turn the device on and off. It is hung on the leg of the device. The saw shown in the photo is connected to an outlet with a switch.

Tip: when attaching such parts that require precision, it is better to avoid welding, as it can distort the desired proportions.

Testing has also shown that some small parts can get very hot when sawing. Keep this in mind. The cutting speed of such a saw is not very fast. you can also cut with a hand-held bow saw just as quickly, but the plus is that the band saw cuts and cuts, and you do not need to take a break. You can also see that the line cut on the table proved to be very useful when working. Allows you to teach a more accurate and even cut.

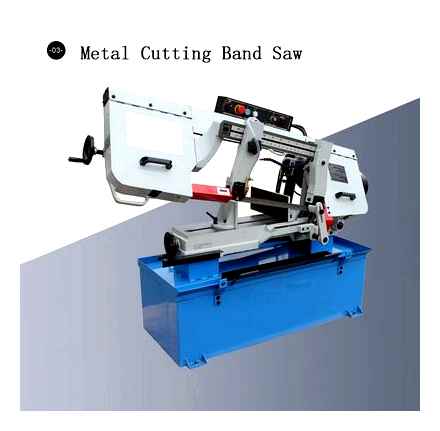

Horizontal band saws for metal

As mentioned earlier, there are different types of saws available. This particular type is defined as such due to blade placement, movement, and overall design.

Homemade Metal Band Saw

Its mechanism is quite simple. It consists of wheels on which the blade rotates indefinitely when cutting material. It also features a holding or clamping mechanism to ensure proper protection of the workpiece during machining.

First, mark the places where you want to cut. Then you make some changes to the machine settings, such as speed, knife tensile strength and safety measures in case of breakage.

Metal band saw

After setting the object in position for precise sawing, a band saw for cutting metal from the company www.vgu.com.ua comes into play at the link https://www.vgu.com.ua/metaloobrabotka/lentochnopilnie-stanki_m/. With access to an elaborate model, you can cut virtually any piece to the size you want. This is less than a metal cutting band saw can help you.

A band saw is a type of hydraulically driven saw that consists of a long, continuous “toothed” band (saw) used to cut various materials. The belt is held in place between several wheels, usually two, to allow continuous rotation and cutting of the belt.

There are many good band saws available, but what sets a horizontal band saw apart is that it is designed to hold the material while cutting. This allows the metal saw blade to make clean and precise cuts as needed.

Using a band saw

Versatility is a key aspect of this tool, so the band saw can be used in many applications for any project available. Some of them will be highlighted below:

Cut out large pieces. This is one of the main features that makes the horizontal saw an excellent tool for the workshop. It is able to handle large pieces of material and cut them to size. It does this accurately and quickly, increasing efficiency and productivity.

Cutting metal blanks. Based on one of the above points, the quality of the blade used allows you to cut metal. Horizontal band saws for metal cutting allow you to change the blade depending on the material you want to cut, and here you can insert a stronger blade that is more suitable for cutting metals.

Processing large volumes of cut. Given that it is a powered tool and does not rely on “hand power”, it can operate for a long, uninterrupted period of time. This means that it can do a lot of work compared to manually viewing the material.

May 5, 2013

What a band saw is made of

There are the following types of materials from which band saws are made: tool steels (“tool steel saws”); high-speed steels (“bimetallic saws”); carbide (“carbide saws”); artificial diamond (“diamond saws”).

Tool steel band saws

These band saws are manufactured from a solid strip of high quality alloy and hardened carbon tool steel. A hardened cutting edge and an extremely flexible backing strip guarantee the high quality of these blades. The hardness of the cutting edges of the teeth does not exceed 50HRC.

Such saws are mainly used for sawing simple materials: unalloyed steels with low tensile strength, for cutting composite materials, for friction sawing on special machines. They are most suitable for use in the repair shop environment.

Bimetal Band Saws

The base blade of such a band saw is made of elastic spring steel (analogue. 45HGNMFA). A high-speed steel (HSS) profile wire is welded to the base blade by electron beam welding, after which the sawtooth profile is milled.

After the subsequent heat treatment, the cutting edges of the saw teeth have a hardness of 67.5. 69 HRC, and also have the outstanding wear resistance and redness characteristic of high-speed steels. This makes it possible to successfully use bimetallic saws in processing up to 90% of steels and alloys used in industry.

Depending on the brand and composition of high-speed steel, bimetallic saws of almost all manufacturers are divided into 2 main types. M42, M51 and M71.

For bimetallic band saws: М42 (analogue 10Р2М10K8). The exceptional quality of this material is the wear resistance of the cutting edges of the saw blade teeth. The decisive factor here is the size of the carbide particles and their uniform distribution (in the presented structure, the white tungsten carbides are evenly distributed in the heat-resistant martensite base). The hardness of the cutting edges of the teeth is 67.5–68.5 HRC. This material is suitable for sawing all major steel grades with hardness up to 40-45 HRC.

M51 (analogue 12P10M4K10). Higher tungsten increases the amount of carbides and therefore increases the resistance to abrasion. High cobalt increases the redness of the cutting edge.

This allows this tool to be used for cutting high-strength, stainless and heat-resistant steels, including workpieces with a large cross-section and hardness up to 45 HRC. Cutting edge hardness 69 HRC. The durability of such a band blade is usually 10-20% higher than that of saws with M42 cutting edge material. M71. This material occupies a special position, as it is obtained from high-quality high-speed steel by powder metallurgy. This made it possible, in contrast to high-speed steels of traditional production (M42 and M51), to achieve the following advantages: 1. To obtain a fine-grained structure with a more uniform distribution of dispersed carbides. 2. Significantly increase the hardness (up to 69-70 HRC), wear resistance and heat resistance, while maintaining the technological plasticity of the material. 3. To increase the reliability of the tool due to a decrease in the likelihood of the formation of defects during cutting, such as burns, chips and microcracks. 4. Increase tool life up to 25-50%.

Sawing austenitic, stainless, acid-resistant and other exotic steels and alloys is no longer a big problem thanks to the combination of the new high-performance M71 cutting edge material and the optimized geometry of the M42 and M51 bi-metal band saws. Carbide Band Saw Blades

TOP-10 of the best band saws for metal, an overview of tools and technical characteristics

In a domestic or industrial setting, a circular saw can cut thin metal sheet, but it cannot handle thick metal workpieces or make shape cuts. In this case, a band saw will come to the rescue, which can cope with any thickness of metal, the main thing is to choose the right blade.

Jet HVBS-712K 414459M

The American-style metal band saw is equipped with a reliable and powerful motor that can work for several years without breakdowns. It has quick-clamping and swivel discs, a built-in lubricating-cooling fluid system, which cools the workpiece during cutting to avoid overheating. The machine can work not only horizontally, but also vertically. With the help of a belt drive, one of four belt speeds is selected. Connects to 220V power supply.

JET J-349V 50000333M

A compact band saw takes up little space indoors, easily handles metal profile blanks with a diameter of up to 12.5 centimeters, so it is most often chosen for small workshops. It has smooth speed control and low vibration. The saw blade is securely and easily attached, giving an even cut. The equipment can be moved independently without resorting to lifting mechanisms.

Top 10 best models

The top of the best models includes both floor and table band saws. While the former are massively used in production, the latter are purchased for households or private workshops. The best metal band saws have a powerful motor and can handle hard metal with ease.

TRIOD BSM-115/230 211015

This small vertical band saw is designed for cutting not only metal but also wood. High-quality assembly guarantees a long service life. Sawing is done vertically or at an angle. Reliable vise eliminates displacement of the workpiece during operation. During operation, the speed is regulated from 20 to 50 meters per minute. The machine has a special tray for storing tools. Even a beginner can handle a saw.

Jet HVBS-712K 414459T

Unlike the above-described machine for metal, this semi-professional one works from a power supply of 380 V. It has a hydraulic feed system and an automatic cut-off switch. Thanks to the powerful motor, this machine can withstand heavy loads and is able to work for a long time. Quick-clamping and firmly holding vise rotates up to 45 degrees. The set includes a wire brush for cleaning the workplace from shavings.

ENKOR Corvette-422

The cheap model hit the top thanks to its high-quality assembly from reliable components. It works with different types of materials, including metals, has a rotary vise and a cut length limiter. The belt drive protects the engine from overload, extending its service life. For convenience, it has an additional work table. Vibration and noise during operation are practically not felt.