What is a bow saw??

A saw is a tool with many cutters, usually teeth, for cutting (sawing) various materials: wood, metal, plastic, stone, and others. A saw is usually in the form of an elongated metal plate or disk with teeth on its working edge.

When you need to cut boards lengthwise, look for hacksaws with teeth that are angled forward. When choosing a wood hacksaw, pay attention to the comfort of the handle. The grip needs to be secure, without slipping. A handle with a rubber grip is best.

Why a compound bow saw is needed?

Short, mostly cross cuts are best made with a jigsaw, longer, longitudinal cuts with a wood saw. And only with a beam saw can a variety of separation cuts be made, and with both dry and wet wood. In addition, the way the wood is cut lengthwise or crosswise is irrelevant to the archer wood saw. If you add to this the possibility of working with one hand (the first “onions” were exclusively two-handed), then it turns out that the tool in question can be used for cutting wood:

The only insurmountable obstacle for the archer saws are the cross dimensions of the workpieces. for thick logs it is still better to use a mechanized tool. However, thick logs are much less likely to be handled.

Do you know which is the best wood saw??

There are three things that make the archer wood saws versatile:

- Adjustable tensioning of saw blade (this process is something like bowstring tensioning, that’s where the name of the tool appeared from). Testing shows that in beam saws tension forces of up to 100120 kg can be created without destroying the saw blade.

- The special shape of teeth, allowing both roughing and finishing cuts.

- The compact dimensions of the saw allow it to be used even in cramped spaces.

Modern manufacturers of beam saws and their accessories. Bahco, Stanley, Intertool, Fiskars and other trade marks. complete their products with different types and designs of saw blades that increase convenience of the tool use.

Block: 2/4 | Number of characters: 1668

The onion saw. Top 5 reliable and quality woodworking tools, and not only

It is considered an essential tool for carpentry work is the onion saw. The device has long held a place of honor among the tools needed for household issues. Only design and weight of the saw blade change to make it easier to work, but the principle of operation is the same. This article will discuss the principle of operation, components, and some models of archer saws.

“Building the Historic Howarth Bow Saw” DVD is Here!

Comparison with a hacksaw

There are some similarities between the hacksaw and the bow saw. First, both are designed for woodwork. And secondly, they are an indispensable tool of a person engaged in household chores.

But still, a hacksaw and a bow saw are different tools, and their purposes are different, and so is the device itself:

- The archer saw is designed for neat sawing, as well as for carving various shapes, which cannot be said about the hacksaw;

- Archer saws weigh less than hacksaws and are more convenient to use;

- When using a bow saw, several people can be involved in the work, while this is not allowed when using a hacksaw;

- the saw is easy to look after.

A bow saw and a hacksaw are two different tools, each of which is necessary for the handyman to be more efficient in his cottage or home activities.

The Bow Saws and their Varieties

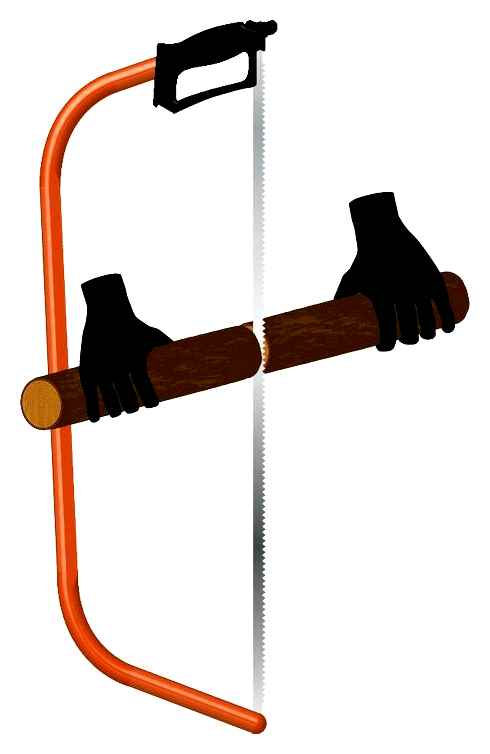

There are many kinds of “archer”, but each of them has the same type of device and consists of the following elements:

- The beam jumper, which is available in several lengths: 35 cm, 53 cm and 76 cm. The shape of the frame depends on the length, which comes in the following types: in the form of a rounded trapezoid. for long tools, in the form of a rounded triangle. for short instruments;

- saw blade, which is designed for cutting various materials, the shapes of the blades and teeth differ from each other;

- the handle of the device, which is made of better quality, because it is on it depends the convenience, as well as the ability to make maneuverable movements of the tool;

- devices for tensioning the saw blade. It is the middle, the stand, the bowstring that holds the saw. But it should not be given weight by these components, otherwise the device will be difficult to use.

When selecting a tool, it is important to familiarize yourself in detail with the structure of the archer saw. It is also necessary to determine the size of the blade and understand whether the unit is comfortable to hold in the hand, whether it is possible to make maneuverable, fast movements. All this will help you choose a device quickly and without problems.

All beam saws are divided into the following types:

- folding is designed to be carried around. The unit may be required, for example, in a camping trip, and it is good when it is available at hand;

- two-handed is designed to work together if a lot of effort is required.

- wooden is designed for dressing wooden products, structures. If not used as intended, the device can quickly fail;

- tool for metal is made of quality hardened steel, so that the device will not blunt and last for a long period of time, it will not break.

Of course, there are other types of “archers” that handle other materials. You can find out the specific model at the store where you are going to buy the device.

Types of blades

Since the archer saw is mainly used when working with wooden products, the following blades for the archer saw for wood are distinguished:

- A blade that has single teeth spaced equally apart. Such saws are used for smooth, accurate cutting of material;

- cutting part that has double teeth (or also called the “Kremlin” tooth). This tooth position is intended for a more complex and precise cut. If the pitch of the teeth is not too frequent, then the material will be cut qualitatively and accurately, there will be few chips;

- saw blade with teeth arranged in two rows at a fixed distance. Heavy material that is difficult to cut is cut with these teeth.

The material from which the cutting blade is made is high quality steel. It is desirable that it be hardened, t.к. This guarantees a long service life as well as good, fast work with various types of materials.

You should also pay attention to the teeth on the cutting part of the saw. They are of the following kinds:

- for dry and hard wood, the tool is used, the teeth of which are shaped as an isosceles triangle, the cut is obtained neatly;

- For dry wood there is a saw blade with teeth in the shape of an equilateral triangle;

- for raw wood, it is recommended to alternate teeth in the form of an isosceles triangle, multilateral, as well as the presence of double teeth, so that the cutting was much faster.

Top 5 in price/reliability ratio

The “onions” range is undoubtedly large, but there are some brands and types that occupy the leading positions. Let’s look at the best of the best, with high ratings among customer reviews.

BAHCO 10-30-51

Single-handled buzz saw. has a simply stunning performance. With its low weight of 900 grams, it can be used for a variety of applications. But its main purpose is to process dry wood. 76 cm long saw blade with triangular teeth. The tool has a comfortable handle, thanks to which the hand of the master will not slip, the work goes quickly, without delays.

Fiskars 1000615 (124810)

The Finnish company Fiskars produces only high-quality saws. The saw is made in the shape of a cupped trapezium, t.к. long enough (70 cm). This device is necessary for the home, t.к., has a low weight (770 grams), secondly, it has “Kremlin” teeth, which alternate with the usual ones, so you can saw both forward and backward. Also, the device has a very comfortable handle, thanks to which the handyman does not get tired of the work. Its main purpose is cutting thick branches and small tree trunks.

Working rules

To make your work with the onion saw comfortable and safe it is worth observing the following recommendations:

- insert the blade into the slots of the handles and fix it with dowels through the side holes

- bring the saw to your chest so that the bowstring touches your body and with one eye carefully examine the position of the blade. Its position must be strictly perpendicular to the line of sight

- by slowly and carefully turning the handle it is possible to achieve an even position of the toothed blade in the fixing holes

- after adjusting the blade slowly turn the handwheel to tighten the bowstring and stretch the struts to keep the blade firmly in place

- do not sharpen or dress working blades for archer saws by yourself. The best option is to buy factory-made blades, characterized by sharpness and accurately aligned “toothed” blades

- it is impossible to be distracted during work, because together with a board it is possible to saw off and some fingers it is not necessary to throw a saw sticking out in a workpiece during a break, because it is possible to break a blade, and to begin work from such position is very difficult.

Before you start, it is necessary to check the tool and make sure that there are no cracks or defects on the wooden parts of the uprights and that the bowstring is intact.

To make the cross-cutting cut as convenient as possible wooden workpieces should protrude (“hang off”) from the immovable support. Experienced craftsmen start sawing from the thumb nail of the hand holding the beam or bar. After the blade has “gnawed into” the workpiece, it can be leaned lightly not on the fingernail, but on the thumb joint. But for maximum accuracy of cut, as well as for making curved cuts, it is worth using templates or a jig.

The arbor saw is excellent for longitudinal sawing. To do this the blade must be clamped at an angle of 0˚ to 90˚ in respect to the horizontal bar. Pressure applied will be less than that of crosscut sawing, so the procedure will take a little longer. This kind of sawing is done with both hands. Masters recommend to dispose a board or a bar in a horizontal plane and move the saw towards yourself, holding the handle and the side post.

If you need to make a curved cut is to buy a narrow blade, the width of which does not exceed 8 mm. Blades for curved cuts are sold with rectangular teeth and a considerable degree of separation, up to about 2.5 nominal of the nominal thickness of the entire blade. If you need to saw a thick board with many knots or oblique layers of wood, you need to choose the widest blade, up to 5 cm wide. It should have a small pitch, but a considerable thickness. It is not recommended to make a curved or curved cut on such material.

Wood buzz saw

Among the wide assortment of hand saws and hacksaws, there is one quite common type of saw. the onion saw. This tool can be in the version for cutting metal parts, as well as to work with wood materials. In this article, we’ll talk about the onion saw on wood. you’ll learn what it is a tool, what are its features and what you need to know to buy a bow saw.

Design of beam saw

Let’s start with the most important thing, the design and function of the compound bow saw. It is used for a longitudinal cut and consists of a special beam, in which the saw blade is stretched. In its turn, the beam itself consists of 2 uprights and handles, as well as a strut, tensioning bowstring and locking twist. Also, instead of a twist, you can often see a screw with a nut that connects to a metal spud. There are cupped beam saws that are used for cutting in a curved line.

If we compare a normal saw (two-handed or hacksaw) with the bow saw, the considered tool has some advantages compared to the normal saw.For example, a bow saw helps to obtain a more even and accurate cut, and it requires much less effort and effort than a hacksaw, for example. In addition, in some cases, the onion can be worked by two, which can not be said about the hacksaw.

Another advantage of the bow saw is the ease of operation and maintenance. For example, a blade for a bow saw does not need to be sharpened, adjusted, or adjusted. a worn blade just need to be replaced with a new one. It should be noted that the clamped beam saw blade almost never jams in the kerf.

Yes, it can be difficult to move the saw in some cases, but in general it does not “jam” the saw permanently, which cannot be said about conventional saws.

For all theirvschestvosimilarity, onion saws from different manufacturers will differ from each other, and in some cases, quite significantly. So, differences exist practically in all structural parts of the tool. it may be different shape of the beam or handle, different way of fixation and tensioning of blades, as well as their tensioning.

Consumer analysis of the archer saws for wood

The Proline beam saw.Designed for cross or rip cuts and.suitable for curved cuts. Like many similar tools, it consists of a bow, in which the saw blade is stretched. In turn, the beam has two struts, spacers, and a tension string. The length of this model saw is 760 mm, which allows her to work with medium-sized logs.

Stanley Raker Tooth beam saw. Designed for medium-speed work with small pieces of wood. The oval cross section of the steel frame gives the tool high durability. Also includes a blade tensioning lever so you can change blades faster if needed. Material of this tool is tool steel, machined and hardened. The American tooth shape ensures that no sharpening or preventive maintenance is needed. It allows the tool to cope very well with both fresh and dry lumber.

Bahco beam saws.Bow saws from the company Bahco presented in different versions, but the most popular models are considered saws 530 mm and 760 mm. These versions are perfectly suited for pruning because they can be easily pulled between the branches to make the cut. But, for all that, to saw with one of these saws is possible only for thin-section timber. For example, a log with a diameter of 10 cm will be very uncomfortable to saw. the bow will catch on the log and the blade will bounce all the time when sawing.

Gardena onion saws.Among the features of this producer’s saws are a screw blade tensioner, as well as an adapter that can be used to attach the rod. In addition, this saw comes with several different kinds of blades. There are models with different lengths, like 750 mm or 350 mm, the difference, as you can see, is considerable. Saws from this manufacturer have unique features.

For example, the 350mm saw has the ability to rotate the blade 360°, fixing it in any set position.Wood buzz saw has an oval tube cross-section, trapezoidal shape with a length of 750 mm, which helps to tightly install the fixed pins with punches, etc.д. The handle of such a tool is quite massive, with rubberized inlays, which makes working with this tool more comfortable.

Otherwise, all kinds of presented saws, have excellent reviews, to buy a bow saw is enough to choose one of the presented models.

Design

The saw is called a “bow saw” not because it can be fired, or even because it resembles Robin Hood’s weapon, but because it is designed with the same principle of resilience as the ancient bow.

At the heart of the entire design is a machine made of sturdy, well-finished and often lacquered struts. Only three uprights. two on the sides and one horizontal. Stands are made of hardwoods, such as oak, hornbeam, or ash. There are identical symmetrical through holes in the bottom of the uprights to attach the handles. The horizontal bar is called the middle bar. The working handle is not even a carpentry art, but a carpentry art, because comfort and productivity level of the whole work depends on its quality. Handles are rounded, with cuts and holes at the end to secure the blade.

The beam saw blade is often a thin strip of tool steel with a slight “jaggedness”. The wider the blade-blade width, the less maneuverability of the whole saw, and the less tensioning force in the clamps.

Any archer-type saw has a bowstring, making it even closer to the throwing weapons of ancient times. However, the purpose of such a bowstring is absolutely peaceful. it is necessary for a firm and reliable tensioning of the blade between the handles. The string is made of natural materials, such as linen rope or hemp twine. Synthetic material is not worth it. Their resilience and durability are not sufficient for cutting solid wood.

What is the name of the long saw?

A two-handed saw is a tool with many teeth for cutting (sawing) wood. Made in the form of a metal plate with teeth on the working edge. Handles are usually made of wood. Designed for two people to work with, although with some skill you can also saw with a two-handed saw alone.

A hacksaw is a manual joinery tool, which is a kind of a sawHacksaws are therefore divided into three categories:

What is the best wood hacksaw??

| Best wood hacksaws | 1 | BAHCO Superior 2600-16-XT11-HP |

| 2 | Gross Piranha 24107 | |

| 3 | Armero A531/400 | |

| Best Metal Saws | 1 | Norgau N403 |

The order of action, how to choose a hand saw on wood, is quite simple: Determine the purpose for which the tool will be used. Choose fine-toothed products for carpentry that guarantee a high precision of cut, and blades with large teeth for carpentry. Frequency of use.

Comparison with a hacksaw

Probably the fault that sabre saws can’t find their buyers in Russia lies on the side of marketing specialists. We should call it “electric hacksaw” and put it not in electric tools between “circular saws” and “bolsters”, but somewhere in the household goods between hammers and mops.

Top 5 in the ratio of price to reliability

The lineup of “archers” is undoubtedly large, but there are brands and types that take the lead. Consider the best of the best, having a high rating among buyers’ reviews.

How To. Use a Bow Saw

BAHCO 10-30-51

One-handled beam saw. Characteristics are simply amazing. With a low weight of 900 grams, it can be used for a variety of works. But its main purpose is to process dry wood. Saw blade is 76 cm long and has three-sided teeth. The tool has a comfortable handle, thanks to which the hand of the craftsman will not slip, the work goes quickly, without delays.

Fiskars 1000615 (124810)

Finnish company Fiskars produces saws of very high quality. The saw is made in the shape of a cupped trapezium, t.к. long enough (70 cm). This is a must-have for the home.к., Firstly, it has a small weight (770 grams), secondly, there are “Kremlin” teeth, which alternate with regular ones, so you can saw both forwards and backwards. It also has a very comfortable handle, thanks to which the handyman does not get tired of the work. The main purpose is cutting thick branches and small trunks of trees.

Stanley Pro 760

760 mm. the bow saw blade for cutting branches of bushes and small trees. Weight of the device is 250 grams (very light and a pleasure to work with). The teeth are alternated and the main thing is that it has double teeth, which makes it quicker and better to work with. These teeth do not even need to be sharpened. The handle is handy, so you won’t have any problems with sawing.

TOPEX 530 mm 10A905

The unit has a small cost, so the characteristics are not at a very high level. From the advantages: tool blade size. 530 mm (this is the standard length), the teeth are alternated (there are double), weight is 500 grams, you can work with both dry and raw wood. The main and most serious disadvantage is the lack of a comfortable handle, which makes the work more difficult and time-consuming.

Brigadier 83000

A beam saw with good parameters, but lacking a comfortable handle. The advantages are the following: the tool is foldable, so it is an indispensable thing for hiking; its length is 70 cm; its weight is 770 g; it is convenient to work with branches, as well as with dry wood. The price is reasonable. Therefore, if used properly, the device will serve for a long time and no problems will arise.

In this article, we gave an idea of the archer saws, considered the best models among the expensive devices, as well as fairly cheap. If you found our article useful, leave a comment and share the link on social networks. We will be very pleased!