Steel rims

Blades made of steel form a large product group, which includes wheels for dry and wet cutting, as well as combined models. Steel discs are very tough and durable, and diamond-coated makes them suitable for the hardest materials.

Diamond grit is applied by the manufacturer in three methods:

- silver solder. the cheapest products suitable for household use. Potential service life is low due to the loss of strength of the solder when heated;

- laser soldering. heavy-duty wheels of a high price segment, used on an industrial scale. They perfectly cope with the processing of workpieces of any strength;

- form-fitting. diamond chips are embedded in the surface during the heating of the disc edge with electricity. They belong to the middle price segment, they serve for a relatively long time, which makes it possible to recommend them for processing large volumes of tiles.

Types of discs for cutting porcelain stoneware and ceramic tiles

Several types of angle grinder discs are suitable for cutting tiles. made of stone or diamond-coated metal. There are several models in the line of diamond discs. solid, segmented, combined. They can be used not only for making simple cuts, but also for finer curly processing of the product.

Tile cutting disc

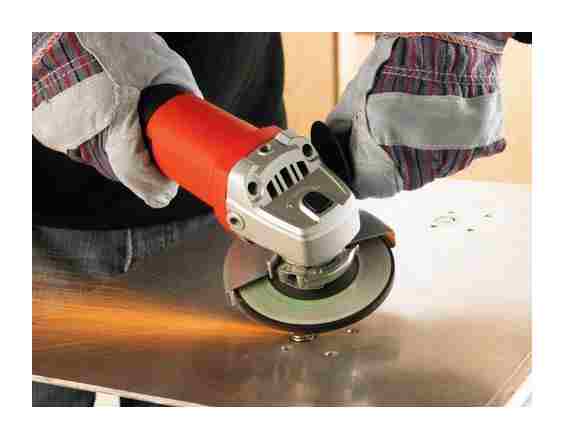

Experienced tilers claim that the most convenient and efficient tile trimmer is the angle grinder, popularly referred to as the angle grinder. The main functional load in the unit falls on a replaceable cutting element, which is a disc of a given diameter and modification. How to choose the right disc for cutting tiles, what determines the price of a part, and how to work correctly with a cutting tool.

Getting rid of dust

One of the disadvantages of an angle grinder is the large amount of dust generated during the sawing process. Here are a few life hacks to help reduce dust:

- Do not cut through the entire thickness of the tile. just make a small groove, and then just break the tile along the mowing line of the cut.

- Use wet cutting or water cooling to keep debris from flying.

- Get a vacuum cleaner designed for construction needs.

You can use a vacuum cleaner without an assistant. The masters propose to build an impromptu hood from a container and a vacuum cleaner:

- Cut off the top of the plastic canister.

- Cut a round hole in the side for the vacuum cleaner hose.

- Place workpiece and angle grinder over the container.

- Switch on the vacuum cleaner and cut over the hood.

Solid dry cutters

Unlike segmented circles, these circles have a flat surface, which makes them versatile. an angle grinder with a solid attachment can not only perform cuts, but also process the edge of the tile with the side of the disc. The absence of slots makes the wheel incapable of continuous work. it can rotate for a maximum of 15 seconds, after which a break of half a minute is required. If there is a need to cut tiles for longer, it will be advisable to use water cooling.

There are three options for supplying water to the work area:

- attract an assistant who will pour liquid from a plastic bottle;

- attach a special nozzle to the body;

- using clamps, screw the armored hose connected to the water supply to the casing.

But water must be used very carefully. if liquid gets under the body of the device, you can get an electric shock.

Fine work disc

For those tile elements where you need to achieve high accuracy and a certain cut configuration, it is recommended to choose a disc more carefully. It is better to use a circle with a small thickness. about 1.5 mm. It will facilitate manipulation with an angle grinder, will not make a wide cut and will not damage fragile tiles.

The result of the work largely depends on the cutting technique. To create oval shapes, the angle grinder makes short cuts tangentially to the outer contour, trying to cut off excess areas.

How to choose the right drive?

Depending on the disc modification, the angle grinder is capable of processing a wide variety of materials. metals, wood, porcelain stoneware, reinforced concrete, natural stone, etc.

Stone discs

Discs made of stone have only one clear advantage. affordable cost. But the disadvantages of this type of attachment are much more:

- short service life;

- rapid wear;

- large cutting thickness.

Since it is impossible to make fine cutting of tiles with stone discs, a lot of dust is generated during the work. The accessory creates a number of limitations in processing. it is used mainly for making simple straight cuts. But for thinner and curly sawing, such discs are not suitable.

Curly cut or curly cut

This type of work is the most difficult. Therefore, it requires a certain skill for high-quality performance.

Work rules:

- Before cutting the ceramic tile with an angle grinder, you need to make a marking with a marker.

- Lay the tiles on a flat surface, fix them.

- Next, make small vertical serifs, cutting off excess material.

- At the end, there will be irregularities that need to be processed with an abrasive wheel.

Diamond wheel

To perform complex types of work, it is recommended to use this particular type of equipment. Its peculiarity lies in a special coating, which consists of small particles of industrial diamonds, applied over a metal base. This allows the disc to withstand increased loads.

Straight cut or straight cut

This is the standard way to cut ceramic tiles. It involves the separation of material along straight lines.

- Initially, you need to mark the cut line. To do this, use a ruler and marker.

- Place the workpiece on a straight surface and remove all unnecessary.

- Fix the tile with a vice.

- Make the first cut to a depth of 1-5 mm, depending on the thickness of the material. When entering a tile, slow down and then increase.

- the angle grinder must be driven away from you, at the same speed, exactly.

- When exiting the material, you should also slow down the speed to avoid chipping.

- Break the workpiece along the mowing line of the cut.

- Sand the edges with a snap.

Important! When cutting, it is necessary to adhere to the selected trajectory as much as possible.

Straight cuts are best done incompletely with subsequent fracture of the workpiece

Combined disc models

This type of tooling is suitable for dry and wet cutting. But unlike segmented ones, it loses in terms of cooling, and from solid ones, it does not give such a high-quality cut.

Important! The disadvantage of combined types of equipment is that they are quickly clogged with small dust particles, and only concrete, silicate bricks can be used to clean them.

Wet cutting

Dross and dust can be prevented by wet cutting. This method involves the contact of the cutting edge with liquid. This can occur by immersing the working surface of the tooling in water or by applying a stream of water to it.

How to cut tiles with an angle grinder at home

When laying ceramic tiles, it will not be possible to do without cuts. over, they can be straight and curved, in the form of a circle. Each type of work requires a certain type of tool. At home, you can use an angle grinder or angle grinder. But in order to make high-quality cuts, you need to know which disc for a ceramic tile angle grinder should be chosen. And it is also advisable to familiarize yourself with the features of the use of this tool.

The tile cutting process of an angle grinder requires certain skills

Is it possible to cut tiles with an angle grinder

The angle grinder can cut any kind of ceramic tile. The only problem is that this type of work is quite traumatic, and also requires a certain skill. over, this procedure will take longer.

Before making basic cuts, it is recommended to practice on the rough pieces.

Features of working with porcelain stoneware

Porcelain stoneware material is particularly durable and reliable. After all, it is made of natural stone. To cut porcelain stoneware without chips, an angle grinder, like tiles, needs to use thin segmented discs up to 1.5 mm thick with intensive continuous diamond spraying. This will reduce the chance of overheating.

The cut of porcelain stoneware should be carried out in the same way as tiles.

Required tools and materials

Cutting ceramic tiles is a laborious process that requires maximum concentration. The difficulty is largely due to the fact that the tiles are made of durable material. Dust-free tiles can be cut and sawed down with a tile cutter, but such a tool is not cheap. This is nearly impossible with conventional cutters and saws, and the cut is likely to be uneven and unattractive. A regular angle grinder is best suited, the cutting wheel of which allows you to neatly cut tiles even at home.

Despite the fact that this process is relatively difficult, if you get the hang of it, it does not take much time and does not require much effort. An ordinary homeowner who has not dealt with such work can cope with this task and will be able to cut off even a “hog” without the help of a tile cutter.

You can cut tiles using the following tools:

- special tile cutter;

- diamond tools;

- Angle Grinder.

The main thing that you need to pay attention to when choosing is the quality of the disc

For cutting ceramic tiles, those that have a diamond coating are suitable. Their use minimizes the formation of cracks and chips. It is forbidden to use discs used for metal work, as they will only damage the tile. Even if you manage to cut with the help of such a circle, it will be uneven and of poor quality. This is due to the sliding of the disc on the tile, due to which the presence of small cracks is inevitable.

At the same time, when it comes to home surface finishing, you can ignore these damages, since they will surely disappear during subsequent processing.

When cutting with an angle grinder, be sure to take proper precautions

Be sure to carry the following attributes with you:

- glasses;

- mask;

- thick gloves.

Please note that the selected angle grinder or grinder must have a speed regulator, since many modern inexpensive tools do not have this function. Such models operate at the highest speed, which is why it is impossible to cut tiles with their help.

Round hole: you have to tinker

- First, you need to apply a marker, with which you will draw the outlines of the required hole on the glossy surface of the tile.

- Next, straight lines of the mowing line are drawn crosswise to find out where the center of the circle is approximately.

- Begin to file the angle grinder gently in a circle from the inside until you go deep enough.

- Rotate the tool so that it gradually fits into the circle you have outlined.

- When the cut turns out to be quite deep, you will also need to cut it crosswise, along the lines drawn in advance, and then carefully get out the four sectors of the circle.

Dry cutters are subdivided into two more types: solid and segmented

The solid disc of the dry cutter allows you to cut the tiles evenly and practically without chips. Due to the lack of detonation at the circle, you can freely clean the edges of the tile, even at an angle of 45 °.

The segmented disc got its name from the slots located from the center to the cutting edge, evenly along the cutting wheel, while dividing the disc into equal parts (segments). Such a nozzle is perfect for cutting through porcelain stoneware and natural stone tiles, it is also suitable for cutting ceramic tiles.

Thanks to the slots, the disc is cooled, thereby protecting it from rapid wear. But due to increased detonation, chips remain on the material.

Important points when working with tiles

Before you start working, you need to figure out how to cut correctly so as not to spoil the finishing material in the future. The disc on the grinder must be tightened with a wrench, the tiles must be laid on a flat surface, preferably a board or plywood, in order to exclude vibration from which fragile ceramics can burst. If possible, then it is better to tighten with a clamp, if not, then it is good to press the tile with your foot.

Angle Grinder Cutting Large Holes

The center of the circle is marked on the ceramics with an alcohol marker and a through hole with a diameter of 3-4 mm is drilled with a carbide drill exactly along the mark. Then, on both sides of the tile, a contour of a circle of a given diameter is applied. an angle grinder with a disc makes cuts 1-2 mm deep along the contour of the future hole on both sides of the tile, and then make through cuts inside the contour and remove small fragments of ceramics from it with nippers. The inner surface of the cut along the perimeter of the hole can be processed with coarse sandpaper or a file until there are no chips.

Tile cutting with an angle grinder is performed using a diamond grinding wheel

Direct cut on the tile with a grinder

On the front of the tile, a marker indicates the cutting line, then the angle grinder turns on, and when it picks up speed, you can start cutting. You need to start from the nearest edge and carefully at the risk to the other side of the tile. When the glaze is evenly cut, make a second pass. Slice until tiles separate from each other.

Important! Ceramic tiles are fragile, so you should not press hard, and the first cut is made to remove the glaze. If you start immediately cutting from the edge, then at the end the tile may burst

Therefore, it is recommended to cut evenly from edge to edge in several passes.

Combined discs

Combination blades allow for both dry and wet cutting.

This is an average option:

- the quality of the cut is lower than that of a solid one, but higher than that of a segment one;

- continuous operation time. less than that of a segment, but more than that of a solid.

How To Cut Tile On A Dry Cut Angle Grinder-Diamond Blade-SIMPLE & EASY!

Combination discs are easier to clog with dust than others. And if it is enough to rotate the segmented and solid discs for cleaning by 180 degrees, then this is not allowed with the combined one. For cleaning, they cut concrete or sand-lime brick.

When cutting dry, the disc must not be cooled by immersion in water: this will lead to an uneven temperature distribution with the subsequent formation of cracks, the circle will immediately fly apart. This applies to both segmented and solid discs and combination discs.

How to cut ceramic tile angle grinder

After you have prepared everything you need, purchase special attachments for the angle grinder and ensure your own safety with simple means of protection, you can begin to figure out how to cut the tile of the angle grinder in such a way as to get a beautiful and even cut as a result, without chips or cracks. an angle grinder will not only allow you to make ordinary straight cuts of tiles, but also to cut them figuratively and even make cuts at an angle.

How To Cut Tile Angle Grinder?

When doing renovations, many homeowners find it necessary to cut ceramic tiles that can be done using an angle grinder. This tool allows you to do this work at a high level, with minimal risk of chips or cracks. In this article, we will show you how to cut ceramic tiles using an angle grinder.

We cut the tiles correctly

Using tiles for wall decoration, a situation will surely arise when you need to cut off part of the slab so that it fits into the remaining space. over, a similar procedure will be required regardless of which type of tile you choose. Cutting is required most often in cases where unique patterns on the walls are created or various decorative objects are formed using tiles.

If you have already prepared all the attributes you need for work, you can consider how the tile should be cut correctly. The angle grinder is an excellent helper in this matter, since with its help you can create not only straight cuts, but also curly cuts. Next, we will look at how to cut tiles in various ways.

using a angle grinder to cut ceramic tiles

A straight cut is as simple as possible:

- First, you need to fix the tile on the plane so that it does not slide and ride on it.

- The part of the tile that needs to be cut must remain in weight. the surface line will be the guideline for the notch mowing line;

- You need to take an angle grinder so that you can see the cut line. If you hide it from yourself, you will not be able to make an even cut.

- You need to direct and move the blade towards you, not away from yourself. This is the mistake many beginners make. Hold the tool firmly and level so that it does not move in different directions, otherwise the cut will be ugly. Holding the angle grinder crooked can damage the disc as it can fly off.

A round hole is made as follows:

- Initially, you need to use a marker to draw the required hole. Draw on the glossy side of the tile.

- Then you need to determine the center of the circle. This can be done using straight lines drawn crosswise.

- Gently saw the tile from the inside in a circle until we go deeper.

- It is necessary to turn the angle grinder so that the blade gradually fits into the outlined circle.

- When the cut is deep enough, it is required to saw through the drawn cross along the drawn lines, after which you carefully take out the resulting 4 sectors of the circle.

You need to cut the tiles only on the front side, since this is the only way to get a cut without various defects. Consequently, all possible damage will be concentrated on the back of the tile, which will be hidden with tile adhesive.

It is best to measure and mark the tiles to be cut from the start.

To cut at a 45 degree angle, follow the instructions below:

- It is important to note that cutting the tiles obliquely is more difficult than making a straight cut. However, this is much easier than creating curly elements. You need to start by doing.

- the angle grinder must be turned so that the disc is located at the angle you need, while you must carefully drive the blade, removing excess, so that at the end an even angular cut is obtained.

- Perfectness can be achieved by using ordinary sandpaper, which is best fixed on a bar.

Abrasive paper should be used for each element as this will help improve the appearance of the cut.

Required tools and materials

Cutting ceramic tiles is a laborious process that requires maximum concentration. The difficulty is largely due to the fact that the tiles are made of durable material. Dust-free tiles can be cut and sawed down with a tile cutter, but such a tool is not cheap. This is nearly impossible with conventional cutters and saws, and the cut is likely to be uneven and unattractive. A regular angle grinder is best suited, the cutting wheel of which allows you to neatly cut tiles even at home.

Despite the fact that this process is relatively difficult, if you get the hang of it, it does not take much time and does not require much effort. An ordinary homeowner who has not dealt with such work can cope with this task and will be able to cut off even a “hog” without the help of a tile cutter.

You can cut tiles using the following tools:

- special tile cutter;

- diamond tools;

- Angle Grinder.

For cutting ceramic tiles, those that have a diamond coating are suitable. Their use minimizes the formation of cracks and chips. It is forbidden to use discs used for metal work, as they will only damage the tile. Even if you manage to cut with the help of such a circle, it will be uneven and of poor quality. This is due to the sliding of the disc on the tile, due to which the presence of small cracks is inevitable. At the same time, when it comes to home surface finishing, you can ignore these damages, since they will surely disappear during subsequent processing.

In no case should you neglect safety measures, since the risk of harm is quite high.

Be sure to carry the following attributes with you:

- glasses;

- mask;

- thick gloves.

Please note that the selected angle grinder or grinder must have a speed regulator, since many modern inexpensive tools do not have this function. Such models operate at the highest speed, which is why it is impossible to cut tiles with their help.

Important nuances

The angle grinder must be set at a low speed so that you can control and adjust its actions. When you have the ability to secure the tool, be sure to do so, as this will simplify your work. Once the angle grinder is secured, you only need to move the tile along the desired trajectory.

If there is no possibility of securing, then the floor is the best place to work. Be sure to put bars or lumber under the slab. It is important to note that a low speed should also be set due to the fact that this will exclude the discarding of the blade or disc upon contact with the surface.

Turning on the maximum speed will surely simplify the cutting process, but this increases the risk of damage to the tiles, which can simply fly to pieces. The easiest way to cut is the straight line cut, since even a beginner can handle this job. When it comes to rounding, then more effort will be required. If you have not previously encountered such work, then we recommend that you first try your skills on defective material.

You can protect the tiles from chips by using a special grinder or sandpaper. This work is not difficult, but it will significantly improve the quality of the cut. Thus, you can get rid of existing defects.

If you decide to choose a grinder for this work, and not sandpaper, then you need to work at the minimum speed.

Be sure to follow these guidelines:

- you need to work in special clothes;

- safety glasses are required;

- it is recommended to use earplugs when working;

- all used devices must be in good condition;

- work can only be performed by adults who know the safety rules for using a cutting tool;

- when wet processing, make sure that the sander does not get into the water, as this can lead to an electric shock;

- you cannot process slices at maximum speed;

- you need to work in a room with good ventilation.

To maintain your health, it is extremely important to follow these recommendations.

Next, see a master class on tile cutting angle grinder.