How to cut fiberglass reinforcement

Before filling the foundation, you need to correctly knit reinforcement for greater strength and stability of the structure. This allows you to tie the reinforcement into a single design, thereby creating a supporting frame of the building. The power of the total foundation design must be provided with additional stiffeners. This will need:

Important! The knitting wire should be a round section, you should not take a square, since when twisting, the wire can damage itself. There are several types of hooks for knitting:

There are several types of hooks for knitting:

The named materials must be chosen very carefully. For example, the knitting wire should be quite thick to avoid its ruptures when the concrete is supplied to the frame. Otherwise, the ligaments may burst, and the design of the strip base will turn out asymmetric, which cannot be allowed in any way.

The transverse rods of the lower layer are laid on the reinforcing fixers, which are installed before work. Shared rods are cut and laid at the distance required from each other, they are noted on them. At right angles to shared rods, jumpers are installed, each of which is connected in the marked places. If the knitting is carried out with wire, then it must be folded in half and firmly fixed with a hook. If clamps are used, then each of them is tightened more. After completing work on the construction of the first row of the grid, you can make the rest of the frame. Perpendicular segments are attached from the inside of the cells in the same way.

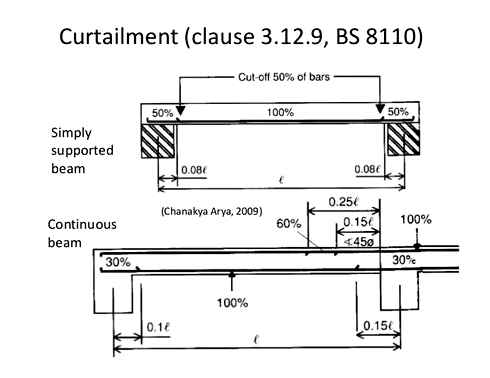

Particularly carefully need to approach the strapping of the corners. In construction stores you can buy special elements that are easily installed in the place of angles

Important! In the corners, the reinforcement can only be knitted manually, without thermal exposure. The finished frame is laid in the formwork in the horizontal position of the nets

The finished frame is laid in the formwork in the horizontal position of the nets.

This method is very common among the builders with whom the knitting of the reinforcement is carried out with their own hands. In addition to him, there are several more options for fastening the reinforcement for the strip foundation:

Important! Before starting work, you need to clearly determine which loads are planned for the strip foundation, and what is the volume of work. This is interesting: ideas for painting walls with water.based paint. we set forth in order

This is interesting: ideas for painting walls with water.based paint. we set forth in order

How to make a reliable frame for the foundation

In order to correctly make the basis for the strip foundation for which fiberglass reinforcement will be used, you can watch the training video and use simple recommendations. So, the algorithm for manufacturing such a frame looks as follows.

Before knitting reinforcement, you need to draw up a drawing of your future frame and cut all the elements for its manufacture in the exact sizes. The transverse rods of the lower layer of the reinforcing cage are positioned using special latches. Such elements can be installed both before the start of the assembly of the reinforcing frame, having previously measured the size of its cells, and after its readiness. The size of the cells depends primarily on the size of the strip foundation that you are going to strengthen. This size can vary wide enough: 15-30 cm. The longitudinal rods of the reinforcing skeleton before knitting, it is better to pre.lay out on the ground and make markers in those places where transverse elements will be fixed on them. Starting to knit reinforcement, you should ensure that the elements are fixed with each other strictly at right angles. The transverse jumpers should be knitted with longitudinal elements of the frame on their bottom. In order for the reinforcing skeleton and, accordingly, the future foundation turns out reliable and stable, plastic clamps or knitting wire in places of joints should be knitted. The horizontal layers of the reinforcing frame are originally made, only then you should knit them with vertical jumper

It is also necessary to fix vertical jumpers on the inside of the frame cells, this will allow you to get a reliable and stable design that will not be separated in the process of pouring concrete and will perfectly perform your reinforcing functions. Corners are a special place of the reinforcing structure, and they need to pay separate attention. Fiberglass reinforcement is not recommended to bend on its own under the influence of heating, which can most negatively affect its strength characteristics

Therefore, the corner elements of the reinforcing skeleton are best knitted from the already bent rods that can be purchased today, or carefully perform a bend without thermal exposure. After the reinforcing structure is completely ready, it must be carefully placed in the inside of the already prepared formwork.

Reinforcement scheme of the angles of the strip foundation

Reinforcement scheme of tape foundation junctions

If you knit elements of the reinforcing frame using wire, then to facilitate your work you can make a knitting hook, for which it is convenient to use the old screwdriver. How to make such a hook and knit with it a reinforcing cage, you can also familiarize yourself with the corresponding video.

The manufacture of a reinforcing frame of rods made of fiberglass is a simple process, which can be judged even by a training video, where it is shown in detail how to knit it. To work with a material such as fiberglass, you will not need special tools and complex equipment, it is easy to cut and knit, it has an easier weight than the reinforcement made of metal.

Reinforcement technology

When reinforcing various types of foundations, rods of reinforcement with a diameter of 0.8 cm are used.

When performing installation with your own hands, you should adhere to the following sequence:

- When installing the formwork, its parts are wrapped in parchment paper to use them several times;

- Using a horizontal level on the details of the formwork, marking is made to which a concrete solution will be poured. This is necessary for the uniform distribution of the concrete composition around the entire perimeter of the foundation;

- Elements of glass.airmator to strengthen any types of foundations are covered with a mixture with a thickness of more than 5 cm. To do this, you can also apply bricks that should be laid on the bottom of the structure;

- Several rows of fiberglass reinforcement are placed on a number of bricks. Whole rods should be used with lack of joints. To calculate the required length of the rod, you must first measure the length of each side of the future foundation. Based on these values, you can rewind or cut off the rods of the required length;

- After laying the longitudinal row of rods, they proceed to strengthen the transverse jumpers with plastic clamps;

- make the upper part of the frame, which exactly repeats the lower part. The size of one cell is about 15 cm. Both levels are fixed with vertical jumpers;

- After knitting the reinforcing frame, the process of filling the concrete composition begins. Experts recommend using M400 concrete.

A competent calculation of fiberglass reinforcement will allow you to avoid unnecessary costs and additional problems due to the lack of reinforcing rods and purchase the right amount of product. The calculation for the foundations of the strip and slab is to determine the length and number of rods, based on the area of the foundation and the step of the reinforcing grid

It must be taken into account that the plate should have two reinforcing belts: lower and upper ones, which are fixed with vertical rods around the entire perimeter of the plate. The process of reinforcing the column foundation is different

Ribbed reinforcement is strengthened vertically, and smooth. horizontally. For the frame, 3-4 rods are needed, their length is equal to the height of the pillar. For a large diameter pillars, a larger number of rods will be needed, and more than 4 horizontal rods are needed for one pillar.

The concrete solution hardens about 3 weeks. At this time, you need to protect the surface of the flooded foundation with polyethylene from moisture. In sunny weather, it is recommended to spray the surface with water.

Most professionals claim that when laying gas and foam blocks, angles should be reinforced using metal valves. Such a combination will give building structures even greater strength, stability and reliability. Often there are disputes about the need to knit glass.airmator with plastic clamps. Knit should be knitted to strengthen the reinforcing frame before pouring concrete mixture until the composition is completely dry. After the surface is hardened, it does not matter whether the frame is connected or not.

In the video below you can see a review about fiberglass reinforcement for the foundation.

Leading manufacturers

The production of composite fiberglass reinforcement is engaged in many regions of our country. This is especially true for areas with developed industrial infrastructure, such as:

- G. and the region. “Factory of Composite Materials”, LLC “NPC“ Special Polymer ”, LLC NPK“ Armastek ”and others;

- G. St. Petersburg and the Leningrad Region-“Leader-Composit” and others;

- G. Yaroslavl. “Yaroslavl Plant of Composites”;

- G. Yekaterinburg and the Sverdlovsk Region. Uralteplostroy, LLC “UZKT”, LLC Elpromtekh, LLC NPF Uralsparmatur;

- G. Saratov. LLC “Volga fittings” (Polarm).

A wide range of spa allows you to choose not only by technical characteristics, but also in the form of implementation

Cutting fiberglast reinforcement boltoresis.

Pros of cutting fiberglass reinforcement boltoresis

Cons of cutting fiberglass reinforcement boltoresis

-a small amount of rods with simultaneous crushes (2-3 maximum);. quite large labor costs during work;. Boltoresis is not a very common tool in the farm with a narrow sector of use, and buying it only for these works is impractical.

The main cutting options

Work with a hacksaw for metal when preparing the material on how to cut reinforcement, it was necessary to analyze many recommendations published on the pages of Internet forums on this topic. The results of the study were reduced, ultimately, to the following main cutting options:

- work with a regular manual hacksaw;

- Cutting with manual scissors for metal (with hydraulics), the so-called “bolom cutters”, which are allowed to be used with a reinforcement diameter of not more than 6-8 mm;

- use of gas cutter;

- Cutting the reinforcement using an “angular grinder” (angular grinding machine) with discs on concrete.

Manual hacksaw

Some forum visitors even offer to use powerful hydraulic scissors, which are equipped with rescue services.

How to unwind fiberglass reinforcement

The reinforcement is supplied in bays and straight rods. both options are acceptable. The rods twisted into the bay are not subjected to deformation, as many consumers believe. The appearance of microcracks is possible only if the material is made without observing technologies. After unraveling it does not need to be straightened. This will happen naturally.

The reinforcement in the bay should be inserted very carefully, especially with a significant thickness of rods.

-

How to do it:

- If you work alone. Disconnect one of the ends of the bay and put it with something quite heavy. The main thing is to fix one end of the rod. Then go back, gradually, slowly, unwinding the material

- If you work in pairs. The process will look approximately the same with the same exception: one of the ends of the reinforcement will hold the assistant

Funds for working with reinforcement

At all stages of work with non.metallic reinforcement, it is necessary to use protective equipment.

Gloves

Composite rods have a slight glass spraying, with contact with which irritation may appear on the skin. Therefore, before picking up a composite rod, put on gloves.

Protective mask

When sawing non.metallic rods, fine dust forms, which, when it enters the respiratory tract, can cause allergies or lead to diseases. The mask will protect you from such troubles.

OPT@trioltorg.RU 8 (347) 2-748-749; 8 (347) 274-11-25; 8-927-302-77-57 reverse call g. Ufa, Safronovsky passage, d. 4/2a (OST.”River Port”) Mon-Fri: from 9-00 to 18-00 SB: from 10-00 to 15-00 Additionally delivery Contacts Certificates Certificates Feedback Partners made in Insales

How can you cut fiberglass reinforcement?

Composite glass.plastic reinforcement is a material that can be cut in different ways. Such reinforcement is often used in construction in both abroad. One of the main methods of cutting fiberglass reinforcement are:

- Cut off with reinforcing scissors (bolt cutter);

- chopping off with an ax;

- sprinkling with a hacksaw for metal;

- Cutting an angle grinding machine (corner grinding).

Choosing the best option of all of the above, it is worth giving preference to a corner grinder with a detachable circle. As for all other options, the first 2 are bad for cutting the reinforcement, as they will have a great influence on the adjacent parts of the material, deforming its edges. Cutting with an ax, the use of bolt cutter or hacksaw for metal can leave almost inconspicuous cracks in the material, which will go deep into the body of the reinforcement.

Important! Cracks that have arisen in the process of sawing or cutting off, become channels into which water and alkali falls. When water enters the microcracks, there is a probability of increasing cracks in size. This is due to the process of freezing and thawing. In addition, the alkali, which is contained in concrete, penetrates the rod inside and destroys the reinforcement from the inside. Thus, the best way to cut fiberglass reinforcement is using a corner grinder. This tool minimally damages the edges of the material, while the pruning process will be as fast as possible. You can buy composite reinforcement and in the region right now with the help of our site. The price of our reinforcement will pleasantly please you.

note! If you are going to cut fiberglass reinforcement, it is worth taking care of protecting the eyes, limbs and respiratory organs. It is worth remembering that in the process of cutting fibers, dust can be created, which negatively affects the respiratory system of a person. In this case, it is necessary to use a respirator. Pay attention to him to fit well. Pay attention also to protect the hands and body. Thin fibers of basalt or other materials can easily penetrate under the skin during operation. You can protect against this with gloves that have a continuous layer of PVF and latex.

To the question: where I will buy high.quality materials for construction, we offer profitable solutions at affordable prices.

Specifications

Glass Armamatics appeared back in the 1960s. Due to its high cost, it was used exclusively in the Far North, where metal structures were rapidly exposed to corrosion. Composite materials were most often used to build bridges supports. Thanks to the rapid development of the chemical industry, the price of fiberglass reinforcement has greatly decreased. This made it possible to become an affordable product that manifests itself only on the good side in all construction structures for various purposes.

The widespread popularity of glass-airmator contributed to the development of GOST 31938-2012, which marks the requirements for the manufacture of reinforcement and its testing methods. In accordance with this state standard, composite fiberglass reinforcement is made with a diameter of 0.4 to 3.2 cm. However, materials with a diameter of 0.6 are in great demand; 0.8 and 1 cm.

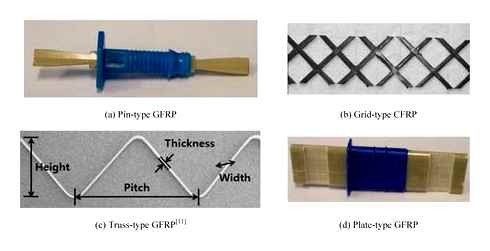

Fiberglass material is high.strength rods of various diameters. They are made of composite material. fiberglass. They are mainly used in concrete structures, as well as for installation instead of iron reinforcement. Fiberglass is subjected to painting, decor, covered with PVC films, and also lends itself to all types of mechanical processing. Depending on the reinforcing additive, glass.composite, carbon dioxide and combined glass.airmator is released.

When choosing a glass airmator for the installation of the foundation of the structure, it is necessary to take into account such technical characteristics as:

- The upper temperature limit of the use of glass.airmator is more than 60ºС;

- The maximum strength during stretching is the ratio of the applied power to the section of the section of the part. Glass.composite reinforcement has a limit strength of 900 MPa, and carbon dioxide. 1400 MPa;

- Elasticity for stretching for carbon dioxide materials is higher than for glass.composite by 3 times;

- The marginal strength during compression for any type of glass.airmator should be higher than 300 MPa;

- The maximum strength of the transverse cut for glass airmatz should be at least 150 MPa, and for carbon dioxide. at least 350 MPa.

Reinforcement cutting tool

What is the best to cut reinforcement, depends on its diameter and class. The smaller they are, the easier it is to cope with the metal rod.

Therefore, for cutting the A-1 reinforcement (up to 10-12 mm in diameter), ordinary bolt cutters are also suitable (they are also called reinforcing scissors or reinforcing nippers). With their help, you can easily cope with a small number of rods, since the effort you do increases due to the work of the double lever system in them.

We advise reading: how to make a foundation for a garage with your own hands. instructions with calculations, photos and videos

For cutting thicker and durable reinforcement, “corner grinding” is more suitable. Its main advantages (low weight and power) allow you to work quickly, and since you can cut the reinforcement with its help everywhere there is a place and there is no control of combustible materials, it is it that masters usually prefer it.

Another option is a special guillotine for reinforcement (for example, Edma Rodcut 0659). Such a device greatly facilitates the process of cutting the reinforcement into segments of a certain length. True, the guillotine costs quite expensive, so specialized companies usually purchase it, and not lovers to build something with their own hands.

You can also use a special machine for cutting reinforcement, which greatly facilitates and simplifies the whole process.

Reinforcement cutting tool

What is the best to cut reinforcement, depends on its diameter and class. The smaller they are, the easier it is to cope with the metal rod.

Therefore, for cutting the A-1 reinforcement (up to 10-12 mm in diameter), ordinary bolt cutters are also suitable (they are also called reinforcing scissors or reinforcing nippers). With their help, you can easily cope with a small number of rods, since the effort you do increases due to the work of the double lever system in them.

For cutting thicker and durable reinforcement, “corner grinding” is more suitable. Its main advantages (low weight and power) allow you to work quickly, and since you can cut the reinforcement with its help everywhere there is a place and there is no control of combustible materials, it is it that masters usually prefer it.

Another option is a special guillotine for reinforcement (for example, Edma Rodcut 0659). Such a device greatly facilitates the process of cutting the reinforcement into segments of a certain length. True, the guillotine costs quite expensive, so specialized companies usually purchase it, and not lovers to build something with their own hands.

You can also use a special machine for cutting reinforcement, which greatly facilitates and simplifies the whole process.

The main cutting options

When preparing the material on how to reduce reinforcement, it was necessary to analyze many recommendations published on the pages of Internet forums on this topic. The results of the study ultimately come down to the following main cutting options:

- Work with a regular manual hacksaw;

- Cutting with hand scissors for metal (with hydraulics), the so-called “bolt cutters”, which can be used with a diameter of not more than 6-8 mm;

- Use of gas cutter;

- Cutting reinforcement “Current” (angular grinding machine) with concrete disks.

Some forum visitors even offer to use powerful hydraulic scissors that are equipped with rescue services.

How to cut a network reinforcement?

For small cuts, you can use a direct grinding blade, but there is a great risk of hiding it, so it is best to cut fiberglass manually using a concave tungsten carbide. Such tools allow you to make cuts with a complex contour.

How to attach glass.plastic reinforcement?

For the knitting of fiberglass reinforcement, special plastic clamps or fasteners of different types are used, depending on the features of the constructed design and the diameter of the used composite reinforcement.

Serve heat to the fiberglass surface for about 30 seconds. Keep a heat gun about 3 inches from fiberglass. Slowly move the heat gun up and down the area you want to bend. Serve more heat or heat to the heat gun closer to fiberglass.

How to cut fiberglass reinforcement?

On the one hand, if we talk just about all possible options, then composite fiberglass reinforcement can be cut in different ways:

- Bite with a bolt cutter;

- Cut off an ax;

- Cut with a hacksaw for metal;

- Cut an angle grinding machine (“corner grinding”).

But the most correct option of all listed above is the use of “corner grinding” with ordinary abrasive or diamond circle. The fact is that the first two methods cause a strong impact on the adjacent areas of the reinforcing rod, leading to its deformation, painting and splitting in these areas. Thus, the adjacent ends of the reinforcing rod will be very split, approximately, as shown in the photo on the right (click on it for viewing in full). Do not be alarmed, in fact, a segment of composite reinforcement is depicted in this photo, destroyed as a result of the compression test, but the nature of the destruction of the edge in the form of longitudinal cracking is the same as when sniffing the composite reinforcement or cutting with an ax. Such breakdown is extremely undesirable, since the resulting cracks can be invisible to the naked eye, but to go quite deeply into the body of a reinforcing rod. Such cracks in the body of the core of composite reinforcement will be capillary channels to get into the water rod, alkalis when pouring concrete. In the first case, there is a danger of further development of cracks due to the cycles of freezing and thawing. In the second case, the destructive effect of the alkaline environment of concrete on the reinforcing rod is aggravated (now this effect is not only outside, but also from the inside)

We draw your attention to the fact that before cutting fiberglass reinforcement, take care of protecting the eyes, hands and respiratory organs. over, pay special attention to the latter! Do not forget that you are going to cut glass or basalt fibers and the dust formed will be a completely unnecessary guest in your lungs! You can protect yourself from this dust using a respirator. But remember that the respirator should fit tightly to the face, excluding the possibility of inhalation of dust bypassing the filter element

But remember that the respirator should fit tightly to the face, excluding the possibility of inhalation of dust bypassing the filter element.

To protect the hands from thin, almost invisible splinter in the form of glass or basalt fibers, having a thickness comparable to the thickness of the human hair, to use ordinary x/w gloves is not suitable! You will need the so.called “awake” gloves or at least m/a gloves with a continuous layer of PVC or latex applied to their inside.

Our philosophy of honesty

We value honesty. Honesty in everything. This means that we will never deceive our buyers in pursuit of momentary profit. We ourselves dissuade potential buyers from the use of fiberglass reinforcement in the ceilings, even if we lose the buyer. The fraud in the construction can lead to victims, but this is not even the point, but that we are recommended for our honesty and we know this and appreciate it. In working with large customers, we will not promise unrealistic delivery time, which we obviously consider it impossible, even if the absence of such a promise on our part threatens to refuse to conclude a contract for supply. The principle of “the main thing is to get into the battle, and there we’ll already figure it out” is not our principle. We value our partners and therefore never deceive them so as not to lose. If the potential Partner does not understand and does not share this simple truth. we will not become partners with him.

The sphere of our interests

Interests apply to all the latest technologies used in construction. This mainly applies to the latest building materials, as well as new tools, equipment and technologies necessary for construction work.

Technical characteristics and production

To understand what characteristics and properties carry such raw materials, it is recommended to consider the process of its production. To do this, use a specially equipped production fishing line for a trimmer, in which there are devices such as winding for bobbin, drying and heating, baths for impregnation with resins, windings for forming a spiral winding.

There are also bunkers for the finish coating, magnesite furnaces, the mechanisms of the broach and automatic cutting of the material.

Several stages of production of fiberglass reinforcement:

- Glassroving processing. Bobbins with rawing are installed on racks, then they are fed to the fishing line for a trimmer. They are dried, warming with hot air, then immersed in a bath with epoxy resin.

- Giving shape and winding. When they gave the diameter and shape, the body is wound on the body of the reinforcement. This is done along the circular trajectory of rotation.

- Polymerization. The material is placed in a magnesite furnace for polymerization and impregnation with resins.

- Cooling and slicing. After the furnace, the product is cooled in the bathroom with water and cut on a special automatic apparatus.

Thanks to this production process, fiberglass reinforcement is endowed with technical characteristics:

- weight. from 25 to 850 grams per meter;

- explosive strength. 1189 MPa;

- elasticity module. 55,000 MPa;

- relative lengthening. 2.2%;

- Density. 2 t/m3;

- The linear coefficient of thermal expansion is 9-12 AX10-6/° C;

- thermal conductivity. 0.35 W/(m ° C);

- corrosion resistance. high.

All these indicators allow us to say that fiberglass reinforcement has an advantage over steel material, so it is used more and more often to fill the foundation.