Arm yourself with an electric jigsaw

It is good if you have an electric jigsaw at home, equipped with a saw for wooden surfaces.

Using this tool is the best option.

Before sawing, mark the cut line with a pencil, and then use a knife or an awl to cut through the laminate film. Now clamp the board tightly (face down).

The speed of the power tool should be high. Try to saw smoothly enough, without jerking the jigsaw to avoid chipping. Having got used to it one can quickly and accurately saw laminate boards. And excellent results are obtained when sawing both along and across the board. It seems that the answer to the question what is the best way to saw laminate flooring is clear. with the electric jigsaw of course.

High power of the jigsaw is a must in order to cut the material and the sawing is of high quality.

In order to cut and saw laminate flooring while achieving a good result, it is necessary to follow certain requirements:

- Cut with the jigsaw at maximum rpm.

- Try to make the entire cut in one go: various slowdowns can lead to unevenness, chipping and other damage to the laminate.

- Press the material along the mowing line of the cut: a reliable fixation of the panel will help to prevent the formation of various defects on the cut.

- The pendulum mechanism of the jigsaw must be switched off.

- Use only those saws that are designed for laminate: if they are not available, choose a saw with fine teeth, etc. п.

saw melamine | no chip | woodworking | dave stanton | how to basics

How to saw evenly with a jigsaw if there are no special saws? A blade with backward-cutting teeth is suitable.

Important! Often the manufacturer tells you exactly how you should cut your laminate flooring on the packaging.

What is better for sawing laminate at home??

Considering, what to saw laminate, it should be noted that the laminated coating is recommended to lay by the same technology as a brickwork, that is, in a gap. Only in this case, the finished floor will look natural and very attractive. The only disadvantage of this laying scheme is that it involves cutting the material in each row.

Cutting laminate flooring is a demanding task that has to be done in such a way that the appearance of the flooring can be influenced. That’s why you should be very serious about this kind of work and carefully understand how and what you need to saw laminate.

How to cut laminate at home

In order to cut a laminate accurately and neatly two basic conditions must be met. First of all, you must mark the cutting line correctly. For this purpose, only carpenter’s squares are used. No markings with laser beams or pointers built into jigsaws or renozzers should be used.

The second condition is a small speed of the cutting tool. The more the cutting edge presses against the laminate material the more the teeth are offset from the direction of travel. Productivity increases, but surface quality decreases many times.

If you cut the material with an angle grinder or a circular saw, you will also need to maintain constant pressure on the tool. This is the only way to cut a laminate floor evenly along the whole length of the panel.

jigsaw blades: marking to help

A non-professional person buying the right sawtooth consumable can be confusing. You can always ask the question, “What are the consumables? Which company’s products are best?”. Many brands produce specialized types for wood, iron, plexiglass, plastic. For the carpenter or do-it-yourselfer, it’s important to understand the purpose of purchasing products and the selection criteria that will help determine the desired functionality.

Alphanumeric markings on the blade and tail coloring will help make the right choice. Each symbol indicates the performance capabilities and area of application, taking into account the material to be machined.

- The T-shaped model is the most common in many manufacturers;

- U-shaped for older models of power tools of the screw-type or pad-type;

- M is a special model with two holes, only for Makita;

- F. standard rectangular shape with one Fein hole.

The penultimate letter is the size of the teeth in ascending order of size:

The last letter. the special properties of the cutting blade:

- X. progressive tooth pitch;

- R. Reverse or reverse teeth;

- O. the especially thin edge of the back of the blade;

- P. ensuring the most precise cut;

- F. made of double alloy for extra strength.

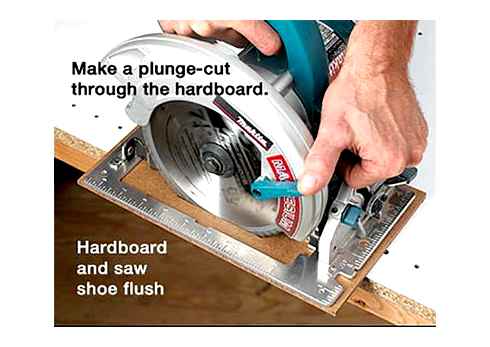

How to cut laminate with a circular saw

For serious craftsmen who work a lot with floors, when cutting laminate, a circular saw or a crosscut saw with the same working principle is ideal. These tools can be classified as semi-professional equipment, and their principle of operation is based on performing a straight straight cut of wooden elements with a rapidly rotating steel disk with teeth.

The simplest circular saw has a safety guard to prevent accidents, a handle with a start button and a material contact plane equipped with a floating ruler to change the sawing position according to the marking.

Trimmer is a much more complex and heavy machine, which has a strong base, the blade guard is lowered to the line of the cut by forcible pressing of the handle. The advantage of this machine is that it can make not only orthogonal crosscutting, but also any angle of cut, for example 30 or 45 degrees. But this device is not designed for longitudinal trimming, because of the immobility of the bed with the blade.

Requirements for the tool

First of all, this applies to devices and mechanisms with which you can cut laminate at home. While cutting ceramic tiles, for example, requires considerable experience and skill, cutting laminate is much easier. This can be accomplished with very little practice.

In this case, if the inexperienced master who took up cutting ceramic tiles, a large percentage are rejects and waste, the percentage of waste when processing laminate does not exceed 10-15%. Of course, if we are not talking about diagonal laying. Exactly 10-15% of the waste must be taken as a basis when calculating the amount of materials for laying the flooring.

Let’s talk in detail about the tools used for cutting laminate flooring. Manual or electric tools are used in practice. For the do-it-yourselfer laying laminate, tools must meet several requirements:

- Have a size that allows you to work in a small room.

- Have a low weight.

- Cut panels at home without chipping and smoothly.

- Be easy to operate and easy to use.

There are several types of tools that meet these requirements:

- Hand saw a hacksaw with fine teeth on wood or metal;

- A mechanical cutter;

- electric circular saw;

- electric jigsaw.

Metal hacksaw

Metal hacksaw. this is what to cut the laminate flooring will be profitable, because the tool is one of those that are in almost every home and you do not have to run to the store.

It’s very convenient to make small trims with a metal hacksaw because

- Laminate is easy to hand-cut;

- The fine tooth of a hacksaw ensures that there are no chips;

- If you do damage the edges, you can easily cover them with a baseboard.

Remember that a hacksaw is suitable for laminate only if the amount of work is small, and other tools are not at hand, also if you do not have a hacksaw handy, it is better to buy a jigsaw in the store, which will be mentioned below.

Sawing should be carried out according to the following instructions:

- First make a clear marking on the lamella, remembering that it must be bright, because when you saw it, it will be covered with a thin layer of dust.

- To get good-quality edges, saw the sheet with the top of the face up.

- Do not apply too much force to the tool so as not to damage the edge to be sawn off.

How to cut a laminate at home. What to saw laminate at home without chipping and damage

It would seem that what could be easier. to cut the lamella evenly, without splinters. There seem to be no problems, but in fact it is quite difficult to cut laminate at home. Especially if you want to get a perfectly smooth joint, without chips and scuffs of the protective film. Usually beginners pay minimal attention to the preparation of cutting tools, believing that to cut the laminate flooring when installing can be an ordinary hacksaw for metal with a fine tooth. The result is a coating with uneven joints and crooked seams.

With a power tool it is possible to cut only on a support or a workbench