What is the difference between angle grinder and grinder?

Construction and repair is not without cutting, scraping and grinding of different surfaces: iron, wood, stone. Do not do without a high-quality angle grinder or grinder. angle grinder. colloquial title of the electronic tool, whose main purpose is the abrasive treatment of metal, and in addition other materials. Today such a tool is used everywhere for cutting metal, stone and wood, as well as for processing various construction materials, including bricks and concrete. Other title of the tool. angle grinder. Common to all the title “angle grinder” appeared due to the fact that the first standards of angle grinder appeared in the Russian Union only in the 70s, and they were manufactured in Bulgaria. The tool has a cylindrical body, nozzle and side handle.

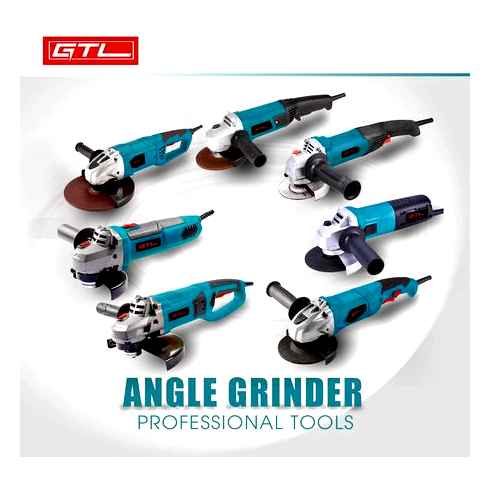

The range of grinders is large enough and according to the power of the motor they are divided into household and professional. The 1st have a small power, lightweight functions and the shortest continuous work time. For home repair and construction your direction. The 2nd ones are distinguished by higher productivity and power. Professional angle grinder are equipped with adjustable number of spindle speed and there are variations to work for a long period without shutting off. Household grinders are fitted with a handle and have a power of 1.5 kW.

Russian automakers equip angle grinders with a variety of useful functions

- balancing, which evens out vibration, preventing the disc from beating against the machined surface;

- disk speed control;

- adjustable speed;

- soft start. they are comfortable to work with. They start at a low rpm and gain power evenly;

- automatic brushes shut off if there is a malfunction in the electrical system.

Popular angle grinder functions

angle grinder in action

Types of polishing tools

Even the most reliable paint coating sooner or later fades. because of this chipping and cracking appear on the surface of the car body. These are the substances that polishing destroys, returning your “iron horse” to its pristine look. Of course, in order to make the game worth playing, you need to choose the right polish and paste:

Means for car body polishing

- Abrasives. Polishing with these agents removes abrasions and scratches from the surface of the car. Remember that such products at the same time destroy a small layer of lacquer, so after polishing the car it needs to be restored. Of course, you should not abuse abrasive polishing. too frequent use of such products can destroy the paintwork of the car body;

- Non-abrasive substances. With the help of such means carry out protective polishing. For your car to look presentable, such a procedure should be performed at least once a year;

- Silicone polishes. These substances fill the smallest cracks in the body. and give the machine a nice shine. Often they are used in combination with abrasives. to consolidate the polish.

How to polish a car with an angle grinder

Despite its simplicity and cost-effectiveness, this method of polishing causes a lively debate among car enthusiasts. Some drivers are firmly convinced that the angle grinder will only ruin the car, while other car owners diligently rub their vehicle with this very tool, and remain completely satisfied with the result. The thing is that polishing. it is a very responsible job, so it must be performed very carefully and attentively. Even one wrong move can wipe out all your efforts.

- Getting ready to work. First of all, clean the car of dirt and dust. If you do not do this, then the polishing will not bring the expected result, and you will waste the substance. In addition, remove the signs of rust. Every driver knows that rust is one of the greatest enemies of the car and that failure to remove rust in time can lead to costly repairs.

- Work the machine with emery paper. Use only a fine grit sandpaper. it reliably removes all deep scratches and paint chips. Because of the degree of grit such paper quickly clogs, so don’t forget to moisten the body surface with water from time to time.

- Using an abrasive polish or paste. angle grinder for polishing should be equipped with a speed regulator. if you choose any other tool, you risk severely scratching your car. Attach the polishing wheel to the angle grinder. apply paste to it. Do not forget to put a little bit of the product on the work area of the car. Remember to polish crosswise, moving slowly horizontally and vertically. Make sure that the angle grinder moves smoothly. if the tool begins to slow, splash water on the work area of the car.

- Using silicone paste. After the surface of the car polished, remove the remaining paste with a soft napkin. Then apply a little silicone paste to the polishing wheel of the angle grinder. and go over the surface of the body.

- Applying the topcoat. In the final phase of the work you do not need an angle grinder. Now you can apply a small amount of protective polish on a soft cloth or on a special glove. Try to spread the layers evenly: then there will be no surplus polish, and sweat can easily be removed with a cloth.

Additional materials and equipment for car polishing

In addition to a quality grinder for work on the polishing of the body, you must also have additional equipment and professional polishes or special sanding discs. Use quality adapters and backing pads with Velcro fasteners to securely hold the polishing wheels. This is especially true if an ordinary angle grinder or an electric drill is used as a grinder. To apply a special paste or wax to the surface of the body requires a special applicator, at home you can use the usual foam rubber, for a better application of a special cotton cloth or flannel.

Grinding wheels differ from each other according to their hardness and the presence of additional elements in their composition. As a rule, circles indicate all the necessary characteristics, but sometimes you can determine the type by the color of the disc: bright orange or yellow colors symbolize the versatility of the material, that is, they can be used for both deep polishing, and to remove minor scratches or create a protective layer. To work with coarse abrasive polish wheels are used mainly white, and with color-forming or protective polish is almost always black.

Polishes serve to improve and protect the paint finish of the car body. Active substances based on polyurethane and other chemical compounds penetrate into the upper layer of the paint, thus enhancing its structure, providing gloss or creating a film that protects the bodywork from the adverse effects of the environment. Can be both liquids and thicker pastes, but all have the same purpose.

abrasive polishes are used to remove minor scratches or even out color, for example after a car has been painted. Protective types contain Teflon compounds, so they are used to protect the bodywork from harmful influences and are used in combination with abrasive or color-enriching polish variants. Wax-based polishes serve to give luster to the paintwork, they do not perform any protective functions, but allow you to smooth out concentric circles, hide microscratches and other small, superficial body defects.

Car polishing machine features and principle of work

A polishing machine can significantly speed up and greatly facilitate the process of polishing the car body. In addition, such a device can be used for other purposes, such as polishing various wooden, plastic or metal surfaces in the home or garage. Professional devices can be several modifications: circular, with an eccentric or orbital, angular, brush, vibratory, belt, etc.д.

The angular type of polishing tool is actually similar to an ordinary angle grinder. The body and grinding wheel form a clear right angle to each other. Such machines are especially suitable for polishing vertical surfaces. In contrast to the angle machine or angle grinder, the shaft of the circular or orbital polisher can produce not only circular movements, but also shift in different directions by several millimeters. It improves the quality of polishing and prevents unnecessary overheating of the surface due to the high friction force. According to the type of power supply, polishing machines are of two types:

The first type of polisher in the home or garage conditions are used very rarely because of the high cost and high performance. Such machines are most often used in car washes and related services, as they require a special compressor and receiver to work with them. Power tools are powered from a regular 220V home network, but can be equipped with a small capacity 12-13V battery, which can be recharged from the car network. They are excellent for polishing both individual parts and the entire body of the car.

Selection criteria

Before buying any product, first of all, the buyer cares about the price issue. Therefore, such polishers are conditionally divided into household and professional. Household options are devices that can easily be used in your garage, they are in an affordable price category and cope with certain tasks. Professional tools have a high price, but their functionality is much wider. It does not make sense to buy an expensive machine for personal use, because it will not be easy to recoup its cost.

Now we should pay attention to the power of the tool. The greater the parameter, the faster you will finish the work. But do not forget that the higher will be the power indicator, the heavier the device will be. You won’t be able to work for a long time with a very heavy tool, your hands will be tired, and you’ll have to constantly take time to rest. Also two tools from different manufacturers with the same power rating may differ in their weight. In this case it is better to choose a lighter device. The functionality of the devices also depends on the power. Machines with low power will not have more features. Just not unimportant criterion is the diameter of the disk. It is faster if it is big, but it is perfect for big surfaces. Since polishers also differ in shape, then here you need to select the model individually, based on your own preferences and wishes.

Zubr ZPM-240

Such a polisher is a compact device with an eccentric stroke. “The Zubr ZPM-240 is suitable for machining paintwork, as well as woodwork and plywood.

The device has two handles. With their help it is easy to hold the device, as well as control its movement. The tool blade has a water repellent layer. Due to this during processing the compound is not absorbed into the surface, which saves time and allows economical use of the paste. It is also worth noting that the disk of this model has a large area, which also reduces the time of work. The kit includes two discs, one of them is designed for basic polishing, and the second for finishing processing.

Diameter of the wheel “Zubr ZPM-240” is 240 mm. Maximum speed is 3200 rpm. Zubr ZPM-240 weight. 2500 grams.

Grinder

This is a professional tool that allows you to qualitatively process large surfaces during finishing. The principle of operation lies in the fact that the base of the sole plate is fixed sandpaper of varying degrees of abrasiveness.

When you turn on the device soleplate starts to move. thereby the surface is grinding. Sanders can be:

- Eccentric. Can be used for polishing parquet and even car bodywork. With their help, it is possible to grind a wooden surface very delicately and extremely accurately, except for corners and shallow recesses, where the disc can not reach.

- Vibratory grinders. Can handle not only wood, but also plastic, and stone surfaces thanks to the ability to regulate the speed. Has a rectangular sole, ideal for finishing large areas.

- Delta sanding. The triangular soleplate enables precise finish sanding of corners and edges.

- Multifunctional. This type of tool can be used for large volumes of work, and for processing hard-to-reach areas and corners. Additional accessories to the soleplate in the form of an iron allow you to grind even the profile.

There are also belt sanders for roughing and polishing, to make the surfaces absolutely smooth.

angle grinder or angle grinder. what’s the difference?

Both devices are varieties of the same electric tool. an angle grinder. They differ in power and actual performance. For example, while some models are used primarily for cutting, others are more suitable for grinding.

angle grinder in the form in which it is presented by most consumers, has a relatively low power, simple functionality. The 1.5 kW motor overheats and has to be switched off for extended periods of non-stop work. It can be successfully used only for household needs, such a tool will not cope with large amounts of work.

Professional grinders have a much more powerful motor from 1.8 to 2.5 kW, which ensures continuous, continuous operation. In such tools it is possible to regulate revolutions, they have higher productivity.

Grinders have a smooth start function, unlike domestic grinders, which gain speed immediately after turning on. At low speeds, they “fade out”, while professional machines continue to run at a set frequency thanks to the load balancer available.

Nozzles

On what attachment is installed on the angle grinder, directly depends on the scope of its application. For each type of material and nature of work performed different nozzles are designed. Their basic types are discs or circles and various kinds of brushes, fixed perpendicularly to the body of the angle grinder on the spindle by means of a threaded connection. Both have a sufficiently large number of modifications and types. Thus, the wheels differ from each other primarily by the type of material to be machined.

There are different circles for: steel, stone, paving and ceramic tiles, various alloys and so on. Although there are also universal cutting-off wheels that are applicable, if not to all materials, then to most of them. Cutting-off wheels also differ in diameter, as mentioned above, and in thickness. In addition to cut-off wheels, there are also end blade grinding wheels, as well as abrasive discs, which require a separate nozzle or flange. In the latter case, the nozzle is screwed to the spindle, and already to it, with the help of so-called Velcro, is attached a sanding disc.

Brushes used on angle grinders, also depend on the material to be processed. So, you can select brushes with bristles made of steel that are mainly used for cleaning rust and paint from metal surfaces. Approximately the same scope of application and have a brass brushes. They’re softer than steel bristles and break down faster, but they don’t spark and leave fewer scratches on metal surfaces. There are brushes with nylon bristles. Their area of application. mainly wood. In addition, brushes are divided into cup-shaped and disk brushes.

Choice of angle grinder for home. Basic criteria

What characteristics of an angle grinder are worth paying attention to before buying? It is obvious that first of all the choice will depend on the kind of intended work. If it is not clear which angle grinder to choose for the home, that is, to choose a universal tool, then you should pay attention to the following characteristics:

- The diameter of the nozzle used. As noted above, a fairly simple selection criterion is used here. the more powerful the tool, the larger the nozzle. In turn, it is obvious that the larger the diameter, for example, the wheel for cutting metal, the thicker the workpiece you can cut.

- Power rating. Here the choice depends on the application. The range of this parameter is quite extensive: from 0.6 to 2.7 kW. So, if you buy an angle grinder for simple sanding of wooden surfaces, for example, there is no point in buying a large, powerful tool. Firstly, because it costs a lot more, and secondly, a heavy professional tool will not be able to unlock its capabilities. And it’s not comfortable to operate the big, heavy machine in this mode, which only leads to rapid fatigue. And vice versa, if you are going to cut concrete or metal workpieces, then you need a powerful angle grinder with a large diameter of the wheel.

- Speed of rotation. The speed range of the spindle of the angle grinder varies from 2800 to 11000 revolutions per minute. In more expensive models it is possible to regulate the speed, and if there is no such a regulator on the tool, then the principle works: the larger the disk, the less speed. The fact is that at high speed of rotation of the nozzle is quite likely to destroy it, which can lead to injury.

- Additional functions. On this criterion of choice let’s dwell in more detail to understand what angle grinder is better and make an informed choice.

Professional

How to choose an angle grinder for construction site work or industrial production? The easiest answer is to choose a large angle grinder. The power rating of such a tool starts at 1.The housing of the professional angle grinder has an output power of 5 kW, which means that it can be used intensively for a long period of time. Overheating of large and powerful angle grinder, in contrast to household tools, is practically excluded. In addition, professional angle grinders have a higher wear resistance of parts, which significantly increases the service life of the power tool.

The body of a professional angle grinder is made of high-strength materials, which well protects the tool from various kinds of mechanical damage. And, finally, professional tools have more additional features, which simplifies working with it. But the angle grinder of the professional type has significant disadvantages, too. First, it is a lot of weight, which is associated with both the large size and the presence of additional nodes. Well and secondly, the price of a professional tool can be many times higher than the price of an angle grinder for domestic use.

Angular grinders also differ in the presence of one or two handles. Everything is clear here. Two knobs are used on large and heavy angle grinders with more than 2 kW. For household mobile grinders is quite enough and one handle to hold them securely during work.

Purpose

First of all, you need to understand when and for what purpose they are used.

- The grinding machine‘s job is to grind concrete, metal, wood, stone, and other surfaces. By grinding, we mean achieving a minimal roughness or irregularity of the surface. The mechanical deformation of the ground surface is an indispensable result of grinding. It is the primary process and always precedes polishing.

- The task of a polisher is to polish the surface. Polishing refers to the final surface treatment to remove the finest layers. If we are talking about metal surfaces, then to a “mirror shine”.

That is, the first thing that distinguishes these machines is their fundamental purpose and the order of application.

Technical characteristics

Based on their purpose, grinders and polishers have different technical specifications. First of all, these are two indicators:

- Number of revolutions. Grinding is always performed at high rpm 5000-15000 rpm./min., Otherwise the performance is very poor. Polishing, especially of car bodywork, is done at 300-600 rpm./min. Otherwise you will damage the expensive paint.

- Speed adjustment. In the range of grinders there are practically no models with adjustable speed, t.к. This function is rarely used here. Whereas with polishers, on the contrary, this function is important for finding the most suitable speed for the surface to be polished. Even if your grinder will be set at minimum speed, suitable for the surface, then from prolonged polishing work in this mode, it will quickly burn out the gearbox.

How to choose an angle grinder. Options

If you want your tool in addition to the mandatory on and off function has additional features, and you are willing to splurge on it, it will be useful to know, before you choose an angle grinder, what you can please the manufacturers of the tool, making it more comfortable and safe to work with it.

- Soft start system. This option allows slow speeds thanks to the balancing of the starting current. This compensates for the power surge when you switch on the tool. The soft start not only extends the service life of the angle grinder, but also protects other plugged-in appliances from power surges that can damage them.

- Disc RPM control. A very useful function, especially for grinding work. This system helps you to choose the optimal mode of nozzle rotation, which significantly prolongs the life of consumables and saves energy.

- The system of protection against restarting. Avoids incidents which can cause serious personal injury if the tool is suddenly switched on after being forgotten to turn it off, for example, during a temporary power outage. The system makes it necessary to press the start button to restart the angle grinder.

- Automatic disc balancing system. Uneven disc wear causes the tool to vibrate, resulting in rapid wear of the spindle components. To avoid such undesirable effects, some angle grinders are equipped with a balancing system that quickly and effectively stabilizes vibration.

- Speed control. Also an extremely useful feature, and before you choose an angle grinder angle grinder for home, it is advisable to make sure it is available. To set the optimal RPM before each job and different kinds of materials to be treated. this means not only to reduce the wear of the nozzle and avoid overheating of the tool, but also to protect yourself from possible injury in case of sudden destruction of the wheel that can not withstand too high RPM. In addition, for some types of processed material, it is undesirable overheating of its surface and reducing the speed of the head simply and effectively solves this problem.

- anti-jamming protection system. Automatically shuts off the tool in case of grinding head jamming, which not only protects the wheel from damage, but also prevents the brushes of the angle grinder motor from getting burnt.

- Quick disc change. Some models are equipped with an improved design of the attachment structure, which allows you to quickly replace the wheels.

Types of angle grinder

Angle grinders. this is one of the most popular power tools, as in the home, and in industry. In terms of popularity among buyers, they are second only to electric drills and screwdrivers. Have in his arsenal of angle grinder just have to do something with their hands every man. This fairly versatile power tool is capable of performing a variety of jobs, including cutting, grinding, and deburring various materials. angle grinder with equal success are subject to: stone, wood, metal, plastic, slate, drywall, etc. д. That is, almost any material used in construction.

What characteristics of the angle grinder you should pay attention to before buying? Obviously, in the first place, the choice will depend on the type of work to be done. If it is not clear which angle grinder to choose for the home, that is, to choose a universal tool, then you should pay attention to the following characteristics: