How to Grease the Gearbox of an angle grinder? Useful tips, masters’ recommendations

Angle grinder (angle grinder) is called in simple terms an angle grinder. With the help of this tool, craftsmen perform many operations. As with all other equipment, it requires extensive maintenance. Moving parts need to be lubricated. Special products are used for this purpose.

There are several options than to lubricate the gearbox of angle grinder. Tips from experienced craftsmen can help you choose the best method. Angle grinder in this case will work long and efficiently.

The role of lubrication and its characteristics

A distinctive feature of the angle grinder is the gearbox, which consists of gears with a helical structure. This assembly is subject to a high load and the greatest wear and tear when the tool is in use. The rotor of an angle grinder generates a torque that travels from a small gear with beveled teeth to its large counterpart. The last gear has a shaft on which the working tool (mill, emery wheel, brush) is mounted.

As the gears move with the friction of the gears against each other, the temperature rises. This leads to weakening of the metal and to early wear. To prevent negative consequences, special compounds are introduced into the rubbing nodes, which significantly reduce the strain and prevent the parts from intensive heating.

Lubricant for the gearboxes of power tools must have the following parameters:

- Its viscosity must not exceed 800 units.

- Tensile strength of over 120 pascal.

- The compound must be classified as refractory (over 100°C).

- have water repellent properties;

- to be held firmly on the parts;

- Do not cause corrosive processes;

- do not contain mechanical additives.

But in addition to the gearbox, angle grinders have two kinds of bearings that also need to be lubricated. One of them helps the electric motor. The other serves as a support for the spindle of the big gear in the gearbox. These bearings operate under different conditions and require different oil compositions.

What can you grease the gearbox of an angle grinder?

Home ” Tools for the cottage industry.

The angle grinder is a popular tool used for cutting various materials. Due to the versatility, the intensity of use of angle grinder by the average owner is quite high, which determines the need for competent maintenance.

The need for lubrication

Like any device with a motor and rotating elements, the angle grinder needs lubrication. Lack of such leads to various negative consequences:

- Decrease in the speed;

- Overheating of the equipment;

- Overheating the disc;

- Deterioration of cutting properties;

- Increased risk of accidents.

Lubrication in the gearbox of an angle grinder is an important contribution to efficiency and safety, since it is this element that is subjected to the greatest loads. Let’s understand what to lubricate the gear reducer angle grinder to ensure optimal performance tools.

Recommendations

Before choosing which grease to lubricate the gearbox of the angle grinder, you should familiarize yourself with the general requirements for it:

Lubricant should not leak under high loads (prolonged operation). Some compounds have the following problem. when heated, they become thinner and lose some of their properties. It is advisable to choose a special grease and the company that made the tool. On the other hand, such compositions are usually more expensive than others. Environmental safety

This requirement has become popular relatively recently, but its importance is hard to deny. Avoid using non-specialized compounds such as solidol or lithol, although in theory you can resort to their help

It is advisable to give preference to silicone-based compositions, as they have high heat resistance and mechanical resistance.

Selection of grease

In the first place, specialized formulations are recommended. Usually, such grease has a blue color and quite a long marking, which reflects the mass of various details: type of additives, viscosity class, compliance with certain standards (usually ISO or DIN).

This type of grease is designed specifically for angle grinder conditions, so it is optimal for its task

Choosing what kind of grease to use for the gearbox of an angle grinder, pay attention to the following parameters:

Maximum and minimum operating temperature

The latter point is especially important in our country conditions. Availability of anti-seize additives

Type of sliding (in most cases we are interested in the bearing type). consistency (must correspond to that recommended in the instructions to the equipment).

GREASE 101: Understanding Different Types of Grease and Lubricants | eReplacementParts.com

Note that general-purpose greases like solidol or lithol are not designed for the operating conditions typical of rotary grinders. They can be used in emergencies, but it is recommended to change to specialized compounds at the first opportunity

In addition, the filling of the gearbox grease is better to trust professionals specialized service centers.

What is grease 158 for?

designed for use in automotive electrical equipment (generators, starters, magneto), where it ensures operation of rolling bearings for several years without changing. This eliminates the need for periodic lubrication of such units in the operation of cars and tractors.

- For grass trimmer

- Cultivator Drive: The Mole and more

- Trimmer

- Plasma cutting attachment

- On electric bicycle/motor

- For a boat motor

- For electric screwdriver

- Sliding gate drive

Gearbox lubricant for angle grinders

Correct and periodic maintenance is the guarantee of longevity for any hand tool. Of course, you can send it to special service centers for maintenance and diagnostics, but as the saying goes, “If you want to do it well, do it yourself”. Therefore, it is worth to understand how to service yourself such a popular tool among home craftsmen, as an angle grinder or angle grinder, in common parlance.

The most subject to wear are the moving parts of the angle grinder. These are the bearings of the armature, gears, as well as the gears themselves, which are in the gearbox. The lubricant (or lubricant) supplied by the manufacturer becomes old over time and loses its properties, which causes increased wear of gears in the gearbox and, as a consequence, increased vibration and noise during operation. Periodic maintenance and lubricant replacement in the gearbox of the angle grinder should be performed at least once a year.

How to properly remove old grease in the angle grinder

Disassembled gearbox of angle grinder should be well cleaned from old lubricant. It is no longer performing its functions, plus it has already accumulated solid particles from the wear and tear of the moving parts. Old lubricant mixed with new lubricant also greatly impairs its characteristics. Therefore, the gearbox and gears must be thoroughly cleaned.

The old grease is removed with a rag, paper towel or just a rag. Removed parts can also be washed in gasoline or solvent. Washed parts must be dried thoroughly before assembly. Residues of solvent or gasoline will mix with the new grease and change its consistency, which again will impair its characteristics.

Expert recommendations

Experienced experts give recommendations, what is the best way to lubricate the gearbox of an angle grinder. They say that if it is impossible to serve the tool branded grease, you can choose a different composition. The second most popular lubricant in our country is recognized as grease for CV joints. It is most often used for tools of domestic manufacture. Some craftsmen choose a grease for the C.V. and foreign angle grinder. However, the quality of original formulations will be significantly higher.

Worse, if the master has given preference to such compositions as lithol or solidol. These products are universal. They are not able to qualitatively serve the gearbox system of the angle grinder. If they are used, the tool will not work to its full potential. In the beginning of operation the difference will not be noticeable. But over time, serious problems may appear in the operation of the unit.

Therefore, experienced craftsmen do not recommend saving on grease for the gearbox. The cost of purchasing original or other high quality products is compensated by the long service life of the equipment.

Lubricant requirements for angle grinder gearboxes

What to grease the gearbox of the angle grinder, the master decides for himself. There is no universal means. for a particular tool you need to pick up your fluid. The right lubricant must meet a number of requirements, including:

- be resistant to corrosion;

- consist of natural components. so as not to be harmful to the craftsman by inhalation of vapors;

- reduce the friction force of the gears, and, accordingly, the temperature of the tool;

- consistency must be thick enough to adhere to the parts, but with a viscosity not exceeding 800 Pa-c;

- The consistency must remain stable and does not change, “melt” or flow out of the mechanism when the temperature rises. the minimum dropping point is 120ºC;

- provide tool operation in the range up to 150 ºС;

- no metallic impurities may be present in the composition

- Tensile strength is not less than 120 Pa;

- be hydrophobic, have water-repellent properties;

- protect “insides” from dirt, dust.

Review of greases for angle grinder

If you lubricate the working tool with lithol or solidol, saving on materials, there is a high probability that, eventually, the technique will refuse to work properly, no matter how good it was.

Some resources claim that preparation of liquid that satisfies all mentioned above items will not be a problem even at home. In some cases, it is recommended to use the grease in combination with oil MS-20, and in other cases it is advised to use a mix of Ciatim-221 and TAD-17. Despite the many positive reviews, in both cases, the consequences can be unpredictable. the manufacturer is unlikely to have taken into account the possibility of filling the gearbox of the technical means not reassigned to him compositions.

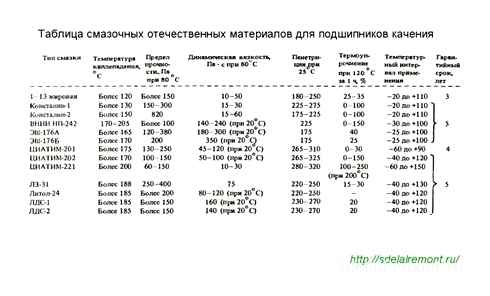

Foreign companies recommend masters than to lubricate the angle grinder, offering specially designed ointments. The manufacturer strongly advises to use exactly the means specified in the instruction manual. They are present in the Russian market, but the price of them is quite high. In this regard, the question of high-quality greases of domestic manufacturer comes up sharply:

- If the original imported lubricant contained molybdenum, you should look for an analogue with the “MoS2” molybdenum designation;

- “NLGI2. for industrial tools and others operating with liquids of the second viscosity class (penentration. 265-295);

- “ISOL-XBCHB 2” for ISO standard;

- “DIN 51825-KPF 2 K-20” for DIN standards.

Among Russian greases stand out materials from Interskol, which has been producing and servicing power tools for a long time. These lubricants adjusted to the peculiarities of equipment not only ensure first-class gearbox operation and meet many requirements, but also are pleasantly gratifying in terms of price. For example, a tube of grease will cost the buyer no more than 100 rubles, but the same lithiol is only half the price. Whether it makes sense to save money in this case, or it is easier to pay a little more, but to get a quality product. each master must decide.

Control

Having studied how to lubricate the gearbox of an angle grinder. Review the procedure for checking that the tool is serviced properly. angle grinder must be assembled and plugged in. When starting the motor, the quality of grease filling of the gearbox is assessed. To do this, briefly run the angle grinder at idle speed.

If after the test the gearbox begins to heat up and there are traces of grease from the gaskets, it means that there is too much substance in the mechanism. After disconnecting the tool from the mains, open the gear cover. Excess oil will be observed on the walls. They are removed from the cavity of the equipment.

If unusual noises are heard during the test run, then you have not used enough lubricant. In this case, the tool is disassembled and additional compound is added to the gearbox. Then the test procedure is repeated. If everything is in order, the tool can be used as usual.

Cara memberi grease pada grinder/How to lubricate angle grinder by grease.

Having considered what to grease the gearbox of an angle grinder, as well as the procedure of this process, every master without problems will be able to service his technique himself.