Gearbox for power tiller

One of the most important mechanisms of a modern power tiller is a gearbox built into its design. Its function is to continuously transmit the engine torque to the wheels of the agricultural machine in use. Gearbox plays quite an important role in the construction of a power tiller, so every owner of the equipment should know how to lubricate and repair the mechanism themselves in case of its breakdown.

Having an understanding of how the gearbox of a power tiller is designed, it will be much easier for the owner of an agricultural machine to lubricate and repair the mechanism.

The gear mechanism of the machine used in agriculture in disassembly is complete with the following elements:

- pulley and protective cover;

- ball bearings;

- the bushing, which is located in the area of the input shaft

- lever for adjustment and timely shifting;

- shift shaft and fork;

- the pinion, located in the area of the intermediate shaft;

- the shaft assembly;

- double-row steel chain;

- washer and rubber seals;

- The input metal shaft;

- clutch and clutch fork.

The location of each of these elements of the reducer of the motor-block in details will show the scheme.

This gearbox design ensures proper operation of the mechanism under almost all conditions. Each part of its construction is important in its own way, so a breakdown or loss of any of them will inevitably lead to a malfunction of the entire mechanism.

What are the reducers of motoblocks. description and features of mechanisms

Gearboxes, which are equipped with modern motor blocks, are divided among themselves according to the purpose. There are the following types of built-in mechanisms:

- angular reducers. the role of this equipment is to dock the installed motor and not connected to it the transmission of the motoblock. Such a mechanism is known for its efficiency and optimal cost. If necessary, the angular gearbox for a power tiller can be refined to increase the endurance and power of the element. Another important advantage is the simple design of modern angular reducers for power tillers. The simple structure of the mechanism allows you to assemble it with your own hands, without spending money on the purchase of expensive parts;

- Reduction reducers. this type of equipment is designed to reduce the number of generated speeds in order to increase the power of the walking tractor several times. The reduction gear reducer for power tillers built into the machine is controlled by a separate air cooling system which guarantees failure-free operation of the machine even in the most difficult weather conditions. Motor blocks with these reducers have high endurance and versatility;

- gear reducers. the advantages of these mechanisms include sufficiently high gear ratios, reliability, high wear resistance and simple design, which allows you to repair them quickly without assistance. The gear reducer is very easy to use and self-maintain;

- Reverse rotation gearboxes. the principle of operation of such mechanisms is called “reversing scheme”, and gives a lot of advantages to a power tiller. The main of them is the ability to move at rear speed, which greatly increases the maneuverability of the machine. The main disadvantage of such gearboxes experts consider their low performance when using heavy attachments;

- worm gearboxes. worm gearboxes are made mainly from durable materials, so they have good characteristics and resistance to wear. It shows high reliability regardless of operating conditions.

The simplicity of the design of modern reducer allows you to make such a mechanism for a domestic motoblock by yourself. Adhering to the correct order of action and having all the necessary materials, the farmer will be able to make a homemade unit, which by its reliability and quality will be almost as good as its market counterparts.

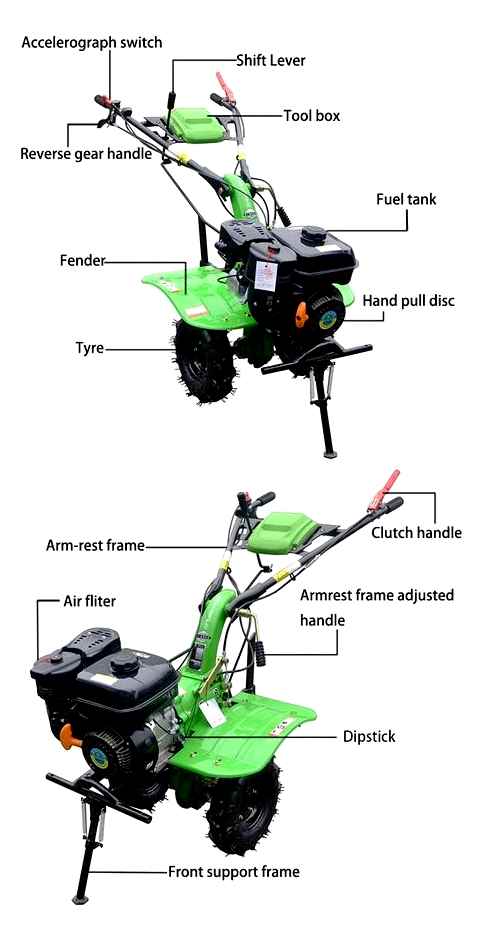

What is a single axle tractor

Engine blocks (MG-tractor) are mobile, compact devices, equipped with special attachments for working on homestead plots. The mini-tractor is a complex unit consisting of several autonomous systems:

The power tillers are equipped with gasoline or diesel engines with liquid or air cooling systems. Gasoline power units are divided into two-stroke and four-stroke, diesel units are only four-stroke.

The MG tractor’s transmission transmits rotational forces from the motor to the unit’s drive wheels and consists of the following units:

In other words, a single-axle tractor is the same vehicle, complete with an internal combustion engine, including all the necessary systems for its successful operation. Therefore it is subject to the same oil classes and the same requirements as the large transport units.

Engine oil for tractor engine

When buying a single-axle tractor, it is always accompanied by an instruction manual for its trouble-free operation, in which the manufacturer gives recommendations and sets the frequency of maintenance, class of the oil used, etc. To avoid premature engine repair or replacement, you must strictly adhere to the manufacturer’s requirements.

The main purpose of the lubricants:

- Friction reduction.

- Heat dissipation.

- Protection of inner surface of power units from carbon and slag deposits.

- Reducing the noise level of the engine.

For technologically correct choice of lubricant it is necessary to take into account that any brand of engine oil for a motor block is designed for certain operating conditions and is selected based on the climatic characteristics of the region and the magnitude of mechanical loads.

Depending on these characteristics, the necessary viscosity index is selected, which is necessary for the quality work of all mechanisms:

In addition to seasonality, the functional purpose of engine oil for a motor block is affected by its base and type of modifying additives. According to the method of production lubricants are divided into the following categories:

Another peculiarity of lubricants is that they are intended for a particular type of engine: gasoline, diesel, two- or four-stroke.

Engine oil for gasoline engines of power tillers

For power tillers with petrol engines the lubricants with index S followed by the letter designation of the degree of mechanical loads:

SA. designed for engine work in a moderate operating mode;

SB. medium level of mechanical loads;

SD. for engines equipped with a crankcase gas recirculation system. PCV;

SH. for all modern minitractors.

SB class is characterized by high antioxidative and anticorrosive properties.

SF. characterized by good anti-sticking properties, especially when using greases in two-stroke engines.

Engine oil for a diesel engine of a power tiller

Oil for diesel engines can be divided into the following categories (API):

CJ-4. intended for powerful units, working under extreme conditions. The brand is distinguished by its high non-stick properties and low sulfur and phosphorus content (04-0,12%).

CI-4. for engines with moderate performance requirements. Characterized by high dispersant and antioxidant properties.

CH-4. for four-stroke units running on any brands of diesel fuel.

CF-2. Oil for MG tractors with two-stroke engines. Good protection for machine parts from premature wear.

CA. for power tillers operated on low-sulfur diesel fuel. Characterized by high non-stick properties.

CB. grease with good corrosion protection properties.

CC. fluid is designed for the lubrication of powerful engines operating in harsh climatic conditions.

Oil for air-cooled four-stroke motorcycle engines

Motor greases for four-stroke motor blocks must meet the following requirements:

- Low kinematic viscosity.

- High anti-friction and anti-wear properties.

- Thermal conductivity.

- Anti-stick qualities with good detergent properties that help easily remove carbon deposits from engine cylinder walls.

- High temperature resistance with negative coking that prevents piston rings from sticking.

Oil for a diesel power tiller

Engines that are filled with diesel. different from gasoline-powered units. Accordingly, a completely different type of grease must be selected to keep them running smoothly.

The main factor when buying a lubricant for the diesel factory engine is its viscosity, which is marked with the designation SAE, followed by a set of letters and numbers.

The latter will tell the customer in which conditions it is best to use the selected grease:

- SAE 0W, SAE 5W or SAE 20W. designed to operate in regions with harsh, long winters;

- SAE 20, as well as SAE 40, SAE 60. marking without letters means that it is a high-viscosity fluid that has proven itself in hot summer weather;

- SAE 5W-30, SAE 10W-40. all-season oils, which work effectively both in winter and in hot summer.

The classification, provided by the American Petroleum Institute, divides motor oils for domestic and professional power tillers by their performance groups. Accordingly, the following types of lubricants are available on the market:

- API CJ-4. are used in branded high-end very powerful engines, which are designed specifically for operation under high loads. Experienced gardeners recommend using factory oils of this type for daily lubrication of engines manufactured by BriggsStratton and Honda brands ;

- API CC for non-injection and turbocharged power units. These oils provide continuous protection of engine parts against corrosion, formation of tarry deposits and increased wear.

When selecting these types of oils, you need to pay special attention to their manufacturers. Users are better to trust the well-known companies, the list of which includes brands Elf, Liqui Moly, Motul, Shell and others.

Is it necessary to add oil to the gasoline for the Moto-Block??

The answer to this common question can be given based on the type of factory engine of the existing motoblock. Agricultural machines are equipped with either 2 or 4-stroke engines. Gasoline for a motor block with a factory 2-stroke motor must be diluted with engine oil, necessarily adhering to the proportion indicated by the brand manufacturer.

It is important to remember that 2-stroke and 4-stroke engines work on different principles. Combustion in motors of the first type occurs continuously in 2 strokes. In this case, the brand oil with which the fuel mixture is prepared. Contains not only lubricants but also additives that improve fuel quality. In factory-built 4-stroke engines, oil and fuel for your motorcycle block are always filled separately, in the manufacturer’s designated tanks.

Oil for a diesel motoblock. peculiarities of choice

When selecting engine oil for your diesel power tiller, you must follow the directions in the owner’s manual. But if you have lost the instructions for use, you will have to study the formulations available on the market more carefully.

Engine oils for diesel engines are classified into the following categories. To determine the type and compliance of the composition for a specific engine block will help a special marking, indicated on the container with the lubricant:

- API CJ-4. compositions with this marking are designed specifically for motor blocks, capacity from 10 liters. с. and more. The composition of these lubricants has a higher viscosity, which guarantees proper operation of all elements of the engine of the machine;

- API CI-4. these oils should be used for engines equipped with different types of injection and supercharging. These oils have good dispersion characteristics and are highly resistant to thermal oxidation;

- API CH-4. lubricants with this marking fully meet all modern requirements and quality standards. Among the advantages of these compositions we should mention the possibility to fill them in diesel engines running on fuel with sulfur content exceeding 0.5%;

- API CA. compositions of this type are optimal if diesel fuel contains small amount of sulfur. Lubricants with this marking protect the engine of a power tiller against harmful deposits;

- API CB. using this oil allows to reduce the risk of corrosion of the motor block bearings;

- API CC. these oils will be the best option for the engine, equipped with a turbocharger, but without a supercharger. These compositions help to maintain the power tillers withstand continuous loads and to work properly in hard conditions;

- API CF-2. oils in this group perform well in heavy-duty motor tractors.

After you have bought the correct motor oil you can fill it in. The procedure is quite simple:

- First, set the unit in a horizontal position;

- Place a wide container under the drain hole in the engine and remove the plug by gently prying it with a screwdriver;

- Wait until the old oil has drained from the engine and screw the plug back into the hole;

- Pour at least 2 liters of new lubricant into the engine.

Remember to change the oil in new motor blocks three times at intervals of 5 hours of moderate use. After this work, change the oil no more than once in 25 hours.

Oil in the motoblock gearbox. how to check and change it?

The gearbox is an important element of a power tiller, whose function is to transmit torque from the engine to the wheels of the machine through the V-belt transmission. Gearbox parts are subject to heavy wear and need regular oiling. Let’s say right away that not all means available on the market are suitable for this purpose.

The best way to lubricate the gearbox is to use gear oil. This type of compound is excellent for lubricating moving parts. The second important question is how much lubricant to put in the gearbox. To find out, a number of specific steps will need to be taken:

- Carefully place the single axle tractor so that its wings are parallel to the surface;

- Take a wire, at least 70 cm long, and bend one of its sides into an arc;

- Slide the wire through the filler hole as far as it will go, then pull it back out.

Next, look at the wire. If it is 30 cm on the wet side, you do not have to refill the gearbox with oil. If the level of lubricant is lower, it is necessary to add as much oil as is needed to reach the 30 centimeter mark on the wire. Pour the lubricant into the Geareducer in the following order:

- Place the single axle tractor on the stands;

- Look for the oil drain plug on the underside of the gearbox. Place a wide container under it and start slowly unscrewing the cover;

- Wait 10 minutes, during which time all the oil will drain from the gearbox;

- Screw the drain cap all the way in, unscrew the filler cap and put a funnel in it;

- Pour about 2 liters of transmission oil into the gearbox;

- Check the level of composition with a wire. if there is less than 30 cm of wire in the oil, then add some more material.

In most cases, you need to change the lubricant in the gearbox of a motoblock at least once per 100 hours of operation of the unit. The frequency of replacement may vary depending on the recommendations of the motoblock manufacturer. If you use your power tiller for more than 4 hours a day you should change the compound once every 50 hours.

Gear oil for your power tiller

Gearbox is filled not with engine oil, but with special gear oil. For different models of power tillers there are different recommendations. For example, for Neva MB-1 motoblocks, such types of oils as TAD-17I, TAP-15V are suitable. For the Neva MB-2 engine block GOSTs recommend oils TEP-15, TM-5, SAE90 API GI-2, etc. д. For power tillers of Zubr and Kentavr it is recommended to use TAP-15 oil.

As well as for choosing lubricants for other models of power tillers, in this case you should also follow the instruction manual and recommendations of the producer. In general, oils for diesel motoblocks are divided into such categories:

- CA. for power tillers subjected to low and medium loads. The oil reduces considerably degree of formation of corrosion on bearings and deposits on engine parts at high temperatures. Not suitable for use in high voltage environments;

- CB. like the previous type, this oil is designed for low and medium loads. Compared to category CA, this oil reduces corrosion even further;

- CC. for use in power tillers, subjected to medium and high loads, whose engines are air-cooled. Reduces deposits on parts at high temperatures and reduces the risk of corrosion on the bearings;

- CD. for air-cooled diesel engines that are designed to operate at higher rpm.

Do I need to add oil to gasoline for my power tiller??

The fuel for a power tiller may be clean, or a fuel mixture may have to be prepared. It depends on the engine type. For two-stroke engines, gasoline for the motoblock must be diluted with oil. The proportions recommended by the producers must be strictly observed (often it looks like 1 part of oil to 4 parts of gasoline). Four-stroke engines do not require this mixture and fill their tanks with pure gasoline.

It is also important to note that motoblocs, which run on diesel, in no case need such mixtures (all diesel engines are 4-stroke). Otherwise everything can end up in a serious breakdown of the unit.

Is it necessary to add oil to petrol for your Moto-Block??

Fuel for your power tiller may be clean, or you may have to mix it with fuel. It all depends on the engine type. For two-stroke engines, gasoline for a power tiller must be diluted with oil. You should clearly observe the proportions that manufacturers recommend (often this proportion looks like 1 part of oil to 4 parts of gasoline). Four-stroke engines do not require such a mixture and fill up with pure gasoline.

It is also important to note that the diesel-powered motor blocks do not need such mixtures in any case (all diesel engines are 4-stroke). Otherwise it could end up in a serious damage to the unit.

Can you fill a single axle tractor with car engine oil?

One should not take chances and fill a single axle tractor with automobile oils, because automobile and tractor engines have different lubrication principles and operating temperature regimes. Also, engines for power tillers have some other peculiar qualities (design, material of which it is made, degree of forcing, etc.) which can be incompatible with engines of automobiles and auxiliary equipment. д.The engines of power tillers and tractors have some other peculiarities (design, material, power level, etc.) that may be incompatible with automotive oils.

Source: http://sadovaja-tehnika.com/motobloki/maslo/

Transmission oil for your power tiller. choosing the right lubricant for your gearbox

To lubricate the planer gearbox, you should use a special gear oil. It must meet a number of important criteria, the most important of which is the viscosity of the material. Gear oil should be viscous enough to coat all rubbing parts of the mechanism with a thin film. However, under no circumstances should too thick a solution be used, as it would not be able to penetrate into all of the parts in the gearbox.

Oil in a motoblock gearbox. how to change it without the help of a specialist?

Changing the oil in the gearbox of a crawler tractor is carried out in much the same way as changing the lubricant in the engine. Each gearbox has a drain and fill hole, closed with the appropriate caps.

The procedure for changing the oil in the gearbox is performed according to the following algorithm:

- The single-axle tractor will need to be stationary mounted on some elevation, at the most, you can put bricks under its frame;

- Next, under the drain hole directly in the bottom of the gearbox you need to put a wide container, completely unscrew the upper fill cap, and start unscrewing the drain plug. As soon as oil starts to flow out, the cover should be removed completely;

- After that you should screw in the drain cap and pour new oil into the gearbox. Use the dipstick to make sure that there is a sufficient amount of lubricant in the mechanism. The dipstick is located on the bottom of the filler cap. To check it, it is necessary to screw in the cap, unscrew it and examine the dipstick. If the bottom of the dipstick is dipped in oil, you do not need to refill.

Most engine-block builders recommend changing the oil in the gearbox of the old engine at least once every 100 hours it has been in operation. However, if a single-axle tractor is used much, then you need to do this procedure every 50 hours of work.

How much oil to fill in a crabby tractor gearbox?

If there is a question about the amount of oil to pour, it is worth following a simple algorithm:

- the single axle tractor must stand on a level surface with the wings parallel to the ground;

- The oil dipstick can act as a wire, a length of 70 centimeters or more;

- The wire when bent should resemble the shape of an arc;

- A wire is shoved down to the bottom of the tank to check the oil level.

If the lubricant for 30 centimeters of wire, it is not topped up any more. If it is dry, at least two liters of grease must be refilled.

How to replace oil seals on a power tiller?

If there is an oil leak, you need to replace the oil seal. Algorithm of replacement of this element is performed according to the following scheme:

- The cutters are removed from the shaft, completely cleaned of dirt and oil residue;

- Unscrew the screws on the cover that protects the gearbox. The cover is tapped with a hammer to make it fit snugly;

- The worn packing is pulled out and the area under it is carefully wiped clean;

- The edges of the new packing are sealed with a sealant. The part is installed and the cover is screwed on.

To disassemble and replace the oil seal is very time consuming. That is why before using a power tiller you need to make sure that the sealant used is completely dried out.

The above recommendations and algorithms are suitable for the following brands of equipment: Neva MB-1 and MB-2, Cascade, Farmer, Oka. So you can do a simple oil change and oil seal replacement yourself.