Hacksaw. Types and operation. Applications and Choices. Teeth

Hacksaw is a hand carpentry and metalwork tool, which is a kind of a saw. Depending on design, it can be used for cutting wood, metal, plastic, aerated concrete, and other materials. It consists of two parts. the cutting blade with sharp serrated teeth and a handle for good grip.

The hacksaw is one of the oldest tools. It appeared much earlier than the modification for working with metals. There are several varieties:

Classic

Also known as wide or regular, it is a standard hand tool for sawing. It is designed to cut longitudinally or transversely. You can use it to shorten a board or cut a branch. It is a standard carpentry and joinery tool. It makes a quick cut, but it is quite coarse and produces coarse chips. Its teeth are triangular and spaced from 1.5 to 6.5 mm apart.

Cupped or narrow

This is a more narrowly defined tool. The small blade width makes it possible to cut curved elements. The main purpose of such a tool is not the usual trimming, but the ability to cut sheet material when you want to work on a strictly defined contour. The narrow blade is more maneuverable and allows to circumvent outlined curves, which cannot be done with wide saws. These saws are much lighter and more compact. They can have teeth on both sides that differ in size. This makes it possible to produce cuts of varying purity. Smaller choice of teeth results in a smoother cut.

Spiked

Also called a cleaver or a shiv, this is a specific tool, the main purpose of which is to remove protruding spikes and grooves. These saws are used by carpenters and joiners for a clean and smooth cut. Blade of this tool is the thinnest, so the cut is narrow. To ensure that the blade does not constantly bend on the opposite side from the cutters is clung to the bead, which increases the rigidity. It is not possible to make a cut deeper than the blade height because of the shank. Such a tool has fine teeth in the shape of an isosceles triangle. It is used exclusively for crosscutting. thickness of the working part is not more than 1-1,5 mm.

Types of tines

Wood is a very special material that can have complications when sawing from different directions. In this regard, hacksaws are divided into three categories:

For a longitudinal cut

Hacksaw has special teeth, which are inclined forward at an acute angle. Their movements produce a shearing effect on the wood fibres and clearing away sawdust. This kind of equipment guarantees the fastest possible work when it is necessary to cut a board in fibre direction. Quite large sawdust is produced, the size of which depends on the height of the teeth. The bigger the teeth, the faster the work. When it is necessary to cut even a thin branch, such a saw will be ineffective.

For cross-cutting

Straight-toothed hacksaw is used. Such a tool would be an excellent choice for cutting boards or branches in the garden. It is the right one for cutting firewood or shortening a shovel cutter. The vast majority of all manual wood sawing equipment is crosscut.

Universal

It is a modification of the transversal, but with a special sharpening of the teeth, which allows to compensate for the lack of the resulting angle of attack to the wood fibers. There are also specialized types of hacksaws in which the teeth are arranged in groups of several. There is a small gap between the groups. This tool is designed to work with raw wood. The indentation between the cutters ensures cleaning of wet chips, which can be removed on their own without the need for manual cleaning.

Specialized

Specialized design with Pobedite tips was developed especially for working with aerated concrete. This tool provides a firmer plunge cut into the surface and faster cutting of tough materials. Such a hacksaw is good for cross-cutting as well as longitudinal cuts.

When choosing a saw it is worth paying attention not only to the direction of the teeth, but also to their size. There are 3 types of cutters:

- 2-2,5 mm. for accurate work with small parts.

- 3-3,5 mm. for medium-sized workpieces.

- 4-6 mm. for rough cuts in lumber and firewood.

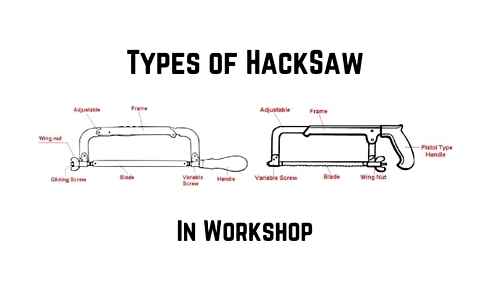

Metal hacksaws

Metal saw has a special design that consists of a cutting blade and a frame for fixing it. Blades are replaceable. They have small teeth that are specially hardened. The blade itself is made of high-speed steel, but it wears out rather quickly as a result of use, and there are cases when individual teeth break. Dimensions of such a tool rarely exceed 400 mm in length. Cutting depth is limited by the height of the frame.

Design

A handheld hacksaw consists of two parts: the cutting blade and the handle. The latter is often referred to as the frame.

A hacksaw can be either a one-piece or an extensible hacksaw. The first type has the advantage that it is possible to fix a blade of the required size to the handle.

One side of the tool carrier has a static head and a part with a handle; the other side has a moving head and a screw to adjust the cutting element tension. Both heads have slots for fixing the metal blade.

The ends of the cutting element are positioned so that the teeth point in the opposite direction from the holder. In this case the fastening holes of blade and head must match perfectly.

After installing the cutting element in the slots, pins should be secured. The tension of the blade must not be too weak, but not too strong either. In the first case, bends in the cutting part of the tool can occur in the course of work. This can adversely affect the quality of the cut or lead to damage to the hacksaw. At the same time the blade can break from even the slightest misalignment if it is stretched too much.

Saws made of soft metal usually have 1 mm pitch, of hard metal 1,5 mm, of steel 2 mm. In carpentry, tools with small spacing (1,5 mm) are usually used. In such a case, a 20-25 cm long hacksaw has 17 cutters in its design.

To reduce the risk of jamming the saw in the material to be cut, each pair of teeth is set in different directions by 0,3-0,6 mm.

Sometimes another method of setting is used. the method of corrugation. In that case, with a small step of 2-3 cutters withdraw to the right, and the next 2-3 cutters. to the left. At a medium pitch, the first cutter goes to the right, the second to the left, and the third stays in its original position.

The standard blade has the following dimensions:

Basic material is mostly galvanized steel or carbon alloy, sometimes tungsten or chrome-alloyed.

Teeth can be hardened or plain. While the former are disposable, the latter can be sharpened numerous times.

Standard tools have a blade up to 55 cm long and medium-sized teeth. A wide blade is more suitable for more frequent use. It is equipped with coarse teeth with large spacing. These tools have a blade length of more than 60 cm.

The universal hacksaw has a rectangular shape. For trimming dry branches, a tool with a rounded blade is recommended.

To keep the hand from slipping on the hanger, it is better to choose hacksaw handles with slots and rubber pads.

How a hacksaw differs from a saw?

A hacksaw is a type of saw. The peculiarity of this tool is that it can be used exclusively by hand.

Saws, in turn, can also be electric or petrol-powered. Most of them, like hacksaws, make reciprocating back and forth movements. But some models, such as circular saws, can rotate.

A hacksaw always has one handle. Saws can have two holders.

The blade of a hacksaw has a smooth shape. The cutting element of a hacksaw can be in the form of a disc, a closed band, or an overflow chain.

When using a hacksaw the cut is made with cutters. As for the saw, it can be sprayed, for example, in the form of diamond mini-particles located along the edge of the edge.

How to choose a hacksaw

How to choose a wood hacksaw

When buying a hacksaw for working with wooden planks, you should pay attention to the following characteristics:

It is necessary to choose, depending on the work that will be carried out. The most practical option is a hacksaw with universal hardened teeth.

How to choose a metal saw

When choosing a hacksaw for metal cutting, you need to consider the following parameters:

- Pay attention to the attachment of the blade. It should be versatile and not inconvenient to replace the blade with a new one.

- Visually inspect the tool. Hold it a little, it should fit comfortably in your hand and weigh little.

- Pay special attention to the handle. It must be comfortable and versatile for small and large hands. Prefer a handle with recesses for your fingers.

- Nut for tensioning and securing the blade. an important attribute. The craftsman should not use additional tools or special efforts to remove it. Change of a broken or blunted blade must be quick and comfortable.

- A hacksaw for metal cutting must be comfortable and move freely in any direction with any angle of inclination.

- The size should be chosen, based on the scope of application.

How to choose a hacksaw for foam concrete

Buying a hacksaw for foam concrete, you need to pay attention to the following points:

- Length. It is worth to give preference to a long tool, it allows to do both transverse and longitudinal cuts.

- Brazing on the teeth. In its presence, the operation of the tool is easier, and the wear resistance is lower.

- Steel thickness. If you choose a medium thickness, the result of the work will be of higher quality, and the chances of warping and deformation will be significantly reduced.

What kind of hacksaws for metal?

The metal saw can cut not only wood, but also plastic, that is, in fact, it is a universal tool. They are convenient to work if the wood caught used with nails, one and the same hacksaw can cut wood and a nail to re-saw.

Hacksaw. Types and work. Applications and how to choose. Teeth

A hacksaw is a manual joinery tool that is a type of saw. Depending on the design, it can be used for cutting wood, metal, plastic, aerated concrete and other materials. The tool consists of two parts. a working blade with sharp teeth and a handle for a comfortable grip.

How Power Hacksaw Works

Types of hacksaws

Hand saws come in two configurations. wood and metal. Saws for wood have large teeth and can also be used for cutting aerated concrete and drywall.

Metal saws are capable of cutting almost any material, including wood, plastic, drywall, aerated concrete, styrofoam, Styrofoam, etc.

They have fine cutters, so the cut is neat and a fine chip is formed.

Classic

Also known as a wide or regular saw, it is a standard handheld tool for sawing. It is designed to cut longitudinally or transversely. You can use it to shorten a board or cut a branch.

It is a standard carpentry and joinery tool. Gives a quick cut but makes a rather coarse cut and results in a coarse chip. Their teeth are triangular in shape with a tooth pitch of 1.5 to 6.5 mm.

Circular or narrow

It is more narrow in focus. Thanks to its small blade width, it can be used to cut curvilinear elements. The main purpose of such a tool is not the usual trimming, but the ability to cut sheet material when you need to work on a strictly defined contour.

The narrow blade is more maneuverable and allows you to bypass marked-out curves, which cannot be done with wide saws. These saws are much lighter and more compact. They can have teeth on both sides that vary in size. This gives the ability to produce clean cuts of any clarity.

Choosing the finer teeth, a smoother cut can be made.

Blade

also called “tongue and groove”, this is a specific tool, the main purpose of which is to remove projecting nibs and grooves. These saws are used by carpenters and joiners to get a clean and smooth cut. Because the blade of this tool is the thinnest, the kerf is very narrow.

To keep the blade from bending constantly, a shank that increases stiffness is hooked on the opposite side from the cutters. Because of the blade’s shank, it is not possible to make a cut deeper than the height of the blade. This tool has fine, isosceles triangle-shaped teeth. It is used exclusively for crosscutting.

Why you should NEVER EVER throw away your old hacksaw blades

Working part thickness is less than 1-1,5 mm.

For a longitudinal cut

A hacksaw has special teeth that are angled forward at an acute angle. They provide wood fiber shearing and sawdust chipping as a result of the movement.

This equipment guarantees the fastest possible work in cases where a board needs to be split in the direction of the fibers. This produces a rather coarse sawdust, the size of which depends on the height of the teeth.

The larger they are, the faster the work is. When even a thin branch needs to be cut, such a saw will be ineffective.

For cross-cutting

Straight-toothed hacksaw is used. Such a tool would be a great choice for cutting boards or cutting branches in the garden. This is the right one for cutting firewood or shortening a shovel handle. The vast majority of all handheld wood sawing equipment is crosscut.

Universal

This is a modification of the transversal, but with a special sharpening of the teeth, which allows to compensate for the lack of the resulting angle of attack to the wood fibers.

There are also specialized types of hacksaws where the teeth are arranged in groups of several. Little space between the tines. The tool is designed for working with raw wood.

The indentation between the cutters ensures cleaning of wet chips, which are removed on their own without the need for manual cleaning.

Specialized

A special design with Pobedite tips has been developed especially for working with aerated concrete. The tool gives a rougher plunge cut and cuts through tough materials more quickly. This sabre saw is suitable for both cross and rip cuts.

When choosing a saw, you should pay attention not only to the direction of the teeth, but also to their size. There are 3 types of sabre saws:

- 2-2,5 mm. for accurate work with small parts.

- 3-3,5 mm. for medium-sized workpieces.

- 4-6 mm. for rough cuts in logs and firewood.

Saws for metal

Metal saws have a special design, which consists of a cutting blade and a frame for fixing it. Blades are replaceable. They have small serrations that are specially hardened.

It is tightly made of high-speed steel, but still as a result of operation rubs off rather quickly, also there are cases of breaking of individual teeth. Dimensions of such tool rarely exceed 400 mm in length.

The depth of cut is limited by the height of the frame.

At the ends of the blade there are holes through which the attachment to the frame is inserted.

Please note that the direction of the teeth is important for cutting, that’s why there are arrows on the blades that guide you to the correct setting. If you get the wrong side, you will work much slower.

Tips for use

It is important in working with hand and electric tools to choose and mount the blade correctly. Each model has its own way of attaching the blade. Lubricate the clamping mechanism with machine oil before installing. Single type 1 blades are better for handheld hacksaws. Blades must be marked HCS or HM.

Choice of blade for electric hacksaws depends on the material to be worked with what density. Do not use a blade with any signs of damage. Single-sided blades are installed with teeth toward the handle. Otherwise they will get stuck in the metal and break.

Rating of hacksaws

Before buying a joinery tool, it is worth paying attention to the reviews of professionals and home masters, who have already managed to assess the quality of work with this or that hacksaw. Our top rated bandsaws with excellent reviews include:

Principles of working with basic locksmith tools, which include a hand hacksaw, are simple, but failure to follow them can lead to saw breakage or poor-quality cuts. The main rules of handling the tool:

- Make sure the operator stands in a comfortable working posture with his feet firmly planted on the ground. Arms at the elbow should be bent at an angle of 90º.

- Securely hold the surface to be sawed. If possible, material should be clamped in a vice.

- Keep the hacksaw blade firmly perpendicular to the surface. It is important to eliminate all oscillation of the tool to prevent it from being damaged.

- Metal tools are held with two hands, while wood or aerated concrete tools are held with one hand.

Tips for use

Whenever possible, it is best to clamp the material in a vice. Position yourself half-turned in front of the vice, with your left foot slightly forward in line with the workpiece, supported with your torso.

The hacksaw should be held with the right hand, the handle should rest on the back of the hand, with the thumb on the handle, and the rest of the tool should be supported on the lower axis.

When cutting, the hacksaw should be positioned horizontally and all hand movements should be as smooth as possible, without sudden jerks. The hacksaw should have such a swing that most of the blade is engaged, not just the center sections. The normative length of the optimum swing is approximately two-thirds of the length of the entire tool.

The tool should be operated at approximately 40-60 strokes per minute (this includes back and forth motion). Dense materials cut at a slightly slower speed, softer materials cut faster.

The hacksaw should be pressed only when facing forward, with any reverse movement no additional force is needed, at the end of sawing the degree of pressure is significantly reduced.

With hacksaw blades of manual type, all work is performed without the use of a cooling system. In order to reduce material resistance and friction force graphite grease and lard mixed in proportion 2 to 1 are used. Such a composition holds for quite a long time.

During sawing the blade turns sideways from time to time. As a consequence, the teeth start to crumble or the tool breaks. In addition, a gash is formed on the object to be cut. The main reason of such troubles is either the lack of tension of the saw blade or the lack of skill to use the saw correctly. If the blade has gone sideways. it is better to start cutting from the other side, because the attempt to straighten the bevel in most cases ends with tool breakage.

If the teeth are not properly hardened, they start to break. Damage to cutters also occurs as a result of excessive pressure, especially when working with narrow workpieces, or if various hard foreign objects are embedded into the material.

If there was a breakage at least of one tooth. there is no sense to continue sawing: it will lead to breakage of neighboring cutters and blunting of all remaining ones.

To restore the sawing ability of the hacksaw, the adjacent teeth are ground on the grinder, the stuck remains of the broken one are removed and the manipulation continues.

If the blade broke during the work, the hacksaw goes into the slot, so the workpiece is turned over and start sawing with another tool.