How to saw furniture board without chipping. Sawing laminated chipboard at home. Choice of circular saw blades and saw blades

You will also need additional tools for sawing:

Cutting Laminated Chipboard is done in the following order:

- Marking the material. For marking blanks ruler and pencil are needed to apply the points on the material sheet from the end. Then the points need to be evenly connected in one line for the trimmer and glue a masking tape on top. A good way to saw laminated chipboard without splitting is with the use of tape, t. к. it helps reduce the number of cracks in sheet material that occur due to increased temperature and high pressure. Sawing Laminated chipboard.

- The next step is sawing Laminated chipboard. We choose what to cut the chipboard with, and put the tool at the required angle to saw the edges of the sheet flat. Cut Laminated chipboard and chipboard panels as cleanly and as smoothly as possible.

- Plate processing. If the sawn chipboard at home is uneven on the cut faces, it is machined with a belt sander. In some cases it is best to deal directly with companies that produce furniture parts to order according to customer dimensions and cut Laminated chipboards on special equipment. To veneer the parts, a special veneer edgebanding is used for processing.

Precision and quality

Formal cutting machines for sawing Laminated wood particle board and particle board have a high quality of cut, which reduces the subsequent costs for the processing of cuts (sanding, removal of chipping and burrs, and so on). That’s why they can make cuts of any complexity and configuration. which means almost unlimited possibilities in furniture production. Fancy children’s furniture, comfortable computer desk tops, carved curved decorations in the doors of kitchen fronts. all this is possible with machine tools.

There are two types of panel cutting machines:

- vertical, which is a strong rigid vibration-resistant welded bed (frame), set vertically with a 50° tilt to the back, with guides at the top and bottom, on which the saw beam moves. It is a bracket for the saw unit, which slides up and down along the beam and rotates 90°, allowing both vertical and horizontal cuts. Cutting precision is amazing. Sawing laminated chipboard, as well as hard, corrugated or porous boards requires a special scoring unit. The saw has a rotation speed of up to 15 000 rpm;

- horizontal, consisting of a table for the board, a carriage to move the saw along the saw mechanism, and the saw mechanism itself, consisting of one or two cutting units. Cutting units are equipped with a main saw and a scoring saw. The principle is simple: the main saw deeply cuts through the chipboard and the scoring saw precisely and accurately cuts the bottom edge (veneer or laminate surface). The saw unit can also be tilted by up to 45°.

The mitre saw is a “domesticated” and greatly reduced copy of a horizontal machine. It doesn’t cut wide sheets of particleboard or laminated chipboard, but it can handle small parts.

How to saw chipboard without splintering

In order to saw off evenly and without splinters Wood chipboard at home, you need to know some tricks. Without any doubt, it is better if you saw with an electric jigsaw. Of course, you can saw with a hacksaw, but the result is unlikely to please you, although saw cut chipboard possible for various purposes, where the quality does not play any role. And so we need a smooth and beautiful cut. For this we take the jigsaw, ruler, tape measure and a square to right angle (if necessary), awl or sharp object with which to trace a line for a trimmer on the laminate on the chipboard. We measure a part that we will saw off with 1-2 mm reserve for the subsequent adjustment and attach a ruler, on it we guide with an awl or a sharp object a fishing line for a saw trimmer, try to press harder to cut through the laminate, and we saw along the line not along the line itself, but exactly along, only catching it with the edge of the saw.

Then with coarse sandpaper bring the edges of our cut to the right condition, and if you are not satisfied with the quality of the sawn end, we take a wax chalk of the desired color t.е. in the color Chipboard and grout the chips. Let’s talk about jigsaws, I personally use BOSSNevsky.

If you need to saw without chipping only one side, you can use a saw with a tooth up and down, I use a small saw with a straight tooth they are less prick and saw both sides is pretty decent. It will be more convenient to work on the sawn end with sandpaper, if you stretch it on an even bar. Furniture wax crayons and markers you can buy in furniture stores, where they sell accessories. If you can’t find a crayon in the color you want. It’s not a problem. you can make it out of several others, mixing it like paints. Simply melt crayons with a candle and drop on a plate, one color on it another, then roll into one and rub the edges with chips, remove the excess with a ruler or knife and polish rag gently, no need to press hard.

How to saw laminated chipboard without splitting.

Before we talk about the absence of chips when sawing Laminated chipboard and making a decision what to saw with, let’s define what it means without chips? Everyone has his own attitude to the number of them after sawing, some a lot, and for someone and a dozen just right. That’s why let’s look at not just one, but three types of home cutting Laminated Particleboard, from which you can choose the most appropriate one. For obvious reasons we will not consider the use of expensive equipment designed for sawing laminated chipboard is the destiny of professionals. We are still amateurs in the furniture business, so we’ll use the appropriate tools.In the photo three parts, the upper was sawed with an electric jigsaw, the middle one is sawed with a hand circular saw (parquet), and the bottom is also sawed with a hand circular saw, but then processed by a hand router. Of course, in each case you can achieve different results, it is all about experience and skill. But in general, the capabilities of the equipment in question give about these results on chips on Laminated chipboard.

In this case three things allow to get more or less good sawing results.

- Guide. There’s no need to get fancy with the jigsaw guide. A simple spirit level and two wire clamps will do.

- Choice of jigsaws for laminate Particle board. the saw cuts the laminated layer and the particle board itself with its teeth, and accordingly the shallower the tooth, the shallower the chips. And the sawing speed is appropriate. The direction of the tooth upwards or downwards indicates only which side of the workpiece will have more chips, the first from the top and the second from the bottom.

- Control over sawing speed. If you feed the jigsaw too strongly, the saw will bend and move aside the kerf, and the kerf will not be perpendicular to the plane of the workpiece. After such sawing you won’t dream of gluing the edges.

Now let’s consider whether it is necessary to “scratch” the laminate. This may help, but only if the following conditions are met. As the saw forms chips not only on these layers, but also on the edge layers of the chipboard, accordingly it is necessary to “scratch” them too. Width of the “scratched” line must exactly match the thickness of the saw (if you make it narrower, it will stab, if you make it wider, it will leave a trace on the workpiece). The lines should be strictly above each other and it is necessary to saw strictly along the line. Think about how realistic it is to do it at home with your own hands, and the answer about “scratching” will be obvious.

Sawing laminated chipboard with a parquet.

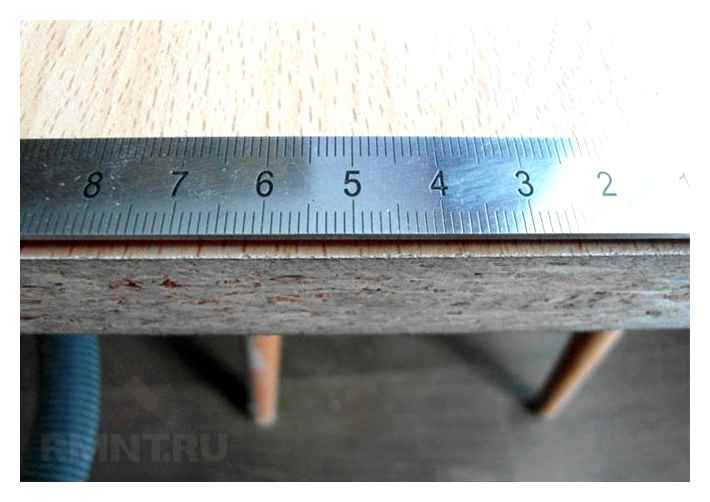

The cause of chipping in this case is the impact of the cutting teeth, but not only in the direction of the kerf, but also on the opposite side. (The vibration of the power tool does not allow to run the parquet perfectly straight resulting in misalignment of the disk relative to the kerf). The guide rail not only cuts the chipboard squarely, it also prevents chips on the opposite side from the sawing direction. When choosing a saw blade for sawing laminated chipboard pay attention to the number of teeth. the more you have, the cleaner the kerf is.

Before processing furniture parts with a router it is necessary to saw them with a reserve of 3-5 millimeters from each processed side. In contrast to previous sawing methods, the hand router leaves a perfect cut surface. splintering is extremely rare and it is possible to keep the cut perpendicular. Until now we have considered only straight sawing, but when it comes to sawing various kinds of circles and roundings there is no alternative to the jigsaw and router. The disadvantages of using a router include the need for skill in working with it. We will talk about them in other articles.

Marking the chipboard

The panel can only be cut very precisely if a line is marked on it beforehand. A sharp awl is used for marking. A small gap must be left as the cut is made. A gap of only 2 mm is sufficient. There is no need to fear that the cut piece of chipboard will not fit the required parameters. Subsequently, the remaining stock can be disposed of without any problems.

method 2. “Reverse cut”.

The first pass is made in an unusual manner. in reverse. That is, the circular saw rotates in the direction of the feed of the workpiece. We set the minimum depth of cut, turn on the saw and move it backwards, not forwards.

If you have a regular saw, you just lock the saw with a minimum outreach over the base. The meaning of the first pass is that the blade, moving along the guide, only grabs our workpiece. We need a small groove on the chipboard.

After the first undercut you will see that there are no splinters in this feed (backwards). The surface is perfect!

Now we set the saw to its full depth and saw the workpiece along this groove with a normal cut. forward feed. We have two cuts per workpiece. No cutting in waves, no burning, no nothing. perfect quality!

Reaction 2. “Reverse cut.”.

The first pass is performed in an unusual manner. in reverse. That is, the circular saw rotates in the feed direction of the workpiece. We set the minimum depth of cut, engage the saw and it moves backwards instead of forwards.

If you have a regular saw, you just lock the saw with as little protrusion as possible over the base. The point of the first pass is that the blade, moving along the guide, only grabs our workpiece. We need a small groove on the chipboard.

If you make the first undercut, you will see that there are no cracks when making the first (back) cut. Perfect surface finish!

Now we set the saw to full depth and cut the workpiece along this groove with a normal forward feed. We have two cuts per piece. No waves, no burns, nothing. perfect quality!

Cutting panels Particleboard

If we have the right tool and the measurements are correct we won’t have any problem cutting the chipboard. The most important thing is that the movements are very slow. Even a fine toothed saw can produce splintering if operated sharply. Cut through the chipboard without trying to partially cut through it. To break the material so that it does not have cracks, then it will be impossible.

Sawing with the cutter

A great way to get a clean cut. First the material is sawed with a jigsaw with 2-3 mm indent from the marking line. Then a router is used to level a trimmer’s line according to a previously prepared template. A cutter with a bearing is suitable for the work.

No problems can arise when cutting simple chipboard, but with laminated chipboard it’s much more complicated.

With this method you can make not only straight but also curvilinear cuts, make radius parts.

We choose the disk for the saw with the biggest number of teeth to provide even cutting.

Of the disadvantages of the method: it is necessary to make an accurate marking, to file the workpiece in advance and set the template under the cutter. That is, the tool is inconvenient to cut several identical parts.

Sawing with a format-cutting machine

The most suitable tool with which to cut boards and pressed materials of varying thicknesses. Precise cuts and stamping of several workpieces.

Professional machines are used for industrial applications.

They are small in size and weight (up to 20 kg) and easy to install. Machine can be removed and relocated if needed. The tool is suitable for longitudinal cuts up to 8 cm deep. Also in the home workshop, you can saw a tabletop with a circular saw with an extended working table.

Household machines are usually used at home.

They are more convenient than household ones, as they allow you to make a cut not only along longitudinal, but also along transverse lines. Maximum cutting depth. 9 cm. Exact marking and safety precautions must be taken at all times.

What saw is better for cutting Particleboard?

Chipboard can be cut with any saw, from a hand hacksaw, to an electric jigsaw, but the fastest, and the cuts will be much smoother, when using circular saws with “Clean Cut” discs. These are discs with the biggest number of teeth with hardfacing.

In construction, chain saws can be used for cutting foam concrete, plastic pipes, stone, etc. д. even such fragile material as particleboard can be cut with a chainsaw by experienced construction workers.

Getting the job done

Once you have chosen a saw, you still need to saw the laminated board correctly at home. Experts recommend to saw along the rail (the rail clamped in the clamps is also suitable). If you use a new, unworn blade, you can cut the chipboard as cleanly as with a circular saw. It is advisable to set the jigsaw to the lowest rpm possible. This will significantly increase the life of each used saw blade.

The blades themselves are placed at right angles to the base of the jigsaw. The easiest way to verify the angle is with a square or protractor. Important: the straight line through the cutting edge of the tool must be parallel to the rigidly fixed part of the jigsaw. the use of special inserts is recommended, reducing the likelihood of splintering. But to make them work more effectively, they usually notch the laminate layer on the side where the blade will come out.

To learn how to saw laminated chipboard with a jigsaw without splitting, watch the following video.

Laminated chipboard and the nuances of processing it

In order to saw the countertop without chipping, you can use a circular saw.

In practice, particleboard only began to be used in 1940 in the United States, but after a very short time popularity has spread around the world, thanks to which there are all kinds of. The most popular variety was Laminated chipboard, which is not just a product of pressing sawdust with glue under high temperature, but also additional physical and chemical protection in the form of melamine film.

When sawing simple chipboard no complications can arise, but with laminated chipboard everything is much more complicated. It is not uncommon for countertops to be coated with multi-layer HPL plastic by the manufacturer, which further complicates the process. Coatings can vary greatly in their properties, but they are always polymer, which makes them have the same nuances in processing.