Easy breathing: why and how to remove the particulate filter

I don’t have to go far to find an example: my diesel Peugeot 308 with a 1.0 diesel engine.6 HDI just put this choice before me this week. During a trip to the Moscow Ring Road the corresponding light flashed on the dashboard, the car slowed down, and the “pedal to the floor” principle did not help. Peugeot refused to go faster than 90 km/h. In general, the emergency mode that limits engine power came on.

Someone will tell you right away that if a diesel car is used properly, the diesel particulate filter serves well and for a long time, there should be no such problems. And he will be right. But the city mode of automobile operation sometimes doesn’t allow the system to switch on regeneration. Besides, the quality of fuel and many other factors that affect the car may play a role.

In my case, the car system gave a burn command, but the burning did not start. Let’s not make Accent on technical aspects of malfunction, especially as specialists have already figured it out. It is better to deal with a more common question: what to do with the particulate filter itself, if it is “clogged”, burning in the automatic and forced modes does not help, and the problem must be solved?

Options: you can either install a new or used filter, or cut out the particulate filter, or clean the contaminated one. Let’s consider each of the ways on a concrete example.

Pros and cons of such decision

The particulate filter itself performs a very useful function. it cleans the exhaust gas from unburned fuel particles, as well as other harmful constituents, which contributes to the overall improvement of the environmental situation. But if you think about it, for all its merits, it struggles with the consequences of providing drivers with low-quality fuel. And also poorly organized road infrastructure, due to which you have to idle in traffic jams for many hours, moving at the lowest speed.

The consequences of this approach will be manifested in the increased content of harmful substances in the composition of GHG, particularly for diesel. soot. Other negative factors arising from the use of such a device will be:

- increased fuel consumption;

- loss of personal time due to the start of regeneration (it can not be interrupted if it has begun) and maintenance of the vehicle;

- significant replacement and maintenance costs;

- periodic deterioration of the car’s performance due to a decrease in the capacity of the particulate filter.

At this point in time, manufacturers are struggling to make cars more environmentally friendly. This leads to the mandatory installation of diesel particulate filters in all diesel-engined vehicles. It is obligatory for trucks since the introduction of EURO 4 protocol, and since 2009, after the introduction of the EURO 5 protocol. The rule also applies to all vehicles with diesel engines.

This cuts down on the soot particles that are inevitably produced by the combustion of diesel fuel. But, the consequence of this was some complication of the design. Still, the additional hedge in the exhaust system affects the power and efficiency of the engine.

Technical features

There are several types of such filters. They are all used in modern vehicles, so it makes sense to understand their features in more detail. The main differences between the different types of such filters are in the cleaning characteristics. These are the types that can be found on passenger cars:

- DPF is a closed filter. Passive regeneration method is used for cleaning. It is impossible to clean them. Typically used in vehicles of Volkswagen concern and some of their partners;

- FAP stands for “closed filter with forced regeneration”. Developed at Peugeot-Citroen. As a rule, when the filter is clogged with soot, the engine control unit gives a command to inject an additive, which causes the filter to be cleaned. In general, the service life of such a device is higher. Widely used in Ford, Toyota and some other vehicles.

How is the particulate filter removed??

Removal of the particulate filter is divided into two steps. Firstly, it is necessary to remove the ceramic matrix itself by opening up the cylinder (“can”) in which it is located. Second, you must firm up the engine management system so that the control software thinks the particulate filter is present and functioning properly. Car repair shop “NewstasEuroService” offers services on qualitative physical removal of particulate filter and can recommend specialists, who will take care of issues with electronics.

Also “NewstasEuroService” can offer owners of diesel cars flushing particulate filter. And owners of gasoline vehicles specialists “NewstasEuroService” will help to solve the problem with the catalyst: with its removal and installation of bumpers.

Ways to clean the diesel particulate filter

Diesel engines are equipped with electronic control systems that clean the filter automatically. But there may come a time when the owner will have to wash and clean the filter with special chemical compositions. The procedure of cleaning with liquids can be performed independently.

Regeneration of the device

As the soot particles settle, it becomes more difficult for the flow of exhaust gases to pass into the atmosphere. In addition to this, it reduces the efficiency of the device. To prevent this phenomenon, it is necessary to periodically regenerate the device. The procedure burns off the soot particles. The process is carried out automatically without any intervention by the driver. The behaviour of the vehicle is not influenced by the ambient temperature.

Regenerating the particulate filter

There are two types of thermal regeneration:

Passive cleaning takes place in constant mode and does not require adjustments in the engine control unit program. The high temperature of the exhaust gas in the filter, which is between 400ºC and 500ºC, cleans it. Heating becomes a catalyst in a chemical reaction in which carbon combines with nitrogen dioxide, thus producing carbon dioxide. An additional reaction promoter is the platinum layer built into the filter honeycomb.

Active cleaning mode is activated by the motor control unit. Activating a special algorithm increases the temperature of the exhaust gases. A similar procedure is automatically activated on cars traveling a short distance that is insufficient for passive cleaning. The mode is activated according to the data from the sensors, the exhaust temperature reaches 650 ºC. Cleaning takes no more than 10 minutes, the chemical processes are similar to the passive mode.

The procedure of particulate filter burn-in on the engine Ford Focus 1,6 TDCI is shown in the video tutorial from the channel “MCAR BMW Mikhail M”.

Washing the particulate filter with your own hands

Filter flushing can be carried out with any type of machine. The procedure is used when the temperature method of regeneration does not allow removal of the soot layer.

TUNAP MP 131 liquid cleaner

MP 131 liquid is produced by German Tunap Group. The additives in the filter actively dissolve the sulfur compounds deposited on the filter surface.

MR 131 and 132 fluids

Cleaning of the particulate filter with liquid TUNAP is performed as follows:

- Remove from the exhaust line the temperature or pressure sensor installed in front of the filter.

- Introduce the liquid spray probe MP 131 into the hole. Make several injections, with a spray time of five seconds. Wait five seconds between feeds to allow the soot layer to soften.

- Flush out the filter with MR 132, which spreads the dissolved soot over the filter surface.

- Reinstall the removed parts and start the engine. The soot and cleaner are burned out in passive or active cleaning mode. Regeneration can be activated manually because the electronics are designed in such a way.

If flushing with MR 131 and 132 fluids did not give the expected effect, you will need to remove the filter to clean it again with more active agents.

Flushing Liuquid DPF

The fluid is made in Germany and contains components which break down deposits and carbon deposits. The substances are completely inert towards the filter materials.

Package of DPF Flushing Liuquid

DPF Flushing Liuquid is cleaned as follows:

- Remove the filter from the vehicle.

- Close one of the channels of the device to prevent the fluid from escaping.

- Fill the filter housing with Flushing Liuquid.

- Keep the product in the filter for at least 10 hours. We recommend shaking the flushing agent every 2-3 hours.

- Drain the flushing solution and rinse the unit with running warm water.

- Dry the filter and install it.

- Add the additional DPF Super Clean to the fuel and flush the filter in the normal manner. It is recommended to switch on the forced regeneration procedure by means of a testing device which is connected to the vehicle.

Self-Cleaning

The oxygen sensor is a spacer for the sensor, which has its own small neutralizer. It is screwed into the body of the gutted neutralizer, and the lambda probe gives out an acceptable signal for the engine’s brains. That’s the theory.

Alas, they’re mostly made from second-rate raw materials. That is why one should not expect that the precious metals they contain will be enough for normal operation of the neutralizer crumbs. It is most actual for modern cars of Euro-5 class and above: the neutralizer error is most often lighted at them right after gutting the filter and installation of the second oxygen sensor bypass. Though the situation is not better with cars of Euro-4 class.

Self-deception

Oxygen sensor cheat. a spacer under the sensor, which has its own small neutralizer. It screws into the gutted neutralizer body and the lambda probe gives out an acceptable signal for the engine’s brains. That’s the theory.

Alas, these cheaters are made mostly from second-rate raw materials. That is why one should not expect that the precious metals they contain will be enough for normal operation of the neutralizer crumbs. It is most actual for modern automobiles of Euro-5 class and above: the neutralizer error usually lights up immediately after you have gutted the filter and installed the bumpers for the second oxygen sensor. Although the situation is not better in Euro 4 cars.

Removal of the particulate filter. consequences

16.12.2020 A significant tightening of international environmental standards in 2000 also affected the cleanliness of the exhaust of vehicles involved in road traffic. As a result, in addition to catalytic converters, many cars now have a particulate filter (SF) with EGR in the exhaust gas pathway. The innovation enabled car manufacturers to meet Euro-4 environmental standards (and even Euro-5 for diesel engines). But the problems with clogging of the system and periodical necessity of element replacement pushes the car owners to remove it themselves. Naturally, many consumers are interested in the consequences of such actions.

Features of devices and identification of failures

SF is indeed an important part of the exhaust pipe, and it is guaranteed to retain 80-90% of soot entering the exhaust. But the “soot particle filter” is not obligatory (at least, here). Nevertheless, it is not cheap, but, as well as other expendables, it has a certain service life. And though foreign car owners assert, that it serves 150 thou. km of run and more, in our operating conditions this number turns out many times less.

When the filter is clogged, certain methods of thermal and chemical cleaning have been developed, but they are not always effective, and often do not save for long. But the destruction of its ceramic lattice can create serious problems for the car. The price of a new part is not affordable for everyone (500-2000 euros). Since the post-Soviet society is not so rich, many car owners simply get rid of the SF with EGR, as it, with the right approach, does not harm the engine and other systems of the vehicle.

Of course, it is better to do it in a good car service with an experienced knowledgeable master. The price of removal of the particulate filter and the consequences associated with this procedure on both diesel and gasoline models is not very different from each other. Depending on the station, the work will be done for 200-250. The high cost of the service is justified by the fact that in addition to the physical removal of the element it is necessary to get rid of it in the ECU firmware, as well as deceive the sensors and devices connected to the path, otherwise you will not avoid problems.

Emerging problems in the particulate filter can be detected by the following signs:

- Interruptions when starting the engine, floating idle speed, hissing;

- Disconnection of the turbocharger and a decrease in traction (rpm drop);

- unexpected increase in fuel consumption;

- Glow plugs light constantly on;

- increase the engine oil level;

- appearance of acrid black exhaust;

- The problem is that it can cause a “check” error on the onboard computer.

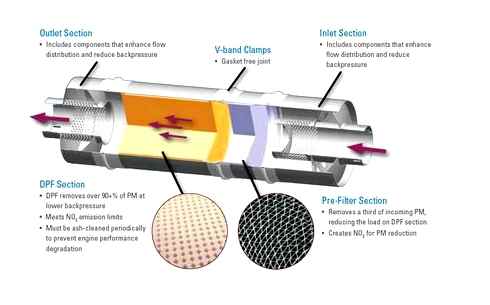

Structurally, particulate filters are made in the form of a thickened tube, in which a purification element is integrated: a ceramic matrix DPF or FAP (depending on the required environmental standard). It can be open or closed, equipped with temperature sensors controlling exhaust gases (before and after the device), differential pressure, airflow meter. The data collected by these devices is processed in the central electronic unit, which makes the appropriate decisions and sends commands to the turbine, engine, EGR.

The latter is a recirculation valve (vortex damper) at the SF inlet, and redirects some of the exhaust gases from the exhaust manifold into the intake manifold for afterburning if necessary. When using domestic fuel, sulfur in which exceeds the European limits, the intake manifold quickly fills with soot, and it becomes impassable. Negative consequences of turning off the EGR is only an increase in toxicity of exhaust (NOx), but will increase the capacity of the exhaust system and the injectivity of the car, will begin to work better engine and turbine.

For painless removal of particulate filter with EGR, there are several options. Some masters completely cut out a piece of the path with a catalytic converter, filter and EGR, welding an empty tube instead. This is the worst of the existing methods, since unpleasant rumble and dark exhaust appear during further operation of the car. Such interference is badly perceived by car electronics as well. It is better, when these elements are removed not completely, but partially: a catalytic converter remains or a flame catalytic converter is installed additionally (it gives similar signals to sensors).

It is left to cheat lambda-zone, but there is no sense to use stubs and emulators. the system detects them in course of time anyway (within a year or two) and starts to emit an error. You can not do without reprogramming of the controller that controls this module. Even if you have decided to change something in the mechanics of the system by yourself, it is highly recommended not to get into the electronics without proper knowledge.

Although there are various software programs available on the Internet, no one can predict the behavior of the software you find in this case. It may turn out to be incompatible with the car’s diagnostic system, and then it will be expensive, time-consuming and difficult to eliminate the consequences of intervention. There is no guarantee that you will get a quality firmware at the first service center. At our station this work is done by well-trained specialists, who know the way out of extraordinary situations. We install programs that fully correspond to car models, produced directly by manufacturers.

It is impossible to state that there are only positive and negative consequences of soot filter and EGR removal. Therefore it is up to the customer to decide whether to change these units or not. We can only warn you what will change with this procedure.

- You will substantially save money when replacing the used parts;

- engine power and injectivity will increase, wear and tear will decrease;

- fuel and oil consumption will be reduced;

- No need for regeneration, which is not good for your car;

- the possibility of occurrence of ceramic dust, dangerous in the operation of the car will disappear;

- unnecessary errors and alarms on the instrument panel disappear.

- Smoke and CO will increase (even in our country you can not pass the technical inspection);

- trips to a number of European countries by car will have to be postponed (will not be allowed);

- If you go to an official car service, you will pay a fine, as the alteration will be fixed;

- the car warranty (if any) will be immediately voided.

Clogged diesel particulate filter: signs and consequences

The role of the “soot particle filter” is such that it only takes power away from the engine. The point is that the soot constantly accumulates inside it, creating a resistance to the movement of exhaust gases. You will not notice it in the city, but on the highway, the car with a hardly filled filter will accelerate less willingly. However, driving on a country highway is very good for the diesel engine, we will explain why later.

Anyway, it is difficult to notice a slight drop in traction. It is much easier and more useful to pay attention to the instrument panel, where a special lamp or a combination of LEDs will outline the severity of the problem. The exact answer to what this or that icon means can only be found in the manual to your car. As an example, we suggest to consider the algorithm of DPF problems signaling on VAG cars:

- DPF icon. The filter is almost full, there is more than one unsuccessful regeneration, but there is still a chance to burn out the soot by standard means. As soon as the icon is illuminated, get on the highway as soon as possible. We will tell you what is what and why.

- DPF check. A sure sign that the particulate filter is clogged. The computer goes into emergency mode, leaving the owner the only option. to burn soot with a special mode.

Dashboard alerts duplicate real things like fuel consumption, engine oil level, gas pedal response. For example, to be guided to the approaching failure of a diesel particulate filter, such signs help:

- The average fuel consumption per 100 km is suddenly increased by 1-2 liters.

- Oil level in the engine has increased due to the ingress of diesel fuel into the crankcase.

The explanation for these events is one thing. unsuccessful regeneration (burning out of soot by conventional means). The purpose of the burnout is to increase the temperature in the particulate filter so that the soot is burned out (converted to carbon dioxide) and the matrix channels become free again. Increase this very temperature mainly due to post-injection of fuel, so that the DT is burned out in the “particulate filter”. If you do not adhere to the manufacturer’s instructions regarding the driving mode during the regenerating measure, you will not get a successful result. Burn-in attempts will be often repeated, which will eventually lead to the mentioned things. increase in fuel consumption and oil level.

We recommend to refuse from the idea to let everything on its own. When the particulate filter is almost clogged, the car does not behave in the best way, because the emergency mode. it is solid restrictions on speed and current fuel consumption. If this fact does not stop, then the result of “ignoring” the emergency alert will work in any case: with a fully clogged particulate filter the car stalls and does not start, or starts and immediately stops.

How to regenerate

The outcome of the conversation at this point is quite clear. the diesel particulate filter can be cleaned. do it, as they say, in a passive way. to conduct cleaning by active method, which is incorporated in the standard electronics.

What is regeneration

We have already talked about what regeneration of the particulate filter is and what its purpose is. Recall that the main task of this activity is to burn off soot accumulated in the channels of the “sootblower. An empty matrix allows the engine to “breathe”, which means that it takes away a minimum of power.

To burn out this very soot, it is necessary to raise the temperature of the exhaust gases. It can be done in two ways:

- Passive. The exhaust temperature rises with increasing engine speed, but the fuel consumption increases. Optimum. constant medium RPM: gases are hot, the share of unburned diesel is minimal. Operating example. driving on the highway at a constant speed.

- Active. Increasing the temperature in the filter by afterburning the diesel before it. Before the exhaust gases are vented from the cylinder, DT is post-injected. Due to its low autoignition temperature we have a flame and a hot exhaust stream right before the soot particle, which heats the last one up to 600 650°С.

Let’s go back to the passive method, to separate the two competing technologies. FAP and DPF. FAP machines are fitted with a special cerium-containing additive. By adding it to the fuel, we can do passive regeneration at lower temperatures. This means that piercing on the piste is more efficient at home. That is, the time of emptying the filter is reduced, which is one of the pluses.

The walls of the DPF matrix have a platinum catalyst. Its task is to promote a series of chemical reactions that eventually rid the tank of soot. Unlike FAP, the gases must be very hot (400 500°C as opposed to 300 350°C) otherwise the burn will not take place. And it means that you will have to “sink” on a freeway after all.

Active piercing

About the passive method it is said a lot. It remains only to specify how to burn the particulate filter in motion without the aid of electronics, namely the approximate speed of movement and engine speed. So, the rate of 70-90 km/h and more than 2,500 rpm on the tachometer is quite enough to slightly empty the filter from soot. How often and how much time you need to burn depends on how often you use your machine. Start with a standard cycle: 5 days of urban congestion, 2-3 weekend trips of at least 40 minutes.

Again, the purpose of active regeneration is to red-hot the particulate filter matrix to 600650°C. This requires the turbocharger to be changed, the EGR system must be shut down, and the fuel injected before the exhaust stroke. Let’s warn at once, the situation is fire dangerous.

The electronic system selects the point at which active burning is necessary. Not spontaneously, but according to the sensor data:

- Exhaust gas temperature sensor. (there are two of them. one is mounted at the inlet to the filter element, the other. at the outlet).

- Differential pressure sensor. Measures the pressure difference between inlet and outlet.

Active combustion starts in different ways. On some cars (e.g. VW) this happens invisibly to the driver and regardless of whether you are in the city and on the highway, on others (e.g. Toyota). the lamp lights up that it is necessary to stop and press a special button.

But it is not a good idea to compare cars based on how their electronics work. So the same VW has a pre-emergency mode, which we described (DPF icon). The only difference is that the owner of VAG needs to drive on the highway until the light goes out, and the Toyota will do everything on the spot.

Something else worth talking about is the signs of active regeneration:

- Increase in engine temperature.

- Fuel consumption increases.

- Oil temperature rises.

- The glowing can begins to clatter loudly, which is clearly audible from outside.

- The color of the exhaust takes on a thick white hue.

- At idle rpm the engine starts “clunking”.

Important! Try not to stop the car, when electronics start burning. A series of failed regenerations means fuel-liquefied oil, high diesel consumption, and even more soot in the filter. What you need to do is get out on the highway as soon as possible and keep 2,000 rpm and 50-70 km/h.

Check Engine” mode.

On some cars, the manufacturer provides an emergency regeneration. Usually, to start it, the soot meter must count some threshold value (in VAG it is at least 58 g.), and the computer to go into “check” mode.

Starting such a cleaning program is possible only on the service station. This procedure is often called Diesel Particulate Filter Restricted/Clogged MIL ON error reset or forced particulate filter burn, which is not much different from the Toyota model of starting active regeneration through the button.

Last chance: the forced burning of diesel particulate filter by standard means

This process is necessary, and its program is prescribed in ECU. It is started from outside, in manual mode. more often with the help of diagnostic equipment. Briefly: a special engine operation mode is activated via the service program (closed EGR post-injection turbocharger geometry change), the idling speed is raised to 1,500-2,000 units and the engine “smokes” for 20-30 minutes on the spot.

In fact, it is the final attempt of active regeneration. Only, say, Volkswagen B6, prefers to give the driver a chance not to visit service unnecessarily. Well, Toyota at once recommends to start the forced burn, and there is no need to use any software. just switch on the button and go.

Aspects of the process

The operation has its own limitations. In VAG-cars regeneration will not start if the system detects signs of a completely clogged diesel particulate filter, namely the fundamental difference in the differential pressure sensor readings (which measures the difference between the inlet and outlet gas pressures) and the soot counter readings (more than 68 grams). The purpose of forced cleaning is to knock down only a part of trapped carbon (on Audi Q7 3,0 TDI the operation is completed at the calculated 56 grams).

For your information. It is impossible to determine the physical volume of solid particles in the filter, so one of two models is used: measuring the pressure and temperature at the inlet and outlet of the cleaner, the engine air consumption or assessing the driving style, information from the exhaust gas mixture temperature sensor and the oxygen sensor.

What to do if the forced burn-in does not start

The pretext for the ban. the detected symptoms of a clogged filter. It is impossible to exclude the failure of the differential pressure sensor, but more often the system does not lie, which is proved by the window with the calculated amount of soot in the diagnostic program. It is possible to reset the counter, but you cannot fool the sensors.

It is realistic to reanimate the component only after passive burning, when the actual amount of soot becomes less. The counter, of course, will put extra figures at the rate of 3-5 grams per 100 kilometers, but the differential pressure sensor readings will already be in condition, and the screwed on will be reset through the new particle filter.

For the record. Hard starts from 0 to 100 km/h knock out the soot particles because of the excess pressure in the exhaust system. 5-6 hard acceleration during first 1030 seconds after engine start can remove about 10 grams of carbon. Accelerations are made only with the engine warmed up.

Particulate Filter: Removal

To understand how to remove the particulate filter, you need to consider the following:

First the body and the filter are removed from the vehicle. Then the body is cut with an angle grinder and the particulate filter is knocked out. If the body also has a catalytic converter, remove the filter carefully. Then the body should be welded using argon welding or a semi-automatic machine.

We also recommend to read the article about what is the EGR system. From this article you will learn how this system works, and if it is necessary to disable EGR, and when disabling EGR is undesirable.

It is also important to treat the weld with rust preventing agents. In some cases, you can install a “downpipe,” but even with the usual empty body without a particulate filter, the sound of the diesel will not change.

The next step is to programmatically disable temperature, pressure sensors, as well as fuel consumption meters. The main task is to completely disable the start of the regeneration process and at the same time get rid of errors in the ECU after removal of the particulate filter.

In practice, the particulate filter requires more attention than it may seem at first glance. Keep in mind that improper particulate filter removal or malfunctions can lead to constant attempts at regeneration.

In some cases it can lead to high oil levels through large quantities of fuel entering the lube system. The result. the diesel engine goes to pieces. At the same time, diesel engine breakdown occurs both with the presence of the filter and with the removed particulate filter.

We also recommend reading this article about why the oil level in your engine is higher than normal. From this article you will learn about the main causes of emulsion and increased oil level in the engine.

The only way to control the process is to constantly check the oil level. If the level is elevated, the particulate filter and regeneration system should be checked, and the faulty particulate filter should be completely removed and the system should be shut down, the particulate filter errors correctly removed, etc.д.

Also add that after removing the particulate filter, there is no need to fill the oil for engines equipped with particulate filters. It is enough to pick up a suitable analogue of the more simple and affordable motor oils. It turns out a small economy without prejudice to the diesel engine and its systems.