Where to fill oil in the hydraulic jack

The range of jack applications is much wider than just using it to change tires on a car. Any experienced car owner knows when to use this device. But in addition to the rules of operation, it is important to know how to properly perform maintenance and replacement of hydraulic material.

Unlike existing lifting mechanisms, the jack has small size and weight, easy operation, has convenience and a high degree of reliability. For every car owner such a tool. a thing necessary and very important.

There are several basic types of jacks:

Can be operated manually or with the help of an electric drive. Some models can support loads up to several hundred tons.

Hydraulic jack

Hydraulic jack. a device that allows you to lift and hold heavy objects at a specified height. The following manipulations can be done with this mechanism:

- to lift and hold the car body during repair work;

- perform lifting of bridge span;

- To carry out the tensioning of high-voltage wires;

- transporting construction loads and equipment;

- piping.

There are single and double plunger models. According to the type of design, the mechanisms can be:

Why the hydraulic models are considered to be the best in the range of jacks? They have significant advantages:

- high efficiency (80%);

- smoothness and quietness;

- stiffness and strength of design;

- braking and stopping at an exact position;

- high capacity.

But in addition to the pluses, it is necessary to note the minuses of design:

- Transportation should be in an upright position to avoid oil spillage;

- low speed;

- low lifting height;

- Impossibility to set the height when lowering the load.

Capacity range of hydraulic models is from 2 to 200 tons. The most popular model is the bottle design, as it is the easiest to use.

The jack can only work on level and hard surface. The jack is mounted on wheels and has a sufficiently large lever, which makes it difficult to reduce the force if necessary.

Control of oil level and cleanliness is essential for long time trouble free operation.

Hydraulic bottle jack

A hydraulic jack is a device that allows you to lift and hold heavy objects at a given height. The following manipulations can be done with this mechanism:

- To lift and hold the car body in the process of repair work;

- to raise the bridge span;

- tensioning of high-voltage wires;

- Transportation of construction materials and equipment;

- piping.

There are single-plunger and double-plunger models. According to the type of design, the mechanisms can be:

Why the hydraulic models are considered to be the best in the range of jacks? They have significant advantages:

- high efficiency (80%);

- smoothness and noiselessness;

- rigidity and strength of design;

- Braking and stopping exactly where you want it to stop;

- significant lifting capacity.

But besides the pluses, it is necessary to note the disadvantages of design:

- Transportation in a vertical position to avoid oil spillage;

- low speed;

- Lifting at a low height;

- Impossibility to set the height when lowering the load.

Capacity range of hydraulic models is from 2 to 200 tons. The most popular model is the bottle design, as it is the easiest to use.

The jack can work only on a level and hard surface. This mechanism is mounted on wheels and has a rather large lever, which makes it difficult to reduce the force if necessary.

Checking the oil level and keeping it clean is essential for the jack to work properly and for a long time.

Selection of material

The car owners often ask what kind of oil they need for the jack.

Tip: choose only high quality oil and never mix it with any other fluid, including brake oil or other types of grease. Mixing will lead to breakage and risk of losing the load during the work process.

The jack must be filled with quality oil that meets the following specifications

- The lubricating oil must be well filtered;

- The foam level is as low as possible;

- the viscosity index and temperature maximums are chosen to be extremely high;

- The high rate of corrosion protection.

Use fluids of I30A, I40A or I50A grades, used in operation of industrial machines, for filling of jacks. Special hydraulic oil is the best option.

What can cause a jack to be less effective?

Jack breakage, as well as any other device, occurs rather slowly. At first, the owner may notice a decrease in efficiency. If this happens, you should think about the causes of the problem and how to fix it. Some of the most common reasons for reduced efficiency include:

- Appearance of air bubbles in the system.

- Beginning of corrosion processes inside the mechanism, which leads to periodic jamming of the device.

- Untimely cleaning of the device from contaminants arisen in the process of operation.

- Exposure to excessive loads over a long period of time or lifting more weight than stated in the manual. Overloading can lead to deformation of the rod and other elements.

Pumping the jack

Pumping of the jack is a preventive measure to prevent tool breakage. Preventive maintenance has to be done regularly.

Why do you need pumping??

The number of maintenance pumpings depends only on how often the unit is used. Pumping may be performed every few weeks at a car service center, but if you use the jack only occasionally or in a garage, you may reduce the frequency of pumping to twice a year.

- Excessive amounts of contaminants in the oil. Impurities can reduce the efficiency of a jack and cause serious damage.

- Appearance of bubbles. Bubbles in the oil indicate that there is air in the system. Although air is rarely trapped in the piston, it will also need to be checked.

- Reduced real lifting power. If the jack can’t lift the weight you’re talking about, it’s a good idea to take it in for preventive maintenance or to have it repaired.

Today’s jacks come in one piece, so rebuilding them is not always possible. Even if repair of the device is not possible, pumping of the system is an excellent solution.

Procedure for Performing the Work

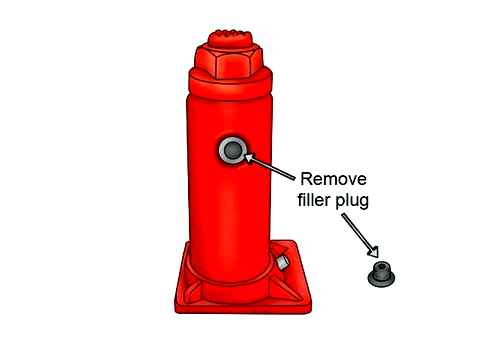

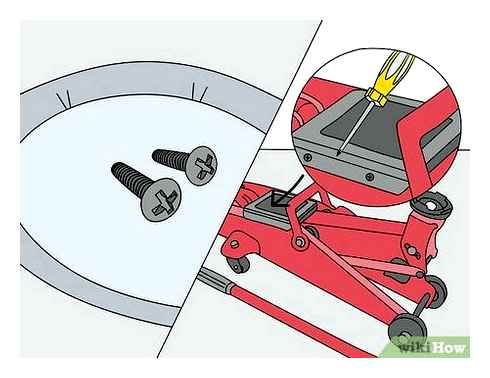

Flushing is carried out in several stages. First unscrew valve and remove plug from oil reservoir. Before pumping it is recommended to change the oil, so the old oil must be drained.

Drain oil until there is only air left in the unit. Such manipulation prevents further damage that could be caused by residual contaminants.

Depending on the owner’s wishes, the internal surfaces can be cleaned with special products. Special flushing is good for removing different deposits and prolonging jack life.

The next step is to fill the lubricant. There are two types of oils for hydraulic jacks. Summer oil does the job well in warm weather, but in winter it may cause performance deterioration. If the jack is constantly used indoors, where the average temperature does not drop below zero, you can safely pour in summer oil. When operating a hydraulic jack in harsh operating conditions, care must be taken to preserve the structure and refill with winter oil.

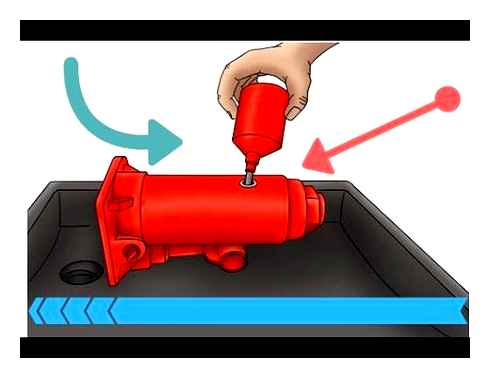

Oil is poured until the cylinder is completely filled and the piston is at its lowest point.

At this stage the work is considered completed, but it is better to pump the jack immediately. To do this, the oil valve is opened, and the unit is pumped intensively with a lever or pedal.

Since faulty collar gaskets are often the cause of malfunctions that lead to air in the system, it is worth replacing them immediately. You should not rely on their integrity, as minor defects on them are almost impossible to see.

Repair and pumping the jack with your own hands

As a rule, all hydraulic jacks are represented by a non-disassembled design that cannot be repaired. However, in all cases, it is possible to perform pumping. When considering how to pump a hydraulic jack, note the following points:

- A special valve is opened, as well as the plug from the oil reservoir. This is required to drain the old fluid and to refill the new fluid when pumping.

- Often the jack is pumped because of a large amount of contaminants getting into the working part of the device.

The bottle-type hydraulic jack is recommended to be pumped according to the recommendations placed by the manufacturer. Removal of the waste is carried out until there is no air in the working cylinder. This is due to the fact that the bubbles significantly reduce the effectiveness of the device, as the gas has a lower density.

How to choose an oil for a hydraulic jack?

In order to determine the type of oil that will then be poured into the hydraulic jack, you should understand some of the differences between the different groups of these elevators, before you fill them with oil.

Hydraulic jacks, depending on the design features, are divided into the following groups:

Depending on the group and design, each jack has its own maximum lifting capacity, which requires the hydraulic fluid to have a maximum level of compression.

Types of hydraulic jack fluid

There are three main types of hydraulic fluids:

The second type is the safest, but it is also the most expensive, because it is created through complex technological processes. Glycol hydraulic fluids are also good for jacks, because they do not interact with working surfaces, and do not harm metals. In terms of price and quality, they are comparable to synthetic.

The cheapest versions of hydraulic fluid should be considered the petroleum or mineral type. For artisanal work, it is a very good choice, but it does not guarantee good and long jack work. For those who prefer cheaper alternatives, the use in the jack will be a good application of used machine oil that has been replaced in the engine. But before you fill up with recycled oil, you need to make sure it’s clean.

The range of jack applications is much wider than just using it to change tires on a car. Any experienced car owner knows when to use it. But in addition to the rules of operation, it is important to know how to properly perform maintenance and replacement of hydraulic material.

Unlike existing lifting mechanisms the jack has small size and weight, simple operation, has convenience and high degree of reliability. For every car owner, such a tool is a necessary and very important thing.

There are several basic types of jacks:

Controls can be manual and electrically operated. Some models can handle loads up to several hundred tons.

How to fill (change) the oil in the hydraulic jack

Here are the basic steps to changing the oil in a hydraulic jack:

- Open the release valve to lower the plunger to the bottom position;

- Unscrew the hydraulic jack and carefully remove it from the jack;

- Get an empty bucket where you can drain the oil. Also, take some cloth cloth to clean the jack;

- Remove the oil plug, which is usually located in the middle of the cylinder;

- Lay the jack on its side and drain all the oil from the jack into a bucket, wipe off any spilled oil;

- Pour new oil inside the jack through the oil hole until it starts to flow out of the drain hole. Do not allow dirt to get inside while pouring the oil;

- Close the drain hole with the oil plug and close the release valve;

- Put the jack back on the elevator;

- Bleed the air from the jack;

- Raise and lower the tool several times to see if everything is working properly.

In order for your jack to work optimally, the oil needs to be added or replaced regularly. As soon as the hydraulic fluid begins to decrease, you will immediately notice a decrease in the ease with which the vehicle can be lifted. This should be the first hint that the fluid needs replenishing. After you first sign of that lack of oil, follow the steps above to keep your jack in proper working order. With regular oil additions and changes, your jack will last you for years.

What kind of oil to put in the jack

This is important, you should only use hydraulic jack oil that is specifically designed for use in engine jacks. Be sure to get good quality hydraulic oil. Do not use transmission fluid, motor oil, brake fluid, or other types of oil that are not specifically designed for hydraulic jacks, and do not mix different types of oil. If you don’t know what type of hydraulic jack oil is right for your jack, check your jack’s manual, which usually lists the recommended products for optimal jack performance.

Recommendations for Changing Oil

Before changing or topping up the service fluid, read the jack operating manual carefully and follow the recommendations.

In the hydraulic jacks it is not recommended to pour brake fluid, as well as alcohol-containing compositions. they can destroy the material of the rubber gaskets and seals used in the construction of the device.

Oil must be poured into the jack in small portions, making sure no air bubbles form in the fluid. After filling, vent any air that is still trapped inside the jack with the oil. Do this by fully inflating several times (raising to maximum and then lowering). After that the stopper is pushed tightly into the oil filling hole.

Do not disassemble check valves and blocking valves unless absolutely necessary. Valve springs and balls require extra care.

Use only special quality compounds for filling the jack. Saving on quality will not only significantly reduce the service life of the instruments. Liquids not designed for hydraulic jacks reduce the safety of the jack and could cause an accident.

Timely maintenance and the use of quality oil for the hydraulic jack will ensure a long service life.

Tips for choosing oil

Quite a common question is what oil is poured into the hydraulic jack. There are several varieties on sale:

Synthetic fluids are the most common. They are characterized by increased safety, since the production is represented by a complex technological process. Glycol versions are also common, the chemical composition of which defines high performance characteristics. In terms of price and quality, glycol ones bypass almost all others.

Oil or mineral oils can be named as the cheapest variant of performance. However, before pouring them into the jack jack it is worth considering the relatively low performance.

Read also: Homemade potato diggers for power tillers with their own hands

In some cases, used machine oil is poured. It is necessary to use a special oil, as it ensures the long-term operation of the device. The lubricant should be changed at the point when the device begins to malfunction.

Tips for choosing an oil

Quite a common question can be called what oil is poured into the hydraulic jack. There are several varieties on sale:

Synthetic fluids are the most common. They are characterized by increased safety, since the production is represented by a complex technological process. Glycol versions are also common, the chemical composition of which determines the high performance characteristics. In terms of price and quality, glycol oils are ahead of almost all others.

The cheapest performance option is petroleum or mineral oils. However, before they are poured into the jack, one should take into account their relatively low performance.

Read also: Handmade potato harvesters for power tillers

In some cases, the filling of used machine oil is carried out. It is necessary to use a special oil, as it ensures the long-term operation of the device. The lubricant should be changed at the moment when the device begins to work improperly.

Types of jacks

To work with this device does not require much physical effort. Simply push the lever and the hydraulic piston begins to lift the load. These systems can easily lift a structure weighing 50 tons. The industry produces several types of these systems:

The main advantage of these products is their large lifting capacity. This made it possible to work with the jacks at service stations, to perform various repair operations with any kind of heavy machinery.

The only disadvantage of such a device is considered the impossibility of transporting the jack in an upside down position. It should only be transported in an upright position.

Choosing the material

Car enthusiasts often wonder exactly what kind of oil is needed for the jack.

Tip: Choose only high quality oil and never mix it with any other fluid, including brake fluid or other types of lubricant. Mixing will cause it to break and risk losing the load during operation.

The jack must be filled with quality oil that meets the following specifications: