Yak vibrati dril

Drill. a tool with a great body and a handle with an electric motor button.

Cordless drill practical without plugging in to the electric wire, it is also possible to drill holes in wood, metal, plastic.

The percussion drill fits into the concrete wall. In the middle of the body at the new switch to the mechanism of the shock mode, and one more handle for the cartridge, the start of the robot every hour, the robot is adjusted to the trim and mitsno.

The difference in price between the models is small, but the hammer drill is universal:

- it is possible to install a drill and drill;

- you can put a mixer and shut up the awesome sums;

- it is possible to install the nozzle from the screw and twist the screws;

- it is possible to navigate the sanding surfaces behind the auxiliary sanding circle.

Drill-mixer for additional special attachments in the form of a wine can help you to quickly fix the difference or a farb. For such drills, most often there are two handles on round handles, and they are handled with tools and handles without baking.

Drill Zhivennya: hemstitch Chuck type: key Impact mode:

Korisna is glad: do not get lost in the hammer drill with the hammer drill:

- Dril mensh taut and signs for other robots. drill open the dowel for a picture or a chandelier.

- A retractable hammer drill is suitable for great wake-up robots. open the anchor for installing doors or lining the duct for ventilation.

The Makita M8100 drills have an ergonomic body, є gum pads, which dampen vibration, the 710 W motor’s pulling power allows for efficient use of wood, steel and plastic. The model can be expanded up to 3200 rpm, and when drilled with a blow up to 48000 rpm

Yak vibrati screwdriver, nutkirut and gvintokrut

Screwdriver, screwdriver and screwdriver calls are similar: a small body with a chuck, one handle in the center, often at the bottom of the battery handle.

The scheme of the robot for all three models is the same: the cartridge with the nozzle is wrapped in the debris from the nozzle, the function of the attachment changes. you can screw in screws, gvinti, self-locking or nuts.

For bazhannyam in the chuck, you can install a drill that vikoristovuvati a screwdriver yak dril. Alle, after a little effort of the yogh dvigun, to solidify the large openings in the metal, it is unlikely to chi viyde, not even talking about concrete.

Okremiy format. tricky nut-roll. In such models, there is no shock mechanism, ale with additional help, you can quickly twist the bolts, screws and nuts, easily tighten the fasteners.

Screwdriver Zhivennya: festoon Chuck type: shvidkozatisny Maximum wrapping moment, H m: 22.

The tricky nut-roll is often called pneumotiscap, it’s victorious to go there, but the classic nut-roll is not fit, for example, in the folding fittings.

A handy, compact and lightweight, twitchy nut-roll is known for robots at service stations, in private mines, at home, in garages and at summer cottages.

The Dnipro-M TD-600 screwdriver has a pressure of 600 watts. There is plenty of space to open it up in wood, concrete and steel, and also quickly twist / unscrew, be it fastening elements. The model has a chuck with a diameter of 10 mm, a maximum torque value of 22 Hm, є reverse function

Vibiraєmo type of living

Whether a tool can be used as an electric net, a battery, or for additional pneumatics.

When robotic from an electrical grid, the tension of the annex is surrounded by only the possibility of wiring. Vibrating model with living from the hedge, to brutalize respect for the old one: do not let the new one get the maximum amount of food, garnish the insolation and strengthen the entrance to the building, but it didn’t break in the future.

Pneumatics (stisnene povitrya) zvvychay vikoristovutsya only for professional purposes: at car service stations and tire service. For a pneumatic robotic tool, an okremium compressor is required, up to which through a pneumatic hose it is possible to connect the switch at once.

Gaykokrut Zhivlennya: stuck povitrya (pneumatics) Chuck type: chotiriggered Maximum wrapping moment, H m: 345

When the battery is alive, the battery life is important;.

For the last minds, the model with the battery вmnistu is 3.0 A / year and is more practical and half as much as the model with the battery mnistu 1 / 2-1 / 5 A / year. Ale vrakhovyte, what more is the battery, Tim Vaughn is important.

Pneumatic nut-wheel Intertool PT-1101 is suitable for robots at service stations and at home, in addition to quickly opening and tightening bolts of different types of cars. The model has a spindle for the robot in importantly accessible missions, it is hard to pull, є the function of reverse, smooth regulation of turns, a set of heads of different sizes and a case in the set

Vibrantly I work with the force of the dvigun

In the accumulators, there is a lot of working springs. Most popular models with batteries 12V and 18V, ale and a tool with a working voltage 10.8 V, 14.4 V, etc.

Chim vishche napruga. tim more pulling dvigun with the same force struma. In the Hotline catalog, all annexes are distributed into groups:

Drill Givennya: fringe Chuck type: key Maximum wrap-around moment, H m: n / a Impact mode: flare up flare

Ale not varto chase after numbers, and if there is more strain. tim more dvigun, the cooling system is more important than pristіy and vishche prіna.

For non-residential households, completely clean the tool with a 500-700 W motor. Models with a strong pull. also a professional class.

Drill Stanley SDH-700 fits into metal, wood, plasterboard, whole and other materials. The model has a keyless chuck, a tilted dvigun 700 W, a two-stage gearbox, for which it is possible to display the number of turns,

Yak vibrati elektrovokrutku

The electric twist is in a small shape: straight, G-like, or at the sight of the gun with a hand handle. It is also possible to tighten the screw, screw, screw.

Elektrovikrutka Zhivennya: accumulator Chuck type: chotiriggered Maximum wrapping moment, H m: 5.

For the size of the electric screwdriver mensha for a high-speed screwdriver, and at it has a lower torque.

You can screw up the mountings at importantly accessible places, where you can’t get there with a very large overall screwdriver: if the furniture is folded, or it takes an hour to repair the electronics.

The Bosch GO 2 electric ropes are suitable for electricians, plumbers, furniture makers and cover makers. The Li-Ion model has a rechargeable battery, capacity 1.5 A / year, low noise level, controllable by one button and a hand grip in any position

Briefly about the features of the impact wrench

An impact wrench is a slightly more specific tool, although its principle of operation is much like that of an electric screwdriver. To distinguish a nut device from a drill, you need to pay attention to the holder. Its attachment is different from the one installed in a drill or electric screwdriver. The tool mechanism is best suited for working with bolts or nuts. He will be able to unscrew even rusted old fasteners.

There are several popular types of impact wrenches:

- pneumatic (run on compressed air from a compressor);

- gasoline (use internal combustion engines);

- hydraulic;

- electrical.

By the type of action, nutrunners can be divided into torque and impact. Torque are used for heavy work, their torque is from 1000 to 12000 Nm. The reverse side of the coin is a low rotation speed. 3-16 rpm.

It can be added that by the type of action there are torque and impact wrenches.

Torque wrenches are used for heavy work, their torque is from 1000 to 12000 Nm. The disadvantage of this type of nutrunner is its low speed (rotation speed 3-16 rpm). Impact wrenches are more widespread due to their relatively high power (from 100 to 4000 W) and relatively affordable cost.

A wrench is an indispensable professional tool that can be found in the assortment of any repairman or assembly worker. The most powerful models have found their application in mechanical engineering.

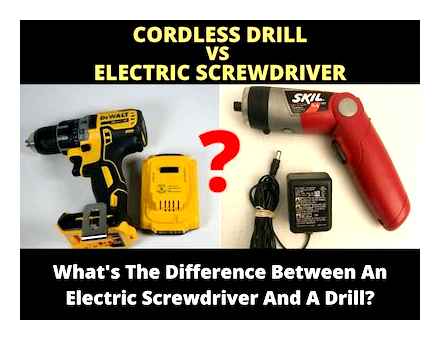

What is an electric screwdriver?

It is an electric hand tool designed to work with a variety of fasteners. with an electric screwdriver, unscrew and screw in screws, bolts and self-tapping screws. Its use can significantly speed up the work, especially if several hundred fasteners need to be tightened. Furniture assembly, renovation work, construction. all these work can be done faster with a drill-electric screwdriver.

Screwdrivers differ among themselves according to several criteria:

- Depending on the type of power supply, network and cordless screwdrivers can be distinguished.

- There are impact and non-impact screwdrivers, which differ in the presence of impact mode.

This tool has several additional features and uses:

- An electric electric screwdriver can replace a not very powerful drill.

- With the right attachments, the electric screwdriver is a great alternative to hex wrenches.

- If the tool has a backlight function, it will be useful when working in low light conditions.

- An adjustable ratchet mechanism allows the heads of the mounts to be positioned precisely on the surface of the material, improving the appearance of the product.

Wrench and electric screwdriver. what is their difference?

Many different tools are required for repairs or workshop work. There are universal ones that can solve most problems, and there are those aimed at narrow application. A prime example is an electric screwdriver and an impact wrench. Despite the similar principle of operation, these tools have differences that make them useful in different situations. Further in the article, we will analyze what is the difference between a nutrunner and an electric screwdriver, as well as in what cases this or that tool will be needed.

Advantages and disadvantages of impact wrenches

One of the key differences between the impact wrench is the tangential impact. When unscrewing, the tool first rips the nut off the bolt and then unscrews it. This approach allows you to work with rusted fasteners without a wrench, without the fear that the nut will fly off to the side due to the high unscrewing force. Impact wrenches are very useful when working with dimensional machinery.

29 for Xiaomi Mijia Electric Screwdriver UNISEX Tool

One of the disadvantages of the nutrunner is the increased noise level, which is due to the high power of the tool. This is especially true for large powerful models. If you can use an electric screwdriver even at a later time, without fear of waking up the neighbors, then it is not always possible to hide the noise when working with a screwdriver.

Models of impact wrenches that do not have a well thought-out system of tangential impact and the subsequent limitation of the unscrewing speed are not very convenient. They can damage the fasteners. However, in modern wrenches, this drawback is eliminated.

Summing up, we can say that the impact wrench will most effectively prove itself in the hands of a skilled craftsman who knows exactly how and for what to use this tool. an electric screwdriver is suitable even for beginners, although it does not have so much power.

The main differences between a nutrunner and an electric screwdriver

The impact wrench is often called a tool for professional work, and the electric screwdriver is often called a household tool. There are several of their key differences:

- The dimensions of the impact wrench are often larger than those of an electric screwdriver. Their weight is also different. the wrench is heavier, but it has a good positive difference in power.

- The impact wrench does not have an attached chuck. Instead, it has a special holder that secures the nut head. an extension that allows you to work with nuts. To use bits or drills on the nutrunner, you will need to install an adapter.

- The wrench is able to apply more force to the fastener. This allows the nuts to be ripped off, even if they seem to be firmly rusted to the bolt.

- Wrenches and screwdrivers have additional functions. Some models may differ in the presence of a speed controller, multiple speeds, backlight, etc. An electric screwdriver also often has a keyless chuck and a 2- or 3-speed gearbox.

- The mechanism of the electric screwdriver is not adapted for the use of tangential impact.

These features allow the use of impact wrenches for work requiring more loosening power. Screwdrivers are used for simple work. By the way, if you use a wrench to screw in screws, you can damage the mounting head with a tangential impact or twist the self-tapping screw. But, if for any reason you need to tighten the fasteners very strongly, the wrench will make it much more efficient.

Is it possible to make a wrench with your own hands?

If you have an electric screwdriver, you can use it as a wrench without purchasing a separate tool. Of course, the power of the tool will remain small, but it will still help to significantly reduce the time of working with nuts when changing wheels on a car. It is enough to install the required nozzle (head) on the electric screwdriver, the dimensions of which will coincide with the parameters of the special key. This can be done using an adapter. To loosen the nut, you will need a wrench, as the power of an electric screwdriver is unlikely to be enough for this. However, after doing this, you can use a homemade impact wrench to speed up the process. This way you can remove the wheels in a few minutes.

Summarizing all of the above, it can be noted that the impact wrench is more specific, high power and tangential impact. It is most effective when working with nuts and bolts. In turn, an electric screwdriver is used for easier work, it quickly unscrews and tightens screws, self-tapping screws, etc.

What drill electric screwdriver to choose and what to look for

There are several signs by which it is possible and necessary to select.

What to choose and how among drills-screwdrivers (DSH)? Key parameters: appearance, functionality and the presence of certain modes, customization and controls.

manufacturer’s warranty

A manufacturer’s warranty is issued for the electric drill and its set, which is placed in a case, for sale. However, not everything is so simple with her.

The warranty itself is governed by the terms of use. As a rule, it is written in the instructions or on the packaging that the warranty does not apply to devices that contain internal contamination that were not repaired in a specialized service workshop and (or) were exposed to significant shock.

Internal pollution is a logical companion of any electrical device and tool for working with materials. Dust and particles of materials will in any case get inside the case, where cleaning is almost impossible. the guarantee is at stake.

Repair not in service is an understandable requirement, because only a specialist trained in the intricacies of working with a brand is able to adequately perform restoration.

As for the impact on the instrument, everything is simple. No matter how direct the hands of the master, in any case, over a long period of work, something falls or hits the instrument, damaging the case. therefore, the closure of the guarantee will sooner or later happen outside the wishes of the master.

electric screwdriver chuck

There are several types of cartridge, each of which is well suited for a specific specificity.

- quick-clamping (BZP). classic structure (spindle, sleeve, collet), the key is not required: the most wear-resistant and reliable, for drills with a round shank, a force greater than usual is required;

- self-clamping or SDS-chuck. even muscular strength is not needed for tightening: the tool will cope with the work when changing nozzles quickly using a design of balls that hold the shank by the recesses in it;

- hex. perfect for bits as an attachment with a corresponding shank: good for screwdrivers, mini-drills, drills;

- bit-chuck. bit chuck: needed for removing (unscrewing) fastening hardware, it is most convenient at home.

The chuck grips the working body, the shape and purpose of which can be different. up to such a solution as a pump for a drill or even a jigsaw.

Which is better: a drill, an electric screwdriver or a drill, and what are their differences

The question of a drill or a drill-electric screwdriver is more difficult, but not critical. A conventional drill (OD) includes a universal chuck as a mounting location for a working tool. The electric drill (DSh) can have both a replaceable chuck-head and a universal one for drills and bits.

There is almost no difference between a drill and an electric screwdriver in appearance: a power cord outlet, a plastic or metal case in the shape of a massive pistol, rubberized handle and pads, control buttons. The complete set may include a depth gauge and a flashlight. Weigh about the same.

The direct difference is in the shape of the cartridge:

- OD has its classic structure. 3 or more collets, clamping the tip of the drill with a wide range of diameter or the tail;

- DSh will be equipped with either a keyless chuck (universal. for bits and drills) or hex (only for bits).

Rotation speed control

The rotation speed of the working tool is controlled manually or automatically.

Manual tuning is done mechanically. For this, the body must have control elements. a button or a switch, after operation with which the rotation speed changes. This is relevant for the LH with a power of 18 V.

Automatic adjustment is carried out through the work of the built-in processor. The signal received from the regulator or toggle switch goes to the processor. It, in turn, sets the operation of the engine and the required rotation speed.

There is also an adjustment by pressing the start button. The bottom line is that the harder you press the button, the faster the number of revolutions will be. In this case, both the force and the depth of pressing the button play a role. The power supplied to the spindle and the working tool will increase in direct proportion to them.

brushless motor

The main feature of this type of DSh in a motor without brushes (brushless type). Failing brushes, which are used to switch electric current, are replaced by an electronic control unit.

The brushless motor has the following list of pros and cons.

- simple adjustment of rotation and change in a wide range;

- lack of brushes and the need for regular replacement, long-term operation;

- profitability and high efficiency;

- lack of sparking and functioning in dusty conditions and in mixtures of explosive gases;

- reduced size and weight;

- the cost is higher than that of other designs.

When using battery power, the service life of the brushless DSH will be longer. For all its advantages, budget constraints often force such models to be bypassed.

ergonomics

The best work is when it is convenient and comfortable. Therefore, the ergonomics of the LH is one of the first factors in the selection. Already when you take it in your hand, it will become clear whether it is easy for your hand to hold the tool and whether you can reach the required buttons with one hand.

The shape should be as streamlined as possible, the color should be bright for quick search and easy identification of damage to the body and handle. The pistol-type design can be either classic or with a slightly displaced forward handle (the angular position of the cartridge is purely individual and not universal). The cordless electric screwdriver is the most ergonomic.

The handle can be tilted or at right angles, and the battery is placed under it. The balance is visible only with the replaceable attachment installed. Retention is reinforced by the surface of the handle. a rubberized or rough surface will ease the effort by creating friction.

What is better electric screwdriver or drill electric screwdriver

How to choose a drill. electric screwdriver

This tool is in great demand both in the professional field and among home craftsmen. In everyday life, saying “electric screwdriver” usually means “drill-electric screwdriver”, but in fact these are different tools.

the electric screwdriver is intended for use with fasteners only. As a rule, this tool is equipped with a cartridge with a depth stop (for working with drywall) or a quick-release, spring-locked, for bits.

The power tool has a built-in mechanism that stops the rotation of the chuck at the moment when the resistance of this rotation reaches its maximum. Also, many screwdrivers work when you press on the screw, you no longer need to press the trigger button. This greatly simplifies the work with fasteners and saves time. Screwdrivers are lighter and more mobile than drills and screwdrivers, and if there is no need for the drilling function, you need to choose an electric screwdriver. This tool is in great demand among those who work with drywall.

As you may have guessed, you can also drill holes with an electric drill. Next, we will consider this tool in more detail.

Brush motors have stood the test of time. But, despite all their advantages, they also have a number of disadvantages. The brushes wear out quickly enough, during operation sparks often occur at the point of contact of the brushes with the armature, a lot of heat is released. Power consumption is much higher than that of brushless.

Brushless motors are free from the disadvantages of the opponent. They have smaller dimensions at the same power, emit less heat, do not “spark” during operation, and do not have wear parts. You can read more about brushless motors in a separate article.

If you can choose between a brushed or a brushless motor, it is definitely worth taking a brushless.

The torque determines the application of the tool. Drill-electric screwdriver is a fairly versatile tool capable of both screwing and drilling a hole.

A wide range of special attachments allows you to expand the tool area even further. With their help, you can turn the drill-electric screwdriver even into a nibbler for metal.

Of course, smart craftsmen expand the scope even more.

Let’s go back to torque. Measured in Nm (Newtonmeter) The greater the torque, the more force the tool can overcome, the more powerful it is. The torque is determined by the power of the tool, which depends on the engine and battery. The documentation for the device usually indicates the maximum possible diameter and length of the screw. In household screwdrivers, the average torque is from 10 to 30 N / m. This is enough to cope with most of the necessary tasks. The professional electric screwdriver can have a torque of 100 N / m or more.

Ratio of torque and screw diameter.

A very important characteristic of a good electric drill is the ability to adjust the torque. The adjustment clutch allows you to set the required torque, thereby choosing the force with which we will work the tool. If you do not calculate the strength of the tool, you can break the nozzles, spoil the heads of the screws. Therefore, the adjustment clutch equipped with 20 or more adjustment steps is intended for such purposes. The higher the step, the more effort the tool applies when working.

Rotation speed indicates the number of revolutions of the working nozzle per unit of time. It should be noted that for ordinary work with screws and self-tapping screws, a speed of 450-550 rpm or even less is quite sufficient. If an electric drill is used for drilling, then this requires a speed of 1000 rpm.

These are relatively small indicators of rotation speed, since, for example, with an angle grinder, the rotation speed can reach 11,000 rpm.

Often. The rotational speed of the drill. Electric screwdriver is regulated by the force of pressing the trigger button. But some tools have 2 or 3-speed gears that are switched using a special toggle switch.

The electric drill can be equipped with a single sleeve keyless chuck or a double sleeve chuck.

In the case of a double sleeve chuck, in order to install the tooling, you need to clamp it and tighten it. In this case, you have to rotate the ring with one hand, and hold the cartridge with the other. Which is not very convenient.

Most power tools now come with a single sleeve keyless chuck. You do not need to hold the chuck to clamp the drill. This convenience is provided by the spindle lock. In the running state of the spindle, blocking is not active. But as soon as the electric motor stops, when the blocking is activated. It becomes impossible to turn the spindle by hand. This makes changing the drill considerably easier. It is enough to insert the snap into the chuck and tighten it.

Despite the fact that such a design of the chuck makes the electric drill universal in use, at the same time, the chuck can interfere with work. As the dimensions of the tool increase. To solve this problem, manufacturers equip models with a quick-release chuck. This allows you to quickly remove the cartridge by retracting the ring at the back and install the bits.

When a person chooses an electric screwdriver for use in everyday life, he does not always pay attention to these parameters. Of course, if you use an electric screwdriver a couple of times a month, they are not critical. But if the tool will be used almost every day for several hours, then criteria such as weight and ergonomics are extremely important.

The sharper the angle between the handle and the working part, the faster you will rub your callus and the faster your hand will get tired during use. If with short-term use this is not critical, then with long-term use it is a very significant problem.

Such a seemingly trifle can entail such unpleasant consequences.

The heavier the tool, the easier it will be to drive screws into hard surfaces. But the hand gets tired much faster. A small tool is more convenient for use in hard-to-reach places, the hand does not get tired so quickly, but at the same time we lose power. Makita also manufactures specialized tools for hard-to-reach places such as angle drills and screwdrivers.

Drill drivers can be powered from the mains or battery.

It is advisable to use a networked electric screwdriver if the work is carried out in a permanent work area with access to the network. However, cordless screwdrivers are more in demand due to the benefits they charge. They are mobile, the power cord does not get tangled underfoot, it is not necessary to have a power supply at the place of work.

Let’s consider in more detail what batteries are and how they differ.

Battery capacity, voltage and type

Nickel-cadmium (NiCd). an outdated type of batteries that large manufacturers refuse to use in favor of better quality.

Nickel-metal hydride (Ni-MH) batteries are also an obsolete type with minor advantages over NiCd and are also a thing of the past.

Lithium-ion batteries (Li. Ion) are a new type of batteries that are actively used in modern cordless tools. This is the best type of battery available today. The price is justified by the long service life. Also, thanks to the interchangeability, you can save money. For example, purchase an electric drill with a battery included and an angle grinder without a battery and use them in turn.

The higher the battery voltage, the higher the maximum torque of the tool. The minimum battery voltage is 9.6V, these batteries are used in screwdrivers or cordless screwdrivers. Next come the batteries 10.8 V, 12 V, 14.4 V, 18 V and 24 V. 24V batteries are already quite serious batteries and are already used in cordless angle grinders or rotary hammers. The maximum voltage is 36V, but such batteries are rarely used since above 36V already constitute a danger to humans and the explosion hazard is higher.

Battery capacity is measured in Ampere-hour (Ah) and the operating time of the tool depends on it. The minimum capacity is 1.5 Ah to 3 Ah. Of course, it is difficult to say exactly how much the tool will work on one charge. Many factors affect the operating time, among them the load on the tool, the ambient temperature and much more. Unambiguously, the larger the capacity, the longer the operating time from one charge, but the weight also grows with the capacity. Most drills run 3-4 hours on a single charge at average load and take less than an hour to charge (many Makita drills charge in 22 minutes using the modern DC18RC charger). with a lot of weight during working hours. Therefore, it is more advisable to charge a battery with a lower capacity during a break. Of course, if you want to pump up without going to the gym, choosing a battery with a large capacity will undoubtedly be justified.

Impact mode allows you to increase the torque at times, which significantly expands the capabilities of the tool both when drilling and when tightening screws.

This chuck has a special fixation that prevents the possibility of unwinding during operation. This option is very useful when working with the tool at high torques.

Quite often, we are faced with the fact that we need to tighten a screw or drill a hole in a place where the room’s lighting does not reach. Working with a flashlight at the ready is inconvenient, to put it mildly. This backlight greatly simplifies such tasks.

This feature is very useful for any rechargeable device. Thanks to it, you will avoid a situation when the tool is discharged during work at the most inopportune moment. Knowing the battery level makes it much easier to plan work.

For a powerful drill, an electric screwdriver is an extremely necessary thing. You get an additional emphasis when drilling hard surfaces, without which it is extremely difficult and inconvenient to drill them.

The electric drill usually comes with a carrying case. Makita has more complete packages. For example, the scope of delivery of the Makita BDF458RFJ cordless drill-electric screwdriver also includes 2 BL 1830 batteries, a charger, a keyless chuck, an attachment, a side handle and a Makpac transport case. By purchasing a tool with two batteries in a set, you can increase the time of continuous operation by alternating the batteries. Also, thanks to the interchangeability of lithium-ion batteries in your Makita tool, you can save money by purchasing a tool without the included battery. For example, DGA452Z angle grinder.

Drill.The electric screwdriver is a very popular tool in both professional and household spheres. Remember, when choosing, the main criterion is the type of work and the tasks that you set for the tool. With constant work with drywall structures, it is enough to purchase an electric screwdriver, which is much lighter and more mobile. When working with harder materials and larger screw diameters, it is better to choose an electric drill, which, if necessary, can pre-drill a hole for the screw.

The versatility of the tool is a definite plus, but if you constantly need to hammer in nails, you should not buy an ax.

Best Screwdriver Brand? Let’s find out! Milwaukee, Dewalt, Makita, Ryobi, Bosch, Pink Power, Metabo

Modes

an electric screwdriver is only able to twist its attachments, while a person can only change the rotation speed. The drill, in addition to everything else, can be used as a percussion instrument.

electric screwdriver or drill: which is better to choose?

Having such a convenient and useful tool as a drill and an electric screwdriver at hand will never be superfluous. This technique allows you to cope with small and large household tasks in a matter of minutes. to drill a hole, screw in a self-tapping screw, and mount equipment. But when buying this functional tool, we often think: what is better to choose. a drill or an electric screwdriver?

Drilling capabilities

Of course, an electric screwdriver can be used to drill a small hole. But if the nozzle bumps into a knot or some kind of solid element, the mechanism will automatically stop. And screwdrivers of poor quality can even become completely unusable.

Cordless Screwdriver or Cordless Drill?

The drill is designed for drilling almost any surface, the main thing is to choose the right speed and the diameter of the nozzle. Also, many drills come with special devices that collect all the dust generated as a result of active work with the tool.

Rotational speed

The main distinguishing feature of the two devices is the rotation speed. an electric screwdriver turns its bits much slower than a drill. This characteristic greatly affects the performance of the device. Therefore, the drill will do the job much faster than the slower counterpart.

electric screwdriver or drill: what are the differences

Safety

In terms of safety, the electric screwdriver wins, since it is not capable of causing severe damage. This is because in the absence of contact with the start button, the mechanism stops rotating. With a drill, the situation is somewhat more complicated. It is recommended to strictly observe safety precautions when handling this tool, as the equipment can cause serious damage to the skin and eyes. Working with a drill requires precise action and maximum concentration. But if a person has extensive experience in such work, then it is possible to allow the screws to be tightened with a drill.

Drill or electric screwdriver: comparison of characteristics

Both instruments have both professional and consumer versions. advanced models allow manipulations of any complexity, and also work almost without interruption. At the same time, the for such equipment will be quite high. The same applies to the cost of consumables, parts and device repairs. Simple equipment options cannot boast of such high performance, but they are much cheaper.

A person who is poorly versed in technology will not even be able to immediately explain what is the difference between a drill and an electric screwdriver, because they have a lot in common:

- the principle of operation of both “rivals” is that the mechanism makes the nozzle rotate;

- the presence of several modes and a variety of removable elements;

- both devices can be powered from the mains or use the charge of a removable battery;

But in fact, these three lines are where the similarities between an electric screwdriver and a drill end. And their differences immediately allow you to understand which tool is suitable specifically for your needs.

Accuracy of work

If you need to screw in a screw, then an electric screwdriver will allow you to accomplish this task more efficiently and safely. When the self-tapping screw enters the required depth, the mechanism will meet resistance and stop. The drill, due to its inertial principle of operation, can make an unnecessary depression in the wall or completely ruin the coating. This is especially true for small fasteners.