Perforator

This machine is designed for drilling, chiselling and breaking parts of particularly durable surfaces, such as reinforced concrete. It is used not only when doing housework, but also in professional construction.

A perforator not only punches concrete walls, but also splits tiles and bricks, removes plaster. It is also convenient for them to perform chasing (hollowing out a recess in the wall for wiring). At the same time, the special design of the handle and its material dampen vibration almost completely. Therefore, when working, the return is minimal.

This tool also has several modes of operation:

- shock;

- drilling;

- punch drilling.

The force applied to it depends on the operating mode of the punch. When working with the percussion type, it is not necessary to additionally press on the tool, in contrast to drilling and even more drilling.

It should be noted here that only drills and blades are inserted directly into the hammer drill. Drills from a drill require an additional adapter.

Drill and hammer drill: what is the difference and which is better to choose?

- Hammer drill

- Perforator

- Tool characteristics

- How to make a choice

Periodic renovations in an apartment can make anyone think about buying their own tools. The modern market provides a wide variety of units for various jobs. Many of them have similar functions. And then a dilemma arises: what is more needed? One of the most common pairs of these tools is the hammer drill and hammer drill. To make a choice, you need to know their characteristics and the expected tasks that they will have to perform.

Hammer drill

This tool is mainly intended for drilling various materials. But its design includes a special percussion mechanism that allows the drill to make striking movements during operation. It’s like hitting a hammer. The function helps to work with durable building materials:

- brick;

- concrete;

- stone.

As a rule, this device has a switch that changes from simple drilling mode to hammer drilling. At the same time, it is necessary to understand that a conventional drill is not enough for crushing strong materials, therefore a nozzle with a victorious tip is used. In addition, this tool is not designed for strong impacts with a large amplitude of longitudinal movements of the drill. The beating movements are carried out within a few millimeters, so they can rather be described as vibration of the drill during the operation of the tool.

The impact force of the drill depends to a large extent on the pressing force on the tool, therefore, in order to make a hole in a durable material, you need to make significant efforts, which is not suitable for everyone.

But the drilling capabilities of this tool do not end there. Attachments in the form of grinding wheels are perfect for the drill, on the sticky surface of which you can fix any sandpaper. This helps to sand the painted surface or putty on any material. Also, with the help of attachments, you can turn an ordinary drill into a brush for removing coloring compounds from metal. When using twisted wire, the processing will be rough, with corrugated wire. finishing.

Thanks to the fast rotating movements of this machine, you can mix cement or putty: just insert a mixer fork. The number of such attachments is varied, thanks to which the drill is a fairly versatile unit.

Tool characteristics

When choosing a hammer drill, it is necessary to take into account the main indicators of impact energy. It is measured in joules. A professional device can have an impact force of up to 15 joules, while a home device can only have 1–2 joules. The higher this indicator, the more efficiently the perforator works, and the larger holes it punches. If such a tool has too little impact force, then it will drill the wall more than drill, and the nozzle will quickly fail.

The second important indicator is the frequency of the striking movements. The more beats per minute the apparatus makes, the faster it will punch a hole. But more speed means more wear on parts in less time. That is why it is worth choosing only high-quality and well-known brands that have already proven themselves. Parts of such tools are made of higher quality materials. They are designed for increased loads.

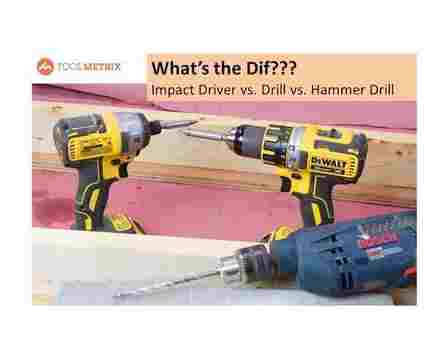

Drill vs Impact Driver vs Hammer Drill

The power in this equipment is not strategically important. The standard is a variation from 800 to 1200 W, depending on the type of cartridge used.

The frequency of rotation of the shaft is also not fundamental, unlike a drill. It’s all about the purpose of this function in the hammer drill. Rotation of the nozzle during chiselling is performed to remove the destroyed material, and not to create a depression.

In addition, the drill bits have a large diameter, and it is difficult for a low-power engine to rotate them at high speed. And a large engine significantly increases the weight of the unit, which complicates its operation. That is why the standard shaft speed in the hammer drill fluctuates at an average level (from 600 to 1500 rpm).

And another important criterion for evaluating the tool is the type of chuck for installing drills and drills.

The punch has three of them:

- SDS plus (the tool weighs 4 kg and punches holes up to 3 cm in diameter);

- SDS max (weight. up to 11 kg, diameter. up to 5.2 cm);

- SDS-top (average weight with a hole diameter of 1.6-2.5 cm).

The latter type of chuck is almost universal, it is installed mainly on Bosch rotary hammers and is optimal for home repairs.

As for the characteristics of the drill, the beat frequency does not play a key role here, since the maximum efficiency in the hammer mode is achieved by pressing the tool firmly. This is the main difference between rock drill and hammer drill specifications.

To successfully perform its main functions in a drill, power and shaft speed are important. The average power of the drill is 500–900 watts. If it is supposed to be used as a mixer, then this indicator should be significant. Then the tool will not overheat during use. However, the higher the power, the greater the weight of the apparatus. Therefore, for homework, it is better to choose average characteristics.

As for the shaft speed, it must be large. At its high value, the holes are drilled evenly. In a home drill, a high RPM helps to compensate for low power. Drill chuck type. cam or key. In the jaw drill, it can be clamped quickly and without the use of additional force. This simplifies and speeds up the process of changing the nozzle. The key cartridge is distinguished by the presence of an additional device in the form of a small key. It takes time to replace the nozzle, but as practice shows, such models break less often.

How to make a choice

From all of the above, the following conclusion can be drawn. If you choose between a hammer drill and an impact drill, then you need to clearly understand what tasks will have to be performed with this tool.

For chiselling, slitting and drilling, a hammer drill should be preferred. If you do not intend to knock out recesses or remove partitions, then an impact drill will be the best assistant in home repairs. Choosing a quality tool from a good manufacturer, you can get not only a drill, but also a hand-held concrete mixer and a grinding machine.

However, when buying any tool, you need to pay attention to a number of additional characteristics:

- the presence of a speed switching relay;

- the presence of a soft start function;

- the ability to fix the button during operation;

- handle shape;

- additional equipment.

Ease of use of the device often depends not only on the power and availability of recoil, but also on the comfortable grip of the device. Comfortable handle with smooth transitions and indentations for fingers can greatly facilitate work.

As for the additional equipment, brand manufacturers put consumables in the kit. Most often this is a minimal set of drills or drills, a spare chuck and lubricant. The presence of these add-ons allows you to get started almost immediately after purchase. In addition, buying these parts separately, there is a risk of overpaying, since the difference in the price of the kit and individual attachments is striking. And on a complete branded device, you can save a certain amount.

In the next video you will find a review of the Sturm RH2591P rotary hammer.

Drill vs. Hammer Drill vs. Impact Driver: What Drill Should I Buy

Principle of operation

The principle of operation of the drill is that two ratchets, which are in contact, transmit impact action and rotation to the drills, while the amplitude of the impact is small, vibration and the force with which it is necessary to press on the tool increase.

The principle of operation of the perforator is that inside it there is an electromechanical or electro-pneumatic percussion mechanism, it itself produces a blow when pressed with a button, there is no need to use physical force.

Drill or hammer drill? Figuring out which is better

Drill and hammer drill. power tools that are similar in appearance, but have a number of fundamental differences in the principle of operation, technical characteristics, power, weight, cost.

The drill is the most common tool. With its help, you can perform such work as drilling holes in various materials (plastic, metal, wood, etc.) Thanks to interchangeable nozzles, the drill is used as a screwdriver, a mixer for mixing glue, mastics. But drilling in very hard materials (reinforced concrete, natural stone) is difficult for a drill.

The hammer drill copes with such work much better. We can say that the hammer drill is a hammer drill with advanced capabilities, a versatile tool that combines the functions of a drill and a jackhammer.

With external similarity, the difference between a drill and a hammer drill is in the way of fixing the drill. In a drill, the drill is clamped in a cam-type chuck, it is securely fixed and does not have the ability to make frontal movements. In a hammer drill, the drill (drill) is held in a special SDS chuck and moves back and forth, which allows you to use both the force of a jackhammer and the torque of the drill at the same time. The device comes with an adapter, it is used to support the drill for the drill, since the perforating chuck does not perform this function.

Impact drills similar to the hammer drill are currently being produced. But their use requires the use of large physical costs when working with concrete, since you have to put pressure on the tool. Such drills can be used for short-term work when renovating an apartment or house.

The impact function is the main one for a hammer drill and an additional one for a drill. The drill can be attributed to household tools. A hammer drill is a professional tool that has a number of additions that are not available with an electric drill: anti-vibration compensating handles, safety clutches and angle fixers for the drill position. These useful additions will always come in handy and make it easier for the professional builder in their daily work.

Technical specifications

The technical characteristics usually indicate the power, the force of the blow, the frequency of beats per minute.

As the power of the drill increases, its ability to punch a hole increases, but the weight also increases.

Rotary hammers are heavier, more compact tools with more power. With a power of more than 1500 W, their weight reaches 11 kg.

The hammer drill and drill are somewhat interchangeable. A drill used as a hammer drill wears out and breaks faster. A hammer drill is a reliable tool, but it is more difficult to work with it, since it is necessary to install a special extension nozzle for the drill to work.

It is more advisable to have both tools, using them as appropriate. When performing the lightest work (drilling wood, metal), it is preferable to use a drill. To work with concrete, stone, it is better to work with a perforator, its impact function will come in handy there.

Drill and hammer drill differ significantly in cost. A hammer drill as a professional powerful tool is much more expensive than a drill, but it is worth it because it takes less time, is easier and more convenient to work, it is felt immediately.

Modern manufacturers of construction tools offer various models of drills and hammer drills. The most popular manufacturers MAKITA (Japan, produce professional tools), BOSCH and KRESS (Germany, produce professional and household tools), SKIL (Holland, produce household tools). The manufactured models are distinguished by their reliability, durability, and the best price.

Popular materials

Performance

Determined by the value of the impact energy. With a hammer drill, it fluctuates between 1.5-20J and is always an order of magnitude higher than that of an impact drill. This largely depends on the mass of the device and the pressure of the master. The technical characteristics of perforators can also indicate the frequency of blows per minute: from 4 to 4.5 thousand blows in more powerful models and 2-3 thousand in less powerful ones.

- What can you feed the tits. How to feed titmouses. titmouse nutrition

- What are the tools for repairing the name. Construction Tools Names Photo.

- All the leaves of the ficus have fallen, can it be saved? Why do ficuses shed their leaves

- That grows in the shade in the garden. List of shade-tolerant vegetables for the garden

- What is the cotyledon in plants. The meaning of the word laquocotyledon “

- Potatoes are very soft, what to do. How to cook potatoes so that they do not boil, but remain round?

- What sub-zero temperatures the roses can withstand. How many degrees of frost can uncovered roses withstand

- Rotary hammer or hammer drill for home, what to choose in. Which is better: hammer drill or hammer drill?

- Rotary hammer or hammer drill for home, what to choose. Impact drill or hammer drill

- Principle of operation and features

- Differences in application

- findings

- What is the best for home punch or hammer drill. What to choose: hammer drill or drill?

- Video IMPACT DRILL OR PUNCHER | WHAT’S BETTER?

- What is better percussion drill or hammer drill? Rotary hammer or impact drill?

- Impact drill or hammer drill. Equipment

- Performance

- The cost

- Impact screwdriver or hammer drill. What is the difference between a hammer drill, a drill and a screwdriver

- What is the drill used for?

- What is the difference between a hammer drill and a hammerless drill?

- What is the Difference Between a Drill and a Rotary Hammer?

- What are the best drills?

Rotary hammer or hammer drill for home, what to choose in. Which is better: hammer drill or hammer drill?

This question is often asked by inexperienced people who purchase a tool for the home. In principle, professionals do not have such doubts, since they certainly know that behind the external similarity there is a great difference that predetermines the capabilities of these two tools.

The drill is originally intended for drilling holes in materials of low density. in wood, plastic, soft metals. The addition of the percussion function has significantly expanded the capabilities of this tool, making it possible, among other things, to easily drill into brickwork and structures made of low-grade concrete. At the same time, like hammerless drills, with the proper equipment, they are able to work with fasteners. For all their versatility, drills have rather modest dimensions and are much cheaper than perforators. Thus, the main reasons for the popularity of impact drills among domestic consumers include their versatility, compactness and affordability.

Accordingly, rock drills are heavier and more expensive. If you compare tools with identical power, the weight and price advantage of rock drills will be obvious. For example, a thousand-watt two-speed drill Makita HP 2071 weighs 2.4 kg and costs about 5000 rubles. With its help, you can drill holes with a diameter of up to 40 mm in wood, up to 16 mm in steel, and by connecting the impact function, “drill” into concrete with a 20 mm drill.

For an M Akita HR 4010 C perforator of a similar power, you will have to pay three times more and it weighs 6.3 kg. In terms of functionality, a hammer drill is significantly inferior to a drill, since it only hammers or drills with a blow, and these two modes are unacceptable for making holes in wood and metals. But in terms of drilling concrete, the designated perforator is out of competition, since it will “pull” not only a large-diameter drill (up to 40 mm), but also a drill bit (up to 105 mm). In addition, this tool can easily replace a jackhammer and will greatly facilitate the work of installing niches and openings, laying communications, chipping off old ceramic tiles, etc. Of course, such a hammer drill is intended exclusively for professionals and is unlikely to come in handy in everyday life.

However, among the hammer drills there are also “lightweights”: for example, the Makita HR 1830 weighs only 1.7 kg, and the price is inferior to the Makita HP 2071 hammer drill. Both of these tools work in the mode of drilling and hammer drilling. over, with the help of a drill, you can arrange technical holes of a much larger diameter in concrete (without taking into account hardness), and in wood, and in steel.

A natural question arises: what is the difference then? First of all, the difference in power consumption: for the compared hammer drill, the power consumption is 440 W, and for the drill. 1010 W. And this is the corresponding load on the network and the cost of paying for electricity on the one hand and an indicator of performance. with another.

But the main difference lies in the purpose, in particular in the main object of the application of efforts. For a drill, drilling concrete is an additional option, and in the hammer drilling mode, the tool works for “self-destruction” (more on that below). A puncher. easily crushing monolith, will not provide high precision drilling of holes in steel, wood and plastic. The reason for this is the design features of the percussion mechanisms of drills and perforators and the used cartridges for fixing the equipment.

In impact drills, the impact is generated mechanically. Everything is extremely simple there. Two toothed ratchets in drilling mode without impact rotate interlocking teeth, as a whole. When the kick function is turned on, the internal ratchet (located closer to the engine) moves back, and the external one begins to “recalculate” its teeth with its own. As a result, impact energy is not generated as such: the impact force is predetermined by the height of the teeth and the pressure exerted on the tool by the user, and the impact frequency is determined by the number of teeth and rotation speed.

This is where the aforementioned “self-destruction” comes from. No matter how strong and wear-resistant the material used for the manufacture of ratchets is, sooner or later the teeth will “come together” and the impact mechanism will finally fail.

The nature of the impact in rock drills is completely different. The crank mechanism converts the rotation from the engine into reciprocating movements imparted to the piston. That, in turn, drives the firing pin, but not directly, but through an air gap, which reduces the load on the piston, thereby contributing to the durability of the tool as a whole, and reduces recoil. Such a percussion mechanism is three times more effective and, of course, more reliable than a drill “ratchet”. In the presented model range of Makita perforators, the impact energy ranges from 1.3 to 19.7 J (models HR 1830 and HR 5210 C. respectively).

Some conclusions can already be drawn from the above. For example, that if intensive work on concrete drilling is ahead, then the hammer drill will “die” pretty soon, and the “heavy” one will not overcome at all. And it is true. But do not be fascinated also by the versatility of three-mode rotary hammers, which are declared by manufacturers as a jack of all trades. As a rule, these are instruments of light (up to 4 kg) and medium (5-8 kg) class. Such rotary hammers, and “heavy” ones too, are equipped with SDS keyless chucks. plus and SDS. max. designed exclusively for special nozzles. drills, blades, etc. whose shanks have a well-defined shape (the presence of grooves and their number). Consumables for rotary hammers are much more expensive than conventional drills, and the use of the latter is not possible due to the specifics of the cartridges. To expand the capabilities of rotary hammers, manufacturers quite often complement their models with additional cam chucks, which are mounted in standard SDS-type holders by means of special adapters. At the same time, the tool becomes more cumbersome, and the beating of the chuck increases significantly, which does not benefit the quality. Interchangeable chucks are an alternative for more accurate drilling. In this case, the main SDS chuck can be easily dismantled, and in its place, thanks to the adapted tip, a conventional cam chuck is installed. for cylindrical drills. An example is the Makita HR 2811 FT hammer drill with a removable SDS chuck. plus. It should be noted that such an arrangement is not so common so far and significantly affects the price of the instrument.

HAMMER DRILL VS. REGULAR DRILL–What’s The Difference?!! (Do You NEED a Hammer Drill?!)

So, answering the first question, we have already noted its incorrectness. Both drills and hammer drills are equally good, but only in the area for which they are intended. The hammer drill is ideal for drilling holes in wood, metals, plastics, masonry and lightweight concrete. In addition, it can be used to work with fasteners, and at low speeds as a mixer. A hammer drill is preferable where you often have to drill and hammer concrete (and reinforced concrete) of varying degrees of density, but it will not provide precision drilling in metals and wood. Rock drills, which are equivalent in power to impact drills, are significantly superior in weight and cost. When working with concrete, rock drills are much more reliable, practical and more durable than impact drills. The versatility of impact drills will come in handy in a domestic environment, and hammer drills are more “professional”. But if you live in a building made of glass and concrete, then in addition to a hammer drill, it will be useful to have at hand, if not the most expensive and powerful, but a perforator.

Impact drill “in the teeth” brick, foam concrete, other types of lightweight concrete. But drilling these materials will be slow and time consuming. The reason is that the impact energy of the drill is low. What is convenient is to drill wood and metal, as well as tighten fasteners.

The hammer drill is most effective when drilling concrete or stone. If you work with it on wood or metal, then the holes are not as accurate as when drilling with a drill. For these works, a cam chuck is installed in the chuck of the perforator, but beating is still present.

The “native” equipment for the perforator will be crowns, chisels, spikes, blades. This is “heavy artillery” for the respective tasks. You can, for example, remove tiles or hammer grooves.

Amateur instruments.

As a rule, such power tools are designed with the understanding that they will not work with them on an ongoing basis, but from time to time, only when such a need arises. In other words, the loads on them will be small. All this characterizes the tool, which has low power, small dimensions and weight, as well as a standard set of features and functions. Often, additional attachments are attached to amateur tools, which can turn them into a completely different tool. for example, a drill can become a grinder or jigsaw.

Impact drill or hammer drill what to choose?

Impact drill (drill with impact function)

This type of tool was developed in order to speed up and facilitate the process of drilling holes in brick and concrete. The principle of operation of the percussion mechanism of the drill is that two ratchets transmit simultaneous rotation and impact to the drill. And this principle has a drawback. a relatively small impact amplitude. In addition, during operation, strong vibration appears, and constant work leads to wear of the ratchet teeth.

Conventional drills

Manufacturers often try to turn a drill into a kind of universal tool that is capable of chiseling, drilling and driving screws. But the all-in-one option cannot be without losses. For example, the ease of screwing in screws cannot be combined with the drilling power of concrete and the impact function, because a light tool, by definition, will have low power. Therefore, a powerful tool, due to its size and high weight, will not be able to easily screw in and out the screws. So, either in a light tool the impact function present there will be practically useless, or in a powerful one the screwdriver function will almost not work. The assortment of additional drill bits, which are also produced by many manufacturers, in theory can turn a drill into almost any electric tool, which naturally seems tempting. This saves money and space, and the entire set is also packed in a case. But here it is important to know that each type of power tool has its own technical features, and the use of such “attachment” equipment leads to low productivity and not the best quality of work.

Perforator

Due to the design of this tool, drilling (breaking through) a concrete wall occurs several times faster than with an impact drill, and during operation it does not need to be pressed. This is because there is an electromechanical (or electro-pneumatic) percussion mechanism inside the hammer drill, which produces an impact on its own. And no additional physical effort is required, because the reciprocating amplitude of the hammer drill is much greater than that of an impact drill. The hammer drill can make holes in particularly hard materials, as well as chisel with a chisel (this is called the function of a jackhammer). The cost of a hammer drill and its consumables is higher than that of a hammer drill, but the quality and speed of its work is also higher.

Drills and hammer drills

There are several types of drills on the market at the moment.

- Regular. They are capable of drilling holes in wood and metal. A subspecies called angle drills allow you to make holes even in hard-to-reach places.

- Drums. Combine drilling and punching capabilities. With their help, you can drill not only metal and wood, but also concrete and brick.

- Drill mixers. These are tools with an extended auxiliary handle and high torque.

- Drill screwdrivers. In addition to their main function, they are capable of unscrewing and screwing screws.

Professional and amateur models

One of the first questions that comes up when buying a power tool is the dilemma between amateur and professional options. The former are cheaper, but their capabilities are limited, and the latter have a high price, although they are distinguished by increased functionality and reliability. So what to prefer in this choice?

Working attachments used and type of fixation

Another parameter that distinguishes the devices from each other is the working tool and the type of fixation of the element. Most often exploited:

- crowns;

- borax;

- chisels;

- strobers.

In drills, as a rule, a working element in the form of a drill is used, on which a soldering from an alloy is applied. This option is relevant for concrete surfaces. It should be noted that the element is fastened to a special clamp in both versions. But their design is different in the devices. Rotary hammers involve the use of a number of systems that allow you to quickly change the working element. These are, in particular, SDS:

- plus;

- max;

- top.

For fixing, special grooves with a special configuration are used. It should also be said about the degree of freedom in relation to the clamp in the direction of the axis. This approach helps to reduce the workload during work.

A standard drill is used only if the device is equipped with a special adapter or a chuck with a cam mechanism is installed instead of the traditional one. The latch facilitates quick and easy clamp changes. The standard model is included with the device. When a cam variation is used, a structure is formed that consists of two clamps, connected in series with each other, and one auxiliary. But in this case, beating occurs during the operation of the device, and the mount is not sufficiently rigid.

From the above, it follows that rotary hammers are used to solve a wide range of tasks compared to impact drills. In addition, they benefit in terms of power and performance. This means that this option is more relevant for performing complex operations. Drills are rational to use for solving small tasks.

Difference in working conditions

Especially significant differences are seen in the operating conditions of the tools. With the same parameters as the hammer drill, drilling and hammer drilling is easier, for example, with the DeWalt D25501K model. To provide optimal power, a drill force of 9-16 kg is required, and a hammer force 5 is required. A lower pressure value also reduces vibration on the hands, which is convenient for the user.

The hammer drill is more convenient, because in the design of the tool there is an air cushion with a softening characteristic. Due to this element, the docking of the tip of the striker and the piston with each other does not occur. This feature makes the hammer drill more practical in comparison with the drill.

Service life and reliability

The period of use of instruments is another important parameter that determines the further purchase. An impact drill such as the Bosch EasyImpact 550 has a shorter operating time than a hammer drill. The advantage is that pneumatics reduce vibrations, therefore, working conditions will be optimal for the entire structure of the apparatus. A special coupling helps to eliminate breakdowns when the drill gets jammed. For example, if the element hit the reinforcement.

The working parts of the drill quickly become unusable, which is due to the acting load on the gears. As a result, vibration affects with great strength and rigidity, negatively affecting the tool components, disabling the elements.

How an impact drill differs from a hammer drill: 7 main criteria

Behind the external similarity lies a number of differences that determine the capabilities of each of these tools. The design of the devices does not allow them to be interchangeable. As a result, operational restrictions are imposed. Therefore, about the difference between these two instruments, below.

Functionality of devices

The first difference is the functionality of the devices. This directly determines the operation of the tools. Drills have a wide range of applications, in particular:

- Drilling holes in thin coatings including wood and plastic surfaces. Using the switch uses the beat option.

- Punching holes on hard surfaces. Here the impact option comes to the rescue, allowing you to work even on brick surfaces.

- Driving and loosening screws, screws and screws. But such actions should be performed subject to the disabling of the shock function.

Rotary hammers also perform the above tasks. In addition, these tools cope with punching holes in materials with high hardness. For example, reinforced concrete. In the process of work, various types of chisels are used, but on condition that it is necessary to make breaks or gutters in walls made of concrete or stone. Such tools operate in three modes:

- turns with blows;

- like a jackhammer;

- execution of revolutions without impact function.

Drills have only two modes. This is drilling with and without blows.

Apparatus performance

If you plan to drill holes in stone surfaces, then it is more advisable to choose a hammer drill. The productivity of these devices is higher than that of drills, which is explained by the indicator of the impact force. For light models, the value is 1.4-1.7 J, and for heavy models. 19-26 J. Working with drills, the impact is determined by the force of pressing the device to the surface. But even if the exponent is high, the value will be small because the amplitude of the pivot element is low. As a rule, the parameter is equal to the height of the gear tooth. The efficiency of the punch is also higher due to the mass of the device. Weight contributes to an increase in this parameter.

The hole made with a drill will be 1.5 times smaller than that made with a punch. When using a crown, the difference becomes even greater. In addition, professional rotary hammers help to solve the problem much faster. The result also depends on the version of the working element used, the power of the apparatus. But the hole made by the punch will always be bigger.

Differences in striking mechanisms

The question is not what is more practical, but for what purpose the device is needed. The impact mechanism of the apparatus determines the main distinctive features. Drills are distinguished by a simpler design. The “body” includes two ratchets, where one connects to the body and the other connects to the rotating chuck. When the shock option is disabled, these elements stop contacting each other, due to the presence of a special stopper.

When turned on, they interact with each other. This is due to the fact that the stopper is removed, and when the drill is pressed against the material, contact occurs. At the same time, the working element and the clamp for it are in motion, which is an axial reciprocating.

Perforators are distinguished by a more complex design, which is made in the form of a knot. The mechanism exists in two variations: electromechanical and electro-pneumatic. The second is used more often than the first, due to the best performance.

The bottom line is that the engine rotates, which is due to the KShM conversion mechanism (crank-connecting rod). A special swinging assembly in the form of a sphere is also used. This leads to the fact that the cylindrical rod acquires a reciprocating motion. A space is formed between this element and the ram, in which a certain force acts, which leads to an increase in the movement of the latter. As a result, the element gives off energy to the working tool.

In other words, hammer drills are mechanics, and rock drills are pneumatic. Due to this, the amplitude and force indicators differ, respectively. With equal power, the functionality of the former will be lower compared to the latter.

Price difference

The cost of the devices, accordingly, also differs, even if their power is the same. Under the same conditions, the price of a hammer drill is 3-4 times higher than a drill. For example, if we consider devices with a power of 700 W, then the Zenit ZDP-700 drill will be cheaper, while the Interskol P-24/700 ER perforator will be more expensive.

Models of tools Zenit ZDP-700 and Interskol P-24/700 ER

You need to choose a model based on a number of parameters:

- required power;

- working material;

- working conditions;

- the scale of the task at hand;

- budget.

If the work is minimal, then buying a hammer drill is irrational.

There is no answer to the question “which is better?” Acquisition is determined by the scope of use and related conditions. If serious repair work is not expected, then it is optimal to choose an impact drill. It is suitable for wood and metal coatings, tightening fasteners. It is rational to choose a hammer drill when it becomes necessary to drill hard surfaces (stone, concrete, brick), prepare large holes or perform dismantling operations.

Watch the video “Rotary hammer and hammer drill: are they replacing each other?”