Even if there is a great desire, a chainsaw cannot be classified as a complex device. And note also: the simplicity of the design is its characteristic feature. However, despite this fact, even such a simple device breaks down, taking a considerable amount of time for repairs.

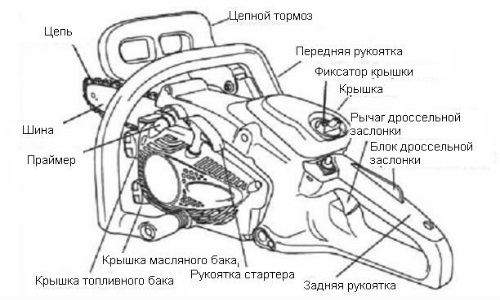

Chainsaw device diagram.

The difficulty is not the repair procedure itself, but the correct determination of the damage. One and the same failure can cause completely different flaws. Therefore, it is not worth rushing to disassemble the engine immediately or the carburetor before the signs of failure are investigated. The instruction manual for the operation and repair of the chainsaw can be of little use here, it will be necessary to connect your own mind more.

The existing failure options can be attributed to one of two categories: damage to the engine system with numerous groups and components in it (ignition, fuel supply, exhaust, cylinder-piston) and damage to other components (lubrication system, brake, tire, clutch, etc.). )

When the engine is faulty

Chainsaw electronic ignition circuit.

It often happens that chainsaws break the usual engine performance. It is the search and repair of damaged engine systems from users that take the lion’s share of the time. They can have manifestations such:

- cannot start;

- chainsaw stalls when it starts;

- job instability;

- normally runs at idle, but stalls at high speeds.

If you plan to repair the chainsaw yourself, it is advisable to use the exception method. consistently check the probable causes of damage. They begin to check those whose correction will take the least time.

Malfunctions in the ignition system

Absolute all the indicated types of engine malfunctions can be caused by malfunctions in the ignition system. If a chainsaw malfunctions, it is necessary to start looking for a malfunction with a candle. What is there and some other meaning: the condition of the candle will give a hint about the work of the fuel group as a whole. If you find any malfunction, you need to analyze the candle, having turned it out first. Why disconnect the wire and use a special key to unscrew it.

The principle of operation of the carburetor chainsaw.

The dryness of the candle indicates that the source of the problem is not connected with the ignition system, but with the absence of fuel liquid in the cylinder. The candle in this situation is screwed back and taken for the analysis of the fuel group.

With a significant contamination of the candles with fuel, they imply an excess of the latter. This phenomenon is associated with deregulation of the carburetor or with non-compliance with the start requirements. The candle in this situation is cleaned and dried, the cylinder is released by shutting off the fluid supply and using a starter to vent the combustion chamber and get rid of excess fluid. Then the candle is returned back and start again.

The presence of abundant dark soot also only confirms the presence of malfunctions in the fuel system.

Violations can occur in the proportions between gasoline and oil, in poor adjustment of the carburetor or in the addition of poor quality oil. They wash the candles with gasoline, remove carbon deposits by means of a needle or an awl, clean the electrodes with an emery cloth and put them back.

Also in relation to all situations, it makes sense to control the gap between the candle electrodes. According to her vintage, he is obliged to correspond to a value from the range of 0.5-0.65 mm. Checks require a sealing candle gasket. If it is worn or damaged, it will provide insufficient tightness for the combustion chamber. And this will cause a decrease in compression in the cylinder and problematic functioning of the engine.

Scheme of a two-stroke engine of a chainsaw.

Even when the control of the spark plug gives reason to believe that the damage is related to the fuel system, the spark plug is tested. At least to exclude suspicions that there are problems with this issue. Perform:

- putting on a spark plug cable;

- using insulated pliers, the candle nut or thread is pressed against the cylinder;

- wring out the starter handle and watch if a spark arises or not.

When the spark does not occur, the candle is changed. If there is no spark when replacing the spark plug, then the high-voltage state is analyzed for breakage and contact with the spark plug.

A failure of the spark may be caused by a malfunction of the ignition module or non-observance of the gap between it and the flywheel magnetic wire. The latter should be equal to 0.2 mm. In particular, violation of the gap becomes quite possible if on the eve the analysis of the saw and the removal of the flywheel with the ignition module were performed. Defective ignition module is replaced.

Having completed all the steps to check the ignition system and not finding deviations, proceed to the analysis of the fuel supply system.

Fuel supply system defective

If during the examination of the candles it was found that the liquid is not supplied to the cylinder, then the probable causes of this fact are clarified. They are:

- fuel is not supplied from the tank due to clogging of the cap opening (breather), and a vacuum appears inside the tank, which prevents the liquid from escaping;

- the fuel filter located in the tank is dirty;

- fuel fluid from the carburetor does not enter or enters in insufficient quantities into the cylinder.

Oil supply for chain lubrication.

In order to diagnose the first 2 reasons, remove the fuel hose from the carburetor and observe whether fuel is leaking or not. When it flows out with a full stream, the filter and breather do not look. If it flows weakly or does not flow at all, then it is believed that the source of damage has been found. The breather is cleaned with a needle.

Video: Chainsaw Stalls At High Speed

Through the hole in the gulf of the empty fuel tank, remove the fuel filter, coupled with a suction hose, using a wire hook. From the last filter is removed and cleaned or changed to fresh. Chainsaw manufacturers recommend changing the fuel filter after each trimester.

A weak flow of fluid into the cylinder from the carburetor or a lack of proportions between the fluid and the air is caused by several reasons:

- clogging the air filter;

- unregulated carburetor, clogging its channels or mesh filter.

Typically, the procedure for repairing chainsaws is accompanied by cleaning the air filter, since its pollution is very fast. When this happens, the air intake to the carburetor decreases, the fuel fluid at the outlet becomes too enriched, which leads to interruptions in the normal functioning of the engine.

Removing a dirty filter for cleaning is done with great care, so as not to shake off dirt in the carburetor. The filter is cleaned or washed with water and a cleaning agent, dried and returned to its place.

Centrifugal clutch of a chainsaw: 1. friction linings, 2. springs, 3. drum.

Adjusting the carburetor eliminates its deregulation. As usual, this is carried out by means of 3 screws. maximum and minimum turns, idle speed. Adjustment is carried out strictly following the descriptions in the instructions. The engine otherwise just breaks down. Other manufacturers of chainsaws provide a single idle screw in order to eliminate unnecessary interference in the performance of the carburetor inexperienced users.

When the carburetor adjustment is ineffective, clean the channels with a filter grid and immediately check the integrity of the membrane. At a chainsaw, the carburetor is considered a moody device, so it should be disassembled and cleaned, understanding the full responsibility of the operation.

The peculiarity of working with it lies in the fact that many small elements of its components have the ability to quietly jump off their places and get lost forever. Having disassembled such a naughty mechanism once without hesitation, you can not assemble it back in the same form.

If there is little or no experience in repairing a carburetor, then it is better not to take it on your own, but entrust this important event to a specialist from the service center. Cleaning the carburetor there is sometimes done by means of ultrasound.

The muffler is out of order

Chainsaw fuel system: 1. fuel filter, 2. carburetor, 3. manual pre-pump.

Often the cause of engine failure, especially when the engine is functioning fine at low revs, and when it is large, gets hot and the chainsaw stalls, is caused by the burning of spark arrester products in the muffler, creating obstacles to a full exhaust.

Repair in such a situation comes down to removing the muffler, disassembling it and wet cleaning carbon deposits with the participation of detergents. After washing a non-separable muffler, it is dried with a hairdryer. Since soot consists of carcinogenic particles, it is unacceptable to carry out dry cleansing, because toxins will enter the respiratory system of the master. After removing the muffler, the outlet opening is plugged with a cloth.

The reason for clogging is the one that uses fuel oil with an excessive amount of oil (more than recommended by the manufacturer), base oil or not suitable for 2-stroke engines.

Damage to the cylinder piston group

Damage to the cylinder-piston group (CPG) is considered more thorough. These include: cylinder and piston wear, scratches on their walls, wear or retraction of the piston rings in the grooves, worn crankshaft bearings. Many of these problems cause a decrease in pressure in the cylinder and the inability to start the engine or to work at full efficiency when the chainsaw heats up and stalls.

Air purification system: 1. the cover closing the fine filter, 2. the fine filter, 3. the cover closing the coarse filter, 4. coarse filter.

The status of CPG is evaluated in one of several ways.

- Removing the muffler allows you to view part of the end surface of the cylinder in the opening opening. Although the foreseeable area is small, it still can shed light on the state of the CPG.

- Compression is measured, which is very informative regarding the state of CPG elements. The procedure is carried out by means of a compressor placed in the hole of the candle.

- Using a drill, use a manual starter or flexible shaft to crank the crankshaft, looking directly at the pressure gauge. For a saw with normal performance, it should be at least 8-9 atm (or 0.8-0.9 MPa). Lowering, it leads to a decrease in engine performance. A pressure of 5 atm still presupposes the operation of the engine, but already at idle.

The accuracy of assessing the condition of the CPG is possible only with a complete analysis of the engine: unlocking from the crankcase cylinder and removing the piston. If it is found on the last scoring, chips or deep scratches, it is replaced. As for the cylinder, in case of damage to the surface or its development, it is bored to the repair size. Slight compression may be caused by wear or coking of the piston ring. The serviceable ring does not contain carbon deposits, it freely holds in the piston groove, adjoining the cylinder surface from the inside quite tightly.

Circuit Lubrication Malfunctions

Without exception, all chainsaw repair manuals contain references to damage to the chain lubrication system, which are quite common. It:

- missing or missing lubricant supply;

- oil leakage.

Coarse air cleaning system: 1. snow filter, 2. strainer.

When the chains are dry, they inspect and clean the channels supplying oil to the tire. Clogging them is not uncommon.

In case of significant (in small quantities, it is considered normal) oil leaks, the connection of the pipes to the pump fitting for leak tightness, which may fall or crack, is examined. Changing the integrity of the oil line (drips do not take into account) may cause insufficient lubrication of the chain. Air draws in the pump, which reduces its performance. Tightness problems are corrected by changing the tubes or by sealing them.

A significant problem of the lubricant group are cracks on the body of the oil pump. Then they change it.

Chain brake failure

This malfunction is caused by contamination of the space under the cover and the brake bands by grease or sawdust. In the first situation, they clean the space under the cover, in the second. they replace the brake band.

Replace parts with a short life

Chainsaw starter device: 1. drum, 2. cable, 3. handle, 4. frame.

Individual elements of chainsaws that wear naturally after the declared period of operation are to be replaced. Violation of their functions does not apply to damage. Elements with a short amortization period are the chain, the main sprocket, the tire, the components of the anti-vibration group, etc.

If you do not replace elements that have developed their expiration date in a timely manner, their increased wear will adversely affect other parts of the chainsaws. For example, untimely replacement of the tire and the main sprocket will lead to increased vibration, which, in turn, will harm the crankshaft bearings.

The sprocket has a depth limit of 0.5 mm for the production of teeth. In fact, they often allow wear and tear to a depth of 1 mm, without thinking that this will lead to an excessive load for the crankshaft bearings and an instant failure of the latter. The operation of 3-4 circuits should be the reason for changing the tire itself, because by this moment its deterioration exceeds the permissible values.

Especially severe is the wear of chainsaw tires in the part, cutting through which is carried out more often than others. In most cases, it is the bottom of the guide rail. For simultaneous wear of parts, changing the chain, the tire is rotated 180º according to the horizontal axis.

Oil pump adjustment: 1. adjusting screw.

When installing a new chain, install a new main sprocket. Since the period of operation of the sprocket exceeds this parameter for the circuit itself, then 1 sprocket is used for the sequential operation of 2 interchangeable circuits. So the sprocket and chain work out their term almost at the same time.

When a new chain is installed on an asterisk that is no longer suitable for operation, then the wear of the leading links of the chain occurs much faster. For the economical operation of chainsaws, you should always combine the consumption of one guide bar with two chain sprockets and with four saw chains.

If the chainsaw stalls when heated, you should immediately look for the cause of the malfunction.

But take this matter seriously. If there is not enough experience in the field of knowledge of the device of chainsaws, it is better to ask a professional to do this. Have a good repair!