Arguments against

- Lithium battery cells cannot be charged above 4.2 volts and discharged below 2.7 volts. In real conditions, this interval is even narrower. If you go beyond these limits, the battery can be damaged. Therefore, in addition to the most lithium cans, you will need to connect and install a charge-discharge controller in the Screwdriver;

- The voltage of one Li─Ion cell is 3.6─3.7 volts, and for Ni─Cd and Ni─MH this value is 1.2 volts. That is, there are problems with assembling a battery for screwdrivers with a voltage rating of 12 volts. From three lithium cans connected in series, you can assemble a battery with a nominal value of 11.1 volts. Out of four ─ 14.8, out of five ─ 18.5 volts, and so on. Naturally, the voltage limits during charge-discharge will also be different. That is, there may be problems with the compatibility of the converted battery with the Screwdriver;

- In most cases, 18650 standard cans are used in the role of lithium cells for conversion. They differ in size from Ni─Cd and Ni─MH cans. In addition, you will need space for the charge-discharge controller and wires. All this will need to fit into a standard battery case. Otherwise, it will be extremely inconvenient for them to work;

- A cadmium battery charger may NOT be suitable for recharging a battery after a redesign. You may need to revise the charger or use universal chargers;

- Lithium batteries lose their performance at low temperatures. This is critical for those who use the Screwdriver outdoors;

- The price of lithium batteries is higher than cadmium.

Arguments behind

Let’s start with the benefits:

- The energy density of lithium-ion cells is much higher than that of nickel-cadmium, which are used by default in a screwdriver. That is, the battery on lithium cans will have less weight than on cadmium ones with the same capacity and output voltage;

- Lithium battery cells are charged significantly faster than Ni-Cd. It will take about an hour to charge them safely;

- No lithium ion batteries memory effect. This means that they do not have to be fully discharged before charging.

Now the disadvantages and complexities of lithium batteries.

What you need to estimate before starting work?

Also, more lithium cells will give more capacity. This means longer operating time of the Screwdriver.

Lithium battery cells 18650

The nominal voltage of lithium cells is 3.6-3.7 volts, and the capacity in most cases is 2000-3000 mAh. If the battery case allows, you can take not 4, but 8 parts. Connect them two by two into 4 parallel assemblies, and then connect them in series. As a result, you will be able to increase the battery capacity. But not every case will be able to pack 8 cans of 18650.

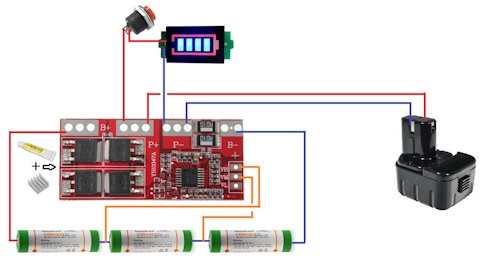

And the last preparatory stage. This is the controller’s choice. According to its characteristics, it should correspond to the rated voltage and discharge current. That is, if you decide to assemble a 14.4 volt battery, then choose a controller with this voltage. The working discharge current is usually chosen half of the maximum permissible current.

Charge-Discharge Controller Board

All pros and cons of redesigning a battery Screwdriver for lithium cells

First you need to think about whether I need this alteration? After all, it will be frank samopal and in some cases can lead to failure of both the battery and the Screwdriver itself. Therefore, let’s consider all the pros and cons of this procedure. It is possible that after that some of you will decide to abandon the conversion of the Ni─Cd battery for the Lithium Screwdriver.

Conversion of the battery Screwdriver for lithium cells

Many screwdriver owners want to convert their batteries to lithium battery cells. Many articles have been written on this topic and in this material I would like to summarize information on this issue. First of all, we will consider the arguments in favor of converting the Screwdriver to lithium batteries and against it. And also consider some moments of the process of replacing batteries.

Replacing batteries in a screwdriver with lithium

Converting a Li-ion screwdriver for home

How to convert a battery from a screwdriver from nickel-cadmium to lithium batteries at home.

I got myself two used screwdrivers. One had a battery, the other had a battery, just the wires were brought out. I cleaned it and decided to complete it with normal batteries. I will convert to lithium-ion.

High-current elements are needed here, they will not work from a laptop. I have used elements, with a residual capacity of a little more than 1 ampere / hour.

Battery conversion process

We disassemble the old battery and remove some of the batteries, leaving only two with a contact group.

Soldering wires to the positive and negative terminals. I rolled directly to the poles, since the contact plates were NOT tinned.

Batteries 18650 We connect in parallel and to them by soldering old elements with a contact group.

So that the contacts with the elements do not fall through, I made resistance from a wooden bar.

Now you need to install a connector for charging each element, a balancing connector. I used the connectors from the motherboard and the computer’s power supply.

We solder everything in order. Plus with the first contact. The second contact to the plus of the second element and so on.

Cut a hole for the connector, and fix the connector with epoxy glue. The glue is dry and we close the battery. Putting aside.

Since I will be charging the battery with a smart charger, I need to do the wiring for it. One part from the power supply, the second from the flopik. We modify the connector from the flopik, cutting off all the guides and keys. After deleting all the keys, it fits my Turnigy fine, it fits Imax too.

We set the charger to charge with balance (3S). After the end of the charge cycle, we use it. I am working on the second battery using this technology, and everything works fine. The first screwdriver with a converted battery proved to be excellent.

In the native charger.

At idle, the charger gives us 19-20V and a short-circuit current. Didn’t measure it. The manufacturer claims the operating current is 1.8A.

Diagram of SD-C804S memory found on the Internet.

The scheme has, in my opinion, a number of incorrect designations, but not the essence. The circuit has nodes that would monitor and limit the charge current. But there is a circuit for monitoring the execution voltage on the U1 microcircuit (not a fact, it did not work to confirm the operability of this node), as well as a charge time limiting node performed on the U2 microcircuit.

What is stopping us: the charging time limiting circuit interferes with us, but you can simply turn it off, otherwise everything seems to be fine. But, I could not get the charger to show the end of the charge. I switched on the native battery to charge, the charge indicator turned on, but breaking the circuit on the battery, i.e. We received the supply voltage at the output, the indicator did not go out, and it should have been, if the end of the charge is regulated by the voltage on the batteries (I am not a specialist in electronics and the concepts of how it completely works, I can’t). And for us this is a critical moment because K. The protection board of our injection molded batteries simply breaks the circuit at the end of the charge.

There were many thoughts on how to do exercises. Here are the modernizations of the current circuit, with automatic selection of which battery is inserted, old or new on simple elements, to goats everything on Arduino with control of everything and everyone. But all this takes a lot of time and effort. It was decided NOT to reinvent the wheel and go like everyone else.

As a charge control, a DC-DC converter with charge current control on the XL4015 chip was chosen read

Foreword

You can use 6 pcs. 18650, which will double our battery capacity, but will require a higher charge current, which will require abandoning the original power supply without alterations, and our charging will last oooooooooo long.

I want to draw your attention and this is very important, the batteries in the photo are not suitable for our task, this is my jamb, I did not think I bought it. Use only high amperage batteries. But Comrade K. I didn’t have options, I did on them.

Why do we need high amperage batteries. Lithium batteries are designed to be used under certain conditions of discharge charge, so that in the photo they are allowed to be cut with currents of 2C, i.e. In this case, it is about 6 A. The screwdriver at the moment of start consumes a current from 15A to 25A and at a constant load of about 10A. As we can see, we have exceeded the manufacturer’s requirements. High-amperage batteries are designed for higher discharge currents from 10A, which guarantees us a longer service life, as well as fewer surprises in the future from improper use. Read in such batteries: read

Board with protection and balancing. It will allow us to operate lithium batteries within the limits recommended by the manufacturers. It will protect our batteries from deep discharge, as well as from overcharge, which is very critical for lithium batteries and violation of this point will lead to very rapid degradation of the battery, i.e. Loss of its capacity. Also, this board has a balancing circuit, which is designed to equalize the charge on each battery cell. Our batteries have a serial connection, which during operation will lead to their uneven charge read, which will lead to see paragraph 1, but this board will eliminate this effect. The presented board, upgraded at the request of workers and self-healing when the protection is triggered.

You can use a ready-made battery with an existing charger, but:

- – there are complaints that the case will be very hot, which many fear. But the design of the charger uses a transformer and heating is normal for it. In my experiments at a current of 1A, he warmed up to 60C. The design does not provide for a current limiting system so that the current in the system can be several times higher and the heating is higher. At the same time, now we need more time to charge the batteries.

- – in the design of the charger there is a system for limiting the charging time and it is one time. THOSE. We will have to juggle the battery to fully charge it.

- – It will be hard to use the native charger if we decide to use 6 parts of the 18650 because The maximum current provided by the manufacturer’s statement must be 1.8A. THOSE. Prolonged use at currents above this value may lead to unknown consequences. For 3 parts with a capacity of 3000mAh and a recommended charge current of 0.5C.1C (1.5A. 3A), we fit into the charger’s parameters. For 6 cells, we need a charge current twice as much. And yes, as I said before, the charger has charge current limiting circuits i.e. In a certain period of time, we will charge our batteries at the aisles of the charger’s capabilities, which is tolerable for 3x, but not for 6 cells.

In principle, these are the main nuances of using a native charger.

For rework according to my version, we need:

- – screwdriver Interskol Da-12ER-02)))

- – soldering iron from 60W because Less powerful you DO NOT solder

- – multimeter (tester)

- – Soldering acid. There are many variations of them, we take with a brush

Assembly:

We use the batteries with already welded ponytails. First of all, we remove the protection from the Khvostikov, then we need to ERASE the ends. RUNNING without using acid (carefully) you will not get it so that we take acid, a soldering iron and solder and tin. We trick from both ends. Apply the acid in a thin layer, this is quite enough, otherwise you will get splashes in different directions.

If you bought acid without a brush, then you can pour it into a tube of nail polish, or you can use a disposable syringe, where you squeeze out a drop and immediately pull it back in, leaving a thin film. We also need to RUN the advantages of the first two batteries, in these places we will connect the batteries to each other.

After you have all tinned, we solder the batteries in series, see Fig. On one of the batteries, the tab is turned in the opposite direction. We also make soldering with a powerful soldering iron, simply by attaching a tongue and pressing it with a soldering iron tip. This is what we should get.

Now we fix everything with electrical tape or it can be done in advance before soldering. Glue double-sided tape to fix the board.

Let’s start soldering the batteries to the board.

We disassemble the native battery. We take out the old batteries (Caution).

We bite off the black piece and solder it. We need thick wires because We will have current for 25A periods or more, which with thin wires can lead to their ignition, and we will also have a loss in power. Put the batteries aside carefully.

Now we need to find a thick, wide soft pad 1.5-2 cm. I tore it from the packaging of a certain gadget. Cut to the size of the case and put it on the bottom, glue the double-sided tape and glue the batteries. We fix that black thing, the protruding end should be of such length that it rested against our batteries and allowed the case to be closed with a certain tension. DO NOT reverse polarity!

In this case, the brown wire is minus, and the black wire is plus. Brown is an order of magnitude thicker than black.

Cutting the wires, making them as short as possible, so as NOT to lose current at losses, but we must take into account that we still need to be soldered to the board. We solder and assemble the case, the battery is ready.

Battery:

- Lithium 18650 batteries, for example, we take batteries with tails. We need high current batteries.

- Balance protection board 3S 40A 12.6V 40A lithium battery protection board

- The wires are short, but thick with a cross section of 1.5

- Double-sided tape

- Thick wide Relatively soft pad 1.5-2 cm

Disassembling the battery case

The body is often assembled on self-tapping screws, other options. With snaps or glue. The glued block is the most difficult to disassemble, you have to use a special hammer with a plastic head so as not to damage the parts of the case. Everything is removed from the inside. Only the contact plates or the entire terminal assembly can be reapplied for connection to the tool, charger.

Battery selection

12 V batteries are often used for screwdrivers. Factors to consider when choosing a Li-Ion battery for a screwdriver:

- In such instruments, elements with high values of the discharge current are used;

- In many cases, the cell capacity is inversely related to the discharge current, so it cannot be selected based on capacity alone. The main indicator is the current. The value of the operating current of the screwdriver can be found in the tool passport. Usually it is from 15 to 30-40 A;

- It is not recommended to use cells with different capacities when replacing a screwdriver battery with a Li-Ion 18650;

- Sometimes there are tips to use a lithium battery from an old laptop. This is absolutely unacceptable. They are designed for much lower discharge currents and have inappropriate technical characteristics;

- The number of elements is calculated based on the approximate ratio. 1 Li-Ion to 3 Ni-Cd. For a 12-volt battery, you will need to replace 10 old cans and supply 3 new ones. The voltage level will be slightly reduced, but if 4 cells are installed, the overvoltage will shorten the life of the motor.

Important! Before assembly, it is necessary to fully charge all elements to equalize.

Battery assembly

Further battery replacement consists of the following steps:

- The disassembled parts of the case are well cleaned;

- Since the dimensions of the new battery cells will be smaller, they must be securely fixed: glue to the inner wall of the case with glue Moment or a sealant;

- The positive and negative wires are soldered to the old terminal blocks, it is placed in the same place in the case and fixed. The protective board is laid, the parts of the battery pack are connected. If they were previously glued, then they are used again Moment.

The advantages of lithium-ion batteries

Nickel-cadmium batteries have a low price, withstand many charging cycles, and are not afraid of low temperatures. But the capacity of the battery will decrease if you put it on charge, and not wait until it is completely discharged (memory effect).

Lithium-ion batteries have the following benefits:

- High capacity, which will provide longer operating time of the screwdriver;

- Smaller size and weight;

- Keeps charge well when idle.

But a lithium battery for a screwdriver does not withstand a full discharge, therefore, factory tools on such batteries are equipped with additional boards that protect the battery from overheating, short-circuit, overcharge in order to avoid an explosion, full discharge. When the microcircuit is inserted directly into the battery, the circuit is opened if the unused battery is separated from the tool.

Conversion of a screwdriver to lithium batteries 18650

The industry has been making screwdrivers for a long time, and many people have older models with nickel-cadmium and nickel-metal hydride batteries. Converting a screwdriver to a cast one will improve the performance of the device, rather than buying a new tool. Now many companies offer services for altering screwdriver batteries, but you can do it yourself.

Converting a screwdriver to lithium batteries

Battery cell connection

The connection of Li-Ion batteries for the screwdriver is performed in several ways:

- Application of Special Cassettes. The method is fast, but the contacts have a large transition resistance, they can quickly collapse from relatively high currents;

- Soldering. The method is suitable for those who know how to solder, since you need to have certain skills. Soldering should be done at an accelerated rate, because the solder cools down quickly, and prolonged heating can damage the battery;

- Spot welding. This is the preferred method. But not everyone has a welding machine, such services can be provided by specialists.

Soldering elements

Important! The cells must be connected in series, then the battery voltage is added up, and the capacity does not change.

At the second stage, wires are soldered to the contacts of the assembled battery and to the protective board according to the connection diagram. To the contacts of the battery itself for power circuits, wires with a cross-sectional area of 1.5 mm are soldered². For the second circuits, you can take thinner wires. 0.75 mm²;

Then a piece of heat shrink tubing is put on the battery, but this is not necessary. You can also put on heat shrinkage on the protective microcircuit to isolate it from contact with the batteries, otherwise sharp soldering projections can damage the cell shell and provoke a short circuit.

Disassembly

Before you disassemble the case of the old battery compartment with your own hands, you should pay attention to the fact that it can be made using the following technologies:

- The individual parts are fastened together with small screws such as self-tapping screw;

- These elements are fixed on the base of a screwdriver using technical glue or special latches (the photo below shows the appearance of such a block).

To disassemble the glued block located on a screwdriver, it is most convenient to use a mallet with a plastic head, which excludes possible damage to the device case. Before dismantling, all unnecessary parts of the structure should be removed from the compartment, leaving only the contact plates (their assembly) necessary for connection to the tool itself and an external charger.

Modification of the compartment

Problem places

To realize the above advantages, it will be necessary to solve a number of issues that arise when converting a screwdriver battery to li-ion, namely:

- Working dimensions of a new product determined from its designation (diameter 18 mm, length 65 mm) do not coincide with the dimensions of the replaced parts

- A full replacement of the batteries is possible only if the battery compartment is modified to accommodate the controller board and the wiring harness;

- When reworking, the voltage difference of each of the elements of the prefabricated source, consisting of several batteries (1.2 Volts in nickel-cadmium versus 3.7 Volts in LI Ion).

Important! Given this circumstance, it is necessary to try in advance to adjust the Total voltage of several new elements to its old value (in the figure below, Nickel-cadmium batteries are shown).

In SEPARATE cases, it is NOT possible to achieve the coincidence of the supply voltages at all, which makes it necessary to abandon alteration or look for other products that are suitable for this parameter. At the same time, it is important to observe the measure and calculate the economic feasibility of switching to a li ion 18650 (otherwise, the upgrade may be more expensive than the tool itself).

Connecting elements by soldering

When using this method, it should be remembered that the elements converted for new operating conditions are connected in series, as a result of which their voltages are added, and the total capacity does not change. In the process of soldering, it is recommended to use low-melting solder and low-temperature flux, since any overheating of the contacts of the 18650 cells can lead to their destruction.

Important! In the process of soldering batteries in the compartment, which is equipped with a screwdriver or drill, it is advisable to use a soldering iron with a capacity of up to 40 watts. This precaution will keep the lithium battery safe and sound.

After completing the connection of the elements in a serial chain, it will be necessary to solder the wires going to the board with the control circuit (controller) to the positive and negative terminals of the assembly. Particular attention is paid to the cross-section of the conductors used, which does not have to be less than 1.5 mm. With this size, they will NOT heat up during prolonged use or charging.

When carrying out this operation, it is advisable to use special insulating tubes that have heat shrink properties. Through THESE insulating products, it is possible to reliably protect the soldering points from unwanted short circuits and oxidation (see photo below).

Conversion of a screwdriver to lithium batteries 18650

The domestic industry has long been producing samples of reliable and inexpensive screwdrivers, most of which are equipped with outdated types of built-in batteries. Self-alteration of a screwdriver to a cast one allows its owner to extend the life of this product and even slightly improve its performance. A modern li ion battery for a screwdriver looks like it is shown in the figure below.

Despite the fact that a large number of companies at a relatively modest price can convert a screwdriver to a new battery, it is more convenient to do it on their own.

LI Ion advantages and disadvantages

First of all, we note that the old nickel-cadmium batteries are quite reliable, inexpensive and can work in low temperatures, withstanding a large number of charge-discharge cycles. However, they have one bad property, which consists in a gradual loss of capacity, if you put them on charge without waiting for a full discharge (the so-called memory effect).

The need for reworking a screwdriver for lithium 18650 batteries is explained by a number of advantages of the latter, the main of which are:

- Large capacity to extend the life of the device;

- Significantly smaller than other batteries in size and weight (photo below)

- Ability good keep charge while NOT under load;

- No memory effect of old batteries.

However, even in the new lithium batteries, there is a disadvantage that the parameters deteriorate when they are completely discharged. At voltages more than 4.2 and less than 2.7 Volts, they feel myself is not very comfortable. That is why, even during production, these products are equipped with built-in controllers that protect them from short-circuit, overvoltage and deep discharge.

Note! The built-in electronic regulator automatically turns them off when the supply circuit is opened, or when the screwdriver battery is outside the compartment of the working tool.

Another disadvantage of converting a screwdriver battery to a cast one is the inability of new batteries to function at low temperatures. However, all these disadvantages are more than overlap with the advantages already discussed earlier.