How to lubricate the gearbox of grass trimmer or brushcutter: proper maintenance of garden tools | (Photo Video)

The shafts of chain saws (gasoline trimmers) rotate in plain bearings, pressed into the boom. Lubricant applied to the shaft penetrates the friction points of the shaft with the bearings, thereby reducing friction forces, slowing component wear and increasing the life of the brushcutter. And as a bonus: reduced vibration and noise, a slight increase in power tool.

Grass trimmer gearbox design

Grass trimmer gearbox is a unit that transmits the rotary motion of the motor shaft to the blade or fishing line. It is located at the lower end of the brushcutter bar. Gearbox is also designed to reduce engine speed grass trimmer.

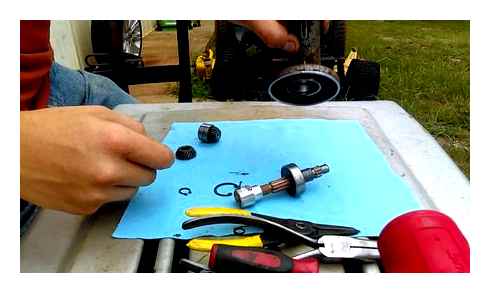

The mechanism consists, depending on the brushcutter model, of several gears rotating at high speed. As a result, they become hot due to the high friction. If there is little or no lubricant, it will overheat and damage parts and lead to complicated repairs. To avoid this, it is important to lubricate the gearbox on time. The disassembled gearbox is shown in the photo below.

Gearboxes of modern trimmer models from different manufacturers differ from each other by design and seating size. It happens:

The most common diameters for round seats are 24, 25.5 and 26 mm.

Mowers are equipped with gearboxes with different types of gears:

- beveled;

- It is located at the lower end of the brushcutter bar;. worm;

- spiroids;

- cylindrical;

- planetary;

- wave-shaped;

- combined.

The drive shaft and gearbox are highly stressed parts of the grass trimmer and are subject to considerable wear and tear. Between them the motion is transmitted because of the meshing of the gear teeth arranged at different angles to each other. Gears work efficiently only if there is no mechanical damage. The mechanism must not overheat, otherwise it can be jammed.

Gearbox design grass trimmer

Grass trimmer gearbox is a unit that transmits the rotary motion of the motor shaft to the blade or fishing line. It is located on the lower end of the brushcutter bar. Transmission unit is also designed to reduce the engine speed trimmer for grass.

The mechanism consists, depending on the brushcutter model, of several gears rotating at high speed. This causes them to heat up due to the high friction. If the lubricant is not enough, or there is none at all, the process leads to severe overheating and failure of parts, and, accordingly, the need for complex repairs. To avoid this, it is important to lubricate the transmission unit in good time. The disassembled gearbox is shown in the photo below.

Gearboxes of modern trimmers of different models from different manufacturers differ from each other by design and the size of the seating. It happens:

The most common diameters for the round seats are 24, 25.5 and 26 mm.

Mowers are equipped with gearboxes with different types of gears:

- tapered;

- worm gears;

- spiroids;

- cylindrical;

- planetary;

- wave;

- combined.

The drive shaft and gearbox are highly stressed parts of the grass trimmer that are highly susceptible to wear and tear. Movement is transmitted between the gears due to the binding of the teeth at different angles to one another. Toothed gears only work efficiently if there is no mechanical damage. The mechanism must not overheat, otherwise it could seize.

Damage prevention

To avoid breakdowns and subsequent expensive repairs, it is recommended to follow a number of simple rules on grass trimmer operation and gearbox maintenance.

- Lubricate this garden tool immediately after purchase. before starting operation. Usually or Huter) applies only small quantities of lubricant, which is sufficient only for the running-in period.

- At the end of the season or before long-term storage of the grass trimmer should disassemble the gearbox, check the condition of the bearings and gears, lubricate the unit.

- It is required to add grease after the tool will work from twenty to forty hours. This time is reduced to twenty hours if you use the machine intensively.

- New grease should be changed when repairing a structure or before the start of the season.

- When a gearbox overheats or makes a loud noise, check for grease. If there is sufficient grease, it is recommended that you completely replace it with new grease.

You can repair and lubricate the gearbox of a brushcutter at home. Adding lubricant is not difficult, a detailed description of this process and recommendations on the selection of an appropriate substance can be found in the instruction manual for the tool or on the video, of which there are many on the Internet. Most gearbox failures are typical for trimmers of different brands, it is quite easy to eliminate them if you know the correct procedure. And to avoid their appearance, it is enough to observe simple rules of operation and conduct timely maintenance of the grass trimmer gearbox.

Possible problems with the grass trimmer gearbox, lawn mower gearbox, brushcutter gearbox

Block: 2/4 | Number of characters: 2644

Signs of common faults

Knowing the internal structure of the lawnmower and the principle of its operation, you can easily troubleshoot your own hands. Some breakdowns are most common and they are highlighted as the main.

- If the lawnmower does not run or even starts, look for engine malfunctions. It is also worth paying attention to this part of the lawnmower, if you hear unusual noises or feel a strong vibration during operation. Engine problems can also be caused by a clogged air filter.

- If the fuel does not flow into the combustion chamber, look for a clogged fuel filter. It is also worth looking at it, if the tool does not work at low speed.

- The starter grid is clogged. the cause of overheating of the engine and its cessation of work. The starter can also fail when the cord rips when starting too hard.

Malfunction. Knife or spool does not turn.

The reason. Wear and tear of transmission components.

The transmission of these chainsaws consists of the bottom gearbox, the shaft and the top gearbox (cup). Let’s take a closer look at them.

The gearbox consists of a housing and gear train, which are subject to wear.

This is caused by the lack of lubrication in the gearbox.

Do not neglect this procedure when using the lawnmower.

Lubrication control will prolong the life of the gearbox.

On sale there are sets of gears for these reducers, but their cost exceeds 60-70% of the cost of the reducer, moreover, the process of replacing them is labor-intensive, a simple solution would be. to replace the gearbox for a new.

A stiff shaft with splines at the end of the shaft transmits power from the engine to the gearbox. Because of the lack of lubrication in the gearbox the splines can wear out. Only replacement of the shaft with a new one will help in this situation. Note that there are 3 types of shafts (7 spline, 9 spline and “square”). The length of the shaft, as a rule, on these models is 152mm. Replacement is very simple. remove the old shaft. install the new one.

In the upper gearbox is installed clutch cup, which has splines for the shaft.

If they are worn, it will be necessary to replace it.

The cup can be replaced as a separate item, or the upper gearbox as a whole.

To remove the cup, you must remove the retaining ring (n.49), catching its “ears” in the cup holes (n.48).

Note that there are also shaft options on the cup (7 splines, 9 splines and “square”)

Gasoline grass trimmer clutch

The blade or spool rotates at idle (assuming “correct carburetor settings)

If this malfunction, you will need to replace the clutch spring, or the clutch assembly.

To replace the clutch it is necessary to unscrew the upper gearbox of the transmission. Then unscrew the spark plug and stop the piston movement with a special stopper. Unscrew the 2 screws securing the clutch (p.57) with washers (n.56), remove the clutch assembly and washers under it (n.53). Change the spring on the clutch or install a new one. Don’t forget to install the washers (nr.53) then the clutch, and tighten the bolts (p.57) with engraved special washers (n.56).

Block: 3/6 | Number of characters: 2231

Repair TOP DRUCK / repair cone metal ringing, clanking, no rotation

What is the upper gearbox. This is a centrifugal coupling. But such a name as “top gear” or “cone” has caught on in the masses of people much more. In this video I have tried to highlight the main aspects and problems of this unit. I think everyone can do the same thing with his or her chain saw. DIRTY DISCUSSION AND VIBRATION when the lawnmower is running

How to disassemble the grass trimmer gearbox video

Everything at hand. Easily and quickly disassemble the lower reducer with your own hands. You do not need a puller. To disassemble the gearbox everything at hand. We only need a washer from an angle grinder, a nut and a washer of the grass trimmer bottom gearbox. Naturally a new gearset for your brushcutter. You can buy a new gearbox at a garden tool spares store. In this video, I show you how to quickly disassemble and assemble the gearbox with their own hands. First we disassemble and assemble the lower part, then the upper part of the reducer. Repair with their own hands is three times cheaper than buying a new gearbox. Have a nice day. Do not forget to subscribe. Who wants to help in the development of the channel will be very grateful Cart number: 5168752011697912

Device

The three-dimensional reducer includes 2 shafts. The first is driven by the engine, and the second is used to rotate the cutting blade of the hedge trimmer or the line of the electric grass trimmer. Bevel gears are made as an assembly with a shaft, but there are options for installing a separate part on a key. Models are available with different tooth angles, depending on the position of the tool. Gearbox versions available with worm, planetary or mixed (multistage) gears.

The gearbox can be damaged by intensive use. Most failures of this unit are typical for different trimmer brands and are fixed in the same way.

- Severe heating of transmission unit. Two causes. new gears not lapped, or poor quality, inadequate or no grease. If lubricant is the problem, it should be replaced with another. And new gears must run in for a short time without heavy loads and with breaks so that the parts have time to cool down.

- Shaft becomes jammed in motion, knocking and play appear. Such signs report bearing wear. It is necessary to disassemble the gearbox and install a new part. Bearing destruction is caused by poor lubrication or lack of it, as well as increased load on the grass trimmer or the ingress of metal objects into its seating, which occurs due to a damaged dust cover. To remove and install a new bearing, you need a special puller or a hammer with a wooden bar. Be careful not to damage the seat. Preheating of it is allowed only in the most complicated cases.

- The gearbox is loose or comes off the boom while mowing. This means the housing is damaged and a new part must be fitted. If the defects are minor, you can use a metal clamp to tighten the broken point.

- If the gear does not hold on the boom, it means that the mating location is worn. You need to replace the rod with a new one, or wind up the mount with duct tape, if it is partially damaged.

- The knife on the shaft doesn’t rotate or stops rotating with an increasing load. One of the gears or teeth are worn as the cause. It is necessary to replace worn parts with new ones.

Most malfunctions of the grass trimmer can be repaired by the owner of the grass trimmer himself. All you need to have the right tools and spare parts (it is advisable to use original spare parts for your particular brushcutter model), as well as knowledge of how to disassemble the gearbox to change a damaged element for a new one.

Basic errors and solutions

To lubricate the gear mechanism of the reducer, there is no need to disassemble the assembly. a special hole is provided for this purpose in the upper part of the housing. In addition to the gears, it is necessary to carefully lubricate elements such as the bearing assembly. Wear of its sealed walls causes the lubricant to escape from the seating and causes the equipment to vibrate. This is a problem with Chinese trimmers. The solution is to replace the original bearings with quality parts. Also the handwheel must be lubricated because during operation the part is covered with grass fragments that create additional resistance when mowing.

Important! also the starter coil latch has to be greased because it makes contact with the handwheel grooves when starting. This leads to wear and tear as well as to mechanical and chemical corrosion due to the fact that the parts are made of different materials (handwheel is aluminium, catch is steel).

solid lubricant or oil is placed inside the unit through a hole protected by a screw. The following steps are performed

- clean all dirt from the gear housing, especially near the choke, to prevent dirt from getting into the unit;

- The brushcutter is delivered with a special tool that is used to remove the oil plug;

Tip! If the gearbox has to be disassembled, the old grease should be removed from the housing, shaft and gear surfaces and then the new grease should be applied. In disassembled form it is very convenient to lubricate the parts with solid substances.

Lubrication of the gearbox is mandatory yearly, and in case of intensive use, this procedure should be performed every 20 hours of operation of the tool. If there are any signs of failure, it is necessary to treat the lubrication points with the composition as soon as possible.

How to choose the right grease

During operation, the nodes of the mechanism are loaded by contact forces on the teeth, the resistance reactions when debris enters, as well as dynamic and shock loads. Depending on the characteristics of the load, you should choose what to lubricate the trimmer gear for grass.

When selecting, the following factors should be taken into account:

- manufacturer’s brand;

- Viscosity of the lubricant (this parameter depends on the torque of the shaft);

- adhesion to the surface of the parts of the assembly;

- intensity of grease consumption (ambient temperature, type and volume of work must be taken into account).

If you do not have the necessary lubricant, you can use a general-purpose. The latter must contain some components:

- Antiwear additives (without toxic lead);

- mineral oils with a high degree of purity (inorganic);

- Solid lubricants with graphite or molybdenum disulfide.

How to lubricate the grass trimmer gearbox

Almost every brushcutter reducer is equipped with a small technological hole, which is plugged with a special bolt in operation. After thoroughly cleaning the node from grass and debris, it is necessary to unscrew the screw and introduce 1.5 to 3 ml of grease into the gearbox cavity, depending on the tool brand. You can use a traditional medicine syringe for easy dosing. Do not allow foreign particles and objects to get into the gearbox during the operation, as this can lead to intensive wear of the gearing as well as to its jamming.

Specialists recommend to disassemble the reducer, wash gears and bearings and relubricate the unit after the mowing season is over and the tool is out of operation for a long time.

Varieties of lubricating compositions

For the care of the mechanism nodes are used greases of different consistencies:

- Semi-fluid. Such formulas contain various additives and admixtures.

- Plastic. Are the most universal option. Most often used for gear and screw drives.

- Solid. Plate suspension in the original state.

Special gear-type compositions refer to the semi-liquid system.

Popular is the lubricant for the grass trimmer “STIHL”. Due to the special composition and components, wear and corrosion resistance are considerably reduced. The main properties of this brand of grease are:

STIHL lubricant is suitable for brushcutters and trimmers and all transmissions with closed housing.

Servicing your petrol grass trimmer

Most brushcutters and trimmers have a flexible shaft. You need to check its condition at least once per 50 working hours. To perform this operation, you need to remove the boom tip, pull out the shaft and inspect it, then lubricate.

For the care of the shaft will be suitable for inexpensive materials, it is more difficult to find them for the gearbox trimmer for grass. What to lubricate this mechanism. depends on the company-manufacturer of the tool. It is best to use materials that contain molybdenum disulfide. The molybdenum disulfide material smoothes and fills cracks in the working surface and is therefore valued by customers.

Important: Using too much grease and too high a density means overheating, higher friction on the working shaft and increased fuel consumption. The materials and preventive maintenance must therefore be carried out responsibly.

Performance

The choice of gasoline mower, or they are also called by the name of the cutting device. trimmers for grass, should be made on the volume of work, the more processed area, the more power is needed. For small plots choose household, for garden plots suit trimmers for grass middle class. farmer, for mowing large areas, especially if there are thickets of weeds or bushes, you need a powerful professional tool. park. Such equipment has an engine capacity of more than 2.5 liters.с. and can run for 3 to 4 hours a day.

Gearbox trimmer for grass includes 2 shafts. the first has a drive from the engine, and the other is used to rotate the cutting blade of brushcutter or line electric trimmer. Bevel gears are made as one piece with the shaft, but there are versions with a separate part mounted on the spline joint. Different tooth angles are available, depending on the tool’s design. Gearbox versions with worm, planetary or mixed (multistage) gears are available.

The shafts are mounted on antifriction bearings, which are sealed by protective washers. Details ensure lubricant retention and prevent penetration of dirt into the raceways. Bearings are installed in the gearbox housing, made of aluminum alloy. The unit is split and consists of 2 symmetrical halves that are joined together with screws. A separate gasket or sealant is used to make the joint airtight.

The lower gear unit for the grass trimmer is installed on the tool via a mounting socket. There are several types of the butt, differing in shape.

The most common are round seating surfaces with diameters of 24 or 26 mm.

There are also tool variants with square or polygonal joints. Transmission of torque is by means of a slotted connection.

Lubricant User Reviews

Specialists advise to use only original materials, the characteristics of which meet the requirements of the manufacturer. If these are absent, it should be clarified what to lubricate the gearbox trimmer for grass. Experienced users do not recommend using solidol, because this material is not suitable for temperature and speed characteristics of the node, as well as the consistency. Also, this material has no anti-wear properties.

The working temperature range of solidol. from minus 40 to 65 degrees, but even at such parameters in the process of heating the density of the material increases, and the grease itself becomes coarse. In case of urgent necessity to treat a tool one can use “Litol-24”.